Whirlpool W10120482A User Manual

INSTALLATION INSTRUCTIONS

GAS DRYER

W10120482A

IMPORTANT: Save these instructions.

IMPORTANTE:

Guarde estas instrucciones.

IMPORTANT :

Conserver ces instructions.

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Índice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table des matières . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

INSTRUCCIONES DE INSTALACIÓN

SECADORA A GAS

INSTRUCTIONS D'INSTALLATION

SECHE-LINGE A GAZ

2

TABLE OF CONTENTS

DRYER SAFETY

DRYER SAFETY .......................................................................... 2

INSTALLATION REQUIREMENTS .............................................. 4

Tools and Parts .......................................................................... 4

Location Requirements.............................................................. 4

Electrical Requirements ............................................................ 6

Gas Requirements...................................................................... 6

Venting Requirements .............................................................. 7

INSTALLATION INSTRUCTIONS – GAS DRYER .................... 9

Install Ventwork ..........................................................................9

Prepare Dryer..............................................................................9

Level and Exhaust the Dryer ....................................................10

Check Operation ......................................................................11

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

follow instructions.

can be killed or seriously injured if you don't

You

instructions.

follow

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of fire, electric shock, or injury to persons when using the dryer, follow basic precautions,

WARNING:

including the following:

■ Read all instructions before using the dryer.

■ Do not place items exposed to cooking oils in your dryer.

Items contaminated with cooking oils may contribute to

a chemical reaction that could cause a load to catch fire.

■ Do not dry articles that have been previously cleaned in,

washed in, soaked in, or spotted with gasoline, drycleaning solvents, other flammable, or explosive

substances as they give off vapors that could ignite or

explode.

■ Do not allow children to play on or in the dryer. Close

supervision of children is necessary when the dryer is

used near children.

■ Before the dryer is removed from service or discarded,

remove the door to the drying compartment.

■ Do not reach into the dryer if the drum is moving.

■ Do not install or store the dryer where it will be exposed

to the weather.

■ Do not tamper with controls.

■ Do not repair or replace any part of the dryer or attempt

any servicing unless specifically recommended in this

Use and Care Guide or in published user-repair instructions that you understand and have the skills to carry out.

■ Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product.

■ Do not use heat to dry articles containing foam rubber or

similarly textured rubber-like materials.

■ Clean lint screen before or after each load.

■ Keep area around the exhaust opening and adjacent sur-

rounding areas free from the accumulation of lint,dust,

and dirt.

■ The interior of the dryer and exhaust vent should be

cleaned periodically by qualified service personnel.

SAVE THESE INSTRUCTIONS

3

WARNING: For your safety, the information in this manual must be followed to minimize

the risk of fire or explosion, or to prevent property damage, personal injury, or death.

–Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

–WHAT TO DO IF YOU SMELL GAS:

•

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use any phone in your building.

•

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

•

If you cannot reach your gas supplier, call the fire department.

–Installation and service must be performed by a qualified installer, service agency, or

the gas supplier.

•

Clear the room, building, or area of all occupants.

4

Location Requirements

IMPORTANT: Observe all governing codes and ordinances.

■ Check code requirements: Some codes limit or do not permit

installation of clothes dryers in garages, closets, or sleeping

quarters. Contact your local building inspector.

INSTALLATION REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools

listed here.

Tools needed

■ Flat-blade screwdriver

■ Phillips screwdriver

■ Adjustable wrench that opens to 2.5 cm (1")

■ 2.5 cm (1") Hex-head socket wrench

■ Level

■ 20 or 30 cm (8" or 10") pipe wrench

■ 1/4" socket wrench or 1/4" nut driver

■ Utility knife

■ Vent clamps

■ Pipe-joint compound resistant to LP gas

■ Caulk gun and caulk (for installing new exhaust vent)

■ Tin snips

Parts supplied

Remove parts bag from dryer drum. Check that all parts were

included.

■ 4 leveling legs

■ 4 gas inlet pipe adapters

Parts needed

Check local codes and gas supplier, and read electrical,

gas and venting requirements before purchasing parts.

Gas supply line must have:

• Shutoff valve

Rigid gas supply line must be:

• Minimum 12.5 mm (1/2") ID pipe

Flexible gas supply hose must be:

• Minimum 10 mm (3/8") ID approved flexible hose

L.P. gas conversion:

Gas conversion kit, part number 279918, available for

purchase from your dealer. Full instructions are supplied

with the kit. Conversion must be made by a competent

technician.

■ Make sure that lower edges of the cabinet, plus the back and

bottom sides of the dryer, are free of obstructions to permit

adequate clearance of air openings for combustion air. See

“Recessed Area and Closet Installation Instructions” for

minimum spacing requirements.

NOTE: The dryer must not be installed in an area where it will be

exposed to water and/or weather. If room temperature is below

7º C (45º F), automatic cycles may not shut off.

■ Maximum slope under entire dryer should not be more than

2.5 cm (1") . If slope is greater than 2.5 cm (1") , install

Extended Dryer Feet Kit, Part No. 279810. Clothes may not

tumble properly and automatic sensor cycles may not operate

correctly if dryer is not level. Floor must be able to support

dryer weight of 79.4 kg (175 lbs).

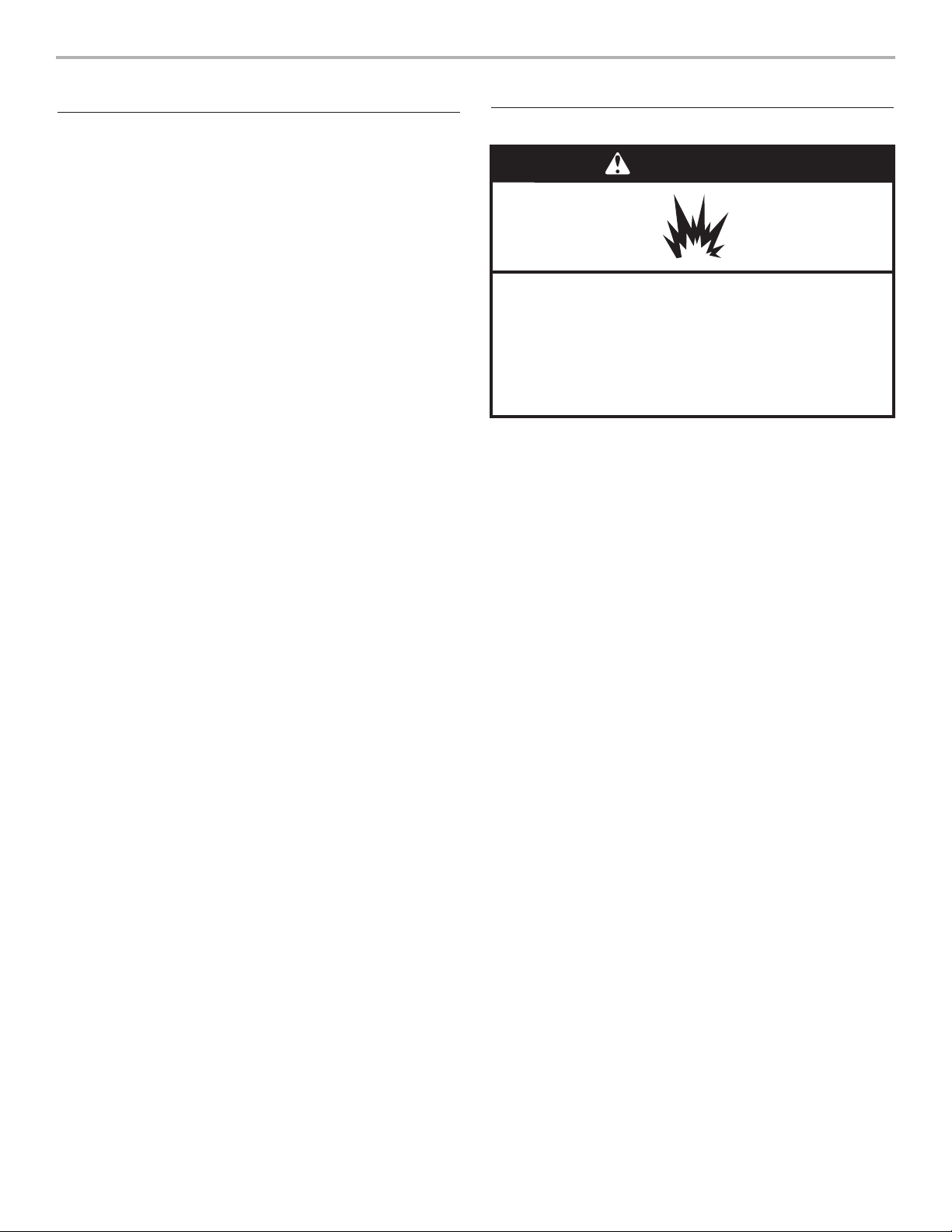

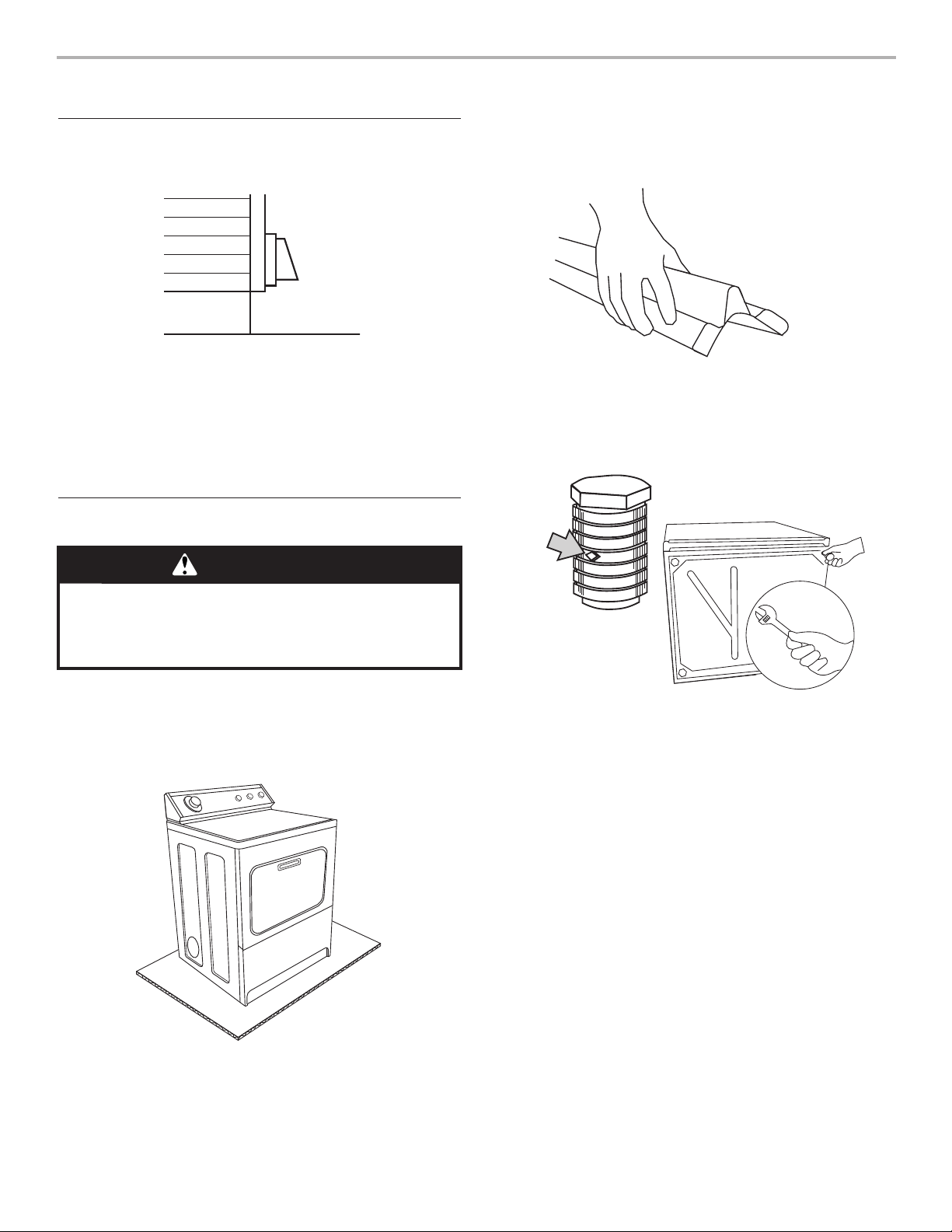

WARNING

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Place dryer at least 46 cm (18 inches) above the floor

for a garage installation.

Failure to do so can result in death, explosion, or fire.

5

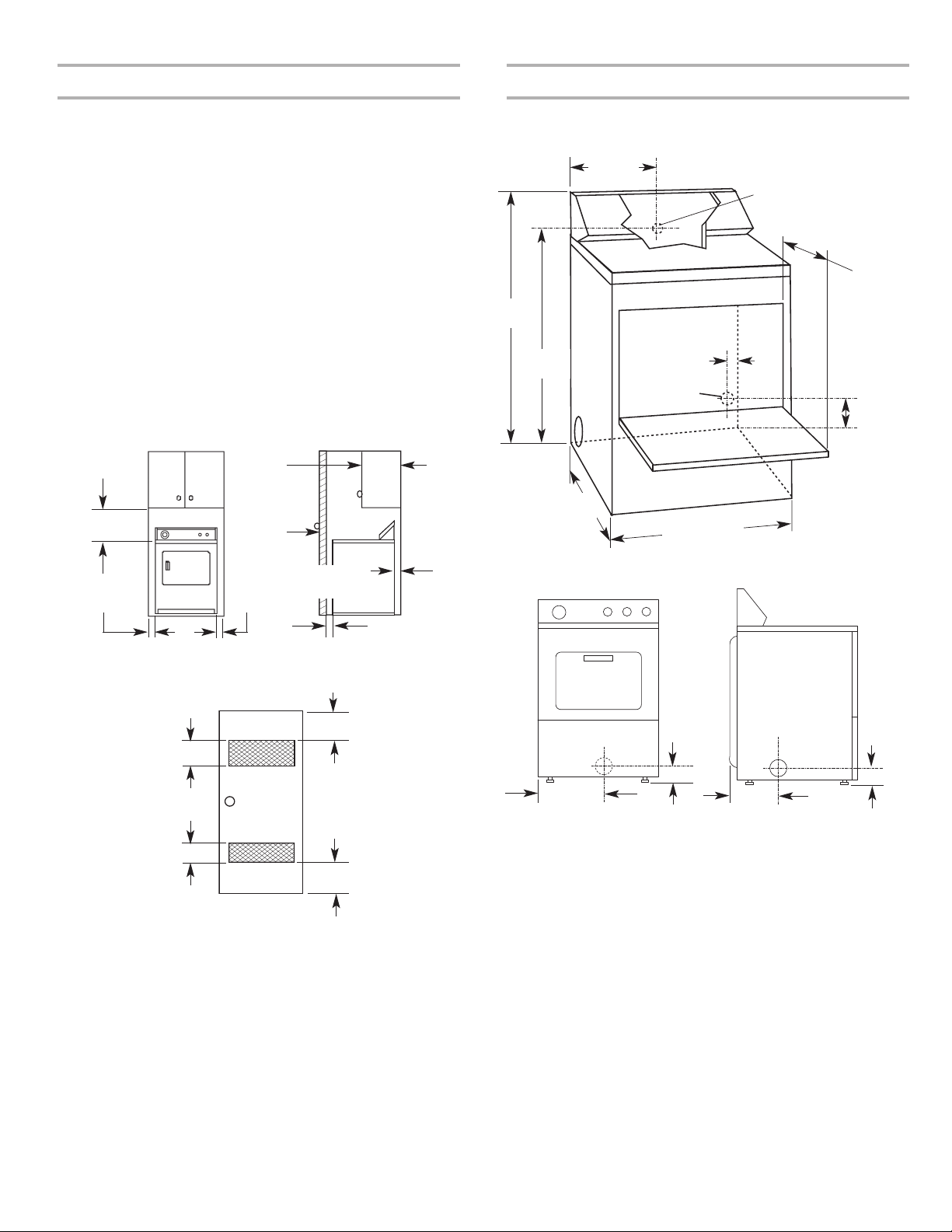

Recessed Area and Closet Installation Instructions

This dryer must not be installed behind a lockable door, a sliding

door, or a door with a hinge on the opposite side to that of the

dryer.

This dryer may be installed in a recessed area or closet. For

recessed area and closet installations, minimum clearances can

be found on the serial tag on the dryer.

The installation spacing is in centimeters (inches) and is the

minimum allowable. Additional spacing should be considered for

ease of installation, servicing, and compliance with local codes

and ordinances.

If closet door is installed, the minimum unobstructed air opening

in the top and bottom is required. Louvered doors with equivalent

air openings are acceptable.

The dryer must be exhausted outdoors.

No other fuel-burning appliance may be installed in the same

closet as the dryer.

Recessed front view Closet side view

Minimum Installation Clearances

Additional clearances for wall, door and floor moldings may be required or if

external exhaust elbow is used.

closet

door

Front

View

7.6 cm (3")

7.6 cm (3")

155 cm

2

(24"2)

310 cm

2

(48"2)

*Opening is the minimum for a closet door.

Louvered doors with equivalent air openings are acceptable.

2.5 cm (1")

Closet

door

35.6 cm

(14") max.

2.5 cm (1")

2.5 cm (1")

45.7 cm

(18")*

10.2 cm

(4")

Product Dimensions

Dimensions shown with feet extended 2.5 cm (1") from

bottom of dryer.

left or right

side exhaust

back

exhaust

10.8 cm

(4-1/4")

26 cm

(10-1/4")

35.9 cm

(14-1/8")

10.2 cm

(4")

Exhaust dimensions

74.3 cm

(29-1/4")

An electrical outlet is

required within 1.4 m

(4-1/2 feet) for the

power supply cord

109.5 cm

(43-1/8")

27.9 cm

(11")

97.2 cm

(38-1/4")

68.6 cm (27")

35.6 cm (14")

door clearance

15.9 cm

(6-1/4")

3.8 cm

(1-1/2")

gas line

opening

6

Electrical Requirements Gas Requirements

Important: Observe all governing codes and ordinances.

This dryer is supplied/fitted with an electricity supply cord and

plug. It should be connected to electricity supply socket at the

voltage shown on the rating plate. The minimum supply fuse

capacity should be 5A. The dryer must be positioned so that the

plug is accessible. If the fitted plug is not used, the electrical

connection must be carried out by a competent electrician in

accordance with local or national codes.

If the supply cord is damaged, it must be replaced with a

specially terminated cord by an authorized service agent or a

similarly competent person.

Do not use an adapter.

Do not use an extension cord.

If codes permit and an additional earth bond wire is used, it is

recommended that a qualified electrician determine that the earth

bond, path is adequate.

OBSERVE ALL GOVERNING CODES AND ORDINANCES.

Gas supply:

Check that dryer is equipped with the correct burner for the

particular type of gas supply. Burner information will be found on

the model/serial rating plate in the door well of the dryer. If this

information does not agree with the type of gas available, see

your dealer.

Natural Gas:

This dryer is factory adjusted for use with NATURAL GAS (G20),

and no further adjustment should be required at installation.

L.P. Gas:

This dryer is also certified for use with L.P (propane or butane)

gases with appropriate conversion. No attempt shall be made to

convert the appliance from the gas specified on the model/serial

rating plate for use with a different gas without consulting the

serving gas supplier.

Conversion must be done by a competent service technician.

Gas conversion kit, part number 279918, is available for

purchase from your dealer. Full instructions are supplied with

the kit.

WARNING

Electric Shock Hazard

This is a 3-wire appliance which must be earthed.

Do not earth to a gas pipe.

Do not change the power supply cord plug. If it does

not fit the outlet, have a proper outlet installed by a

qualified electrician.

Do not use an extension cord with this dryer.

Failure to follow these instructions could result in

death, fire, or serious injury.

WARNING

Explosion Hazard

Connect this dryer to a regulated gas supply. Supply

pressure must be in accordance with the Technical

Specifications (see last page).

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure

gas pressure is correct.

Failure to do so can result in death, explosion, or fire.

7

Supply line requirements:

Provide a rigid gas supply line to the dryer location. It should be

minimum 12.5 mm (1/2"

) ID. When acceptable to the gas

supplier and local codes, 10 mm (3/8") ID rigid supply line may

be used for lengths under 6.1 m (20'). Pipe-joint compounds

resistant to the action of L.P gas must be used.

Gas connection to the dryer itself should be made by means of a

flexible gas hose suitable for the appliance and gas category in

accordance with national installation regulations. If in doubt,

contact the gas supplier. It should be minimum 10 mm (3/8") ID.

A means of restraint should be used between the appliance and

the wall to prevent straining of the rigid gas supply when the

appliance is moved. An appropriate length of chain and a wall

hook is recommended.

The dryer gas inlet connection is a 10 mm (3/8") NPT thread. An

adapter is supplied for conversion to standard ISO.228-1 thread

10mm (3/8" BSP).

Check for leaks by using an approved noncorrosive leakdetection solution. Bubbles will show a leak. Correct any leak

found. A pressure measurement tapping is provided on the gas

valve within the dryer, accessible after removal of the lower front

panel.

The dryer must be disconnected from the gas supply piping

system during any pressure testing of that system.

Venting Requirements

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

■ The dryer vent must not be connected into any gas vent,

chimney, wall, ceiling, or a concealed space of a building, or

any other vent used for venting.

■ Do not use an exhaust hood with a magnetic latch.

■ Do not install flexible metal vent in enclosed walls, ceilings or

floors.

■ 10 cm (4") heavy metal vent and clamps must be used.

■ Use clamps to seal all joints. Vent must not be connected or

secured with screws or other fastening devices which extend

into the interior of the vent. Do not use duct tape.

IMPORTANT: Observe all governing codes and ordinances.

Use a heavy metal vent. Do not use plastic or metal foil vent.

Rigid metal vent is recommended to prevent crushing and

kinking.

Flexible metal vent must be fully extended and supported when

the dryer is in its final position. Remove excess flexible metal vent

to avoid sagging and kinking that may result in reduced airflow

and poor performance.

An exhaust hood should cap the vent to prevent rodents and

insects from entering the home or business.

Exhaust hood must be at least 30.5 cm (12") from the ground or

any object that may be in the path of the exhaust (such as

flowers, rocks or bushes).

WARNING

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

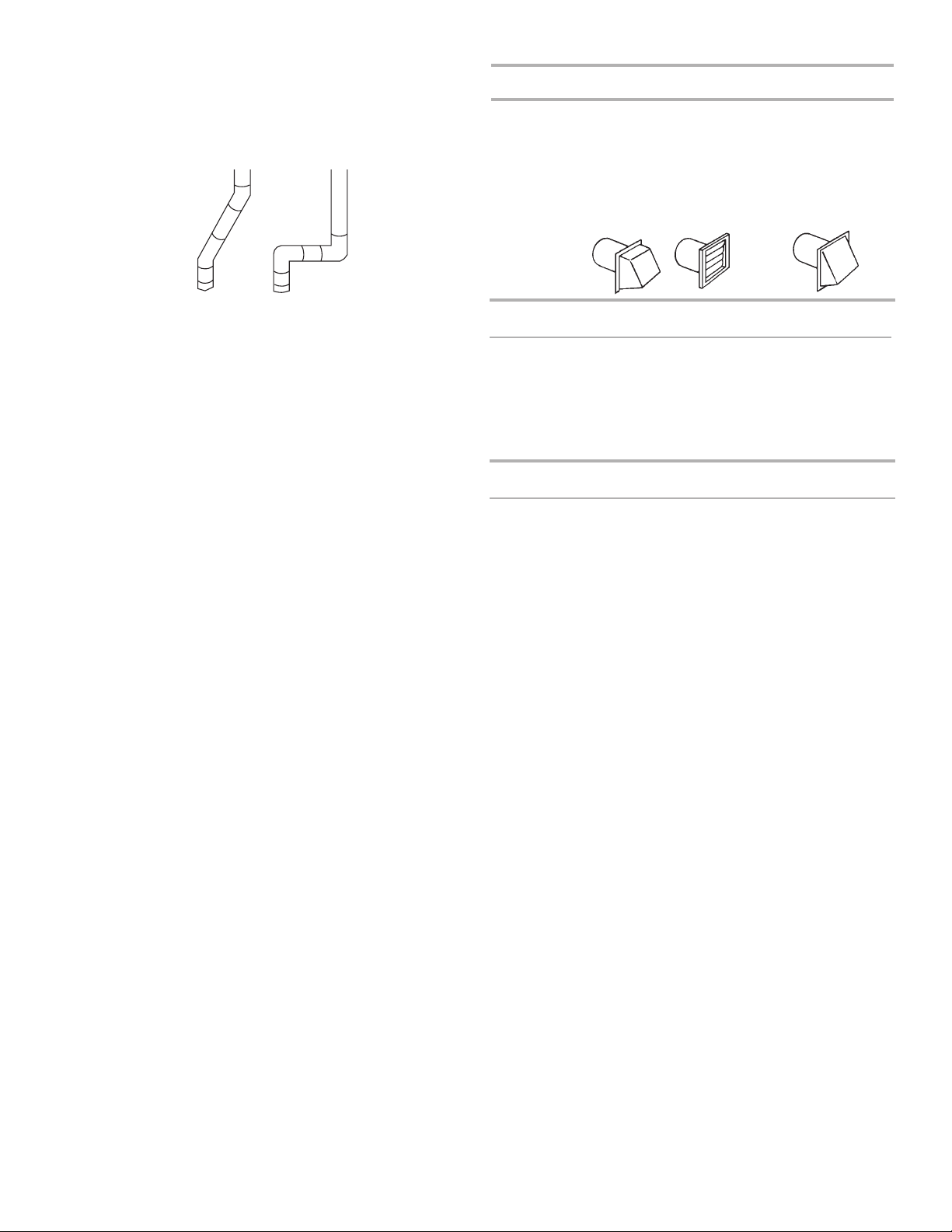

Vent System Length

Maximum length of vent system depends upon the type of vent

used, number of elbows and type of exhaust hood. The maximum

length for both rigid and flexible vent is shown in the chart.

For vent systems not covered by the vent specification chart

(such as multiple unit hookups, plenums, and power-assist fans),

see Whirlpool Service Manual, “Exhausting Whirlpool Dryers,”

Part No. LIT603197, available from your Whirlpool parts

distributor.

If dryer is installed in a confined area, such as a bedroom,

bathroom or closet, provision must be made for enough air for

combustion and ventilation. (Check governing codes and

ordinances.) See “Recessed Area and Closet Installation

Instructions” in the “Location Requirements” section.

A 10cm (4") outlet hood is preferred. However, a 6.4 cm (2¹⁄₂")

outlet exhaust hood may be used. A 6.4 cm (2¹⁄₂") outlet creates

greater back pressure than other hood types. For permanent

installation, a stationary vent system is required.

No. of 90° turns

No. of 90° turns

Flexible Metal Vent

10.2 cm (4") Diameter Exhaust Hoods

Maximum Vent Length

15.8 m (52 ft.)

13.4 m (44 ft.)

11.0 m (36 ft.)

8.2 m (27 ft.)

6.1 m (20 ft.)

9.4 m (31 ft.)

7.9 m (26 ft.)

6.7 m (22 ft.)

6.1 m (20 ft.)

5.5 m (18 ft.)

0

1

2

3

4

0

1

2

3

4

13.4 m (44 ft.)

11.0 m (36 ft.)

8.5 m (28 ft.)

6.4 m (21 ft.)

4.3 m (14 ft.)

7.0 m (23 ft.)

5.5 m (18 ft.)

4.3 m (14 ft.)

3.7 m (12 ft.)

3.0 m (10 ft.)

Box Hood and

Louvered Style

Angled Hood Style

Box Hood and

Louvered Style

Angled Hood Style

Rigid Metal Vent

If using an existing vent system, clean lint from the entire length

of the system and make sure exhaust hood is not plugged with

lint. Replace any plastic or metal foil vent with rigid metal or

flexible metal vent.

Plan installation to use the fewest number of elbows and turns.

Avoid making 90º turns.

Allow as much room as possible when using elbows or making

turns. Bend vent gradually to avoid kinking.

The vent can be routed up, down, left, right, behind the dryer or

straight out the back of the dryer.

Service check: With the dryer running, dynamic pressure in any

exhaust system used must not exceed 15.2 mm (0.6") in water

column, measured with an incline manometer at the point that the

exhaust vent connects to the dryer.

The exhaust outlet is located at the center of the rear of the dryer.

The design of the flue system should ensure that any condensate

formed when operating the appliance is either retained and

subsequently evaporated or discharged. Following these

installation instructions should adequately meet this requirement.

A

B

Exhaust Air Flow

A. Better

B. Good

8

9

INSTALLATION INSTRUCTIONS – GAS DRYER

Install Ventwork

1. Install exhaust hood. Use sealing compound to seal exterior

wall opening around exhaust hood.

2. Connect exhaust vent to hood. (Exhaust vent MUST fit inside

hood.) Secure vent to hood with a 100 mm (4") clamp.

3. Run exhaust vent to dryer location. Use the straightest path

possible. Avoid 90° turns. Use 100 mm (4") clamps to secure

vent peices. Tin snips may be needed to cut vent to required

length.

2. Take two cardboard corners from dryer carton and place

them on floor in back of dryer. Firmly grasp body of dryer

and gently lay it on its back on the cardboard corners.

3. Start to screw legs into holes by hand. Use an adjustable

wrench or 2.5 cm (1") hex-head socket wrench to finish

turning legs until you reach the ridge with the diamond

marking.

4. Stand dryer up on cardboard or hardboard.

diamond

marking

Prepare Dryer

1. Remove tape from dryer cabinet. Open dryer door and

remove tape from dryer drum. (Not all dryer drums are

taped.) Remove drying rack, if included. Turn dryer drum

counterclockwise to make sure all tape was removed. Wipe

drum with damp cloth to remove any dust.

WARNING

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

10

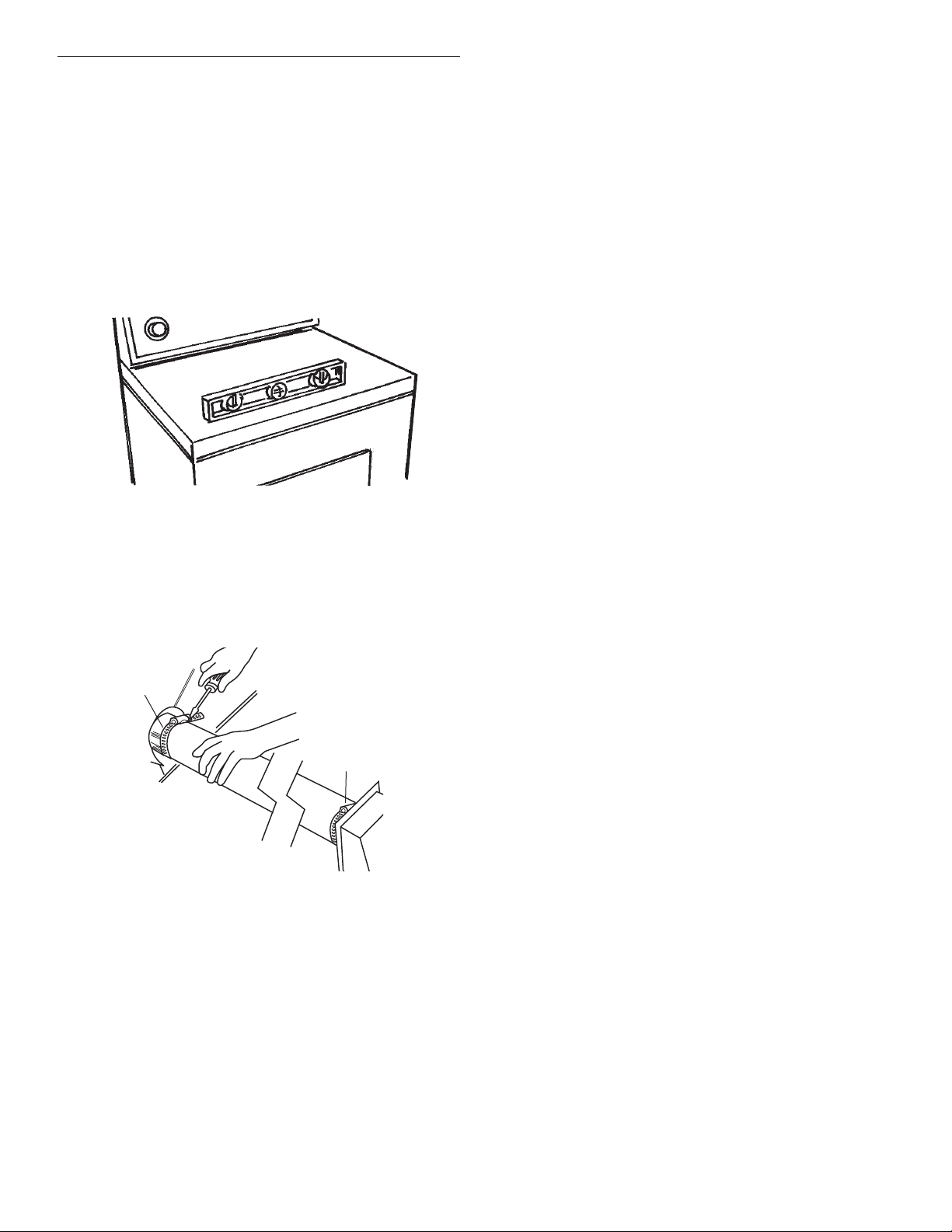

Dryer must be level to reduce noise and assure proper

performance.

Slide dryer onto cardboard or hardboard before moving across

floor to prevent floor damage.

1. Move dryer close to its permanent location. Leave enough

room to connect exhaust vent. Remove cardboard or

hardboard from under dryer.

2. Check levelness of dryer by placing a level on top of dryer,

first side to side, then front to back. If dryer is not level,

adjust dryer legs up or down.

3. If legs are not long enough to level dryer, order Extended

Dryer Feet Kit, Part No. 279810 (sold two legs per kit), from

your dealer.

4. Connect exhaust vent to exhaust outlet in dryer. The exhaust

vent must fit over the dryer exhaust outlet and inside the

exhaust hood vent.

Use 10.2 cm (4") vent clamps to seal all joints and to secure

exhaust vent to dryer exhaust outlet.

5. Move dryer into final position.

Level and Exhaust the Dryer

10.2 cm (4")

clamp

10.2 cm (4")

clamp

Loading...

Loading...