Whirlpool W2GC3 Installation Instructions

CONDENSING UNIT INSTALLATION INSTRUCTIONS

Table of Contents

CONDENSING UNIT SAFETY........................................................1

INSTALLATION REQUIREMENTS................................................2

Tools and Parts ............................................................................2

System Requirements..................................................................2

Location Requirements................................................................2

Electrical Requirements ...............................................................3

INSTALLATION INSTRUCTIONS..................................................4

Inspect Shipment.........................................................................4

CONDENSING UNIT SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

Connect Refrigerant Lines ...........................................................4

Make Electrical Connections .......................................................5

Complete Installation....................................................................8

SEQUENCE OF OPERATION ........................................................8

SYSTEM MAINTENANCE ..............................................................8

ASSISTANCE OR SERVICE...........................................................8

WARRANTY ..................................................................................11

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

Whirlpool Gold™ Model W2GC3

48299L005

follow instructions.

can be killed or seriously injured if you don't

You

instructions.

follow

INSTALLATION REQUIREMENTS

These instructions are intended as a general guide only and do

not supersede any national or local codes in any way. The

installation must comply with all state, and local codes as well as

the National Electrical Code.

■ The condensing unit is designed and approved for outdoor

use only.

■ The condensing unit must be installed with no ductwork in

the airstream. The outdoor fan is not designed to operate

against any additional static pressure.

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools Needed

■ To rc h

■ ¹⁄₄" nut driver

Parts Needed

Check local codes and HVAC supplier. Check existing electrical

supply, and read “Electrical Requirements,” “Location

Requirements,” “System Requirements” and “Connect

Refrigerant Lines.”

NOTE: Some condensing units do not contain a factory-installed

filter dryer. With those units, a properly sized filter dryer must be

field installed in the liquid (high pressure) line set between the

outdoor condensing unit and indoor evaporator unit.

System Requirements

Condensing unit system matches are derived from actual

laboratory testing of matched systems. It is recommended that

only matching equipment be used to ensure proper operation

and efficient performance.

■ The designed system matches are listed in the condensing

unit specification sheets and on the condensing unit

refrigerant charging instructions located on the back of the

service access panel.

■ Refrigerant charging instructions include a list of matching

indoor equipment with the proper expansion device size and

amount of refrigerant charge required.

■ This condensing unit has been factory charged with a

quantity of refrigerant (R22) sufficient for a matched indoor

coil and a maximum 15 ft of refrigerant line.

Indoor System Expansion Device

■ ⁵⁄₁₆" nut driver

Location Requirements

■ This condensing unit is designed to be located outdoors with

sufficient clearance for free entrance to the inlet and

discharge air openings. The location must also allow for

adequate service access. See “Minimum Clearances.”

■ Where possible, select a location for the condensing unit

which is shaded from the direct rays of the sun most of the

time. North or east locations are usually most desirable.

Position the condensing unit to avoid direct contact with

water, snow or ice from a roofline overhead.

■ The condensing unit must be installed on a solid, level

mounting pad that will not settle or shift. Isolate the pad from

the building structure to avoid possible transmission of sound

or vibration from the condensing unit into the conditioned

space.

■ The condensing unit foundation should be raised to a

minimum of 3" above finish grade. In areas which have

prolonged periods of temperatures below freezing, and/or

snowfall, the condensing unit should be elevated above the

average snow line.

■ Avoid placing the condensing unit near areas such as

sleeping quarters or study rooms. Normal operating sound

levels may be objectionable if the condensing unit is placed

near certain rooms.

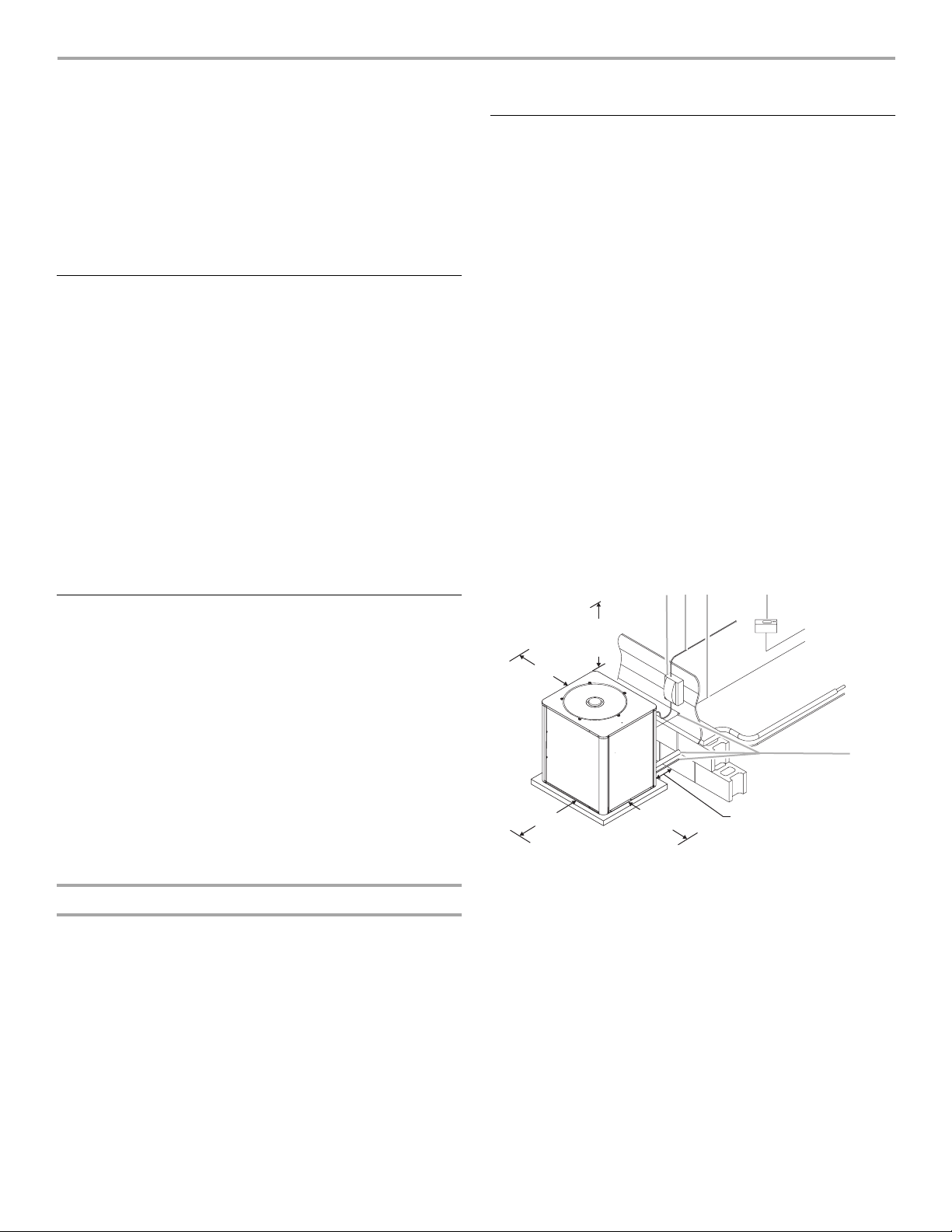

Minimum Clearances

AB C D

48" Overhead

Clearance

(Discharge

Air)

12" Clearance

(Inlet Air)

36" Clearance

(Inlet Air)

A. Weatherproof disconnect switch

B. NEC class 1 wiring

C. NEC class 2 wiring

30" Service

Access Clearance

To

Power

Supply

Indoor

12" Clearance Between

Unit and Building

D. House thermostat

E. Seal openings

To

Unit

To

Indoor

Coil

E

■ Check the indoor coil expansion device to see whether it

matches the required expansion device for the indoor coil

and condensing unit being installed.

■ Refer to the refrigerant charge label located on the inside of

the condensing unit access panel for the correct expansion

device size required.

■ Replace the expansion device with the correct size if this size

is not already installed in the indoor coil. Instructions for

replacing the expansion device are provided with the indoor

coil.

2

Line Set Isolation

B

The following illustrations demonstrate procedures which ensure

proper refrigerant line set isolation.

Installing Horizontal Runs

This shows how to install line sets on horizontal runs.

NOTE: To hang line set from joist or rafter, use either metal

strapping material or anchored heavy nylon wire ties.

Installing Vertical Runs (new construction shown)

This shows how to install line sets on vertical runs.

NOTE: Similar installation practices should be used if line set is

to be installed on exterior of outside wall.

IMPORTANT: Refrigerant lines must not contact structure.

A

B

C

D

C

8’

B

A

D

8’

G

E

F

A. Floor joist or roof

rafter

B. Strapping material

(around vapor line

only)

C. Wire tie (around

vapor line only)

D. Tape or wire

tie

E. Metal sleeve

F. Ta p e o r w ire

tie

G. Strap the vapor line

to the floor joist or

roof rafter at 8"

intervals, then strap

the liquid line to the

vapor line.

Transition from Horizontal to Vertical

This shows how to make a transition from horizontal to vertical.

A

B

G

C

A

K

L

A. Outside wall

B. Refrigerant lines must

not contact wall.

C. Vapor line wrapped in

armaflex

D. Liquid line

Electrical Requirements

E

J

E. Wire tie

F. Inside wall

G. Strap

H. Sleeve

I. Wood block

between studs

WARNING

E

F

G

H

E

I

E

G

H

J. Caulk

K. Fiberglass

insulation

L. PVC pipe

F

E

A. Anchored heavy

nylon wire tie

B. Strap liquid line

to vapor line.

C

D

C. Liquid line

D. Vapor line—

wrapped in

armaflex

F

E

E. Metal sleeve

F. W a l l s t ud

G. Automotive muffler-

type hanger

C

D

Electrical Shock Hazard

Electrically ground condensing unit or heat pump.

Connect ground wire to ground lug.

Use copper wire for supply connection.

Correct wire gauge is shown in the chart below.

Failure to follow these instructions can result in

death or electrical shock.

Rating Plate Ampacity

Less than 15

16 - 20

21 - 30

31 - 50

AWG

14

12

10

8

NOTE: All outdoor wiring must be suitable for outdoor use. Use

copper conductors only.

3

■ All field wiring must be done in accordance with National

Electrical Code requirements, applicable requirements of UL,

or local codes, where applicable.

INSTALLATION INSTRUCTIONS

Inspect Shipment

WARNING

Excessive Weight Hazard

Use two or more people to move and install

condensing unit or heat pump.

Failure to do so can result in back or other injury.

This condensing unit is shipped in one package, completely

assembled and wired. The thermostat is shipped in a separate

carton when ordered.

1. Check the condensing unit rating plate to confirm

specifications are as ordered.

2. Upon receipt of equipment, inspect it for possible shipping

damage. Examine the unit inside the carton if the carton is

damaged.

If damage is found, it should be noted on the carrier’s freight bill.

Damage claims should be filed with the carrier immediately.

Claims of shortages should be filed with the seller within 5 days.

NOTE: If any damages are discovered and reported to the carrier,

do not install the unit, because your claim may be denied.

■ Electrical wiring, disconnect means and over-current

protection are to be supplied by the installer. Refer to the

rating plate for the maximum over-current protection,

minimum circuit ampacity, and operating voltage. See the

wiring diagrams in “Make Electrical Connections.”

3. Remove valve cores.

4. Wrap the service valves with a wet rag.

5. If not provided, install a filter dryer in the liquid line between

the outdoor condensing unit and the indoor evaporator coil.

6. Connect the suction and liquid lines, using a brazing

compound. Braze with an alloy of silver or copper and

phosphorus with a melting point above 1,100°F.

NOTE: Do not use soft solder.

7. Make sure indoor coil has been put in place according to the

Installation Instructions and is connected to the refrigerant

lines.

8. Replace valve cores.

9. Pressurize the lines and indoor coil with dry nitrogen not to

exceed 20 psi.

10. Leak test the refrigerant lines and indoor coil.

11. Evacuate the indoor coil and lines to a minimum of

500 microns to remove contamination and moisture, then

disconnect the vacuum pump.

12. Open the suction and liquid service valves fully.

13. Insulate the suction line with refrigerant line insulation

material of ¹⁄₄" or more wall thickness.

14. Pack insulating material around refrigerant lines where they

penetrate the structure to protect the lines and to minimize

vibration transmission.

Connect Refrigerant Lines

Refrigerant lines must be connected by a licensed, EPA certified

refrigerant technician in accordance with established procedures.

IMPORTANT:

■ Connecting refrigerant lines must be clean, dehydrated,

refrigerant-grade copper lines. Condensing units should be

installed only with specified line sizes for approved system

combinations with elevation differences up to 15 ft and total

length of up to 50 ft. See the Suction Line Sizes and Liquid

Line Sizes charts later in this section.

■ Avoid sharp bends or possible kinking in the refrigerant lines

during installation as this may cause a reduction in

performance.

■ To avoid contamination of the refrigerant system, do not

remove the caps from the lines or system connection points

until connections are ready to be completed.

1. Route the suction and liquid lines from the fittings on the

indoor coil to the fittings on the condensing unit. Run the

lines in as direct a path as possible, avoiding unnecessary

turns and bends.

2. For product efficiency, be sure that the suction line is

insulated over the entire exposed length and that both

suction and liquid lines are not in direct contact with floors,

walls, ductwork, floor joists, or other piping.

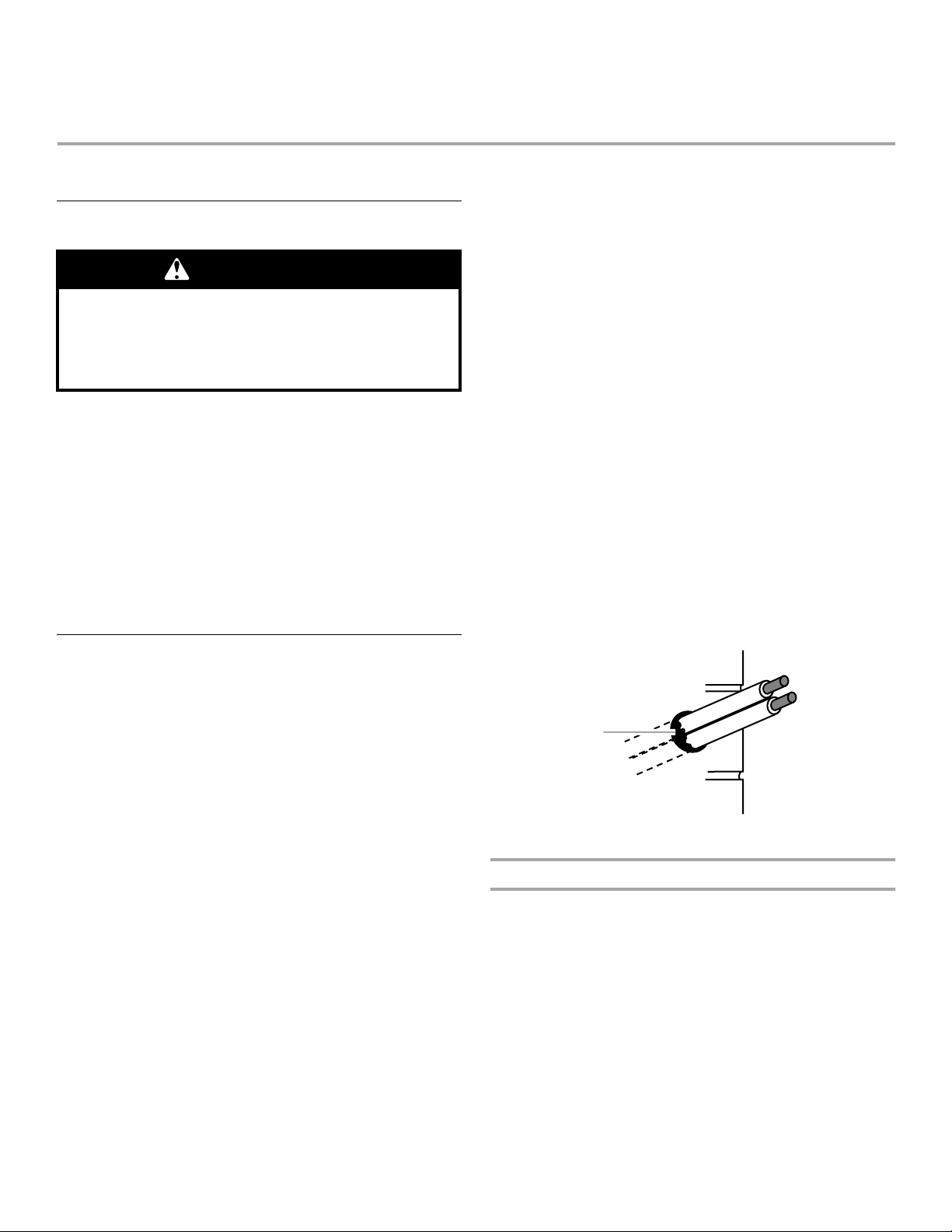

A

A. Seal openings where refrigerant lines penetrate structure.

Refrigerant Charge

Refrigerant lines must be connected by a licensed, EPA certified

refrigerant technician in accordance with established procedures.

IMPORTANT:

■ Refrigerant charge adjustment will be required for line set

lengths greater than 15 ft and for non system-matched

evaporator coils.

■ The condensing unit is factory-charged with the proper

refrigerant charge amount for a matching evaporator and

15 ft of refrigerant line. Refer to the condensing unit rating

plate for the exact amount of this factory charge.

4

Loading...

Loading...