Whirlpool WFW94HEXL2 Parts Diagram

FOR SERVICE TECHNICIAN’S USE ONLY

Voltage Measurement Safety Information

When performing live voltage measurements, you must do the following:

Verify the controls are in the off position so that the appliance does not start when energized.

Allow enough space to perform the voltage measurements without obstructions.

Keep other people a safe distance away from the appliance to prevent potential injury.

Always use the proper testing equipment.

After voltage measurements, always disconnect power before servicing.

IMPORTANT: Electrostatic Discharge (ESD) Sensitive Electronics

ESD problems are present everywhere. Most people begin to feel an ESD discharge at

approximately 3000V. It takes as little as 10V to destroy, damage, or weaken the main control

assembly. The new main control assembly may appear to work well after repair is finished,

but a malfunction may occur at a later date due to ESD stress.

Use an anti-static wrist strap. Connect wrist strap to green ground connection point or

unpainted metal in the appliance

-OR Touch your finger repeatedly to a green ground connection point or unpainted metal

in the appliance.

Before removing the part from its package, touch the anti-static bag to a green ground

connection point or unpainted metal in the appliance.

Avoid touching electronic parts or terminal contacts; handle electronic control assembly

by edges only.

When repackaging main control assembly in anti-static bag, observe above instructions.

This service data sheet is intended for use by persons having electrical, electronic, and

mechanical experience and knowledge at a level generally considered acceptable in the

appliance repair trade. Any attempt to repair a major appliance may result in personal injury

and property damage. The manufacturer or seller cannot be responsible, nor assume any

liability for injury or damage of any kind arising from the use of this data sheet.

Contents

IMPORTANT SAFETY NOTICE — “For Technicians only”

Whirlpool Control Panel ........................................ 2

Maytag Control Panel ........................................... 3

Diagnostic Guide .................................................. 4

Activating Service Diagnostic Mode ...................... 4

Service Diagnostic Menu ...................................... 4

User Interface Test ............................................... 5

Software Version DIsplay ..................................... 5

PART NO. W10254474B

DO NOT REMOVE OR DESTROY

Quick Diagnostics ................................................ 6

Fault/Error Codes ...........................................7–10

Troubleshooting Guide .................................. 11, 12

Test Procedures ........................................... 13–21

Manually Unlocking the Door Lock System ......... 22

Component Removal .......................................... 22

Wiring Diagrams ..........................................23, 24

PAGE 1

FOR SERVICE TECHNICIAN’S USE ONLY

)” button: press once

q

to turn off top segment of display.

“Delay Start (

display segment.

Press each modifier button

once to turn off its respective

button once to turn off

its respective indicator.

Option buttons: press each

Rotating the cycle selector knob turns off each corresponding cycle

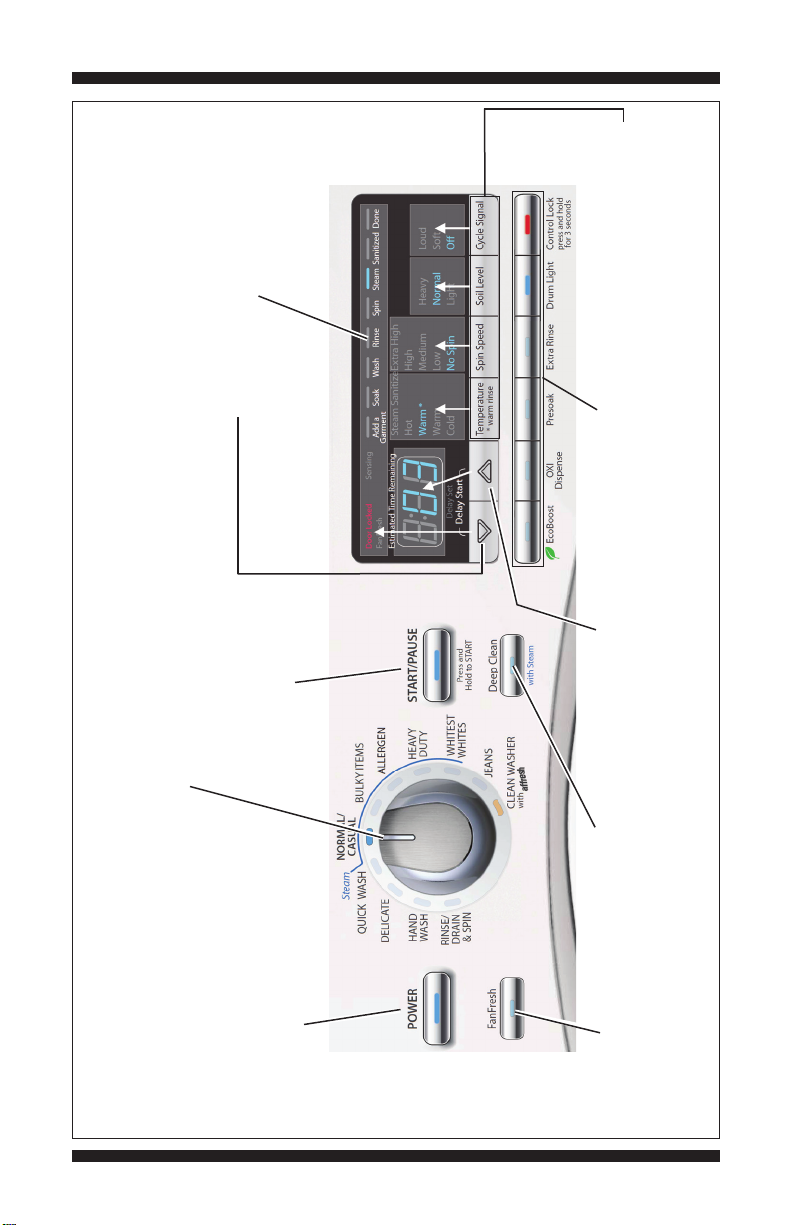

WHIRLPOOL CONTROL PANEL (features and appearances may vary between models)

PAGE 2

or continue test. Press once

“START/PAUSE” button: begin

indicator. (Features and appearances vary between models).

“POWER” button: press once to turn

service diagnostic modes and return

off indicator. Press twice to exit most

to turn off indicator.

to standby mode.

“Delay Start (p)”

seven-segment display.

button: press once to turn off

once to turn off indicator.

“Deep Clean” button: press

Not available on all models.

“FanFresh” button: press

once to turn off indicator.

Not available on all models.

DO NOT REMOVE OR DESTROY

Figure 1 - User Interface Test

FOR SERVICE TECHNICIAN’S USE ONLY

respective indicator.

button once to turn off its

Option buttons: press each

press once to turn off

seven-segment display.

“delay start (+)” button:

Diagnostic Mode).

(Recommended buttons to access

Press each modifier button once to

turn off its respective display segment.

“delay start (–)” button:

press once to turn off the

upper right corner of display.

to turn off indicator.

“start/pause” button: begin

or continue test. Press once

appearances vary between models).

the knob through all of its positions. (Features and

The cycle selector LED will turn off after slowly rotating

most service diagnostic modes and

turn off indicator. Press twice to exit

“power/cancel” button: press once to

MAYTAG CONTROL PANEL (features and appearances may vary between models)

DO NOT REMOVE OR DESTROY

return to standby mode.

“steam for stains” button:

Not available on all models.

press once to turn off indicator.

once to turn off indicator.

“fresh hold” button: press

Not available on all models.

Figure 2 - User Interface Test

PAGE 3

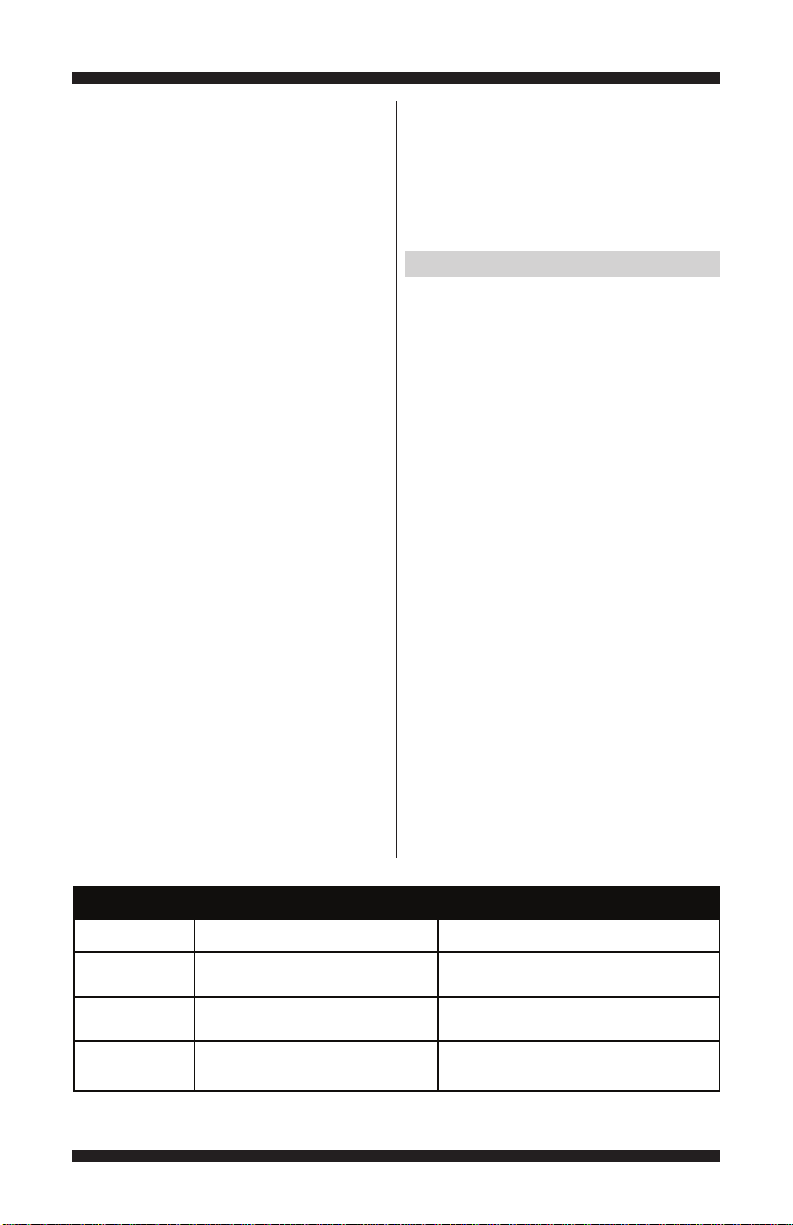

FOR SERVICE TECHNICIAN’S USE ONLY

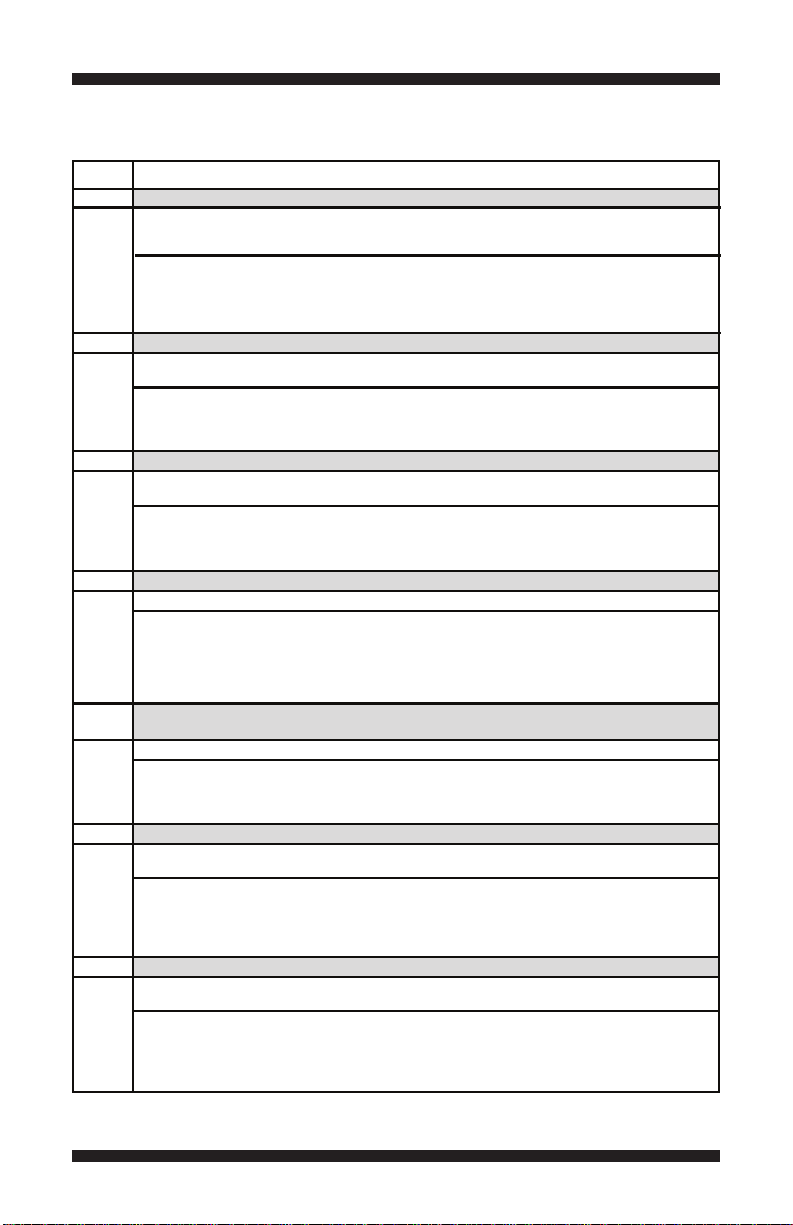

Button Press Function Behavior

1st Button- Momentary press

- Press and hold for 5 secs.

- Activates User Interface Test

- Exits Service Diagnostic Mode

2nd Button- Momentary press

- Press and hold for 5 secs.

- Activates Quick Diagnostic Test

- Software Version Display

3rd Button- Momentary press

- Press and hold for 5 secs.

- Displays Next Error Code

- Clears the Error Codes

SERVICE DIAGNOSTIC MENU

ABBREVIATIONS

CCU: Central Control Unit

IF: Interference Filter

MCU: Motor Control Unit

UI: User Interface (center/modifier PCBs

& housing)

DIAGNOSTIC GUIDE

Before servicing, check the following:

Make sure there is power at the wall outlet.

Has a household fuse blown or circuit breaker

tripped? Was a regular fuse used? Inform

customer that a time-delay fuse is required.

Are both hot and cold water faucets open

and water supply hoses unobstructed?

All tests/checks should be made with a

VOM (volt-ohm-milliammeter) or DVM

(digital-voltmeter) having a sensitivity of

20,000 Ω per volt DC or greater.

Resistance checks must be made with

washer unplugged or power disconnected.

IMPORTANT: Avoid using large

diameter probes when checking harness

connectors as the probes may damage

the connectors upon insertion.

Check all harnesses and connections

before replacing components. Look for

connectors not fully seated, broken or

loose wires and terminals, pin insertion,

or wires not pressed into connectors

far enough to engage metal barbs.

A potential cause of a control not

functioning is corrosion or contamination on

connections. Use an ohmmeter to check for

continuity across suspected connections.

SERVICE DIAGNOSTIC MODE

These tests allow service personnel to test

and verify all inputs to the machine control

electronics. You may want to do a quick and

overall checkup of the washer with these tests

before going to specific troubleshooting tests.

ACTIVATING SERVICE DIAGNOSTIC MODE

1. Be sure the washer is in standby mode

(plugged in with all indicators off).

2. Select any three (3) buttons (except

POWER) and follow the steps below, using

the same buttons. Remember the buttons

and the order that the buttons were pressed.

Within 8 seconds,

• Press and Release the 1st selected button,

• Press and Release the 2nd selected button,

• Press and Release the 3rd selected button;

• Repeat this 3 button sequence 2 more times.

3. If the Service Diagnostic mode has

been entered successfully, all indicators on

the console are illuminated for 5 seconds

with “888” showing in the Estimated Time

Remaining seven-segment display. If there

are no saved fault codes, all indicators on the

console will momentarily turn off, and then

only the seven-segment display will come

back on and display “888”.

NOTE: The Service Diagnostic mode will time

out after 5 minutes of user inactivity, or shut

down if AC power is removed.

PAGE 4

DO NOT REMOVE OR DESTROY

FOR SERVICE TECHNICIAN’S USE ONLY

Unsuccessful Activation

If entry into Service Diagnostic mode is

unsuccessful, refer to the following indications

and actions:

Indication 1: None of the indicators or display

turn on.

Action: Select any cycle.

If indicators come on, check the functionality

for the three buttons used to activate the

Service Diagnostic mode. Verify that the

button responds and a beep sound is heard

when pressed. If the button is faulty, it will

not be possible to enter the diagnostic mode

using that button. Replace the user interface

and housing assembly. Refer to Component

Removal on page 22.

If no indicators come on after selecting the

cycle, go to TEST #1, CCU Power Check,

page 13.

Indication 2: All console indicators begin

flashing immediately.

Action: If all console indicators begin flashing

on and off immediately, replace the user

interface.

Activation with Saved Fault Codes

If there is a saved fault code, it will be flashing

in the display. Review the Fault/Error Codes on

pages 8–10 for the recommended procedure.

If there is no saved fault code, “888” will be

displayed.

USER INTERFACE TEST (Figures 1 & 2)

NOTE: The Service Diagnostic mode must be

activated before entering the User Interface Test;

see procedure on page 4.

Active Fault Code Display

in User Interface Test

If the display begins flashing while in User

Interface Test, it is displaying an active fault

code. Active fault codes are codes that are

currently detected. Only one active fault code

can be displayed at a time.

Entry Procedure

Press and release the 1st button used to

activate Service Diagnostic mode. All console

indicators turn on and “888” is displayed.

User Interface Test

Pressing each button will turn off its

corresponding indicator(s) or display segment

and sound a beep as shown in figures 1 & 2.

WHIRLPOOL: Rotating the cycle selector knob

turns off each corresponding cycle indicator.

MAYTAG: The cycle selector LED will turn off

after slowly rotating the cycle selector knob

through ALL of its positions

If indicators do not turn off and beep after

pressing buttons and rotating the cycle

selector knob, go to TEST #2: User Interface

on page 14.

Exit Procedure

To exit User Interface Test, press and hold the

1st button used to activate Service Diagnostic

mode for 5 seconds, or press the POWER

button once or twice.

SOFTWARE VERSION DISPLAY

NOTE: The Software Version Display mode will

time out after 5 minutes of user inactivity and

return to standby mode.

Entry Procedure

To enter Software Version Display, press

and hold the 2nd button used to activate the

Service Diagnostic mode for 5 seconds. Upon

entry, the display will automatically cycle

through the following information:

• UI software revision code (u: major

revision number, minor revision number,

test revision number)

• UI Hex file revision code (h: major revision

number, minor revision number, test

revision number)

• CCU software revision code (c: major

revision number, minor revision number,

test revision number)

• CCU Hex file revision code (h: major

revision number)

• MCU software revision code (h: major

revision number)

Exit Procedure

To exit Software Version Display, press and

hold the 1st button used to activate Service

Diagnostic mode for 5 seconds, or press the

POWER button once or twice.

DO NOT REMOVE OR DESTROY

PAGE 5

FOR SERVICE TECHNICIAN’S USE ONLY

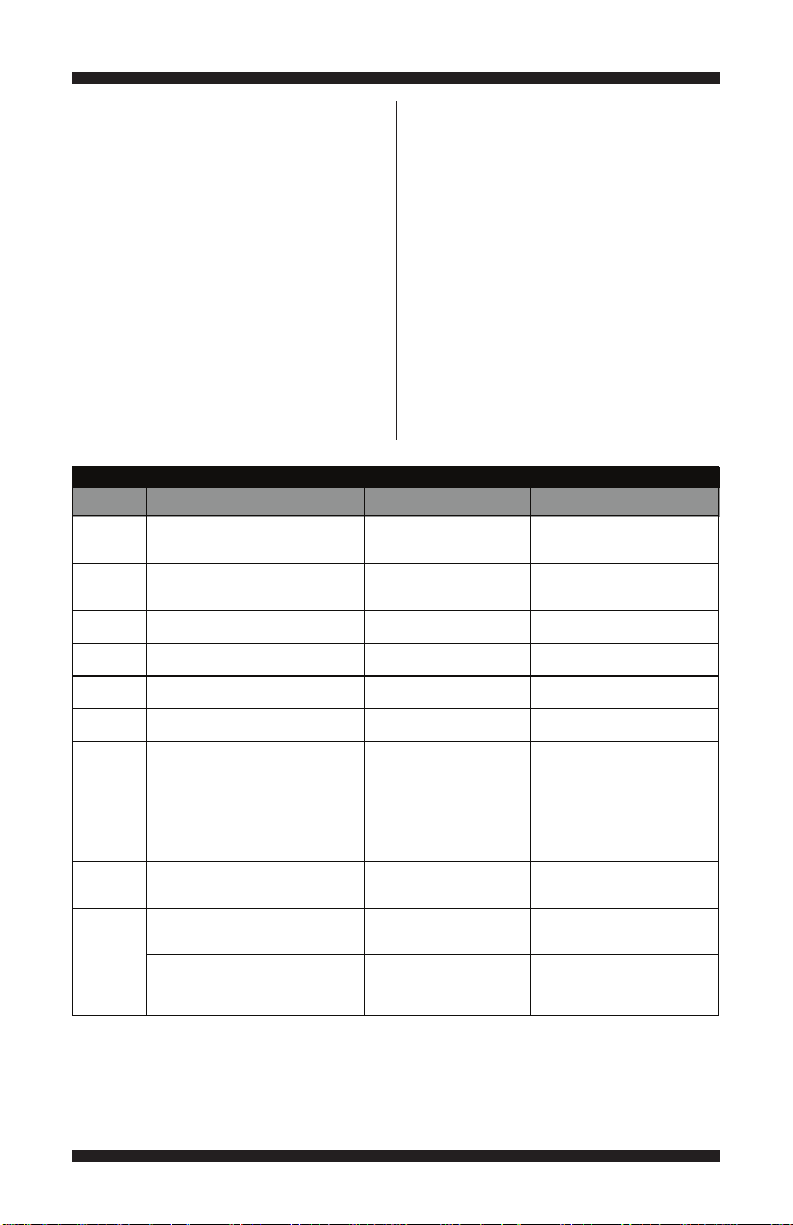

TEST

PHASE

WASHER FUNCTION COMPONENT PHASE ENDS…

C00 * Door lock motor is actuated. Door

unlocks, and then locks again.

Pump is activated for 15 seconds.*

• Door Lock System

• Drain Pump*

on completion ONLY.

C01 †

steam models

only

Heater is turned on.

Steam valve is actuated.

• Heater

• Steam Valve

• Te mperature Sensor

on completion or at key press.

C02 Cold water valve will actuate. • Cold Water V alve

• Flow Meter (Steam only)

on completion or at key press.

C03 Dispensing system is set to the Prewash

position #1.

• Dispenser Motor

• Dispenser Contact

on completion ONLY.

C04 Hot water valve will actuate. • Hot Water Valve

• Flow Meter (Steam only)

on completion or at key press.

C05Drum rotates clockwise at wash speed. • Motor

• Motor Control Unit (MCU)

on completion or at key press.

C06 ‡ Heater is turned on to heat water

to pre-set temperature level.

Drum rotates clockwise and counterclockwise at wash speed.

Water valve is activated to fill drum to

minimum water volume required to

wash. (If there is enough water in the

drum, the water valve will not turn on.)

• Heater

• Te mperature Sensor

• Motor

• Motor Control Unit

• Cold Water V alve (if needed)

• Pressure Sensor/Switch

on completion or at key press.

C07Drain Pump is actuated until there is no

water in the system—plus an additional

15 seconds.

• Drain Pump

• Pressure Sensor/Switch

on completion or at key press.

Drum rotates counter-clockwise from 35

rpm > 100 rpm > 150 rpm > 100 rpm in

~ 1-1/2 minutes.

• Motor

• Motor Control Unit

on completion ONLY.

Drum rotates counter-clockwise at

maximum speed.

Door lock motor is actuated. Door

unlocks.

• Motor

• Motor Control Unit

• Door Lock System

on completion or press of the

power button.

C08

QUICK DIAGNOSTIC TEST

QUICK DIAGNOSTIC TEST

NOTE: The Service Diagnostic mode must be

activated before entering the Quick Diagnostic

Test; see procedure on page 4. If, at any point,

the user presses the POWER button, the

washer exits to standby mode.

Active Fault Code Display

in Quick Diagnostic Test

If the display begins flashing while in the Quick

Diagnostic Test, it is displaying an active fault

code. Active fault codes are codes that are

currently detected. Only one active fault code

can be displayed at a time.

i Press power button at any time to exit i

QUICK DIAGNOSTIC TEST NOTES:

*C00 – For STEAM models, the drain pump is activated as part of the APS (Analog Pressure Sensor) calibration routine. For NON-STEAM

models, the drain pump is only activated if the CCU detects a significant amount of water in the tub. Drain time will depend on water in tub.

† C01 – This test phase is performed only on STEAM models. NON-STEAM models skip this test.

‡ C06 – This test will run until a pre-set temperature level is reached. Water temperature will affect the duration of the test.

PAGE 6

Entry Procedure

To enter the Quick Diagnostic Test, press and

release the 2nd button used to activate the

Service Diagnostic mode. The power button

indicator turns on and the start button indicator

begins to flash. Press the START button to

perform the Quick Diagnostics tests listed below.

Each test phase is indicated on the display.

IMPORTANT: If entry into Quick Diagnostics

is performed too quickly after activating the

Service Diagnostic mode, the test will not start.

Exit Procedure

To exit Quick Diagnostics, press the POWER

button, or press and hold the 1st button used

to activate Service Diagnostic mode for 5

seconds.

DO NOT REMOVE OR DESTROY

FOR SERVICE TECHNICIAN’S USE ONLY

FAULT/ERROR CODES

(Refer to fault/error code charts on pages 8–10.)

Fault/Error Code Display Method

Fault codes are displayed by alternately

showing F# and E#. All fault codes have an

F# and an E#. The F# indicates the suspect

System/Category. The E# indicates the

suspect Component system.

Up to four Fault/Error codes may be stored.

When the oldest fault code is displayed,

additional presses of the 3rd button will result

in a triple beep, then display of the most recent

fault code. If each press of the 3rd button

results in a triple beep and the display shows

“888”, no saved fault codes are present.

Entry Procedure

To display the Fault/Error Codes, press and

release the 3rd button used to activate the

Service Diagnostic mode.

Advancing Through Saved Fault/

Error Codes

Procedure for advancing through saved

fault codes:

Press and release g beep tone g most recent fault

the 3rd button code is displayed.

used to activate

Service Diagnostics

Repeat g beep tone g second most

recent fault code

is displayed.

Repeat g beep tone g third most

recent fault code

is displayed.

Repeat g beep tone g fourth most

recent fault code

is displayed.

Repeat g triple beep g back to the most

recent fault code.

Clearing Fault Codes

To clear fault codes, enter Service Diagnostic

mode. Then press and hold the 3rd button

used to enter Service Diagnostic mode

for 5 seconds. Once the fault codes are

successfully erased, the seven segment

display will show “888”.

Exit Procedure

To exit Fault/Error Codes, press and hold the

1st button used to activate Service Diagnostic

mode for 5 seconds.

EXITING SERVICE DIAGNOSTIC MODE

Use either of the two methods below to exit

diagnostic mode.

• Pressing and holding the 1st button

used to activate the Service Diagnostic

mode for 5 seconds.

• Pressing the POWER button once or twice,

depending on diagnostic procedure.

DO NOT REMOVE OR DESTROY

PAGE 7

FOR SERVICE TECHNICIAN’S USE ONLY

Display EXPLANATION AND RECOMMENDED PROCEDURE

SudSUDS DETECTED

Fault is displayed when Suds prevent the basket from spinning up to speed or the pressure sensor detects

rising suds level. The main control will flush water in attempt to clear Suds. If the water flush is unable to

correct the

p

roblem, this may indicate:

Possible Causes

• Not using HE detergent or excessive detergent usage.

• Check/clean drain pump filter and hose of foreign objects.

• Ensure drain height does not exceed 8' (2.4 m) from washer base.

F0E1 (rl) LOAD DETECTED DURING THE WASHER CLEANING CYCLE (rl = remove load)

During the cleaning cycle, a load was detected inside the drum. Clear error code and run a Cleaning Cycle

to verif

y p

roblem.

Possible Causes

• Load inside the washer during clean cycle.

• Mechanical friction on drive mechanism or basket. (Clothing between basket and tub.)

F1E1 CCU ERROR

A corrupted onboard EEPROM or communication error between the CCU and onboard EEPROM has

occurred. One of the main rela

y

s is not working properly.

Possible Causes

• Check the electrical outlet for damage.

• A power surge/drop may have caused this problem. Unplug or disconnect washer. Verify power at outlet

(voltage, polarity, grounding, and dedicated circuit). Reconnect power and retest.

• A relay on the CCU may be welded.

See TEST #1 (CCU Power Check) on page 13.

F1E2 MCU ERROR - MULTIPLE RESETS

Motor Control Unit (MCU) has an internal malfunction, repeating under or over voltage, or over current

conditions. Can also be caused by momentary loss of neutral feed to MCU during the spin cycle. If the

error occurs during a high-speed spin, the door will remain locked for 3 minutes.

Possible Causes

• See TEST #3 (Motor Circuit) on page 15.

F2E3 UNSUPPORTED CYCLE

Cycle corruption, or CCU is not compatible for this specific model of washer.

Possible Causes

• Intermittent communication between CCU and UI. Check harness for continuity.

• Rotate cycle selector knob and verify cycle information on console. CCU may be corrupted.

• CCU is not compatible with washer—replace CCU.

F3E1 PRESSURE SWITCH / PRESSURE SENSOR ERROR

The CCU detects an out of range pressure signal. The use of analog pressure sensor or digital pressure

switch is model de

p

endent, but the procedure to detect this error does not change.

Possible Causes

• Check connections from tub to air trap, air trap to pressure ho se, and pressure hose to pressure sensor.

• See TEST #7 (Pressure Sensor/Switch) on page 17.

F3E2 TEMPERATURE SENSOR ERROR

This error is displayed if the water temperature sensor value is out of range (23°F to 217°F [–5°C to 103°C]).

To find the correct ohm reading, refer to temperature chart on page 21.

Possible Causes

• See TEST #11 (Temperature Sensor) on page 21.

F4E0 HEATER IS NOT DETECTED

This error is generated when the CCU cannot detect the temperature rising during step C01 of the

Quick Diagnostic Test. This error code is available only in service diagnostics.

Possible Causes

• Heater element unplugged or open.

• See TEST #10 (Heating Element), page 20.

• See TEST #11 (Temperature Sensor), page 21.

Is pressure hose pinched, kinked, plugged, or leaking air?

FAULT/ERROR CODES #1 — The fault codes below may be indicated

under various conditions and can be accessed through Service Diagnostics.

PAGE 8

DO NOT REMOVE OR DESTROY

FOR SERVICE TECHNICIAN’S USE ONLY

Display EXPLANATION AND RECOMMENDED PROCEDURE

F5E2 DOOR LOCK ERROR

At the start of a cycle, the washer attempts to lock the door 6 times. If door cannot be locked, the washer

goes into pause mode and a code is generated. This code is available only in service mode.

Possible Causes

• Door not completely closed due to interference.

• Check door lock mechanism for damage, misalignment, or foreign objects.

• See TEST #4 (Door Lock System) on page 16.

F5E3 DOOR UNLOCK ERROR

At the start of a cycle, the washer attempts to unlock the door 6 times. If door cannot be unlocked, the washer

goes into pause mode and a code is generated. This code is available only in service diagnostics.

Possible Causes

• Verify door latch is secured to front panel.

• Check for misaligned, broken, or over-tightened door latch.

• See TEST #4 (Door Lock System) on page 16.

F6E1 COMMUNICATION ERROR BETWEEN CCU AND MCU

Communication between the Central Control Unit and the MCU has not been detected.

Possible Causes

• Check door switch operation. Faulty switch may interfere with power to MCU.

• Check drive system for worn or faulty components.

• Verify continuity in cable between CCU (MI3 & MS2) and MCU. See wiring diagrams on pages 23–24.

• See TEST #1 (CCU Power Check) on page 13.

• See TEST #3 (Motor Circuit) on page 15.

F6E2

COMMUNICATION ERROR UI TO CCU

F6E3 COMMUNICATION ERROR CCU TO UI

Communication between Central Control Unit (CCU) and User Interface (UI) has not been detected.

Possible Causes

• Verify continuity in cable between CCU (UI7) and UI (C2). See wiring diagrams on pages 23–24.

• Check AC and DC supplies. See TEST #1 (CCU Power Check) on page 13.

• See TEST #2 (User Interface) on page 14.

F7E1 DRIVE MOTOR SPEED SENSING ERROR / WASHER OVERLOAD

The MCU is unable to properly detect motor speed and the washer shuts down. If error occurs during

high-spin, the door remains locked for 2–3 minutes.

Possible Causes

• Washer is overloaded.

• Verify that the shipping system, including shipping bolts and spacers, is removed.

• Mechanical friction – verify that drum rotates freely.

• See TEST #3 (Motor Circuit) on page 15.

F7E2 MCU OVERHEAT AND/OR MOTOR OVERHEAT

The heat sink exceeds 212°F (100°C). If this occurs, the CCU will reset the MCU and wait for the motor

and/or the MCU to cool down before restarting. After 4 attempts, F7E2 is displayed.

Possible Causes

• Improper installation of washer. Ensure that washer is not located near a heat source and has proper ventilation.

• Check that drum is not overloaded with clothes.

• Mechanical friction – verify that drum rotates freely.

• Check drive system for worn or faulty components. See TEST #3 (Motor Circuit) on page 15.

F5E1 DOOR SWITCH ERROR

This code is generated if the door has not been open for 3 consecutive cycles, or the door switch is open

while the door is locked for more than 5 seconds. If this occurs during normal operation, the buzzer beeps

3 times. This error code is available only in service diagnostics.

Possible Causes

• User presses START without closing door.

• Door not open for 3 consecutive cycles.

• Door switch mechanism damaged or obstructed.

• See TEST #4 (Door Lock System) on page 16.

FAULT/ERROR CODES #2 — The fault codes below may be indicated

under various conditions and can be accessed through Service Diagnostics.

DO NOT REMOVE OR DESTROY

PAGE 9

FOR SERVICE TECHNICIAN’S USE ONLY

Display EXPLANATION AND RECOMMENDED PROCEDURE

F8E1 NO WATER DETECTED ENTERING WASHER OR PRESSURE SWITCH TRIP NOT DETECTED

The washer does not detect water input after 13 minutes of filling.

Possible Causes

• Is water supply connected and turned on?

• Check for blocked or kinked inlet hoses.

• Low water pressure or blocked hose screens.

• Check for proper drain hose installation. Is water siphoning out of the drain hose? Drain hose must not

be more than 4.5" (113 mm) into drain pipe.

• Check connections from tub to air trap, air trap to pressure hose, and pressure hose to pressure sensor.

• See TEST #6 (Water Inlet Valves) on page 17.

• See TEST #7 (Pressure Sensor/Switch) on page 17.

F8E2 DISPENSER SYSTEM ERROR

Dispenser motor is unable to reach the desired position.

Possible Causes

• Check the mechanical linkage from dispenser motor to top of dispenser.

• See TEST #12 (Dispenser Distribution System) on page 21.

F8E3 OVERFLOW CONDITION

The overflow condition occurs if there is too much water or foam in the washer and the overflow contact

on the pressure switch is closed for more than 2 minutes, 30 seconds or 5 times during the same cycle.

If overflow occurs, the valves are closed and the drain pump switches on for at least 30 seconds.

Possible Causes

• Check inlet valves for proper shutoff.

• Verify that drain hose is not plugged or kinked.

• Check/clean drain pump filter of foreign objects.

• Check connections from tub to air trap, air trap to pressure hose, and pressure hose to pressure sensor.

• See TEST #6 (Water Inlet Valves) on page 17.

• See TEST #7 (Pressure Sensor/Switch) on page 17.

• See TEST #8 (Drain Pump) on page 19.

F8E4 FLOW METER FAULT

If less than 0.1L of water has entered the tub after 30 seconds from the start of the Quick Diagnostic Test,

this error will be displayed. This error code is available only in service diagnostics.

Possible Causes

• Is water supply connected and turned on?

• Check for blocked or kinked inlet hoses.

• See TEST #6 (Water Inlet Valves) on page 17.

• See TEST #9 (Flow Meter) on page 20.

F9E1 LONG DRAIN

If the drain time exceeds 8 minutes without reaching reset level in pressure sensor, the valves are turned

off and the drain pump will stop running. NOTE: Suds can cause delays in draining. Washer drains for

4 minutes, pauses 5 minutes, then tries again for 4 additional minutes of draining. F9E1 will display if washer

does not drain. (Normal drain takes less than 2 minutes)

Possible Causes

• Verify that the drain hose is not blocked or kinked.

• Make sure drain hose is not sealed into drain pipe.

• Make sure the drain hose height does not exceed 96" (2.4 m).

• Check/clean drain pump filter of foreign objects.

• Check connections from tub to air trap, air trap to pressure hose, and pressure hose to pressure sensor.

• See TEST #8 (Drain Pump) on page 19.

Is pressure hose pinched, kinked, plugged, or leaking air?

Is pressure hose pinched, kinked, plugged, or leaking air?

Is pressure hose pinched, kinked, plugged, or leaking air?

F8E0 STEAM INLET VALVE ERROR (Not available on all models)

This error is displayed when the steam valve malfunctions. This error can be seen only in service diagnostics.

Possible Causes

• Is water supply connected and turned on?

• Check for blocked or kinked inlet hoses.

• Low water pressure or blocked hose screens.

• Check steam valve operation. See TEST #6 (Water Inlet Valves) on page 17.

FAULT/ERROR CODES #3 — The fault codes below may be indicated

under various conditions and can be accessed through Service Diagnostics.

PAGE 10

DO NOT REMOVE OR DESTROY

FOR SERVICE TECHNICIAN’S USE ONLY

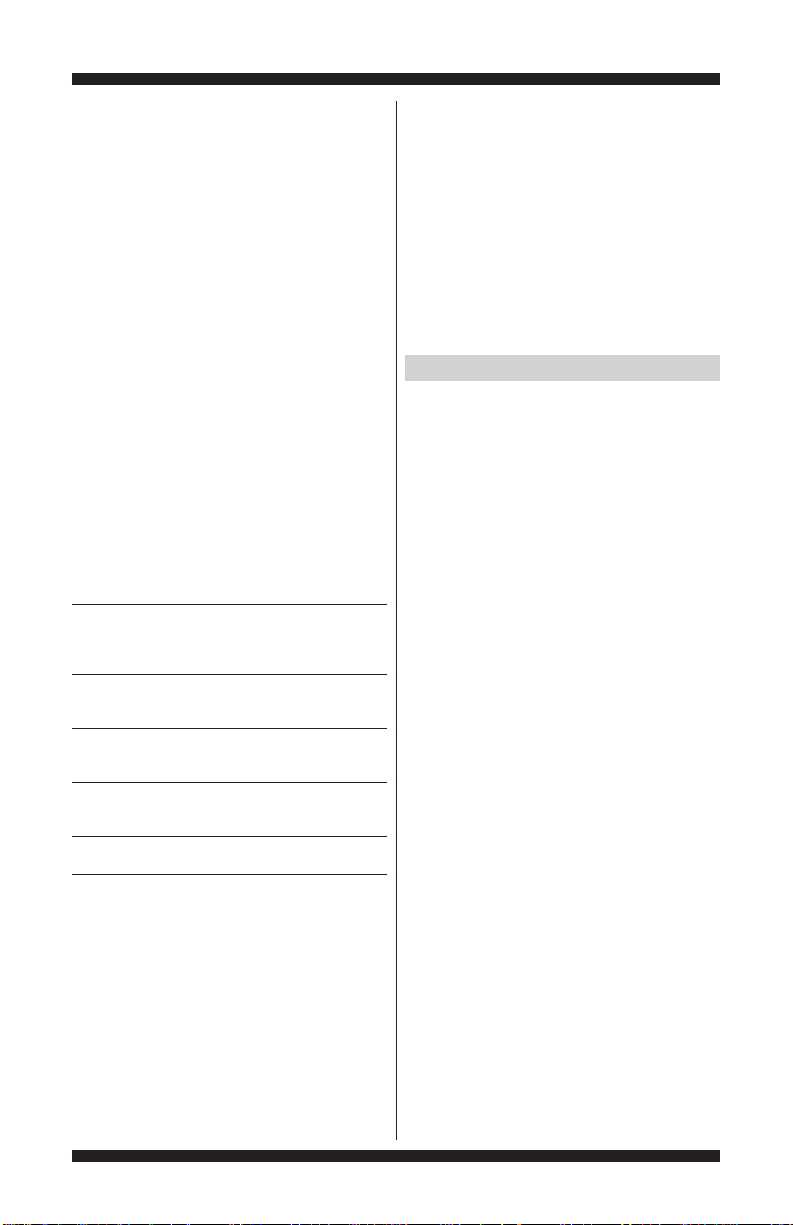

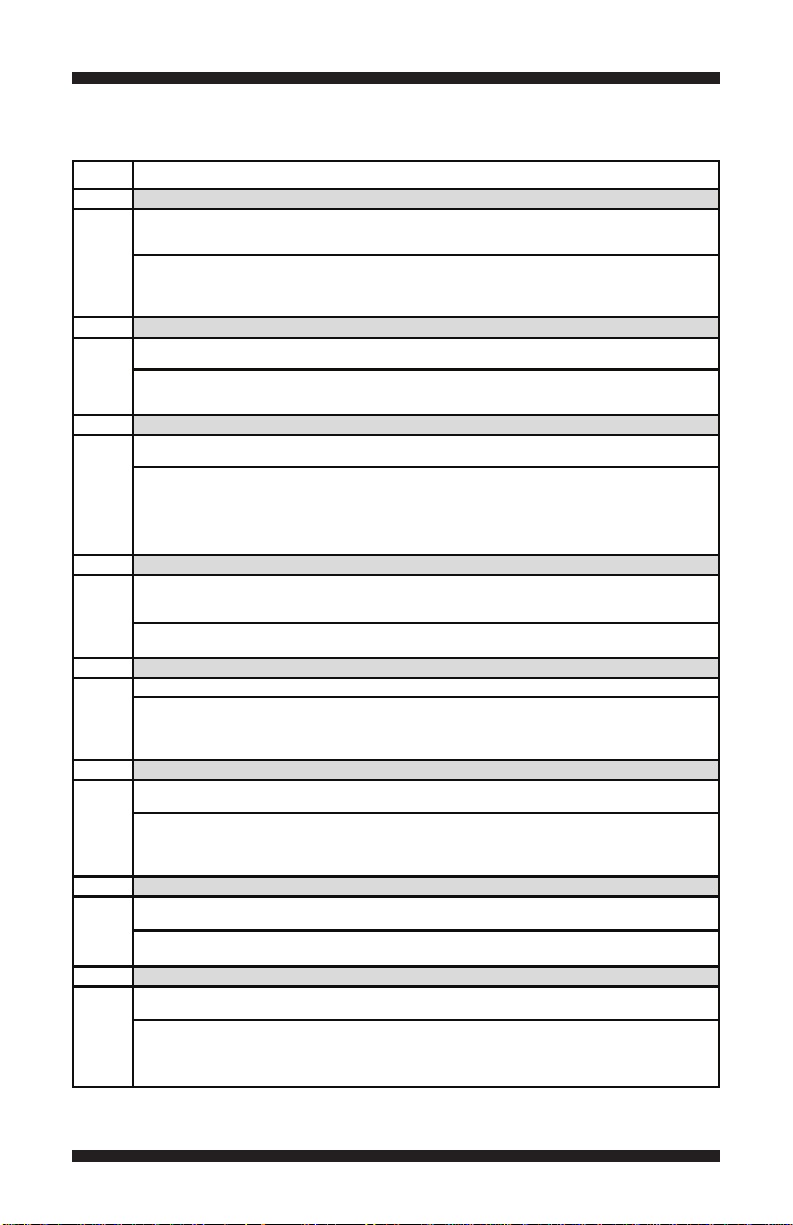

PROBLEM POSSIBLE CAUSE CHECKS & TESTS

No power to washer.Check power at outlet, check circuit breakers,

fuses, or junction box connections.

Connection problem between AC plug

and CCU.

Check connections between the AC power

cord and CCU for continuity.

Connections between CCU and UI. Check connections and harness continuity

between CCU and UI.

CCU problem.See TEST #1: CCU Power Check, pg. 13.

User interface problem.See TEST #2: User Interface, pg. 14.

Door lock mechanism not functioning. 1. Door not closed due to interference.

2. Lock not closed due to interference.

3. See TEST #4: Door Lock System, pg. 16.

Connections between CCU and UI.Check connections and harness continuity

between CCU and UI.

User interface problem.See TEST #2: User Interface, pg. 14.

CCU problem.See TEST #1: CCU Power Check, pg. 13.

Connections between CCU and UI.Check connections and harness continuity

between CCU and UI.

User interface problem. See TEST #2: User Interface, pg. 14.

CCU problem.See TEST #1: CCU Power Check, pg. 13.

Door not closed. Ensure that door is completely closed.

Door lock obstructed. Check mechanism for obstruction.

Door lock mechanism not functioning. See TEST #4: Door Lock System, pg. 16.

Reset washer.Unplug and reconnect the power cord. Wait 2

minutes to see if the washer door unlocks.

Misaligned, broken, or over-tightened

door latch.

Check door lock mechanism and repair as

necessary.

Door lock mechanism not functioning. See TEST #4: Door Lock System, pg. 16.

No water supplied to washer.1. Check water connections to washer.

2. Verify hot and cold supply is on.

Dispenser clogged with detergent. Clean obstruction from dispenser.

Valve problem.See TEST #6: Water Inlet Va lves, pg. 17.

Dispenser system problem.See TEST #12: Dispenser Distribution System,

No water supplied to washer or low water

pressure.

1. Check water connections to washer.

2. Verify hot and cold supply is on.

Plugged filter/screen. Check for plugged filter or screen in the water

valve or hoses.

Drain hose installation. Check for proper drain hose installation.

Is water siphoning out of the drain hose?

Valve problem.See TEST #6: Water Inlet Va lves, pg. 17.

Pressure sensor/switch problem.See TEST #7: Pressure Sensor/Switch, pg. 17.

Drain hose/filter is plugged. Check for hose and drain filter obstructions.

Valve(s) not shutting off. See TEST #6: Water Inlet Valves, pg. 17.

Pressure sensor/switch problem.See TEST #7: Pressure Sensor/Switch, pg. 17.

Drain pump problem.See TEST #8: Drain Pump, pg. 19.

Is door lock showing open during the cycle? See TEST #4: Door Lock System, pg. 16.

Harness connections.Check harness continuity and connections

between CCU > MCU > and drive motor.

Motor problem.See TEST #3: Motor Circuit, pg. 15.

Mechanical friction.Check for obstruction between spin basket

and outer tub.

Harness connections.Check harness continuity and connections

between CCU > MCU > and drive motor.

Motor problem.

See TEST #3: Motor Circuit, pg. 15.

WON’T POWER UP

•

No operation

• No keypad response

• No LEDs or display

WON’T START CYCLE

No response when Start

Button is pressed.

UI WON’T ACCEPT

SELECTIONS

WON’T FILL

(Normal water level is

only 2.5" to 5" [63.5 mm

to 127 mm] inside tub.)

DOOR WON’T LOCK

DOOR WON’T UNLOCK

(See pg. 22 for manually

unlocking the door lock

system.)

MOTOR OVERHEAT S

DRUM WON’T ROTATE

OVERFILLS

WON’T DISPENSE

pg. 21.

No hot water dispensed. Ensure that household hot water is present

at the tap. Minimum 120°F (49°C).

Te mperature sensor problem.See TEST #11: Te mperature Sensor, pg. 21.

Heater element problem.

See TEST #10: Heating element, pg. 20.

SANITIZE LED DOES

NOT TURN ON

TROUBLESHOOTING GUIDE #1

DO NOT REMOVE OR DESTROY

PAGE 11

FOR SERVICE TECHNICIAN’S USE ONLY

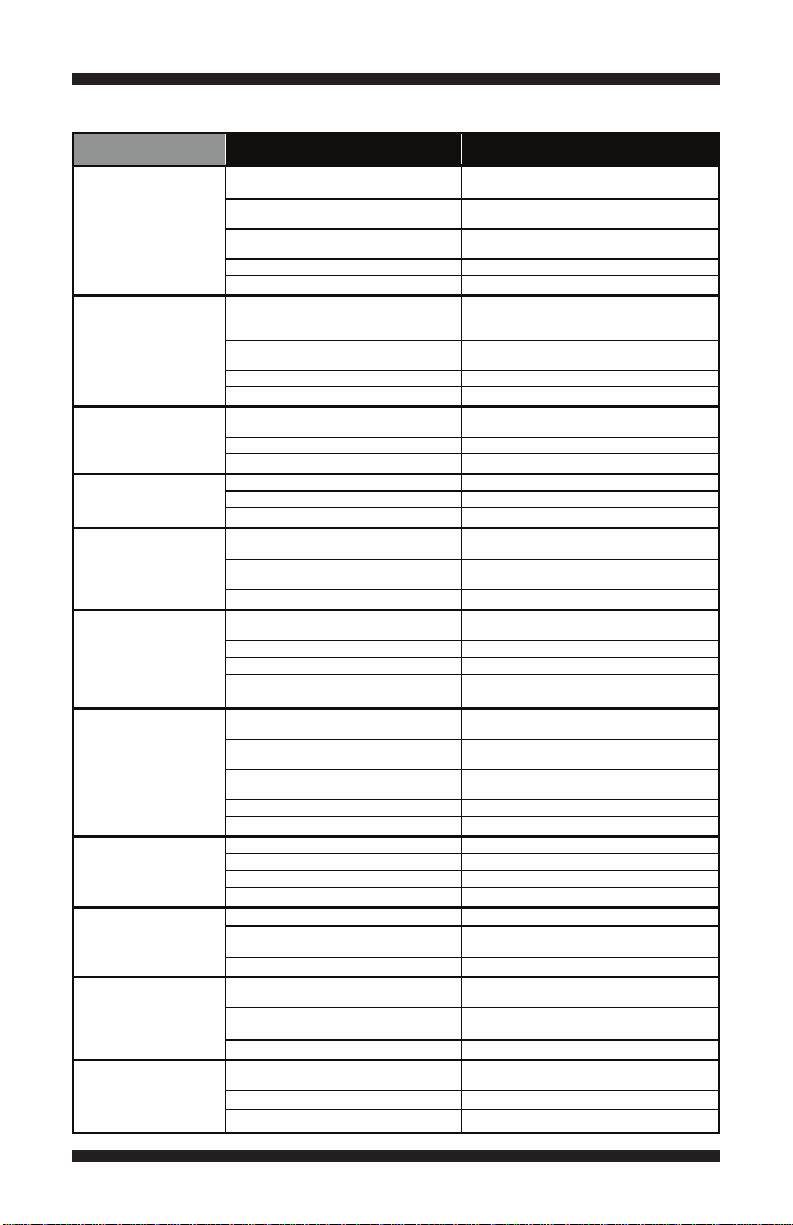

PROBLEM POSSIBLE CAUSE CHECKS & TESTS

Drain hose installation. Check for proper drain hose installation. Make

sure it is not inserted more than 4.5" (113 mm).

Plugged drain hose. Check drain hose for obstructions.

Obstructions to drain pump. Check and clean drain filter for obstructions.

Harness connections.Check harness continuity and connections

between CCU and drain pump.

Drain pump problem.See TEST #8: Drain Pump, pg. 19.

Water hose installation. Make sure inlet hoses are connected properly

and valves are turned on fully.

No hot water dispensed. Ensure that household hot water is present

at tap. Minimum: 120°F (49°C)

Heating element problem.See TEST #10: Heating Element, pg. 20.

Te mperature sensor problem.See TEST #11: Te mperature Sensor, pg. 21.

Supply hose connections.Check hose connections and damaged rubber

gasket due to over-tightening.

Drain hose installation. Check for proper drain hose installation.

Plugged drain hose. Check drain hose for obstructions.

Overloading the washer.Overloading can partially push door open.

Internal hose connections.Check internal hose connections for leakage.

Check bellows.Remove, reposition, and reinstall the bellows.

Make sure bellows is not wrinkled.

Shipping kit not removed. Verify shipping bolts and spacers are removed.

Washer not level. Level washer per installation instructions.

Floor stability. Weak floors can cause vibration and walking

of the washer.

Rubber feet not installed. Install rubber feet on leveling legs.

Leveling lock nuts not tightened. Tighten leveling lock nuts.

High-pitched noise. May be caused by clogged inlet screens.

Disconnect hoses and clean screens.

Spring/damper installation. Check for proper spring and damper placement

and installation.

Hardware. Inspect panels for bending, warpage, or damage.

Check for loose hardware.

Oversuds.1. Verify use of HE detergent.

2. Excessive detergent usage.

3. Check drain hose and filter for obstructions.

Incorrect water level. See “WON'T FILL”, pg. 11.

Clothes wet after cycle is complete. 1. Single or tangled items in washer.

2. Oversuds (see above).

3. See “WON’T DRAIN”, above.

Load not rinsed. 1. Check proper water supply.

2. Not using HE detergent.

3. Washer not loaded properly.

4. See TEST #6: Water Inlet Valves, pg. 17.

Not cleaning clothes.1. Washer not loaded properly.

2. Not using HE detergent.

3. Not using correct cycle.

4. Not using dispensers.

Fabric damage. 1. Washer overloaded.

2. Bleach added incorrectly.

3. Sharp items in tub.

Wrong option or cycle selection. Refer customer to “Use & Care Guide”.

WON’T DRAIN

INCORRECT WATER

TEMPERATURE

POOR WASH

PERFORMANCE

Please reference

Use & Care Guide

VIBRATION OR NOISE

LEAKING

Door switch problem.See TEST #4: Door Lock System, pg. 16.

Harness connections.Check harness continuity and connections

between UI and drum light.

Drum light problem.See TEST #5: Drum Light, pg. 16.

DRUM LIGHT DOES

NOT TURN ON

(Steam models only)

TROUBLESHOOTING GUIDE #2

PAGE 12

DO NOT REMOVE OR DESTROY

FOR SERVICE TECHNICIAN’S USE ONLY

RP2

VFS2

TEST PROCEDURES

IMPORTANT: The following procedures

may require the use of needle probes

to measure voltage. Failure to use needle

probes will damage the connectors. To

ease the process of measuring voltage

and resistance, test points for each pin are

accessible through the slots in the plastic

beneath each CCU connector.

TEST #1: CCU Power Check

This test checks for incoming and outgoing power

to and from Central Control Unit (CCU). This test

assumes that proper voltage is present at the outlet.

1. Unplug washer or disconnect power.

2. Remove top panel to access the

machine electronics.

3. Visually check that all connections to the

interference filter (IF) are securely connected.

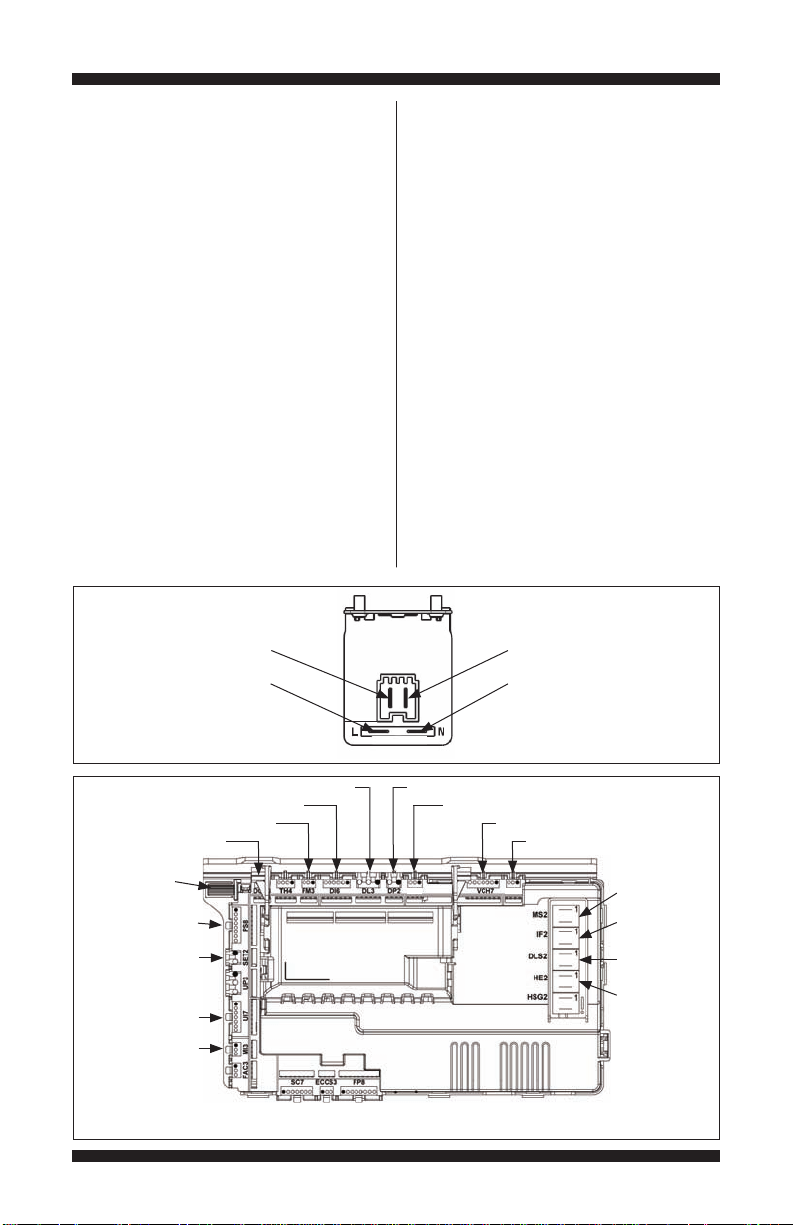

See Figure 3, below.

4. Visually check that all connections to the

CCU are fully inserted. See Figure 4, below.

5. If both visual checks pass, go to step 6.

Filter Output - Line (PK)

Filter Input - Power Cord Line (BK)

6. Plug in washer or reconnect power.

7. With a voltmeter set to AC, check for line

voltage at the input of the interference filter.

See Figure 3.

If line voltage is present, go to step 8.

If line voltage is not present, verify the

continuity of the power cord. If it fails the

continuity check, replace the power cord.

8. With a voltmeter set to AC, check for line

voltage at the output of the interference filter.

See Figure 3.

If line voltage is present, go to step 9.

If line voltage is not present, replace the

interference filter.

9. With a voltmeter set to AC, check for input

line voltage to the CCU across pins 1 and 2 of

connector IF2. See Figure 4.

If line voltage is present, go to step 10.

If line voltage is not present, check

harnesses and connections between the

filter and the CCU. Repair as necessary.

Filter Output - Neutral (PK)

Filter Input - Power Cord Neutral (WT)

Figure 3 - Interference Filter (IF)

DI6-Detergent Dispenser Motor

FM3-Flow Meter (steam model)

DCS3-Door Closed Switch

Locking Tab

PS8-Pressure

Sensor/Switch

SET2-Temperature

Sensor

UI7-User Interface

MI3-MCU

Communications

Figure 4 - Central Control Unit (CCU)

DL3-Door Lock Coil

DO NOT REMOVE OR DESTROY

DP2-Drain Pump

RP2-Vent Fan

VCH7-Hot/Cold Valves

VFS2-Steam Valve (steam model)

MS2-MCU Power

IF2-Interference

Filter

DLS2-Door

Lock Switch

HE2-Heater

Element

•

= pin-1

PAGE 13

FOR SERVICE TECHNICIAN’S USE ONLY

10. DC Supplies

• +5V DC is used to power IC’s and

processors on the circuit boards. If +5 V DC

was missing, the washer would become

unresponsive. To verify +5V DC ± 5%,

measure voltage at UI7 pin 7 (GND) to pin 2

(+5V [Vcc]). (Red lead to Vcc.)

• +12V DC is used to actuate most of the

120V AC relays, triacs, and switches on the

CCU. If +12V DC was missing, the motors,

valves, and pumps would not turn on. To

verify +12V DC ± 5%, measure voltage

at UI7 pin 3 (–7V) to pin 2 (+5V [Vcc]).

(Red lead to Vcc.)

Troubleshooting: Refer to the wiring diagrams

on pages 23–24 when troubleshooting the DC

supplies. If +5 or +12 V DC is missing on

the CCU, unplug washer or disconnect power,

and then disconnect all components from the

CCU relying on that supply. Plug in washer or

reconnect power and check if the DC supply

has returned. If not, replace the CCU. If it has,

turn washer off and reconnect one connector

at a time until the component loading down

that supply has been identified.

11. Unplug washer or disconnect power.

12. Reassemble all parts and panels.

13. Perform the “Quick Diagnostic Test”

on page 6 to verify repairs.

TEST #2: User Interface (UI)

This test is performed when any of the

following situations occurs during the

User Interface Test (see page 5):

3None of the indicators or display turn on

3Some buttons do not light indicators

3No beep sound is heard

None of the indicators or display turn on:

1. Unplug washer or disconnect power.

2. Remove the top panel to access the CCU.

3. Visually check that all CCU connectors are

inserted all the way into the CCU. See Figure 4.

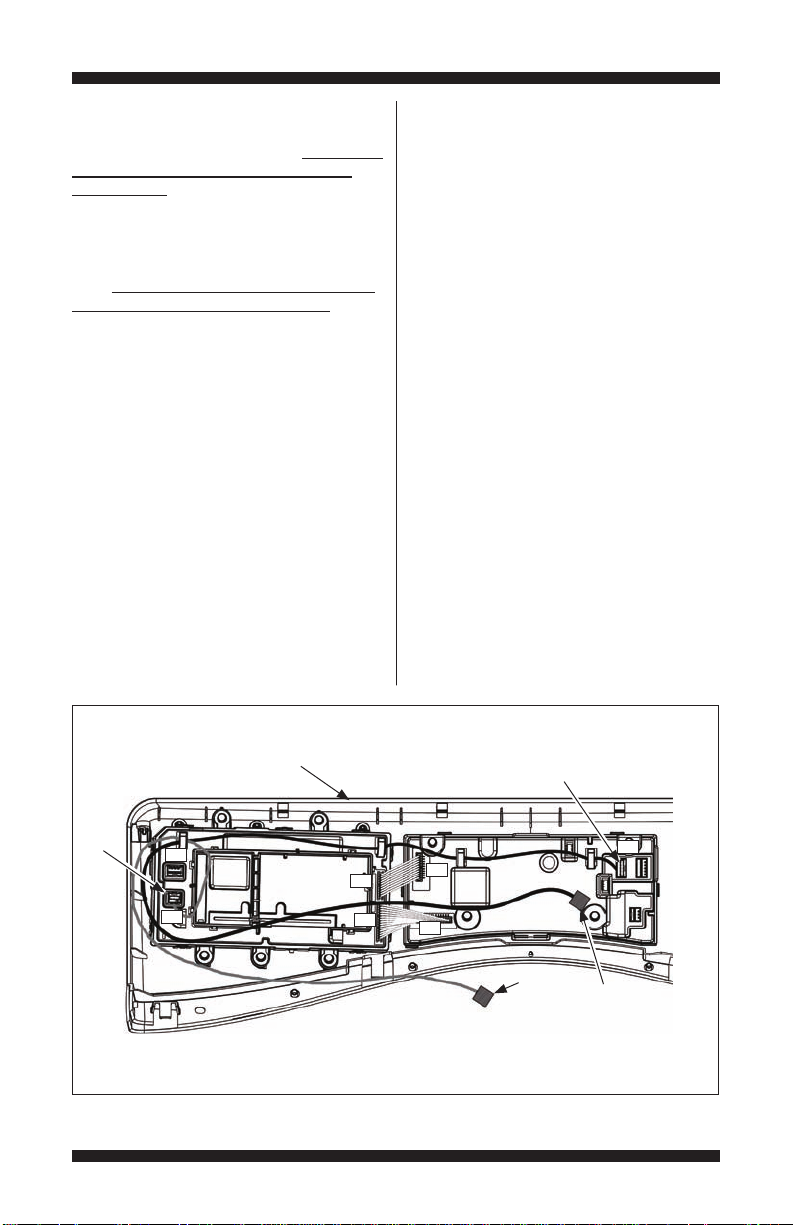

4. Remove console assembly. Do not pull

on the wires between the console and CCU.

5. Visually check that all UI connectors are

inserted all the way into the UI. See Figure 5.

6. Visually check that the UI and housing

assembly is properly inserted into the front

console.

7. If all visual checks pass, perform TEST #1: CCU

Power Check, page 13, to verify supply voltages.

If supply voltages are present, replace the

user interface and housing assembly.

If supply voltages are not present, replace

the CCU.

8. Reassemble all parts and panels.

Figure 5 - User Interface (UI), Housing Assemblies, and Cabling

Console/Housing Assembly

P13 -

to

Drum

Light

P13

P12

Modifier PCB

P09

P08

P07

P06

NOTE:

The User Interface (UI) must be replaced

as an assembly. The UI includes the Modifier

and Center PCBs, and housing assemblies.

PAGE 14

P02 - to CCU

P02

Center PCB

To Drum

Light

To CCU

DO NOT REMOVE OR DESTROY

FOR SERVICE TECHNICIAN’S USE ONLY

Motor Harness

Windings

Pins 1 & 2

8.5 - 14.0 Ω

Pins 2 & 3

8.5 - 14.0 Ω

Pins 1 & 3

8.5 - 14.0 Ω

9. Plug in washer or reconnect power.

10. Perform the “User Interface Test”

(see page 5) to verify repair.

Some buttons do not light indicators:

1. Unplug washer or disconnect power.

2. Remove the top panel to access the CCU

and User Interface (UI).

3. Visually check that the UI and housing

assembly is properly inserted into the front

console.

4. If visual check passes, replace the UI and

housing assembly.

5. Reassemble all parts and panels.

6. Plug in washer or reconnect power.

7. Perform the “User Interface Test”

(see page 5) to verify repair.

No beep sound is heard:

1. Unplug washer or disconnect power.

2. Remove the top panel to access the CCU.

3. Visually check that all CCU connectors are

inserted all the way into the CCU. See Figure 4.

4. Remove console assembly. Do not pull

on the wires between the console and CCU.

5. Visually check that all UI connectors are

inserted all the way into the UI. See Figure 5.

6. If all visual checks pass, replace the UI

and housing assembly.

7. Perform the “User Interface Test”

(see page 5) to verify repair.

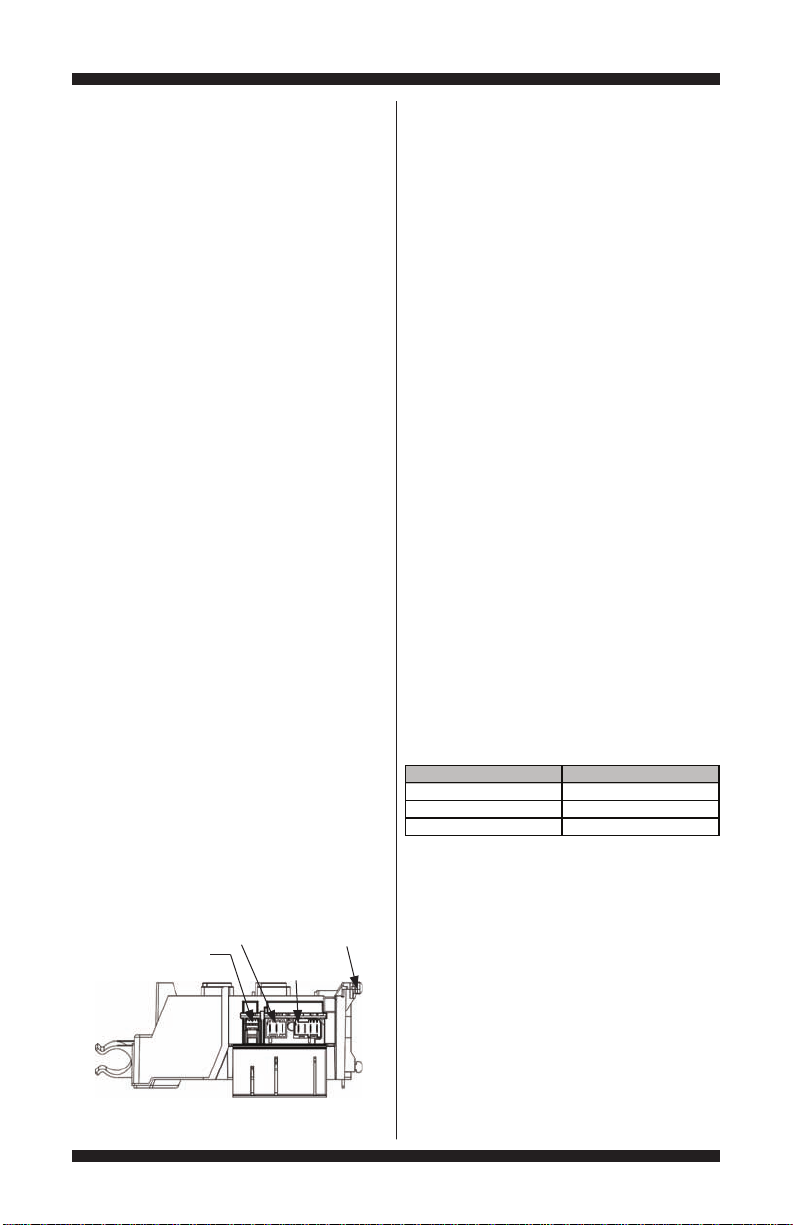

TEST #3: Motor Circuit

This test checks the motor, motor control unit

(MCU), and wiring.

IMPORTANT: A guide (W10271535) is

required to assemble the rotor onto the shaft.

The guide is inserted into the threaded hole,

and then the rotor is slid on over the guide.

From CCU MI3

(MCU Communications)

Figure 6 - Motor Control Unit (MCU)

DO NOT REMOVE OR DESTROY

To Motor

From CCU MS2

(MCU Power)

Locking Tab

NOTE: If the harness between the CCU and

MCU is removed or communications are

interrupted during operation, the MCU puts

the motor into a braking mode, resulting in a

significant drag on the drum when turned by

hand. This mode can be cleared by removing

power from the washer for a few seconds.

1. Check the motor and electrical connections

by performing the “Quick Diagnostic Test” on

page 6. The following steps assume that this

step was unsuccessful.

2. Unplug washer or disconnect power.

3. Check to see if basket will turn freely.

If basket turns freely, go to step 4.

If basket does not turn freely, determine what

is causing the mechanical friction or lockup.

4. Remove the top and rear panels to access

the machine electronics and motor components.

5. Visually check that connectors MS2 and MI3

are inserted all the way into the CCU. Refer to

CCU diagram on page 13.

If visual checks pass, go to step 6.

If visual checks fail, reconnect MS2 and

MI3, and repeat step 1.

6. Visually check that all connectors are inserted

all the way into the MCU (see Figure 6, at left).

If visual checks pass, go to step 7.

If visual checks fail, reconnect the

MCU connectors and repeat step 1.

7. Check the motor windings. Disconnect the

motor harness from the MCU. With an ohmmeter,

verify the resistance values as shown below:

If the values are outside the range or open,

replace stator assembly; otherwise, reconnect

the motor harness and go to step 8.

8. Check the two harnesses between the

CCU and MCU for continuity.

If there is continuity, go to step 9.

If there is no continuity, replace the main

lower harness.

9. With a voltmeter set to AC, connect the

leads across pins 1 and 2 of connector MS2.

10. Plug in washer or reconnect power.

11. Run the “Quick Diagnostic Test” on page

6. IMPORTANT: Door must be closed and

locked to run motor.

PAGE 15

FOR SERVICE TECHNICIAN’S USE ONLY

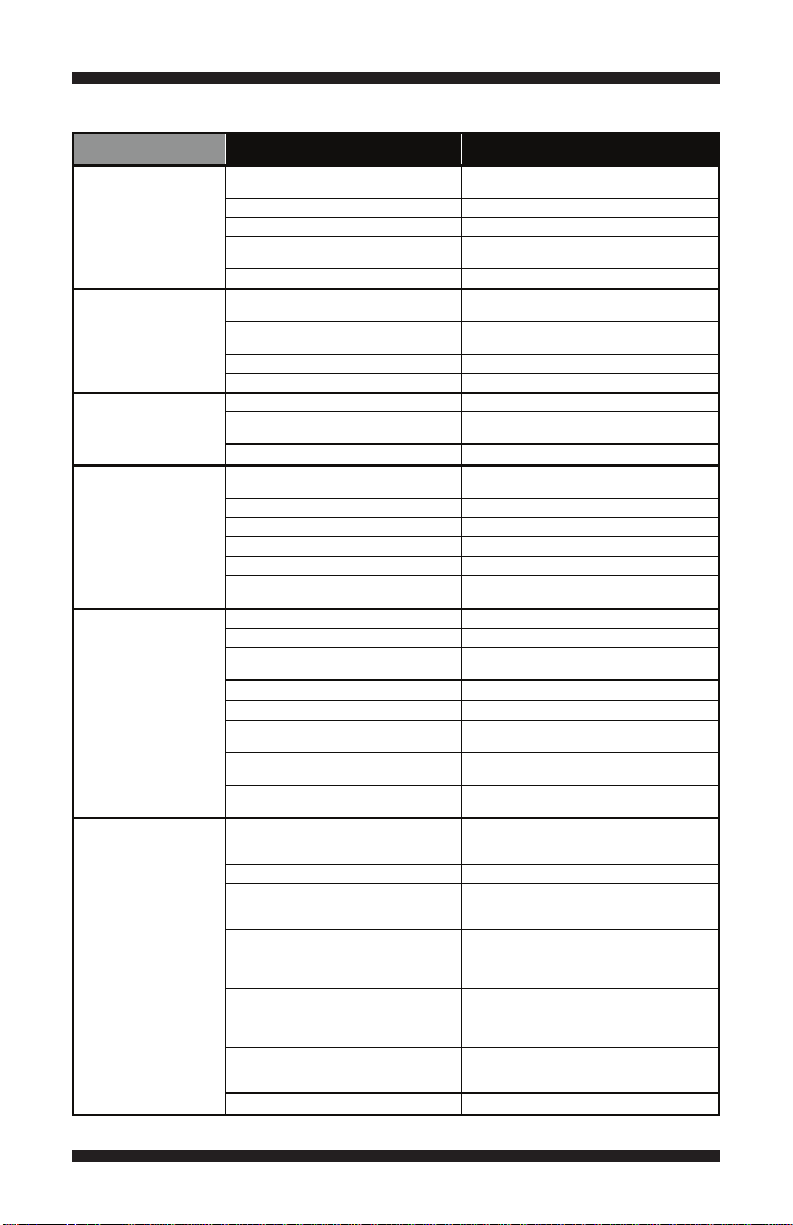

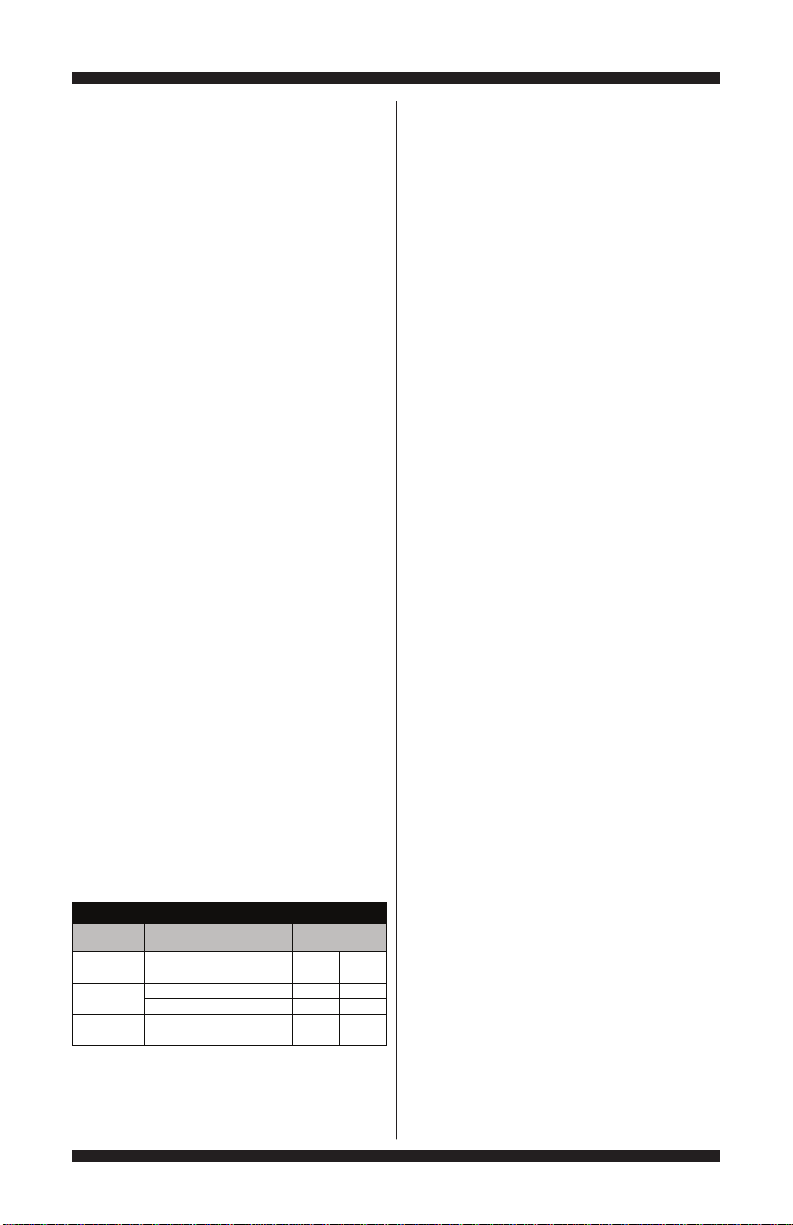

Component

Door Switch DCS3-1 DCS3-3

DL3-1 DL3-2

DL3-2 DL3-3

Door Lock

Switch

DLS2-1 DLS2-2

Locked = Continuity

Unlocked = Open Circuit

Resistance

Lock Coil = 50–74 Ω

Door Lock

Coils

Contacts

Measured

DOOR LOCK RESISTANCE

Door Closed = Continuity

Door Open = Open Circuit

Lock Coil = 50–74 Ω

12. When the test shows “C05 & C08” on the

display, the motor is powered and line voltage

from the CCU should be present across pins

1 & 2 of connector MS2.

If line voltage is present, replace the MCU.

If line voltage is not present, replace the CCU.

13. Unplug washer or disconnect power.

14. Reassemble all parts and panels.

15. Perform the “Quick Diagnostic Test”

on page 6 to verify repair.

TEST #4: Door Lock System

Perform the following checks if the washer

does not lock (or unlock).

1. Check lid lock mechanism for obstruction

or binding. Repair as necessary.

2. Unplug washer or disconnect power.

3. Remove top panel to access machine

electronics.

4. Visually check that the DL3, DLS2, and

DCS3 connectors are inserted all the way into

the CCU. Refer to CCU diagram on page 13.

If visual check passes, go to step 5.

If any of the connectors are not inserted

properly, reconnect and retest door lock.

5. Referring to the chart below, disconnect

the specified connectors from the CCU. With

an ohmmeter, verify resistance values listed

in the chart. NOTE: To measure the door lock

switch in the “locked” position, plug in washer

or reconnect power. Press the POWER button,

select any cycle, and then press START.

Actuation of the door lock solenoid should be

heard. At that point, unplug the washer and

disconnect DLS2 from the CCU and measure

resistance across pins 1 & 2.

If resistance values are good, go to step 6.

PAGE 16

If any of the measurements do not match the

values shown in the chart, check the harness

of the suspected component between the

CCU and door lock mechanism for continuity.

If the harness and connections are

good, replace the door lock mechanism.

IMPORTANT: To minimize risk of damage

to door lock/switch wires, remove the door

lock mechanism screws before removing

the front panel.

6. If the preceding steps did not correct the

lock problem, replace the CCU and retest door

lock mechanism.

Unplug washer or disconnect power.

Replace the CCU.

Reassemble all parts and panels.

Perform the “Quick Diagnostic Test”

on page 6 to verify repair.

TEST #5: Drum Light (Steam Models)

This test is performed if the drum LED does

not light.

1. On Whirlpool models, pressing the “Drum

Light” button on the console should toggle the

button indicator on and off.

If the button indicator does not turn on, go

to TEST #2 – “Some buttons do not light

indicators” on page 14.

If the button indicator toggles on and off,

go to step 2.

2. Unplug washer or disconnect power.

3. Remove the top panel to access CCU

and user interface (UI).

4. Verify the drum light connector (P13)

is securely connected to the UI. See Figure 5.

5. Check harness and connections between

the drum light and the UI.

If the connections are OK, go to step 6.

If not, repair or replace as needed.

6. Unplug the drum light connector (P13)

from the UI.

7. Plug in washer or reconnect power.

8. On Whirlpool models, press the “Drum

Light” button on the console until the button

indicator is on. On Maytag models, press and

hold the “Steam for Stains/Drum Light” button

on the console to activate the LED circuit.

9. With a multimeter set to milliamps, measure

the current across UI connector P13, pins 1

DO NOT REMOVE OR DESTROY

Loading...

Loading...