Whirlpool WAHMS, WAHME Installation Instructions And Owner's Manual

AIR HANDLER INSTALLATION INSTRUCTIONS

Table of Contents

AIR HANDLER SAFETY................................................................. 1

INSTALLATION REQUIREMENTS................................................ 2

Tools and Parts............................................................................ 3

System Requirements ................................................................. 3

Location Requirements................................................................ 3

Electrical Requirements............................................................... 4

Ductwork Requirements.............................................................. 4

INSTALLATION INSTRUCTIONS.................................................. 4

Inspect Shipment......................................................................... 4

Installation Configurations ........................................................... 5

Install Condensate Drain.............................................................. 7

AIR HANDLER SAFETY

Install Ductwork ........................................................................... 8

Verify Orifice Size......................................................................... 8

Connect Refrigerant Lines........................................................... 8

Make Electrical Connections....................................................... 9

Complete Installation................................................................. 17

SEQUENCE OF OPERATION...................................................... 19

Cooling—Cooling Only or Heat Pump ...................................... 19

Heating—Electric Heat Only...................................................... 19

Heating—Heat Pump................................................................. 19

AIR HANDLER MAINTENANCE.................................................. 19

ASSISTANCE OR SERVICE ........................................................ 20

Accessories................................................................................ 20

Recognize this symbol as a safety precaution.

Recognize Safety Symbols, Words and Labels

The following symbols and labels are used throughout this

manual to indicate immediate or potential hazards. It is the

owner’s responsibility to read and comply with all safety

information and instructions accompanying these symbols.

Failure to heed safety information increases the risk of serious

personal injury or death, property damage and/or product

damage.

WARNING

Hazards or unsafe practices could result in property

damage, product damage, severe personal injury or death.

Goodman 1

CAUTION

Hazards or unsafe practices may result in property

damage, product damage, personal injury or death.

CAUTION

Hazards or unsafe practices may result in property

or product damage.

Goodman 9

WARNING

Installation and repair of this unit should

be performed ONLY by individuals meeting

the requirements of an “Entry Level Technician”

as specified by the Air-Conditioning, Heating and

Refrigeration Institute (AHRI). Attempting to

install or repair this unit without such background may

result in product damage, personal injury or death.

Goodman 7

WARNING

HIGH VOLTAGE!

Disconnect ALL power before servicing.

Multiple power sources may be present.

Failure to do so may cause property damage,

personal injury or death.

Goodman 6

Whirlpool® Models WAHMS, WAHME

WPIO-355B

WARNING

This product is factory-shipped for use with 208/240/1/60

electrical power supply. DO NOT reconfigure this air

handler to operate with any other power supply.

Goodman 33

WARNING

To avoid property damage, personal injury or death due to

electrical shock, this unit MUST have an uninterrupted,

unbroken electrical ground. The electrical ground circuit

may consist of an appropriately sized electrical wire

connecting the ground lug in the unit control box to the

building electrical service panel.

Other methods of grounding are permitted if performed

in accordance with the National Electric Code (NEC)

/American National Standards Institute (ANSI) /National

Fire Protection Association (NFPA) 70 and local/state

codes. In Canada, electrical grounding is to be in

accordance with the Canadian Electric Code (CSA) C22.1.

Goodman 34

CAUTION

When installing or servicing this equipment, safety

clothing, including hand and eye protection, is strongly

recommended. If installing in an area that has special

safety requirements (hard hats, etc.), observe these

requirements.

Goodman 35

WARNING

Do not connect to or use any device that is not designcertified for use with this unit. Serious property damage,

personal injury, reduced unit performance and/or hazardous

conditions may result from the use of such non-approved

devices.

Goodman 36

DANGER

CARBON MONOXIDE POISONING HAZARD

Special Warning for Installation of Furnace or Air Handling

Units in Enclosed Areas such as Garages, Utility Rooms or

Parking Areas.

Carbon monoxide producing devices (such as an

automobile, space heater, gas water heater, etc.) should

not be operated in enclosed areas such as unventilated

garages, utility rooms or parking areas because of the

danger of carbon monoxide (CO) poisoning resulting from

the exhaust emissions. If a furnace or air handler is

installed in an enclosed area such as a garage, utility room

or parking area and a carbon monoxide producing device is

operated therein, there must be adequate, direct outside

ventilation.

This ventilation is necessary to avoid the danger of CO

poisoning which can occur if a carbon monoxide producing

device continues to operate in the enclosed area. Carbon

monoxide emissions can be (re)circulated throughout the

structure if the furnace or air handler is operating in any

mode.

CO can cause serious illness including permanent brain

damage or death.

Goodman 38

Goodman 37

WARNING

To prevent the risk of property damage, personal injury, or

death, do not store combustible materials or use gasoline

or other flammable liquids or vapors in the vicinity of this

unit.

INSTALLATION REQUIREMENTS

These instructions are intended as a general guide only for use by

qualified persons and do not supersede any national or local

codes in any way. Compliance with all local, state, or national

codes pertaining to this type of equipment should be determined

prior to installation.

Read this entire instruction manual, as well as the instructions

supplied in separate equipment, before starting the installation.

All models are designed for indoor installation only.

The installation of the air handler, field wiring, warm air ducts, etc.

must conform to the requirements of the National Electrical

Code, ANSI/NFPA No. 70 (latest edition) in the United States, and

any state laws, and local ordinances (including plumbing or

wastewater codes). Local authorities having jurisdiction should

be consulted before installation is made. Such applicable

regulations or requirements take precedence over the general

instructions in this manual.

IMPORTANT: The United States Environmental Protection

Agency (EPA) has issued various regulations regarding the

introduction and disposal of refrigerants in this unit. Failure to

follow these regulations may harm the environment and can lead

to the imposition of substantial fines. These regulations may vary

by jurisdiction. A certified technician must perform the installation

and service of this product. Should questions arise, contact your

local EPA office.

This product is designed and manufactured to permit installation

in accordance with national codes. It is the installer’s

responsibility to install this unit in accordance with national codes

and/or prevailing local codes and regulations.

Install the conditioned air plenum, ducts and air filters (not

provided) in accordance with NFPA 90B Standard for the

Installation of Warm Air Heating and Air-Conditioning Systems

(latest edition).

The air handler is provided with flanges for the connection of the

plenum and ducts.

Air filters (not provided) must be listed as Class 2 furnace air

filters.

The air handler can be used with R-410A from the factory.

The air handler is shipped from the factory completely

assembled. Some models are configured for upflow air discharge

only, and some models are configured for upflow or horizontal

left-hand air discharge. The air handler cabinet conforms to

2 percent or less air leakage.

2

Do not remove the cabinet knockouts until it has been

determined which knockouts will need to be removed for the

installation.

Select the final installation position which best suits the site

conditions. Consider required clearances, space, routing

requirements for refrigerant line, condensate disposal, filters,

ductwork, wiring, and accessibility for service. Refer to the air

handler rating plate on the air handler for specific information.

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools Needed

■ ¹⁄₄" nut driver

■ Level

■ Screwdriver

■ Adjustable wrench

■ Tape measure

■ Hammer

■ Sealant

Parts Needed

Check local codes, check existing electrical supply, and read

“Ductwork Requirements” and “Electrical Requirements” before

purchasing parts.

■ UL-Listed wire connectors

■ Replacement orifice (if needed). See “Verify Orifice Size.” The

correct orifice size may be contained in the replacement

orifice package located inside the control box of the outdoor

unit. If this package does not contain the correct orifice for

your air handler, you must purchase the correct orifice size.

System Requirements

The air handler is designed to match, and must be used with

outdoor units as rated. The indoor units are manufactured with an

interchangeable refrigerant metering orifice to provide optimum

refrigerant control and system performance with a variety of

different capacities of outdoor units.

In some cases, the rating of the outdoor unit may require that the

air handler coil assembly orifice be changed to obtain rated

performance.

Location Requirements

NOTE: When used on cooling applications, excessive sweating

may occur when the air handler is installed in a very humid

space.

■ If the air handler is installed in an unconditioned space,

sealant should be applied around the electrical wires,

refrigerant tubing, and condensate lines where they enter the

cabinet.

■ Electrical wires should be sealed on the inside where they exit

the conduit opening. Sealant is required to avoid air leakage

and condensate from forming inside the air handler, control

box, and on the electrical controls.

■ The air handler must be installed in such a way as to allow

free access to the coil/filter compartment and blower/control

compartment.

■ The air handler must be installed in a level position to ensure

proper condensate drainage.

Installation Clearances

Non-Duct Return Closet Installation

The air handler can be installed in a closet with a false bottom to

form a return air plenum or be installed with a return air plenum

under the air handler.

Louvers or return air grilles are field supplied. Local codes may

limit the application of systems without a duct return to singlestory buildings.

■ For an air handler installed in a closet with a louvered return

opening, the minimum open area for the louvers will be as

shown below.

2

18" and 24" (45.7 cm and

320 sq. in. (2,065 cm

61 cm) models

30" and 36" (76.2 cm and

360 sq. in. (2,323 cm

91.4 cm) models

42", 48" and 60" (106.7 cm,

450 sq. in. (2,903 cm

121.9 cm and 152.4 cm) models

■ If the free area is not known, assume a 25% free area for

wood louvers or a 75% free area for metal louvers or grilles.

■ Using the louver dimensions and the 25% or 75%

assumption, determine if the louver open area meets the

minimum open area listed in the previous chart.

■ If the return air plenum is used, the return air grille should be

immediately in front of the opening in the plenum to allow for

the free flow of return air.

■ When the air handler is not installed in front of the opening,

there must be adequate clearance around the air handler to

allow for the free flow of return air.

■ The unit clearance from a combustible surface may be 0".

■ Allow a minimum of 24" (61 cm) in front of the unit for service

clearance.

■ Do not install the air handler in a location that violates the

instructions provided with the condenser.

■ If the unit is located in an area with high ambient temperature

and/or high humidity, the air handler may have condensation

on the casing. On these installations, a wrap of 2" (5.1 cm)

fiberglass insulation with a vapor barrier is recommended.

■ Consult all appropriate regulatory codes prior to determining

final clearances.

■ When installing this unit in an area that may become wet,

elevate the unit with a sturdy, non-porous material.

■ In installations that may lead to physical damage (for

example. in a garage) it is recommended that a barrier be

installed to avoid such damage.

)

2

)

2

)

3

Electrical Requirements

WARNING

To avoid the risk of injury, electrical shock or death, the

furnace must be electrically grounded in accordance with

local codes or, in their absence, with the latest edition of the

National Electric Code (NEC).

NOTES:

■ Use copper conductors only.

■ All field wiring must be done in accordance with National

Electrical Code, applicable requirements of UL and local

codes where applicable.

■ Electrical wiring, disconnect means and overcurrent

protection are to be supplied by the installer. Refer to the air

handler rating plate for maximum overcurrent protection,

minimum circuit ampacity, as well as operating voltage.

■ The power supply must be sized and protected according to

the specifications supplied on the product.

■ This air handler is factory-configured for 240-volt, single

phase, 60 cycles. For 208-volt applications, see “208-Volt

Conversion” in the “Make Electrical Connections” section.

■ For optional electric heater applications, see “Accessories.”

Refer to the instructions provided with the accessory for

proper installation.

Goodman 31

Ductwork Requirements

■ Install the conditioned air plenum, ducts and air filters (not

provided) in accordance with NFPA 90B Standard for the

Installation of Warm Air Heating and Air-Conditioning

Systems (latest edition).

■ The air handler is provided with flanges for the connection of

the plenum and ducts.

■ The air handler is equipped with flanges that can form a filter

rack for the installation of the air filter, or the filter may be

installed as part of the return air duct system.

■ Air filters must be listed as Class 2 furnace air filters.

CAUTION

Do not operate this product without all the ductwork

attached.

■ Supply and return ductwork must be adequately sized to

■ Supply plenum should be the same size as the flanged

Goodman 39

meet the system’s air requirements and static pressure

capabilities. To ensure correct system performance, the

ductwork is to be sized to accommodate 375 to 425 CFM per

ton of cooling with the static pressure not to exceed 0.5"

W.C. Ductwork should be insulated with a minimum of 1"

(2.5 cm) thick insulation with a vapor barrier in conditioned

areas or 2" (5.1 cm) minimum in unconditioned areas.

opening provided around the blower outlet and should

extend ideally at least 36" (91.4 cm) from the air handler

before turning or branching off plenum into duct runs. The

plenum forms an extension of the blower housing and

minimizes air expansion losses from the blower.

INSTALLATION INSTRUCTIONS

Inspect Shipment

These air handlers are completely factory assembled, and all

components are performance tested. Each air handler consists of

a blower assembly, refrigerant coil, and controls, in an insulated

galvanized steel factory finished enclosure. Knockouts are

provided for electrical wiring entrance.

■ Check the air handler rating plate to confirm specifications

are as ordered.

■ Upon receipt of air handler, thoroughly inspect it for possible

shipping damage. Closely examine the air handler inside the

carton if the carton is damaged.

■ If damage is found, it should be noted on the carrier’s freight

bill. Damage claims should be filed with the carrier

immediately. Claims of shortages should be filed with the

seller within 5 days.

NOTE: If any damages are discovered and reported to the carrier,

do not install the air handler because your claim may be denied.

Return Air Filters

Each installation must include a return air filter. This filtering may

be performed at the air handler or externally such as a return air

filter grille. Air handlers mounted in the downflow orientation,

including “B” series, require external filtering. A washable filter is

available as an accessory. To ensure optimum performance,

frequent filter cleaning is advised.

WVAHM

WAHMS

1729

1824

3030

1931

3636

3642

3743

4860

WAHME Filter

Number

N/A FIL 18-32 1

1830 FIL 36-42 1

3036

3137

4260

FIL 48-61 1

Quantity

Required

4

Installation Configurations

C

A

For ease in installation, it is best to make any necessary coil

configuration changes before setting the air handler in place. See

“Installation Configuration Options.”

■ Upflow air discharge contains only 1 drain pan.

■ Upflow or horizontal airflow contains 2 drain pans.

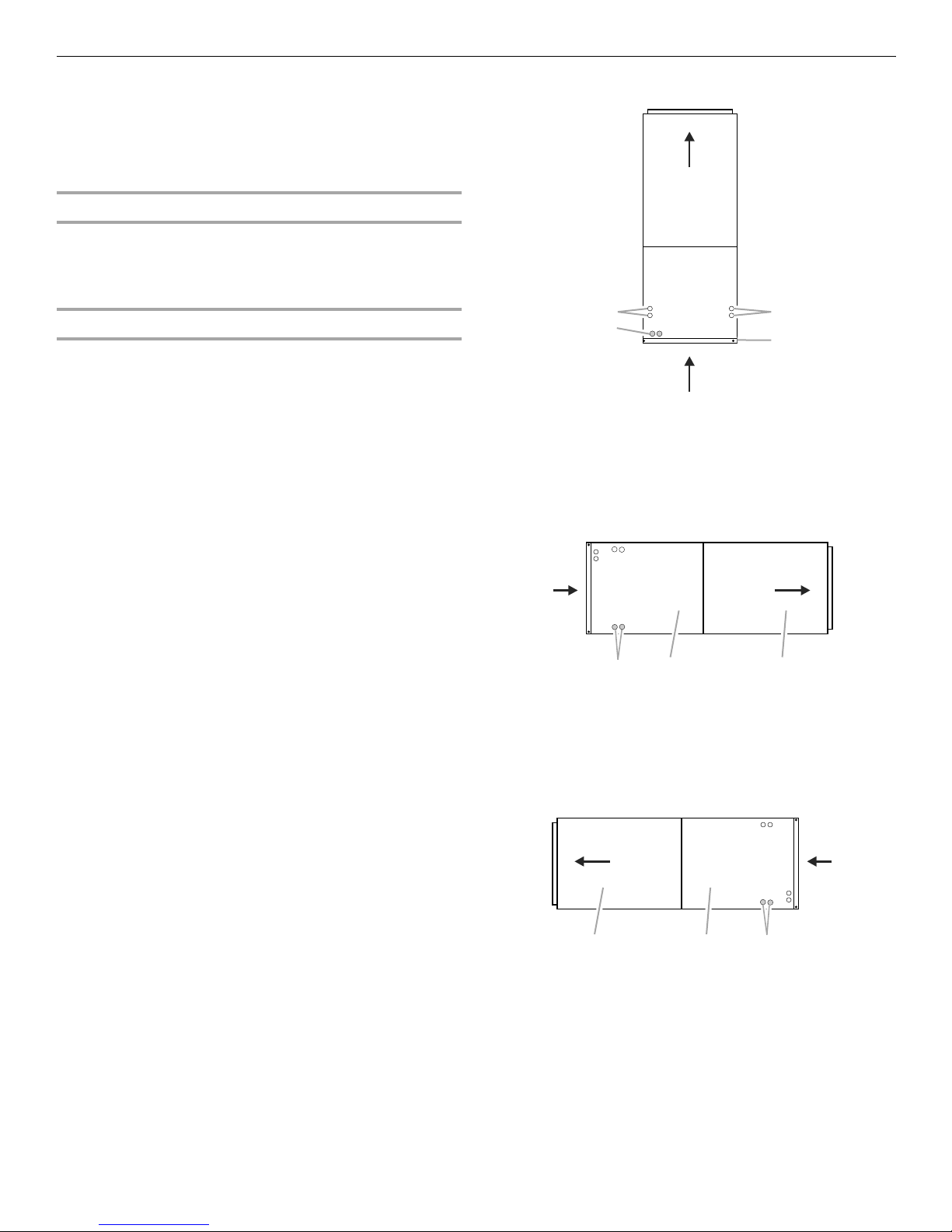

Vertical Installations

Upflow

The air handler must be supported on the bottom only and set on

a field-supplied supporting frame with an air return opening.

Securely attach the air handler to the supporting frame.

Horizontal Installations

Horizontal installations can be left-hand or right-hand air supply.

Adequate support must be provided to ensure cabinet integrity.

Ensure that there is adequate room to remove, service and

access panels if installing in the horizontal position. For the

correct horizontal coil installation, see “Installation Configuration

Options” later in this section.

IMPORTANT:

■ This coil is provided with a secondary drain that should be

trapped and piped to a location that will give the occupant a

visual warning that the primary drain is clogged. See “Install

Condensate Drain.”

■ When an evaporator coil is installed in an attic or above a

finished ceiling, an auxiliary drain pan should be provided

under the air handler as specified by most local building

codes.

A

B

A. Horizontal drain connections

(left or right hand)

B. Upflow drain connection

C. Bottom/filter frame

Installation Configuration Options—Horizontal Right

NOTES:

■ Left to right airflow

■ As shipped from the factory

Drains

Suspended Cabinet Installation

NOTE: Air handlers cannot be installed horizontally lying on or

suspended from either the front or back of the air handler. It must

be positioned with one side parallel to the floor when in the

horizontal position.

The suspending means must be field fabricated, and should

consist of 2 “cradles” made by attaching 2 rods to a length of

angle iron or suitable gauge steel.

Installation Configuration Options—Upflow

NOTES:

■ As shipped from the factory.

■ Return in bottom.

■ Shading indicates proper line connections.

A

A. Drain connections

B. Coil access cover

C. Blower access cover

CB

Installation Configuration Options—Horizontal Left

■ Right to left airflow

■ Requires drain pan location change

A. Blower access cover

B. Coil access cover

C. Drain connections

.

Drains

BA

C

5

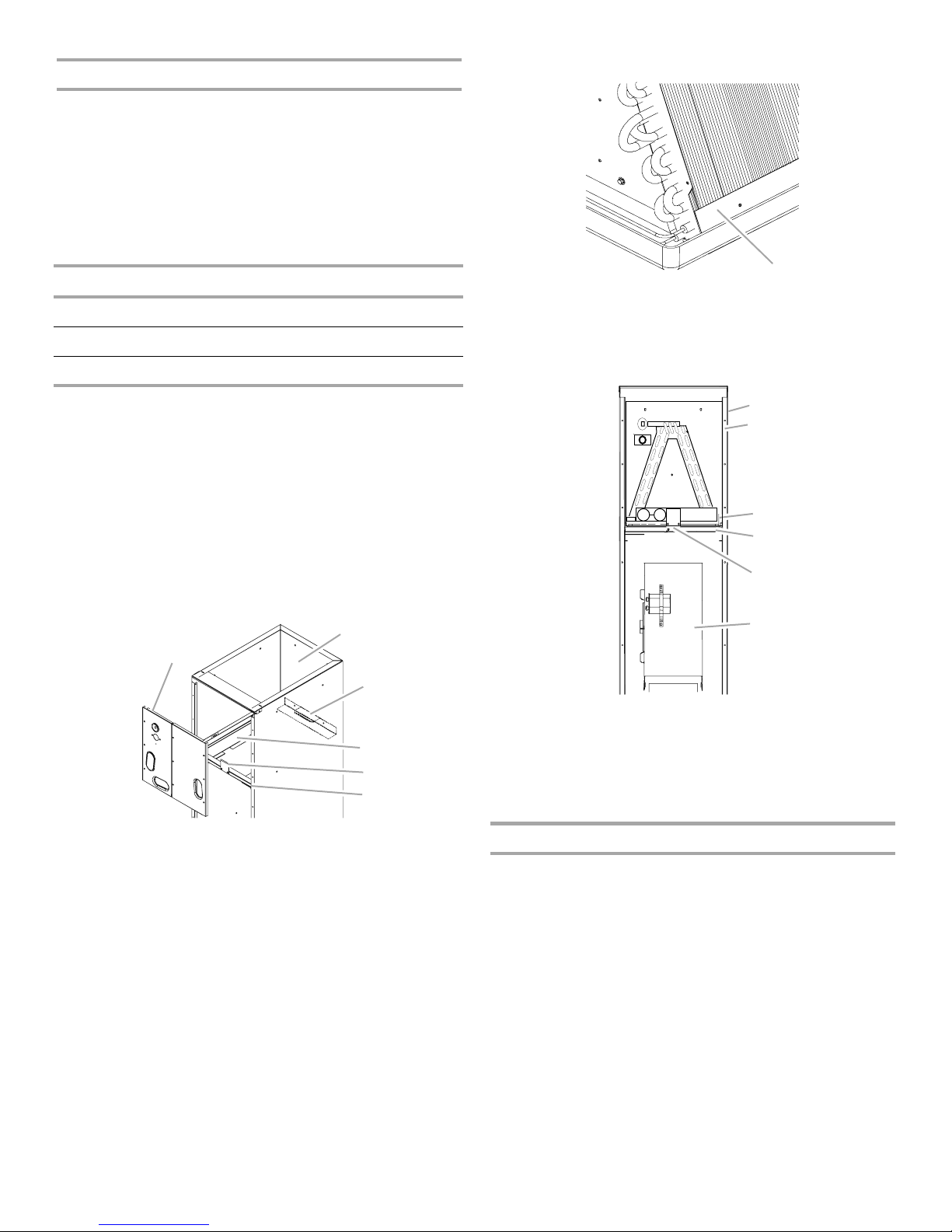

Downflow Conversion

C

D

E

F

A

B

C

D

E

“D” nomenclature models are factory equipped for dedicated

downflow operation and no field conversion is required.

Conversion to downflow must be performed in an area that

allows access to all sides prior to placing the air handler in its

final location. To keep the evaporator coil pan from sweating, the

DPI accessory insulation kit is to be used when performing this

conversion.

NOTE: The DPI kit is not supplied with this product and is to be

purchased separately. See the following chart for the correct DPI

kit.

WVAHM or WAHMS Model Insulation Kit

1824 DPI18-30/20

3030/1931/3636 DPI36-42/20

3642/3743/4860/4961 DPI48-61/20

1. Before inverting the air handler, remove all access panels, the

coil rear channel bracket, and the filter close-off panel.

2. Remove the evaporator coil and the horizontal drain pan.

3. Discard the horizontal drain pan.

4. Install the plastic plug (provided) into the vacated access

panel.

5. Remove the 2 zee coil support brackets and insulation

retaining brackets.

6. Remove the tie bracket.

7. Install the DPI Insulation Kit onto the bottom of the drain pan.

Evaporator Coil Pan

A

A. 3" (7.6 cm) flat insulation retainer (both sides)

To complete the conversion, slide the evaporator coil into the

chassis and attach the 3 access panels.

Evaporator Coil

Invert Air Handler

B

A

A. Access panel

B. Return air side of unit

C. Rear channel bracket

8. Install the zee coil supports and the wrapper stiffeners.

9. Install the tie bracket.

10. Install the rear channel bracket.

11. To avoid possible condensate “blow off,” the insulation

retainers are to be laid into the evaporator coil pan as shown

in the “Evaporator Coil Pan” illustration.

D. Zee coil support bracket

E. Coil retaining bracket

F. Tie b r ac k e t

F

A. Wrapper

B. Insulation jacket

C. Zee coil support

D. Wrapper stiffener

E. Drain pan insulation kit

F. Blower assembly

NOTE: When the air handler is converted to the downflow

position, the coil may protrude above the cabinet on some

models.

Horizontal Conversion

Dedicated downflow models are not suitable for horizontal

application and must not be used for this type of installation. The

only field modification required for conversion to “Horizontal

Right-Hand” is the removal of the plastic knockouts in the

horizontal panel drain connections. To keep the horizontal drain

pan from sweating in high humidity applications, it is

recommended that a DPIH insulation accessory kit be used.

6

Loading...

Loading...