Whirlpool W2PH3, W2PC3, W4PH4, W4PC4 Installation Instructions Manual

INSTALLATION INSTRUCTIONS FOR

PACKAGE HEAT PUMP OR PACKAGE COOLING UNIT

Table of Contents

HEAT PUMP/ELECTRIC COOLING SAFETY...............................1

INSTALLATION REQUIREMENTS................................................2

Tools and Parts ............................................................................2

Location Requirements................................................................2

Ductwork Requirements ..............................................................2

Electrical Requirements ...............................................................3

INSTALLATION INSTRUCTIONS..................................................3

Inspect Shipment.........................................................................3

Place Heat Pump or Condensing Unit in Final Location .............3

Convert to Downflow ...................................................................4

Connect Condensate Drain .........................................................4

Install Ductwork............................................................................5

Install Accessory Heater ..............................................................5

Make Electrical Connections .......................................................6

HEAT PUMP/ELECTRIC COOLING SAFETY

Complete Installation....................................................................7

SEQUENCE OF OPERATION ........................................................7

Cooling Cycle—Cooling Only ......................................................7

Cooling Cycle—Heat Pump Only.................................................7

Heating Cycle ...............................................................................8

Defrost Cycle................................................................................8

Adjust Defrost System .................................................................9

Troubleshoot the Defrost System................................................9

Circulating Air Blower (PSC Motor)............................................10

Circulating Air Blower (Variable Speed Motor) ..........................10

SYSTEM MAINTENANCE ............................................................11

TROUBLESHOOTING ..................................................................12

ASSISTANCE OR SERVICE.........................................................16

Accessories ................................................................................16

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

can be killed or seriously injured if you don't

You

instructions.

Whirlpool® Models

W2PH3, W2PC3,

W4PH4, W4PC4

48373F007

Whirlpool® Home Cooling and Heating

14610 Breakers Drive

Jacksonville, FL 32258

follow

INSTALLATION REQUIREMENTS

These instructions are intended as a general guide only for use by

qualified persons and do not supersede any national or local

codes in any way. Compliance with all local, state, or national

codes pertaining to this type of equipment should be determined

prior to installation.

Read this entire instruction manual, as well as the instructions

supplied in separate equipment, before starting the installation.

The installation of the heat pump or condensing unit, wiring,

warm air ducts, venting, etc., must conform to the requirements

of the National Fire Protection Association; the National Electrical

Code, ANSI/NFPA No. 70 (latest edition) in the United States, and

any state laws, local ordinances (including plumbing or

wastewater codes). Local authorities having jurisdiction should

be consulted before installation is made. Such applicable

regulations or requirements take precedence over the general

instructions in this manual.

Tools and Parts

Gather the required tools before starting installation. Read and

follow the instructions provided with any tools listed here.

Tools needed

■ ⁵⁄₁₆" nut driver

■ Screwdriver

■ Tape m e a sure

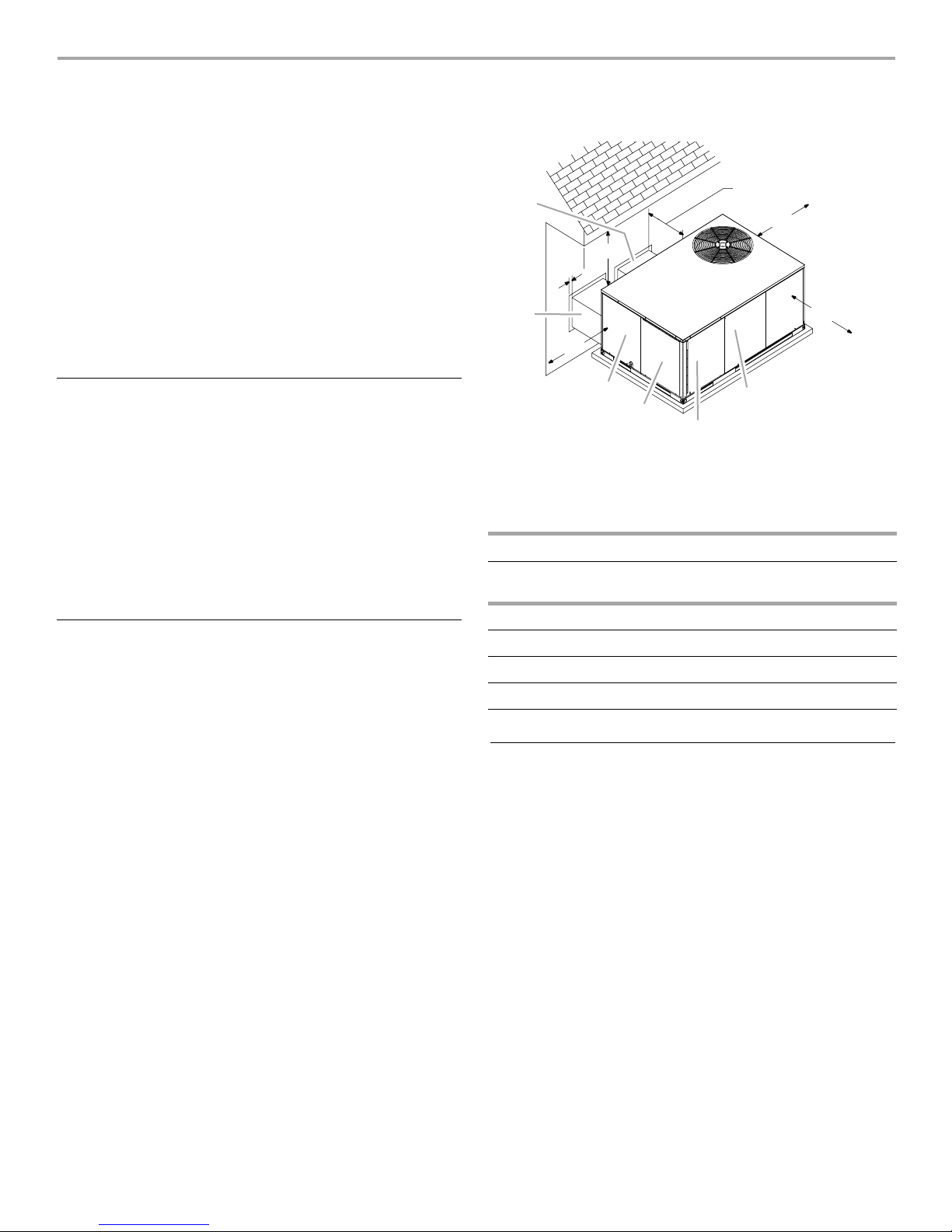

Minimum Clearances

F

36"

2"

E

30"

D

C

A. Heater compartment access panel

B. Blower access panel

C. Evaporator coil access panel

Minimum - 3"

Recommended - 24"

24"

48"

Front side of unit

A

B

D. Filter access panel

E. Return air duct

F. Supply a i r duct

Parts needed

Check local codes and existing electrical supply. Read “Electrical

Requirements” and “Ductwork Requirements” before purchasing

parts.

Location Requirements

■ This heat pump or condensing unit is designed to be located

outdoors with sufficient clearance for free entrance to the

inlet and discharge air openings. The location must also allow

for adequate service access. See “Minimum Clearances.”

■ Where possible, select a location for the heat pump or

condensing unit which is shaded from the direct rays of the

sun most of the time. North or east locations are usually most

desirable. Position the heat pump or condensing unit to avoid

direct contact with water, snow or ice from a roofline

overhead.

■ The heat pump or condensing unit must be installed on a

solid, level mounting pad that will not settle or shift. Isolate

the pad from the building structure to avoid possible

transmission of sound or vibration from the heat pump or

condensing unit into the conditioned space.

■ The heat pump or condensing unit foundation should be

raised to a minimum of 3" above finish grade. In areas which

have prolonged periods of temperature below freezing and

snowfall, the heat pump or condensing unit should be

elevated above the average snow line. If the heat pump or

condensing unit is to be installed on a flat roof, it should be

on a platform or other support which will raise the base a

minimum of 8" above the surface of the flat roof.

■ Avoid placing a heat pump or condensing unit near areas

such as sleeping quarters or study rooms. Normal operating

sound levels may be louder than desired if the heat pump or

condensing unit is placed near certain rooms.

Minimum Clearance Requirements

For Optimum

Service Access

Front 48" 24"

Rear 24" 3"

Condenser End 24" 3"

Blower End 30" 0"

Top 36" 36"

For Optimum

Operation

Ductwork Requirements

■ Install all conditioned air plenums, ducts and air filters in

accordance with NFPA 90B Standard for the Installation of

Warm Air Heating and Air-Conditioning Systems (latest

edition).

■ The heat pump or condensing unit is provided with flanges

for the connection of the plenum and ducts.

■ All air filters must be listed as Class 2 air filters.

■ All ductwork must be made of materials and insulated to

meet local, state and national codes. Ductwork installed

outdoors must be sealed, weatherproof and protected

against physical damage. Caulking, flashing or other means

of adequately providing a permanent weather seal should be

used where duct penetrates a building or structure opening.

2

Electrical Requirements

WARNING

Electrical Shock Hazard

Electrically ground condensing unit or heat pump.

Connect ground wire to ground terminal

marked “GROUND”.

Use copper wire for supply connection.

Correct wire gauge is shown in the chart below.

Failure to follow these instructions can result in

death or electrical shock.

■ All field wiring must be done in accordance with National

Electrical Code requirements, applicable requirements of UL,

or local codes, where applicable.

■ Electrical wiring, disconnect means and over current

protection are to be supplied by the installer. Refer to the

rating plate for the maximum over current protection,

minimum service ampacity, and operating voltage. See the

wiring connection diagrams in “Troubleshooting.”

■ This heat pump or condensing unit must be electrically

grounded in accordance with National Electric Code (ANSI/

NFPA 70) requirements, applicable requirements of UL, or

local codes, where applicable.

Rating Plate Ampacity

Less than 15

16 - 20

21 - 30

31 - 50 8

NOTE: All outdoor wiring must be suitable for outdoor use. Use

copper conductors only.

AWG

14

12

10

INSTALLATION INSTRUCTIONS

Inspect Shipment

WARNING

Excessive Weight Hazard

Use two or more people and mechanical equipment to

lift, move and install condensing unit or heat pump.

Failure to do so can result in back or other injury.

This heat pump or condensing unit is shipped in one package,

completely assembled and wired. The indoor thermostat and

accessories are shipped in a separate carton when ordered.

1. Check the heat pump or condensing unit rating plate to

confirm specifications are as ordered.

2. Upon receipt of heat pump or condensing unit, inspect it for

possible shipping damage. Be sure to examine the heat

pump or condensing unit inside the carton if the carton is

damaged.

If damage is found, it should be noted on the carrier’s freight bill.

Damage claims should be filed with the carrier immediately.

Claims of shortages should be filed with the seller within 5 days.

NOTE: If any damages are discovered and reported to the carrier,

do not install the heat pump or condensing unit as your claim

may be denied.

Place Heat Pump or Condensing Unit in

Final Location

WARNING

Excessive Weight Hazard

Use two or more people and mechanical equipment to

lift, move and install condensing unit or heat pump.

Failure to do so can result in back or other injury.

IMPORTANT: Place the heat pump or condensing unit in the final

location and position it in the proper orientation to the house so

that connecting ducts and electrical supplies is easily done.

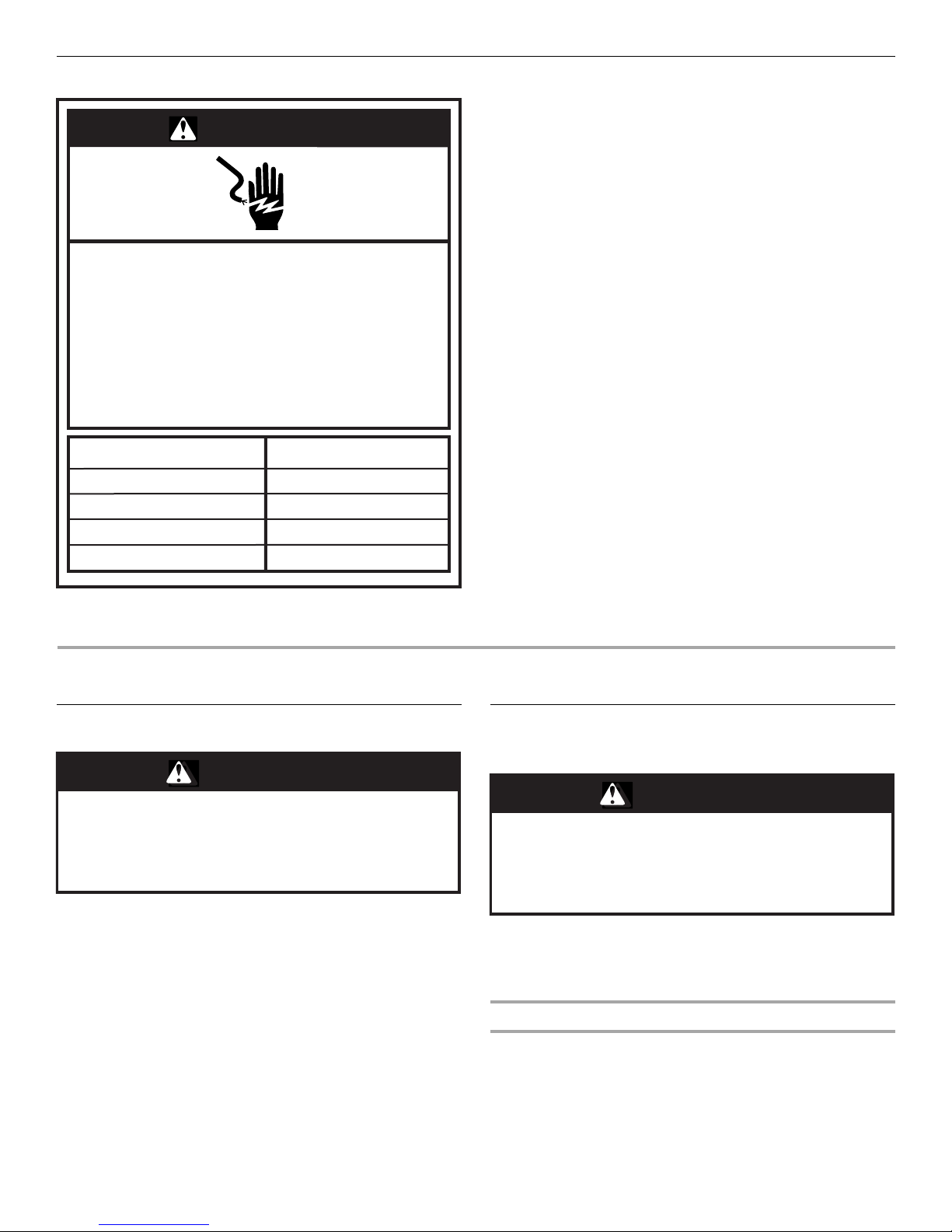

Hoisting may be required.

Hoisting

An accessory lift kit must be purchased to hoist the heat pump or

condensing unit. See “Accessories.” Attach the rigging to the

lifting brackets on each corner.

NOTE: All access panels must be secured in place before

hoisting.

3

The heat pump or condensing unit should be hoisted with 2 lifting

slings. Attach the slings to rigging shackles that have been

hooked through holes in the lifting brackets.

Place 2 spreaders on top of the heat pump or condensing unit to

protect it from damage from the pressure exerted by the slings.

Make sure that all equipment is rated to handle at least 750 lbs

and that the slings will not allow the heat pump or condensing

unit to shift. See “Typical Sling Configuration.”

Typical Sling Configuration

A

A. Spreaders

B. Cables

C. Lifting bracket (accessory lift kit)

B

C

D

E

D. Sheet metal

screw

E. Pallet

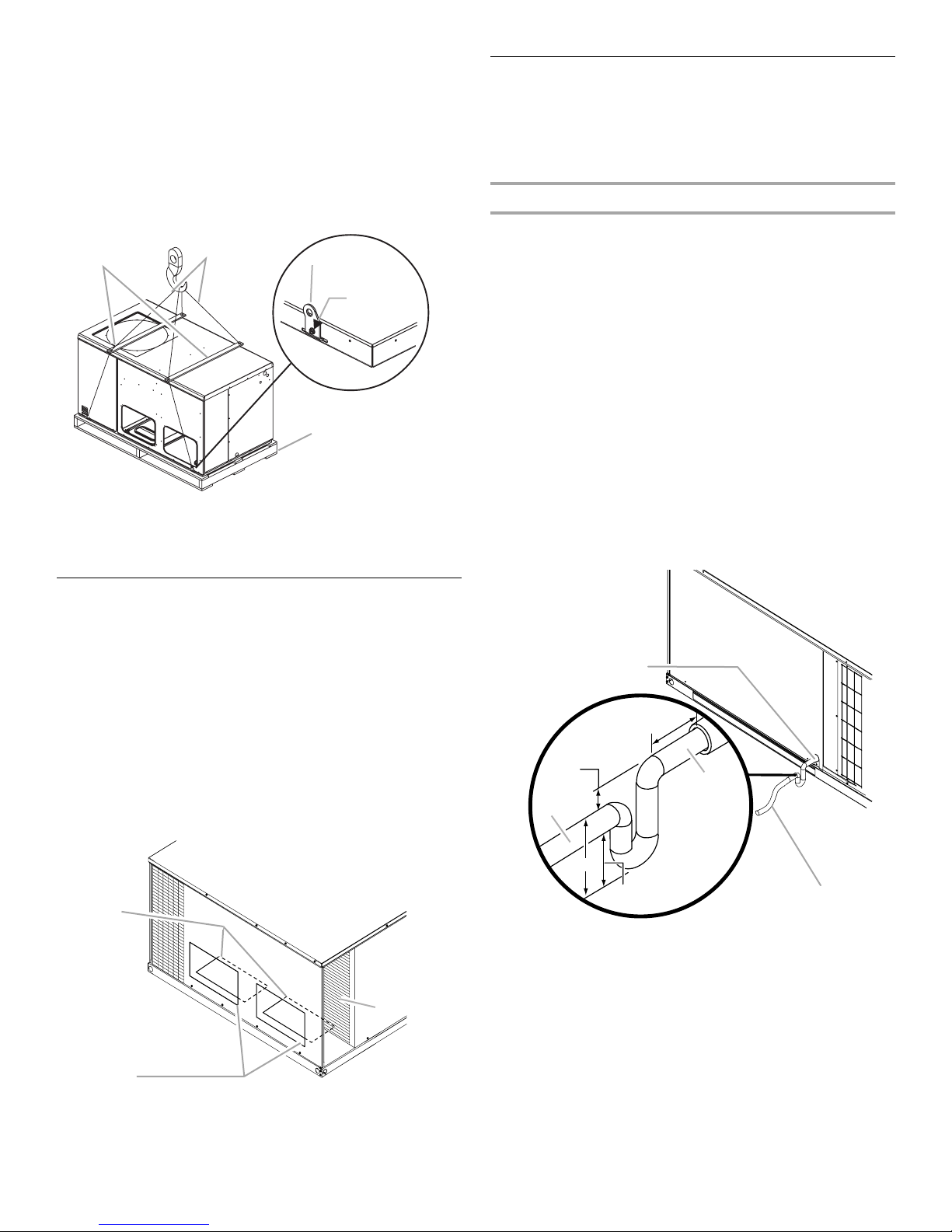

Connect Condensate Drain

The condensate drain outlet is a ³⁄₄" threaded PVC fitting located

at the bottom on the side of the heat pump or condensing unit. A

³⁄₄" drain line with trap must be installed on all applications to

avoid accumulation of condensate under or around the heat

pump or condensing unit.

Install Condensate Trap

1. Construct the condensate trap from PVC tubing as shown in

“Condensate Trap Construction.”

NOTES:

■ The condensate trap allows a standing column of water of

at least 2" (50 mm).

■ The top of the drain trap inlet must be at least least 1"

(25 mm) above the top of the drain trap outlet.

■ The trap should be installed as close to the heat pump or

condensing unit as possible, while still providing proper

drainage.

■ For service access, do not block heat exchanger access

panel or the filter access panel with the drain line.

2. Thread the drain assembly into the ³⁄₄" PVC fitting.

NOTE: Do not glue the threaded fitting so it can be removed

during servicing of unit.

3. Run the drain line to an open drain or other suitable disposal

point.

Condensate Trap Construction

Convert to Downflow

This heat pump or condensing unit is factory-built for horizontal

airflow applications and may also be field-converted for

downflow use.

To convert to downflow use:

1. Remove the filter access panel.

2. Remove the two downflow duct cover plates (one screw and

tab for each) found in the return and supply air

compartments.

3. Using eight #10 x ³⁄₄" screws (field supplied), install the

previously removed duct covers on the horizontal return and

supply air openings. Use the pilot holes provided.

4. Reinstall the filter access panel.

A

B

A

12" Max.

1" Min.

D

3" Min.

2" Min.

A.

³⁄₄

" PVC fitting (threaded) drain

condensate connection

³⁄₄

" drain pipes, field provided

B.

C

B

C. Drain trap outlet

D. Drain trap inlet

C

A. Horizontal return and supply air openings

B. Filter access panel

C. Downflow duct cover plates

4

Install Ductwork

D

A

■ Install ductwork in accordance with NFPA 90B and any local

codes.

■ The use of flexible, noncombustible connectors between the

main trunk ducts and the supply and return air plenums is

recommended to minimize vibration transmission.

■ Plenums must be individually sealed to heat pump or

condensing unit casing with ducts terminating inside the

structure.

■ Flashing used to cover ductwork must permit removal of

access panels and top. See “Minimum Clearances” in the

“Locations Requirements” section.

Filters

Filters are not supplied with these heat pumps or condensing

units; however, filters must be used. It is the installer’s

responsibility to install a filter rack with the ductwork and to

install properly sized filters in accordance with the Minimum

Required Surface Area for Disposable Filters chart.

Install Accessory Heater

WARNING

All return air must pass through a filter before entering the heat

pump or condensing unit. An electronic air cleaner, filter rack or

other accessible filter arrangement must be installed in the return

air ductwork. Minimum recommended filter areas are listed in the

Minimum Required Surface Area for Disposable Filters chart, and

are based on a face velocity of 325 ft (99.1 m) per min. for

disposable filters and 525 ft (160 m) per min. for cleanable filters.

Minimum Required Surface Area for Disposable Filters

Nominal Cooling Filter Area (sq. ft)

24,000 2.67

30,000 3.33

36,000 4.00

42,000 4.67

48,000 5.33

60,000 6.67

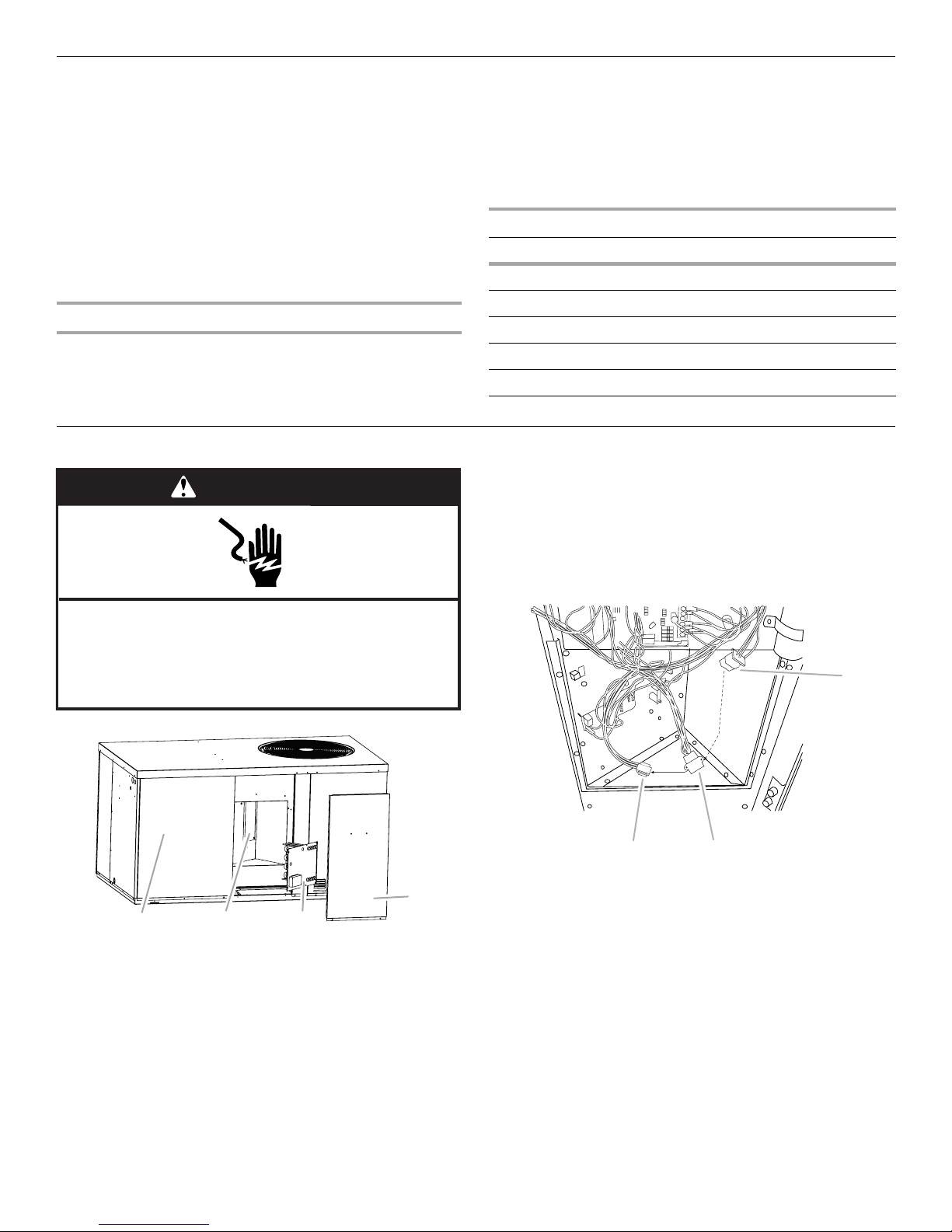

3. Remove the heater blockoff by removing the 4 screws

holding it in place.

4. Insert the heater kit into the control panel and fasten in the

same mounting holes.

5. Disconnect the plugs connecting the no-heat wire harness to

the control assembly wire harness.

6. Remove the no-heat wire harness plugs.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

A

A. Blower access panel

B. Heater blockoff

1. Disconnect power.

2. Remove the heater compartment access panel.

BC

C. Heater kit

D. Heater compartment access panel

C

A. No-heat wire harness

B. Control assembly wire harness

C. Heater wire harness

7. Plug the heater wiring harness into the control assembly wire

harness.

8. See “Make Electrical Connections” for instructions on

connecting power to the heater kit.

9. Replace the heater compartment access panel.

10. Reconnect power.

B

5

Loading...

Loading...