WHIRLPOOL WAG HID 53F LE X Daily Reference Guide

Quick guide

EN

THANK YOU FOR BUYING A WHIRLPOOL PRODUCT

In order to receive a more complete assistance, please

register your product on www . whirlpool . eu/ register

PRODUCT DESCRIPTION

FIRST TIME USE

AIR VENT (FOR THE SUCTION VERSIONS)

Connect the hood and discharge holes on the walls with a diameter

equivalent to the air outlet (connection ange).

Using the tubes and discharge holes on walls with smaller dimensions

will cause a diminution of the suction performance and a drastic

increase in noise.

Any responsibility in the matter is therefore declined.

! Use a duct of the minimum indispensible length.

! Use a duct with as few elbows as possible (maximum elbow angle: 90°).

! Avoid drastic changes in the duct cross-section.

! The company declines any responsibility whenever these regulations

are not respected.

FILTERING OR DUCTING?

! Your cooker hood is ready to be used in suction version.

To use the hood in ltering version the special ACCESSORY KIT must be

installed.

Check if the ACCESSORY KIT is furnished or must be bought separately.

Note: If furnished, in certain cases, the additional activated carbon ltering

Before using the appliance carefully read the Safety

Instruction.

system may be installed on the hood. Information about the conversion of

the hood from suction version to ltering version is present in the Manual

“Safety Instructions & Installation”.

DUCTING VERSION

In this case the fumes are conveyed outside of the building by means

of a special pipe connected with the connection ring located on top of

the hood.

Attention! The exhausting pipe is not supplied and must be purchased

apart. Diameter of the exhausting pipe must be equal to that of the

connection ring.

Attention! If the hood is supplied with active charcoal lter, then it

must be removed.

FILTER VERSION

The aspirated air will be degreased and deodorised before being fed

back into the room.

In order to use the hood in this version, you have to install a system of

additional ltering based on activated charcoal.

CONTROL PANEL

CAUTION! This hood has an automatic operation system (see

paragraph "Automatic operation (sensor)").

Calibration occurs automatically each time the hood is reconnected

to the electrical network (e.g.: the rst time it is installed after a

blackout). It can also be performed manually (see paragraph "Setting

of parameters for Automatic Operation - Manual setting" ).

During calibration, which lasts for 5 minutes, the controls will ash and

only the lights button can be used.

FILTER SATUR ATION IND ICATOR

The hood signals when necessary to perform lter maintenance:

Grease lter (every 40 hours of use): all Leds with red light.

Activated charcoal odour lter (every 160 hours of operation): all

LEDs with red light, LEDs L2 and L3 blink.

RE SET F ILTER SATUR ATION

After performing lter maintenance, press and hold buttons T1 and T3,

Leds L1, L2 and L3 blink briey in red and then turn o for good.

• Activation indicator for odour lter saturation with activated

charcoal: This indicator is normally disabled. To enable it, proceed

as follows:

With the hood o, press and hold simultaneously T1 and T2: L1

turns on rst, then L2 and L3 and after that, when the buttons are

released, the Leds L2 and L3 ash briey to indicate successful

activation.

T1. ON/OFF button “Automatic operation

(sensor)” - see the function list in the

next paragraph

T2. Suction speed (power) control button:

1, 2, 3, intensive

Note: Intensive speed lasts for about 5

minutes, then it is automatically set to

speed 2.

T3. ON/OFF button (short press) and light

intensity setting (long press).

• Disabling the LED for charcoal lter saturation: repeat

the operation above; rst the LEDs L1, L2 and L3 turn on

simultaneously, then only L1, and after that, when the buttons

are released, the leds L1, L2 and L3 turn on again to indicate

successful disabling.

AUTOMATIC OPERATION SENSOR

CAUTION! We recommend running the “Automatic operation

settings” procedure (see below) before running the unit in automatic

mode.

AUTOMATIC OPERATION SENSOR

The hood will turn on at the speed most suited to the cooking

conditions detected by its sensor.

To activate this function:

Press button T1 briey, LED L1 will turn on white.

PARAMETER SETTING FOR AUTOMATIC OPERATION

Parameter setting duly takes place automatically whenever the hood

is connected to the mains (for example: with the rst installation or

after a power cut) or manually.

Note: All the manual operations of calibration, selection, setting and

logical connection described below are possible with the hood OFF

and automatic operation OFF (T1 OFF- L1 OFF).

MANUAL SETTING

To be performed when you notice that automatic operation is

functioning unsatisfactorily; it must be performed when there are

normal environmental conditions in the kitchen.

Manual setting includes:

• Calibration of the hood:

• Selecting the type of hob (gas - induction or electric).

CALIBRATION OF THE HOOD:

Hold down the button T1 (approximately 10 seconds), the LED L1

ashes to indicate that calibration has begun, the calibration process

will last about 5 minutes.

SELECTING THE TYPE OF HOB GAS INDUCTION OR ELECTRIC

Hold down the button T2 (about 10 sec), all the LEDs start ashing for

5 sec.

Within this period press T1 to select the hob that you own:

Orange LED: gas hob.

Blue LED: induction hob.

White LED: electric hob

Wait 5 sec. to allow the hood to record the selection made and until all

LEDs go out.

TECHNICAL DATA

Height (cm) Width (cm) Depht (cm) Ø of exaust tube (cm)

36.7 52.3-72.3 29 15

CLEANING AND MAINTENANCE

CLEANING

• Do not use steam-cleaning equipment.

• Disconnect the appliance from the mains.

Important: do not use corrosive or abrasive detergents. If any such

products unintentionally come into contact with the appliance, clean

the appliance immediately with a damp cloth. Do not use alcohol.

• Clean the surfaces with a damp cloth. If it is very dirty, add a few

drops of washing-up detergent to the water. Finish o with a dry

cloth.

Important: do not use abrasive sponges or metallic scrapers or

scourers. Over time, these can ruin the enamel surfaces.

• Use detergents specically designed for cleaning the appliance

and follow the manufacturer's instructions.

Important: clean the lters at least once a month to remove oil and

grease residue.

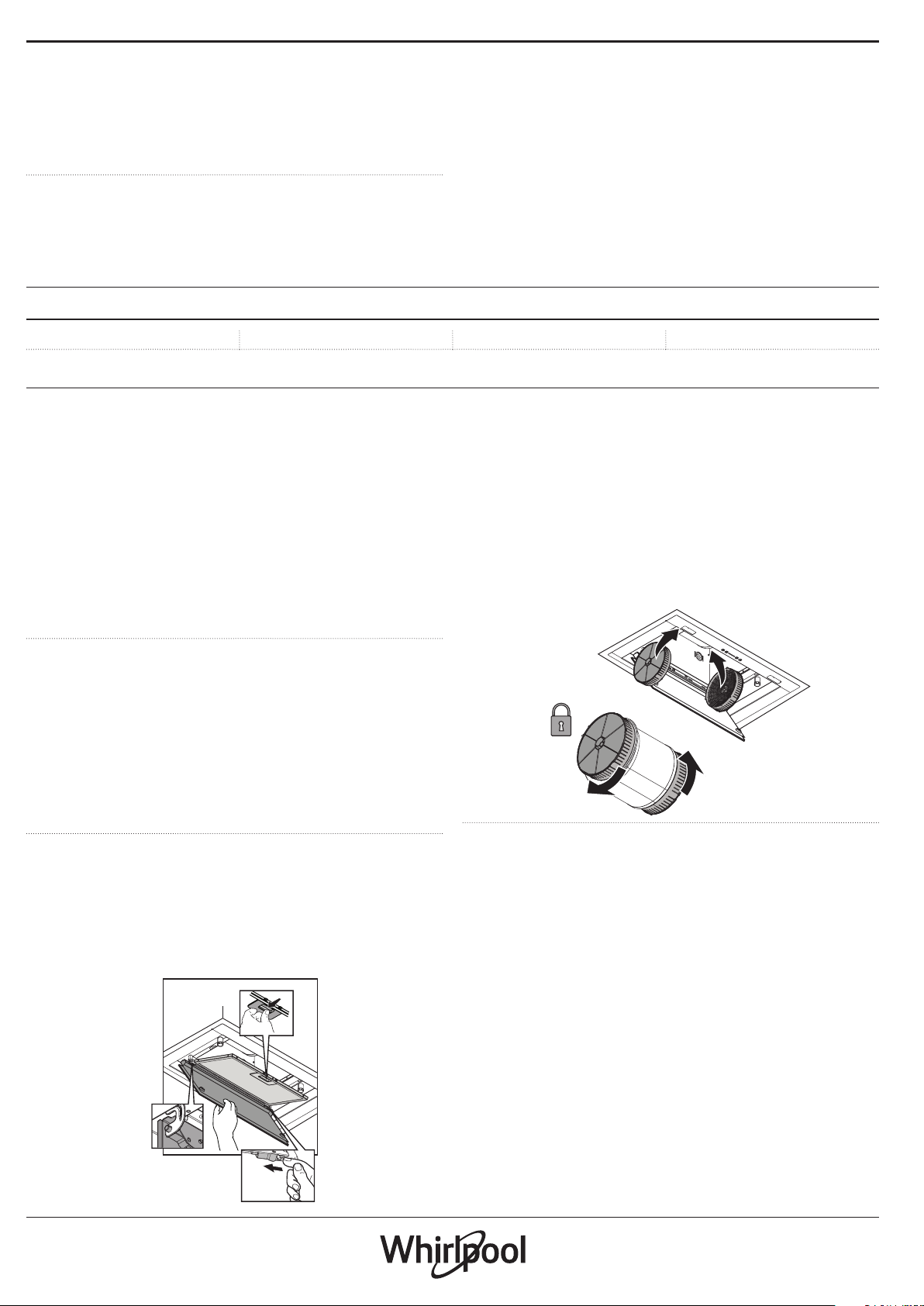

MAINTENANCE OF THE CHARCOAL FILTER

(FOR FILTRATION MODELS ONLY)

This lter retains the unpleasant odours produced during cooking.

Saturation of the carbon lter occurs after a relatively long use,

however this depends on the type of cooking and how regularly

the grease lter is cleaned. Regardless, it is necessary to replace the

cartridge every 4 months. It CANNOT be washed or recycled.

Fitting or replacing the carbon lter

1. Disconnect the hood from the mains.

2. Remove the grease lters.

3. Fit 2 carchoal lters (one each side of the conveyour), attachment.

4. Reinstall the grease lter in place.

Proceed in reverse order to remove.

MAINTENANCE OF THE PANEL

Disassembly:

a. pull the panel (FRONT SIDE) downwards energetically;

b. unhook it from the back hinges.

Cleaning:

the suction panel must be cleaned as frequently as the grease lter, use

a dampened cloth with neutral liquid detergents.

Avoid using products containing abrasives. DO NOT USE ALCOHOL!

Assembly:

The panel must be hooked in the back and xed in the front (with

magnets).

Attention! always check that the panel is tightly xed to its place.

MAINTENANCE OF THE GREASE FILTERS

This must be cleaned once a month using non aggressive detergents,

either by hand or in the dishwasher, which must be set to a low

temperature and a short cycle.

When washed in a dishwasher, the grease lter may discolour slightly,

but this does not aect its ltering capacity.

Pull out the handle to remove the lter.

Once the lter has been washed and left to dry, proceed in reverse

order to ret the lter.

REPLACING THE LAMPS

Note: For replacement LED, please contact the Technical After-sales Service

Centre.

Loading...

Loading...