Page 1

Quick Reference

Table of Contents:

Pages

Before you start

Electrical requirements

Product dimensions

Cabinet dimensions

Countertop cutout dimensions

Vent system requirements

Interior-mounted vent motor

Installation steps

Vent system requirements

Exterior-mounted vent motor

Installation steps

Use and Care Information

Accessories

Installation Instructions and

Use and Care Guide

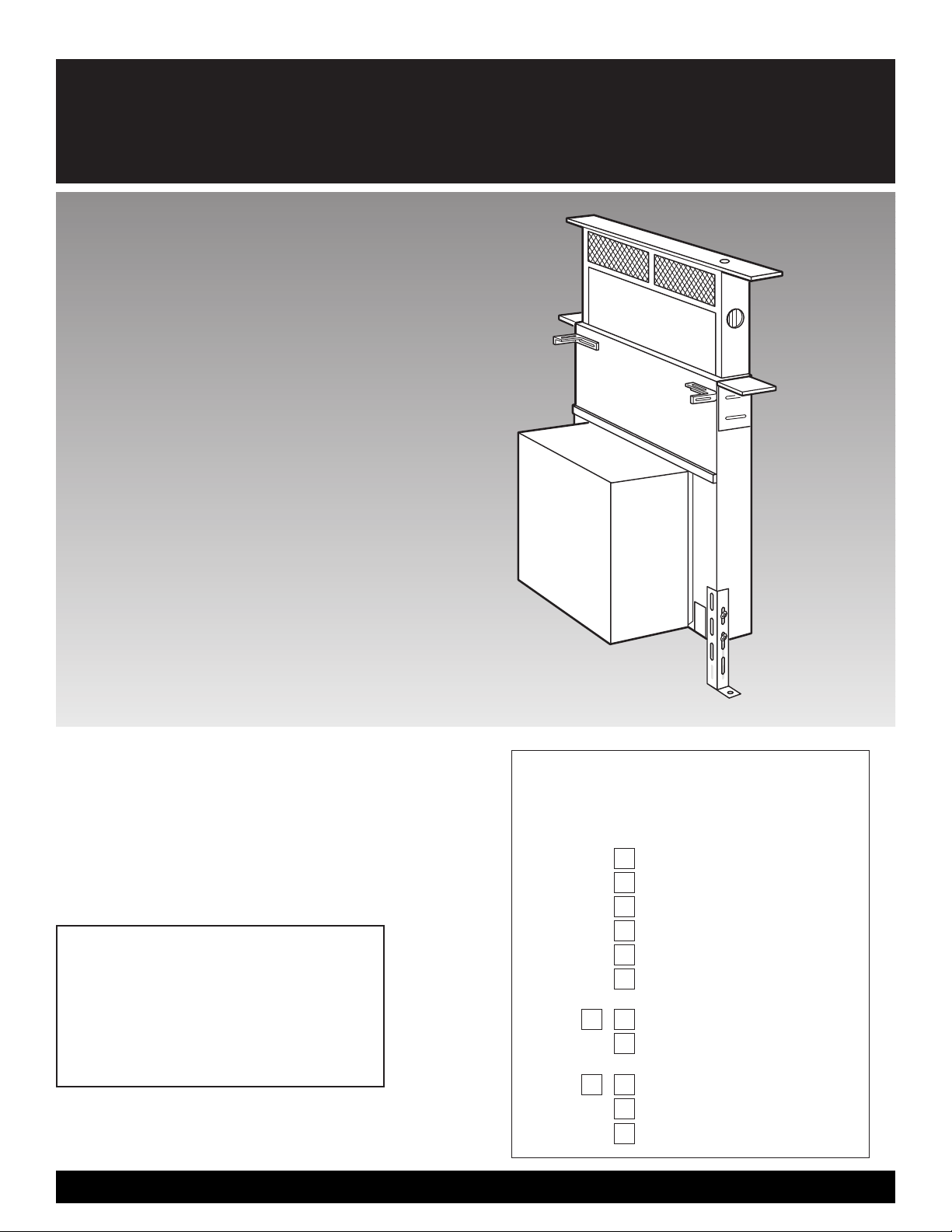

30" (76.2 cm)

36" (91.4 cm)

42" (106.7 cm)

Retractable (Pop-up)

Downdraft Vent Systems

IMPORTANT:

Read and save

these instructions.

IMPORTANT:

Installer: Leave Installation Instructions with

the homeowner.

Homeowner: Keep Installation Instructions for

future reference.

Save Installation Instructions for local electrical

inspector's use.

Part No.

4329225/4360363

2

3

4

4

5

6

7- 9

9

11

12

13

10 -

Page 2

Before you start...

Proper installation is your

responsibility. Make sure you

have everything necessary for

correct installation. It is the

responsibility of the installer to

comply with the installation

clearances specified on the

model/serial rating plate. The

model/serial rating plate is located

on the front of the downdraft vent

above the wiring box cover.

Check location where downdraft

vent will be installed. The location

should be away from strong draft

areas, such as windows, doors

and strong heating vents or fans.

Before making countertop cutout,

check that downdraft vent and

cooktop location will clear cabinet

walls, backsplash, and rear wall

studs inside cabinet.

ALL OPENINGS IN THE WALL OR

FLOOR WHERE RETRACTABLE

DOWNDRAFT VENT IS TO BE

INSTALLED MUST BE SEALED.

Important: Observe all governing

codes and ordinances.

This is the safety alert symbol.

This symbol alerts you to

hazards that can kill or hurt

you and others. All safety messages

will be preceded by the safety alert

symbol and the word “DANGER” or

“WARNING”. These words mean:

You can be killed or seriously injured

if you don’t follow instructions.

DANGER

WARNING

Your safety and the safety of

others is very important.

We have provided many important

safety messages in this manual and

on your appliance. Always read and

obey all safety messages.

All safety messages will identify the

hazard, tell you how to reduce the

chance of injury, and tell you what can

happen if the instructions are not

followed.

You will be killed or seriously injured

if you don’t follow instructions.

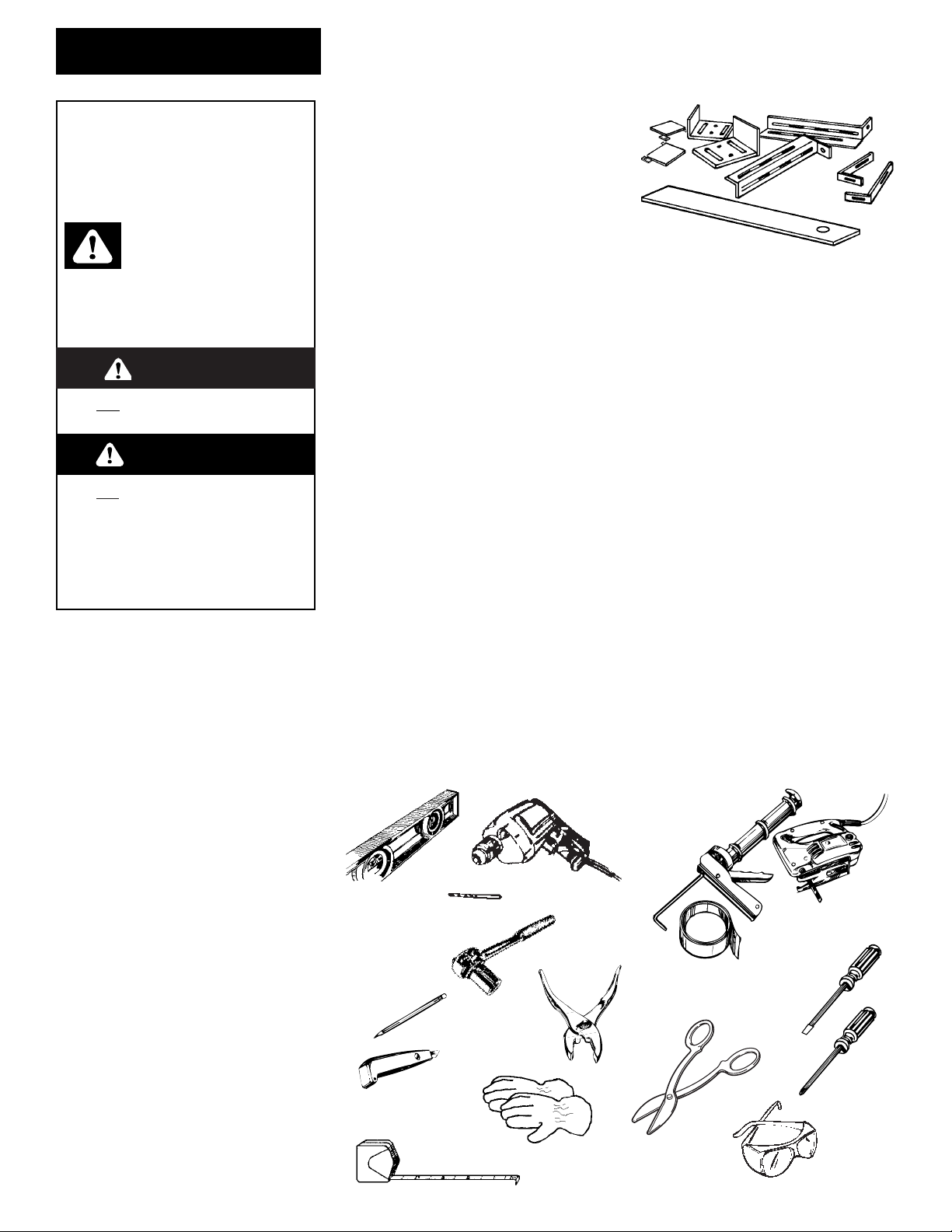

Parts supplied

for installation:

Parts needed

for installation:

Tools needed for installation:

Phillips

screwdriver

flat-blade

screwdriver

caulking gun and

weatherproof

caulking

compound

duct tape

metal

snips

pliers

pencil

saber or

keyhole saw

drill

1/8" drill bit

level

wire stripper

or utility knife

2

Electrical ground is required. See

“Electrical requirements,” page 3.

When installing downdraft vent,

the cabinet drawer will need to be

removed and the drawer front

installed permanently to cabinet.

Note: Downdraft vent is installed

directly behind the cooktop. Install

downdraft vent first.

Downdraft vent is not approved

for use in mobile homes.

Cabinet construction: Downdraft

vent is designed for use in a

cabinet with a depth of 24"

(61 cm). Some installations

require a countertop deeper than

25" (63.5 cm). See chart on page

5. The maximum depth of the

overhead cabinet is 13" (33 cm).

Overhead cabinets installed at

either side of the downdraft vent

must be 18" (45.7 cm) above the

cooking surface.

See cooktop Installation

Instructions before making any

cutouts and for the minimum

distance between the front edge

of the countertop and front edge

of cooktop. The minimum

horizontal distance between the

overhead cabinets is the same as

the width of the installed

downdraft vent.

When installing a 36" (91.4 cm) or

42" (106.7 cm) retractable

downdraft vent with “Create-ACooktop” modules, the optional

support must be installed on the

front of the downdraft vent. See

installation steps for details.

3/8" (9.5 mm)

nut driver or

ratchet

gloves

measuring tape

safety glasses

• 1 top trim

• 2 end caps

• 2 lower support legs

• 2 overcounter support brackets

• 2 undercounter mounting brackets

• 1 bag of fasteners

• 1 metal cover

• 1 backdraft damper

• literature package

• optional support and two screws

(36" (91.4 cm) or 42" (106.7 cm)

models only)

• 2 U.L.- or C.S.A.-listed 1/2" (12.7 mm)

conduit connectors (3 are required if

the exterior-mounted vent motor is

used.)

• 1 wall cap for interior-mounted motor

• vent system

• power supply cable

• wiring cable for optional remote blower

kit.

Page 3

3

WARNING — TO REDUCE THE

RISK OF FIRE, ELECTRIC SHOCK,

OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

Installation work and electrical

wiring must be done by qualified

person(s) in accordance with all

applicable Codes and Standards,

including Fire Rated

Construction. The combustion

airflow needed for safe

operation of fuel-burning

equipment may be affected by

this unit’s operation. Follow the

heating equipment

manufacturer’s guideline and

safety standards such as those

published by the National Fire

Protection Association

(NFPA),and the American Society

of Heating Refrigeration and Air

Conditioning Engineers

(ASHRAE), and the local code

authorities.

When cutting or drilling into wall

or ceiling, do not damage

electrical wiring and other

hidden utilities.

Ducted fans must always be

vented to the outdoors.

WARNING — To reduce the risk

of fire, use only metal ductwork.

Electrical requirements

Important: Observe all governing

codes and ordinances.

It is the customer’s responsibility:

• To contact a qualified electrical

installer.

• To assure that the electrical

installation is adequate and in

conformance with National

Electrical Code, ANSI/NFPA 70

— latest edition*, or CSA

Standards C22.1-94, Canadian

Electrical Code, Part 1 and

C22.2 No. 0-M91 - latest

edition** and all local codes

and ordinances.

If codes permit and a separate

ground wire is used, it is

recommended that a qualified

electrician determine that the

ground path is adequate.

Do not ground to a gas pipe.

Check with a qualified electrician

if you are not sure downdraft

vent is properly grounded.

Do not have a fuse in the neutral

or ground circuit.

IMPORTANT:

Save Installation instructions for

electrical inspector’s use.

E.A U.L.- or C.S.A.-listed, 1/2"

(12.7 mm) conduit connector

must be provided at each end of

the power supply cable (at the

downdraft vent and at the

junction box).

A.A 120-volt, 60-Hz, AC-only

electrical supply is required on a

separate 15-ampere circuit, fused

on both sides of the line. A timedelay fuse or circuit breaker is

recommended. The fuse must be

sized per local codes in

accordance with the electrical

rating of the downdraft vent as

specified on the model/serial

rating plate located on the front

of the downdraft vent above the

wiring box cover.

B.THE DOWNDRAFT VENT

MUST BE CONNECTED WITH

COPPER WIRE ONLY.

C.Wire sizes and connections

must conform to the

requirements of the National

Electrical Code, ANSI/NFPA 70 —

latest edition*, or CSA Standards

C22.1-94, Canadian Electrical

Code, Part 1 and C22.2 No. 0-M91

- latest edition** and all local

codes and ordinances.

D.This downdraft vent should

be connected directly to the fused

disconnect (or circuit breaker)

through flexible, armored or nonmetallic sheathed, copper cable.

Allow some slack in the cable so

the downdraft vent can be moved

if servicing is ever necessary.

F. A wiring diagram is located

on the downdraft vent base

above the wiring box cover.

* National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

** Canadian Standard Association

178 Rexdale Boulevard

Etobicoke (Toronto), Ontario M9W 1R3

Page 4

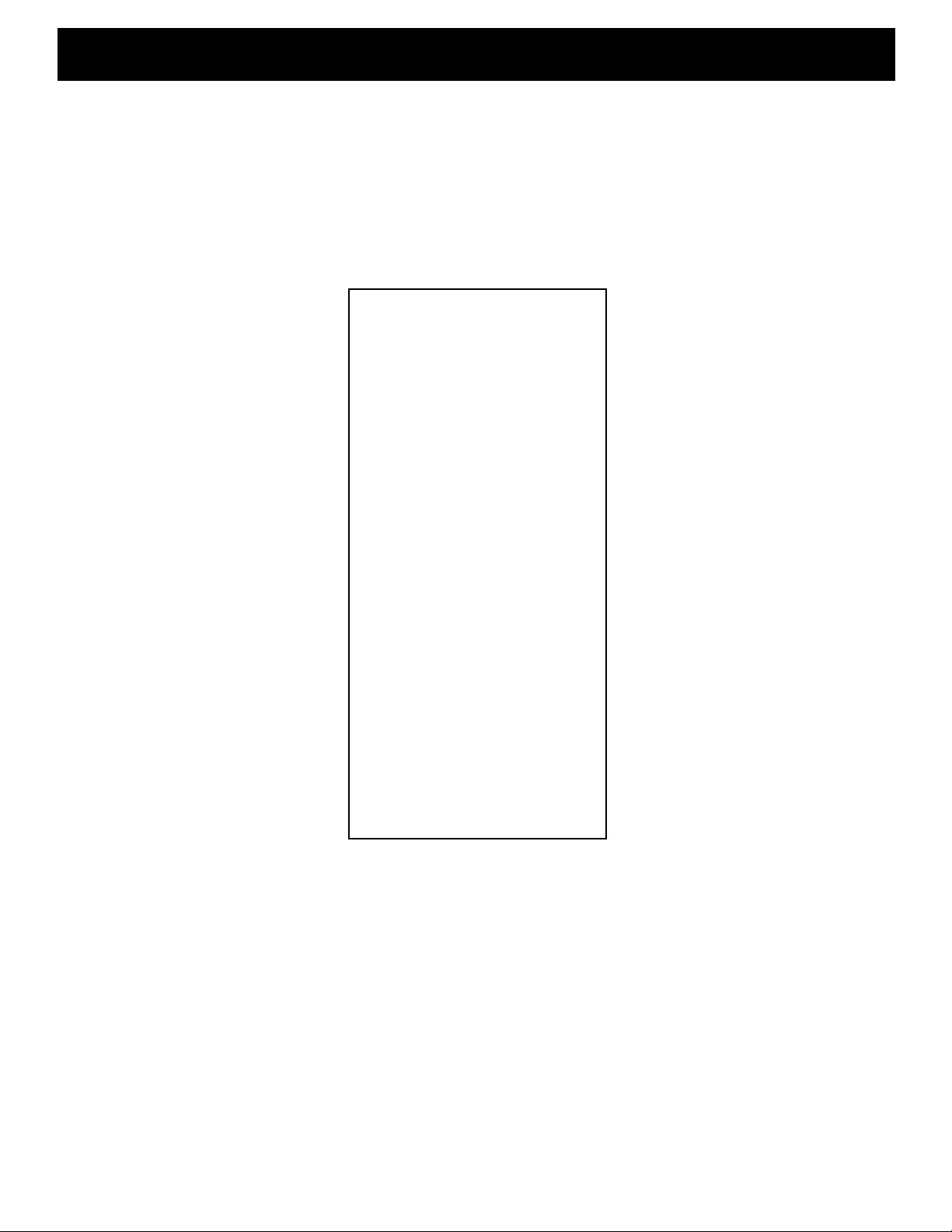

4

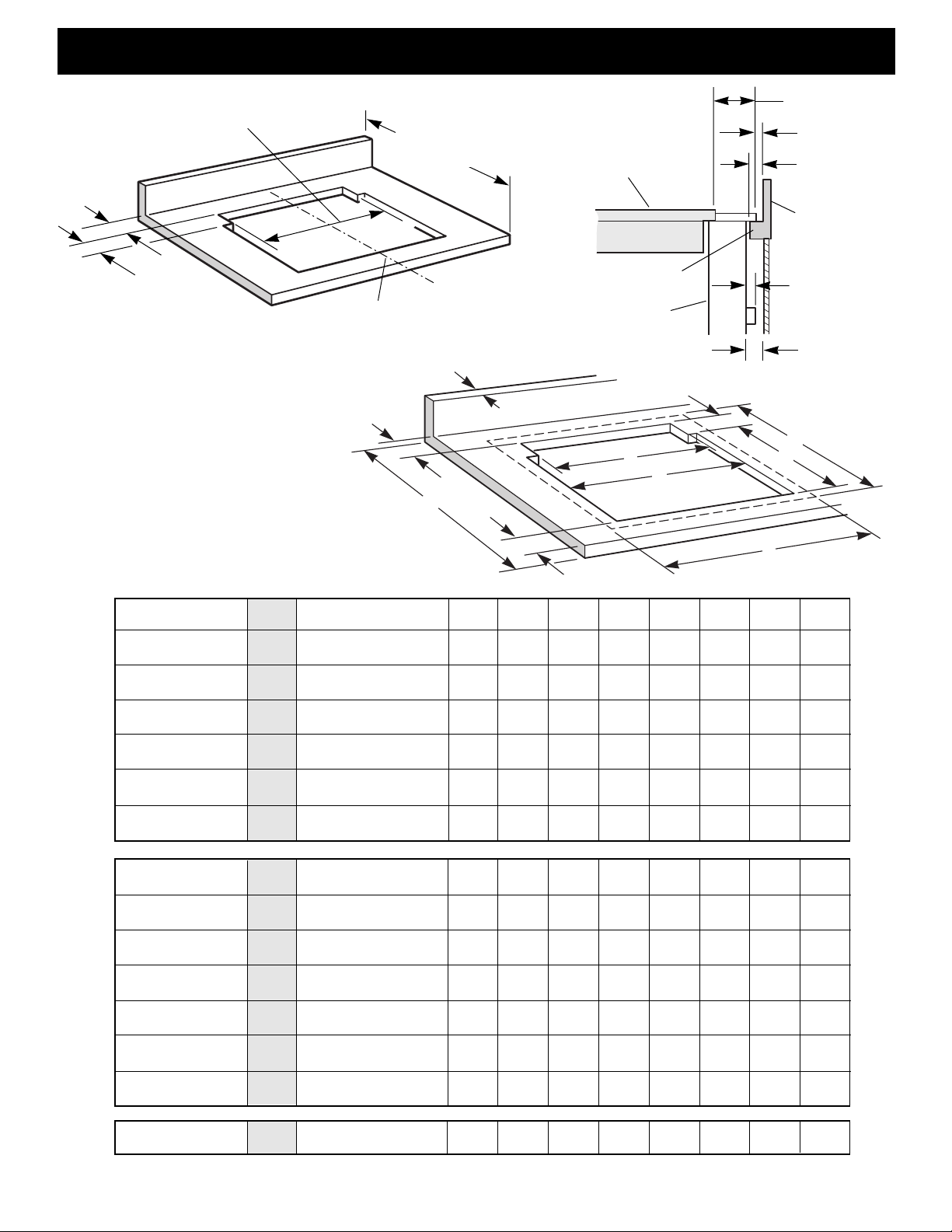

Cabinet dimensions

Product dimensions

top trim widths

30" vent (76.2 cm)

36" vent (91.4 cm)

42" vent (106.7 cm)

3/8" (9.5 mm)

8-1/4" (21 cm)

retractable

vent height

1-7/8"

(4.8 cm)

26-1/8"

(66.4 cm)

2-1/8”

(54 cm)

INTERNAL

BLOWER

MOTOR

EXTERIOR-MOUNTED

BLOWER MOTOR

5/8"

(15.9 mm)

4"

(10.2 cm)

8"

(20.3 cm)

9" (22.9 cm)

Diameter

16"

(40.6 cm)

8"

(20,3 cm)

16"

(40.6 cm)

5/8"

(15.9 mm)

9-3/8"

(23.8 cm)

16"

(40.6 cm)

16"

(40.6 cm)

4-1/8"+A

(10.5 cm)

17-9/16"

(44.6 cm)

17-3/16"

(43.7 cm)

A = 1/2" (12.7 mm)

min.

23-9/16"

(59.8 cm)

3/8"

(9.5 mm)

centerline of

cooktop cutout

3-1/4"x 10"

(8.3 cm x 25.4 cm)

See cooktop manufacturer’s

instructions for cooktop cutout

depth and width.

Use dimensions for vent system

cutout location that applies to

your installation.

Vent system cutout dimensions for internal

blower models only.

Exterior mounted blower systems connect

with 9" (22.9 cm) round vent. The cutout

locations for this vent system will depend

upon your specific installation.

Locate power supply

junction box at lower

right hand rear corner of

cabinet.

all cutouts are for

3-1/4" x 10"

(8.3 cm x 25.4 cm)

vent system

27" (68.6 cm) for 30" (76.2 cm) vent

33" (83.8 cm) for 36" (91.4 cm) vent

39" (99.1 cm) for 42" (106.7 cm) vent

Page 5

5

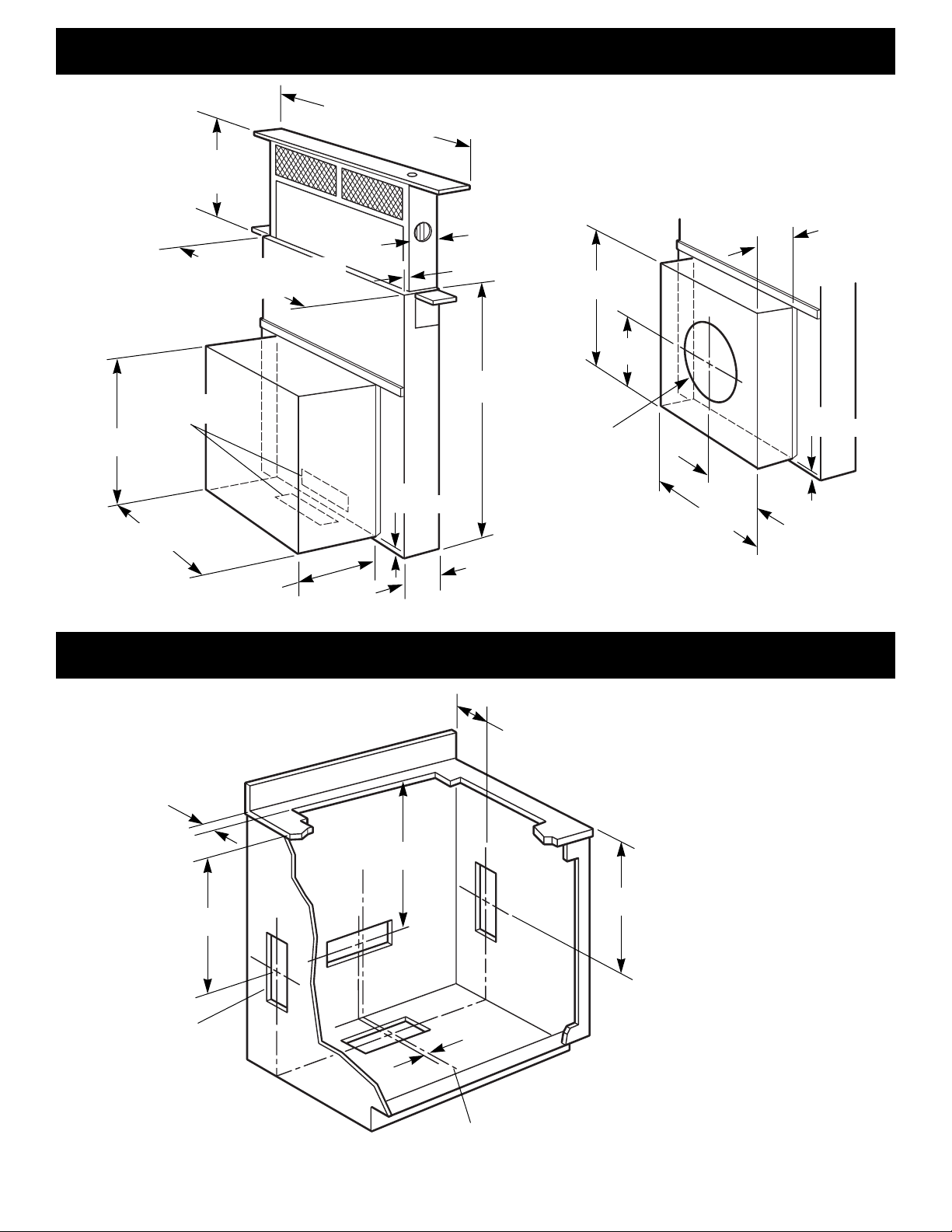

Countertop cutout dimensions

27-1/2" (69.9 cm) for 30" (76.2 cm) vent

33-1/2" (85.1 cm) for 36" (91.4 cm) vent

39-1/2" (100.3 cm) for 42" (106.7 cm) vent

See cutout

dimensions

chart below.

A = 1/2"

(12.7 mm)

min.

centerline of

cooktop cutout

Some models require a

countertop deeper than

25" (63.5 cm); see cutout

dimensions chart below.

1/4"

(6.4 mm)

1/4"

(6.4 mm)

1-7/8"

(4.8 cm)

cooktop

backsplash

downdraft

vent

countertop

1/2"

(12.7 mm)

min.

1/2" (12.7 mm)

minimum

* Installation with vent system requires countertop and base cabinet deeper than standard 25" (63.5 cm) deep countertop and 24" (61.0 cm) deep base cabinet.

It is recommended that the cooktop

and vent cutouts be drawn on the

countertop before making any

cutouts to avoid mistakes.

See Cooktop Installation Instructions

for complete cutout dimensions,

location dimensions and installation

details.

IMPORTANT: Countertops with a

bullnosed front edge are not

recommended for these installations.

Cooktop Installed with

Cooktop Models Size Vent System Models A B C D E F G H

KGCT305G KGCS105G 30" KIRD801HSS KIRD802HSS 29" 27-1/2" 19-5/8" 2-1/8" 1-3/4" 31-3/8" 23" 25"

(76.2 cm) KIRD801XSS KIRD802XSS (73.7 cm) (69.9 cm) (49.8 cm) (5.4 cm) (4.4 cm) (79.7 cm) (58.4 cm) (63.5 cm)

KECC501G

*

KECC502G*30" KIRD801HSS KIRD802HSS 29-1/2" 27-1/2" 20-1/2" 2-1/8" 2" 31-1/2" 23-1/4" 25-7/8"

KECC507G

*

KECC508G*(76.2 cm) KIRD801XSS KIRD802XSS (74.9 cm) (69.9 cm) (52.1 cm) (5.4 cm) (5.1 cm) (80.0 cm) (59.1 cm) (65.7 cm)

KECS100G

*

30" KIRD801HSS KIRD802HSS 28-7/8" 27-1/2" 19" 2-1/2" 3-3/8" 31-1/2" 23" 25-5/8"

(76.2 cm) KIRD801XSS KIRD802XSS (73.3 cm) (69.9 cm) (48.3 cm) (6.4 cm) (8.6 cm) (80.0 cm) (58.4 cm) (65.1 cm)

SCS3004G SCS3014G, 30" GZ7930XGS 29" 27-1/2" 19-5/8" 2-1/8" 1-3/4" 31-3/8" 23" 25"

GLT3014G (76.2 cm) GZ7930XHS (73.7 cm) (69.9 cm) (49.8 cm) (5.4 cm) (4.4 cm) (79.7 cm) (58.4 cm) (63.5 cm)

RCC3024G

*

GJC3034G*30" GZ7930XGS 29-1/2" 27-1/2" 20-1/2" 2" 2" 30" 23" 25-3/4"

(76.2 cm) GZ7930XHS (74.9 cm) (69.9 cm) (52.1 cm) (5.1 cm) (5.1 cm) (76.2 cm) (58.4 cm) (65.4 cm)

RCS3004G

*

RCS3014G*30" GZ7930XGS 28-7/8" 27-1/2" 19" 2-1/2" 3" 31-1/2" 23" 25-1/2"

YRCS3014G

*

(76.2 cm) GZ7930XHS (73.3 cm) (69.9 cm) (48.3 cm) (6.4 cm) (7.6 cm) (80.0 cm) (58.4 cm) (64.8 cm)

KGCT365G KECT366G 36" KIRD861HSS KIRD862HSS 35-1/4" 33-1/2 19-5/8" 2-1/8" 1-3/4" 37-1/2" 23" 25"

KGCS166G (91.4 cm) KIRD861XSS KIRD862XSS (89.5 cm) (85.9 cm) (49.8 cm) (5.4 cm) (4.4 cm) (95.3 cm) (58.4 cm) (63.5 cm)

KECC562G

*

KECC567G*36" KIRD861HSS KIRD862HSS 35-1/2" 33-1/2" 20-1/2" 2-1/8" 2" 37-1/2" 23-1/4" 26-7/8"

KECC568G

*

(91.4 cm) KIRD861XSS KIRD862XSS (90.2 cm) (85.9 cm) (52.1 cm) (5.4 cm) (5.1 cm) (95.3 cm) (59.1 cm) (68.3 cm)

KECS161G

*

36" KIRD861HSS KIRD862HSS 35" 33-1/2" 19" 2-1/2" 3-3/8" 37-5/8" 23" 25-5/8"

(91.4 cm) KIRD861XSS KIRD862XSS (88.9 cm) (85.9 cm) (48.3 cm) (6.4 cm) (8.6 cm) (95.6 cm) (58.4 cm) (65.1 cm)

SCS3614G 36" GZ7936XGS 35-1/4" 33-1/2" 19-5/8" 2-1/8" 1-3/4" 37-1/2" 23" 25"

(91.4 cm) GZ7936XHS (89.5 cm) (85.9 cm) (49.8 cm) (5.4 cm) (4.4 cm) (95.3 cm) (58.4 cm) (63.5 cm)

GLT3614XG 36" GZ7936XGS 35-1/4" 33-1/2" 19-5/8" 2-1/8" 1-3/4" 36-5/8" 23" 25"

(91.4 cm) GZ7936XHS (89.5 cm) (85.9 cm) (49.8 cm) (5.4 cm) (4.4 cm) (93.0 cm) (58.4 cm) (63.5 cm)

GJC3634G

*

36" GZ7936XGS 35-1/2" 33-1/2" 20-1/2" 2" 2" 36" 23" 25-3/4"

(91.4 cm) GZ7936XHS (90.2 cm) (85.9 cm) (52.1 cm) (5.1 cm) (5.1 cm) (91.4 cm) (58.4 cm) (65.4 cm)

RCS3614G

*

36" GZ7936XGS 35" 33-1/2" 19" 2-1/2" 3" 37-5/8" 23" 25-5/8"

(91.4 cm) GZ7936XHS (88.9 cm) (85.9 cm) (48.3 cm) (6.4 cm) (7.6 cm) (95.6 cm) (58.4 cm) (65.1 cm)

KGCS127G 42" KIRD821HSS 42-3/4" 39-1/8" 19-5/8" 2-1/8" 1-3/4" 44-1/2" 23" 25”

(106.7 cm) KIRD822HSS (108.6 cm) (99.4 cm) (49.8 cm) (5.4 cm) (4.4 cm) (113.0 cm) (58.4 cm) (63.5 cm)

3/4" (19.1 mm) max.

backsplash depth

1/2" (12.7 mm)

minimum to

splashguard or

rear wall

E

H

D

C

G

F

Overall width of cooktop

and downdraft vent system

Overall depth of cooktop

and downdraft vent

system

B

A

Required min.

countertop depth

Page 6

6

Vent system requirements

Venting system must terminate

to the outside.

Do not terminate the vent system

in an attic or other enclosed area.

Do not use 4"(10.2 cm) laundrytype wall caps

Do not use plastic or metal foil

vent.

Vent work needed for installation

is not supplied.

Wall cap is Not provided with

interior-mounted motor.

Determine which venting method

to use. Vent system can extend

through either the wall or roof.

The length of vent system and

number of elbows should be kept

to a minimum to provide efficient

performance.

The size of the vent should be

uniform.

Do Not install two elbows

together.

Use duct tape to seal all joints in

the vent system.

Use caulking tape to seal the

exterior wall or floor opening

around cap.

Do Not cut joist or stud. If vent

cutout falls over a joist or stud, a

supporting frame must be

constructed.

Flexible metal vent is Not

recommended. If it is used,

calculate each foot of flexible vent

as two feet of rigid metal vent.

Flexible elbows count twice as

much as standard elbows.

NOTE: Make sure there is proper

clearance within the wall or floor

before making exhaust vent

cutouts.

Recommended vent system

length

For either interior-mounted or

exterior-mounted blower

installations, vent system length

should not exceed the maximum

lengths listed in the “Maximum

length of vent system” chart. (See

this page for Interior-mounted

vent motor; page 9 for exteriormounted vent motor.)

Interior-mounted vent motor

Installation requirements

Island location

Built-in cabinet locations

down vent

down vent

rear vent

left vent

right vent

a

a

a

a

a

a

a

aa

a

aa

aaa

a

a

a

a

a

a

a

aa

a

a

aa

a

a

a

a

a

aa

aa

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

aa

aaa

a

a

a

a

a

a

a

aa

a

a

aa

a

a

a

a

a

aa

a

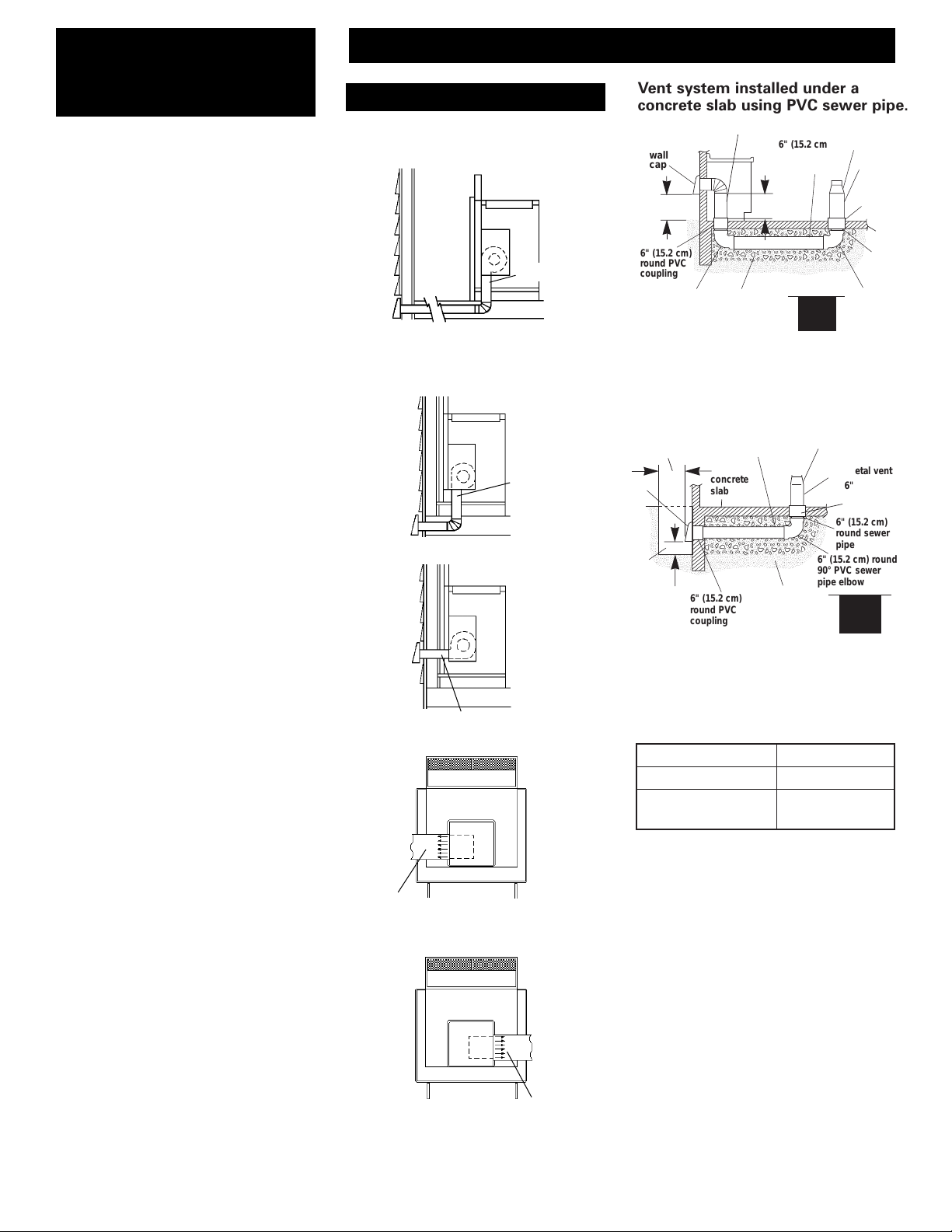

Vent system installed under a

concrete slab using PVC sewer pipe.

wall

cap

6" (15.2 cm)

round PVC

coupling

6" (15.2 cm)

round PVC

sewer pipe

6" (15.2 cm) round metal vent

Tightly pack

gravel or sand

completely

around pipe.

transition

6" (15.2 cm)

round metal

vent

6" (15.2 cm)

round PVC

coupling

concrete

slab

6" (15.2 cm)

round PVC

sewer pipe

6" (15.2 cm)

round 90°

PVC sewer

pipe elbow

6" (15.2 cm)

round 90°

PVC sewer

pipe elbow

16" (40.6 cm)

maximum

12" (30.5 cm)

minimum

SBCCI

a

a

a

a

a

a

a

aa

a

aa

aa

a

a

a

a

a

a

a

a

aa

a

a

aa

a

a

a

a

a

aa

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

aa

aaa

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

aa

a

wall

cap

window

well

6" (15.2 cm)

min.

Tightly pack

gravel or sand

completely

around pipe.

transition

6" (15.2 cm)

round metal vent

6" (15.2 cm)

round PVC

coupling

6" (15.2 cm)

round sewer

pipe

6" (15.2 cm) round

90° PVC sewer

pipe elbow

concrete

slab

6" (15.2 cm)

round PVC

coupling

12" (30.5 cm)

minimum

6" (15.2 cm) round

PVC sewer pipe

Optional vent system installed under

a concrete slab into a window well.

Do not vent a gas cooktop into

a window well.

SBCCI

Seal the space between the outside

of wall cap inlet inside of PVC

coupling with caulking metal.

Maximum length of vent

system

For best performance, use no more

than three 90° elbows. If more than

one elbow is used, make sure that

there is a minimum of 24" (61 cm) of

straight vent between any two

elbows. Do Not install two elbows

together. It is recommended that

you use round vent instead of

rectangular vent, especially if

elbows are required. If rectangular

vent is required, it should be

transitioned to 6" (15.2 cm) round

vent as soon as possible.

Determining the length of

system you need:

To calculate the length of system

you need, add the equivalent feet

for each vent piece that will be

needed. See example for 6"

(15.2 cm) round vent system.

Vent Length

6" (15.2 cm) round 35 feet (8.9 m)

3-1/4" x 10" 35 feet (8.9 m)

(8.3 cm x 25.4 cm)

Page 7

7

Excessive Weight Hazard

Use two or more people to move

and install downdraft vent.

Failure to do so can result in back

or other injury.

WARNING

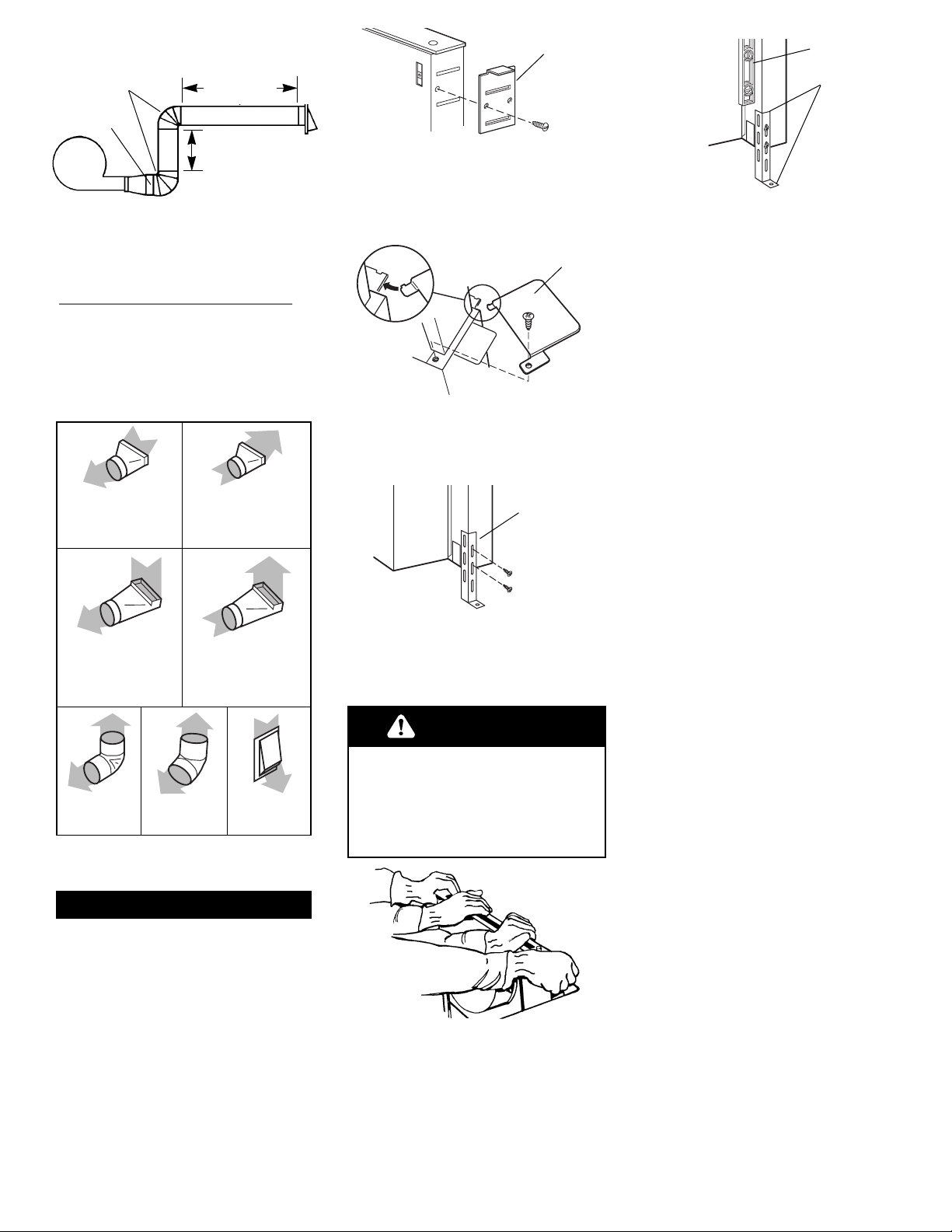

6" (15.2 cm) round

vent system

6 ft. (1.8 m)

2 ft. (0.6 m)

90° elbows

transition

Maximum length = 35 ft. (8.9 m)

1 - wall cap = 0 ft. (0 m)

8 ft. (2.4 m) straight = 8 ft. (2.4 m)

2 - 90° elbows = 10 ft. (3 m)

Transition = 4.5 ft. (1.4 m)

Length of 6"

(15.2 cm) system = 22.5 ft. (6.9 m)

Recommended standard

fittings

3-1/4" x 10"

(8.3 cm x 25.4 cm)

to 6" (15.2 cm)

= 4.5 ft. (1.4 m)

90° elbow =

5 ft. (1.5 m)

45° elbow =

2.3 ft. (0.8 m)

6" wall cap =

0 ft. (0 m)

6" (15.2 cm) to

3-1/4" x 10"

(8.3 cm x 25.4 cm)

= 1 ft. (0.3 m)

3-1/4" x 10"

(8.3 cm x 25.4 cm)

to 6" (15.2 cm)

90° elbow =

5 ft. (1.5 m)

6" (15.2 cm) to

3-1/4" x 10"

(8.3 cm x 25.4 cm)

90° elbow =

5 ft. (1.5 m)

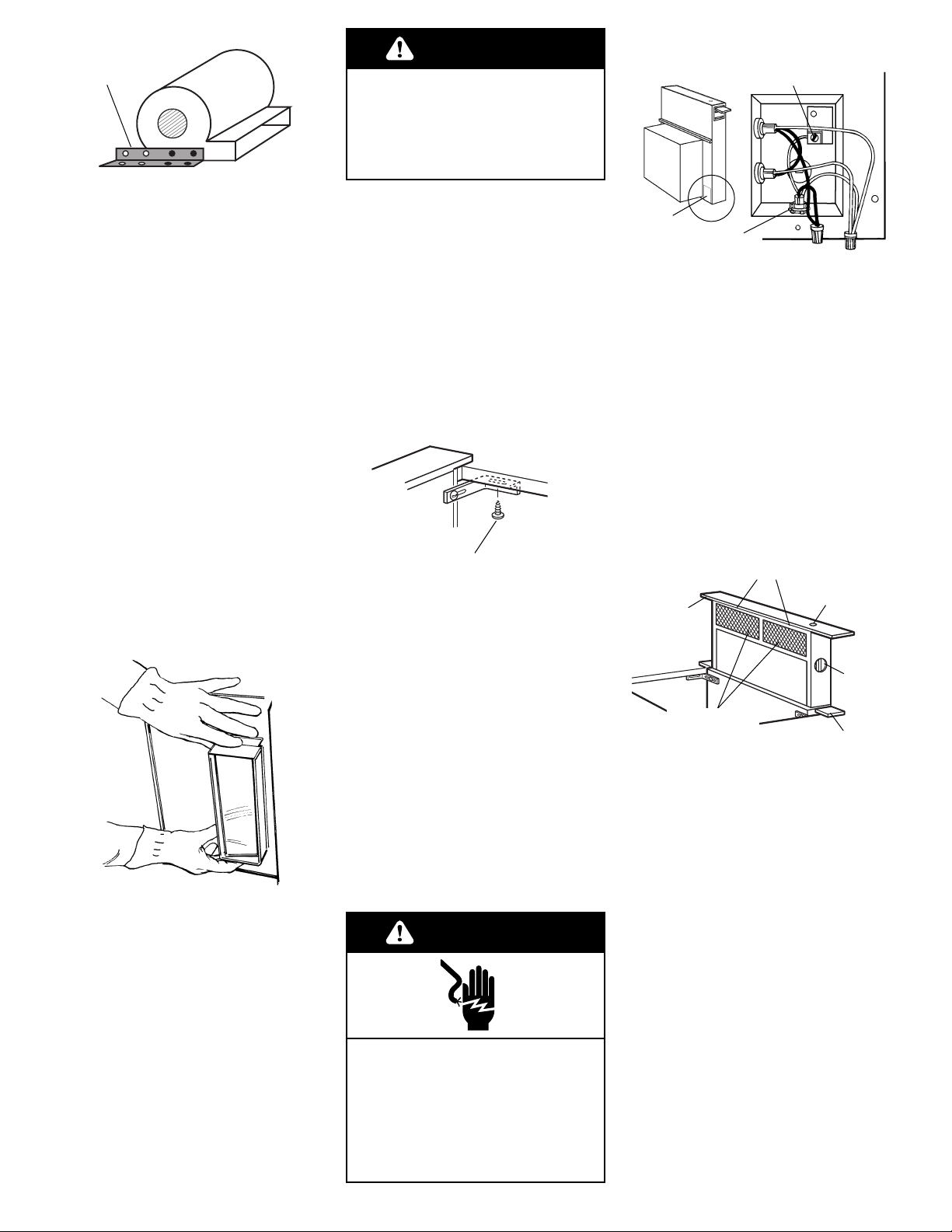

1. Put on gloves and safety

glasses. Place cardboard or

another form of protection on top

of a flat surface where you can

easily assemble the downdraft

vent system. Remove parts

packages, downdraft vent and

blower box from carton. Remove

all shipping materials, tape and

protective film from downdraft

vent and blower box.

3. Attach the left side and right

side end caps to the downdraft.

Use 1 screw with each end cap.

2. Attach the left side and

right side overcounter support

brackets to the downdraft. Use 1

screw with each bracket.

5. Carefully insert downdraft

vent into countertop cutout. Two

people are recommended to

support the weight of the

downdraft vent during lifting.

Check that downdraft vent is

parallel to side of cutout and that

mounting brackets overlap

countertop.

6. Move support legs down

against cabinet floor. Place a level

against front of downdraft vent

base and adjust until downdraft

vent is level vertically. Use a

pencil to mark the top of each leg

on downdraft vent. Then mark

location of support leg mounting

holes on cabinet floor. Remove

downdraft vent from cutout. Drill

starter holes at each mounting

screw location on cabinet floor.

Align top of legs with pencil

marks on face of downdraft vent.

Tighten screws in legs.

7. Determine which direction

(down, rear, left, or right) vent

will need to run from blower vent

when installed in cabinet.

Down venting:

Downdraft vent is shipped with

blower in down venting position

so no modification is required.

Go to Step 8.

Left or right venting:

a. Remove 4 hex nuts that attach

blower box to downdraft vent

base. Remove blower box.

b. Rotate blower box 90° to left or

right so that vent blower is

repositioned in the direction

needed.

c. Reattach blower box to

downdraft vent base with 4 hex

nuts.

Rear venting:

a. Remove 4 hex nuts that attach

blower box to downdraft vent

base. Remove blower box.

b. Note how wiring cable is

installed under plastic clips inside

vent base. Then carefully remove

wiring cable from plastic clips.

Disconnect blower wiring cable.

c. Remove 6 Phillips-head screws

attaching blower to blower box.

Remove blower.

Installation steps

over counter

support arm

4. Attach support legs to side

of downdraft vent with 2 screws

in each leg. Do not tighten

screws.

support leg

mark

level

end cap

Page 8

8

d. Remove screws attaching

brackets to each side of blower.

Reposition brackets on blower as

shown. Then reinstall screws.

e. Reinstall blower in blower box

with mouth of blower pointing out

open side of blower box. Secure

blower to blower box with 6

Phillips-head screws.

NOTE: Square metal frame

attached to mouth of blower must

be installed for proper operation.

f. Attach metal cover from parts

bag over down-venting knockout

in blower box. Remove rear

knockout cover on back of vent

base.

g. Reconnect blower wiring cable.

Secure wiring cable in 2 black

plastic clips inside vent base.The

wiring cable must be properly

secured in the 2 clips (see step b.)

Reattach blower box to downdraft

vent base with 4 hex nuts.

bracket for

rear venting

8. Attach backdraft damper

over blower box knockout with 2

Phillips-head screws.

9. Remove the 2 Phillips-head

screws attaching the wiring box

cover. Determine which direction

(rear or down) electrical connection

will need to run from appliance

wiring box. Knock out rear or lower

wiring opening in wiring box.

Excessive Weight Hazard

Use two or more people to move

and install downdraft vent.

Failure to do so can result in back

or other injury.

WARNING

10. Insert downdraft vent

into countertop cutout. Two

people are recommended to

support the weight of the

downdraft vent during lifting.

Position downdraft vent so it is

centered in cutout and parallel to

edge of cutout. Check that

downdraft vent is level vertically.

Then fasten lower support legs to

cabinet floor with screws.

11. Attach one undercounter

bracket on front upper right

corner of downdraft vent with slot

over vent mounting hole and

flange against countertop. Attach

other bracket to left side of

downdraft vent. Carefully drill

starter holes through

undercounter mounting brackets

into underside of countertop.

Insert appropriate length screws

into holes and tighten brackets to

countertop.

When attaching undercounter bracket

to underside of countertop, make

sure that the screw length will not go

through countertop when tightened.

Electrical Shock Hazard

Disconnect power before

making electrical connections.

Connect ground wire to green

ground screw in terminal box.

Failure to do so can result in

death or electrical shock.

WARNING

12. Remove required

knockout and install conduit

connector. Feed the power supply

cable through the conduit

connector and into the wiring box.

Connect the white wires together

with a twist-on wire connector.

Connect the black wires together

with a twist-on wire connector.

Attach the green (or green and

yellow) ground wire to eyelet with

green ground screw. Tighten the

conduit connector clamp screws.

Reattach the wiring box cover.

wiring

box

green

ground

screw

conduit

connector

13. Turn power supply on.

Push and hold for a few seconds

the button on the top of the

downdraft vent. Retractable section

of downdraft vent will rise and

blower will start. Position the top

trim over the retractable section

and snap trim into place.

14. Turn the control knob on

side of vent to check the operation

and speed of blower.

If blower does not operate:

• Check that filter or filters are

pressed in as far as they will go.

• Check that circuit breaker is not

tripped or house fuse blown.

• Disconnect power source and

check that wire connections have

been made correctly.

ON/OFF

button

blower

control

knob

end cap

top trim

filter or filters

depending on

model

microswitches behind filters.

Page 9

9

15. Connect vent system to

blower. Vent system must end with

a wall or roof cap. Use duct tape

to seal all joints.

16. Install cooktop according

to manufacturer’s instructions.

Check that rear of cooktop overlaps

edge of retractable downdraft vent

by 3/8" (9.5 mm).

To get the most efficient

use from your new

retractable downdraft vent,

read the Use and Care

Information section on

page 12.

Keep Installation

Instructions

and Use and Care

Information close by for

easy reference.

Island location

Built-in cabinet location

Built-in cabinet location

Roof venting

KIRD and YKIRD

MODELS ONLY

NOTE: Exterior-mounted vent

motor installations require exterior

blower system, Part No.

KPED890T, available from your

dealer or authorized parts supplier.

3-1/4" x 14"

(8.3 cm x 35.6 cm)

vent

Vent Length

9" (22.9 cm) round 55 feet (16.8 m)

3-1/4" x 14" 55 feet (16.8 m)

(8.3 cm x 35.6 cm)

Maximum length of vent

system

For best performance, use no more

than three 90° elbows. If more than

one elbow is used, make sure that

there is a minimum of 24 inches

(61 cm) of straight vent between

any two elbows. Do Not install two

elbows together.

It is recommended that you use

round vent instead of rectangular

vent, especially if elbows are

required. If rectangular vent is

required, it should be transitioned

to 9" (22.9 cm) round vent as

soon as possible.

Determining the length of system

you need:

To calculate the length of system

you need, add the equivalent feet

for each duct piece that will be

needed. See example for 9"

(22.9 cm) round vent system.

Note: The exterior-mounted vent

motor requires a separate wiring

cable that should be installed at

the same time the vent work is

installed.

9" (22.9 cm) round

vent system

2 - 90 elbows = 10 ft. (3 m)

10 ft. (3 m) straight = 10 ft. (3 m)

Length of 9"

(22.9 cm) system = 20 ft. (6.1 m)

Maximum length = 55 ft. (16.8 m)

left vent

right vent

Installation requirements

Exterior-mounted vent motor

Page 10

3-1/4" x 14"

(8.3 cm x 35.6 cm)

to 9" (22.9 cm)

= 4.5 ft. (1.4 m)

90° elbow =

5 ft. (1.5 m)

45° elbow =

2.3 ft. (0.8 m)

9" (22.9 cm) to

3-1/4" x 14"

(8.3 cm x 35.6 cm)

= 1 ft. (0.3 m)

3-1/4" x 14"

(8.3 cm x 35.6 cm)

to 9" (22.9 cm)

90° elbow =

5 ft. (1.5 m)

9" (22.9 cm) to

3-1/4" x 14"

(8.3 cm x 35.6 cm)

90° elbow =

5 ft. (1.5 m)

Recommended standard

fittings

Installation steps

1. Put on gloves and safety

glasses. Place cardboard or another

form of protection on top of a flat

surface where you can easily

assemble the downdraft vent

system. Remove parts packages,

downdraft vent and blower box

from carton. Remove all shipping

materials, tape and protective film

from downdraft vent and blower

box.

4. Attach support legs to side of

downdraft vent with two screws in

each leg. Do Not tighten screws.

Excessive Weight Hazard

Use two or more people to move

and install downdraft vent.

Failure to do so can result in back

or other injury.

WARNING

7. Attach damper plate

(supplied with exterior blower

system) to front of downdraft vent

using 4 hex washer nuts.

5. Carefully insert downdraft

vent into countertop cutout. Two

people are recommended to

support the weight of the

downdraft vent during lifting.

Check that downdraft vent is

parallel to side of cutout and that

mounting brackets rest gently on

countertop.

6. Move support legs down

against cabinet floor. Place a level

against front of downdraft vent

base and adjust position of legs

until downdraft is level vertically.

Use a pencil to mark the top of

each leg on face of downdraft vent.

Then mark location of support leg

mounting holes on cabinet floor.

Remove downdraft vent from

cutout. Drill starter holes at each

mounting screw location on

cabinet floor. Align top of legs with

pencil marks on face of downdraft

vent. Tighten screws in legs.

8. Remove the 2 Phillips-head

screws attaching the wiring box

cover. Determine which direction

(rear or down) electrical connection

will need to run from appliance

wiring box. Remove cover. Knock

out rear or lower wiring opening in

wiring box.

Power supply cable needed

between exterior blower assembly

and blower box is not provided.

9. Determine the location where

the exterior blower box will be

located. Cut opening in roof or wall

for vent system to exterior blower.

Install exterior blower.

Wall Installations

• Use caulking compound between

mounting flange and wall.

Roof Installations

• Follow standard roofing

procedures.

• The flashing sheet should be

entered over the roof opening.

• Lower edge of flashing should lie

on top shingles and upper edge

underneath shingles.

• Seal assembly between roof, fan

and flashing with roofing mastic

to prevent leaks.

10

3. Attach the left side and right

side end caps to the downdraft.

Use 1 screw with each end cap.

2. Attach the left side and

right side overcounter support

brackets to the downdraft. Use 1

screw with each bracket.

over counter

support arm

support leg

mark

level

end cap

Page 11

11

10. Insert retractable

downdraft vent into countertop

cutout. Two people are

recommended to support the

weight of the downdraft vent

during lifting. Position downdraft

vent so it is centered in cutout and

parallel to edge of cutout. Check

that downdraft vent is vertical.

Then attach lower support legs to

cabinet floor with screws.

11. Attach one undercounter

mounting bracket on front upper

right corner of downdraft vent

with slot over vent mounting hole

and flange against countertop.

Attach other bracket to left side of

downdraft vent. Carefully drill

starter holes through

undercounter mounting brackets

into underside of countertop.

Insert appropriate length screws

into holes and tighten brackets to

countertop.

When attaching undercounter bracket

to underside of countertop, make

sure that the screw length will not go

through countertop when tightened.

12. Remove required

knockout and install conduit

connector. Feed the power supply

cable through the conduit

connector and into wiring box.

Connect the white wires together

with a twist-on wire connector.

Connect the black wires together

with a twist-on wire connector.

Attach the green (or green and

yellow) ground wire to eyelet with

green ground screw. Tighten the

conduit connector clamp screws.

Reattach the wiring box cover.

Remove 4 hex nuts that attach vent

box to downdraft vent box and

remove box.

Remove knockout and install

conduit connector.

Feed exterior-mounted vent motor

wiring through conduit connector.

Do not wire the exterior-mounted

vent motor into the wiring box. It

must be connected as shown.

Connect the white wires together

with a twist-on wire connector.

Connect the black wires together

with a twist-on connector. Tighten

the conduit connector clamp

screws.

Reattach the vent box with 4 hex

nuts.

wiring

box

cover

green

ground

screw

conduit

connector

13. Turn power supply on.

Push and hold for a few seconds

the button on the top of the

downdraft vent. Retractable

section of downdraft vent will rise

and blower will start. Position the

top trim over the retractable

section and snap trim into place.

14. Turn the control knob on

side of vent to check the

operation and speed of blower.

If blower does not operate:

• Check that filter or filters are

pressed in as far as they will go.

• Check that circuit breaker is not

tripped or house fuse blown.

• Disconnect power source and

check that wire connections

have been made correctly.

exterior-mounted

vent motor wiring

ON/OFF

button

blower

control

knob

end cap

filter or filters

depending on

model

microswitches behind filters.

15. Connect vent to blower.

Position vent to avoid wall studs

and floor joists. Complete all vent

work. Use duct tape to seal all

joints. Vertical vent for wallmounted installations should pitch

down slightly toward the vent to

allow moisture to run outside.

16. Install cooktop according

to manufacturer’s instructions.

Check that rear of cooktop overlaps

edge of retractable downdraft vent

by 3/8" (9.5 mm).

To get the most efficient

use from your new

retractable downdraft vent,

read the Use and Care

Information section on

page 12.

Keep Installation Instructions

and Use and Care

Information close by for

easy reference.

Electrical Shock Hazard

Disconnect power before

making electrical connections.

Connect ground wire to green

ground screw in terminal box.

Failure to do so can result in

death or electrical shock.

WARNING

Page 12

12

Use and Care Information

The retractable downdraft vent system is designed to remove smoke, cooking vapors and odors from the cooktop area.

For the best results, the vent should be operating before cooking is started. If you use large or tall utensils, place them

on the large rear element or burner surface. A higher heat setting than normally used may be needed when the

downdraft vent is operating.

WARNING — To reduce the risk of fire or electrical

shock, do not use this fan with any solid-state speed

control device.

WARNING — TO REDUCE THE RISK OF FIRE,

ELECTRIC SHOCK, OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer. Before servicing or cleaning unit,

switch power off at service panel and lock switch

power off at service panel and lock service panel to

prevent power from being switched on accidentally.

When the service disconnecting means cannot be

locked, securely fasten a prominent warning device

such as a tag to the service panel.

CAUTION: For general ventilating use only. Do not

use to exhaust hazardous or explosive materials and

vapors.

WARNING — TO REDUCE THE RISK OF A RANGE

TOP GREASE FIRE:

Keep fan, filters and grease-laden surfaces clean.

Always turn hood ON when cooking at high heat.

Use high range settings on range only when

necessary. Heat oil slowly on low to medium setting.

Don’t leave range unattended when cooking.

Always use cookware and utensils appropriate for

the type and amount of food being prepared.

WARNING — TO REDUCE THE RISK OF INJURY TO

PERSONS IN THE EVENT OF A RANGE TOP GREASE

FIRE, OBSERVE THE FOLLOWING:

SMOTHER FLAMES with a close-fitting lid, cookie

sheet, or metal tray, then turn off the burner. BE

CAREFUL TO PREVENT BURNS.

If the flames do not go out immediately, EVACUATE

AND CALL THE FIRE DEPARTMENT.

NEVER PICK UP A FLAMING PAN — You may be

burned.

DO NOT USE WATER, including wet dishcloths or

towels — a violent steam explosion will result. Use

an extinguisher ONLY if:

You know you have a Class ABC extinguisher, and

you already know how to operate it.

The fire is small and contained in the area where it

is started.

The fire department is being called.

You can fight the fire with your back to an exit.

Operating downdraft vent

Push and hold for a few seconds

the button on top of downdraft

vent. This slight delay prevents

raising the vent during cleaning.

Retractable section of downdraft

vent will rise and blower will

begin to vent. Turn knob on side

of downdraft vent to adjust the

setting to the amount of venting

you need. The knob has infinite

settings. Place cooking utensils

on cooking surface and turn

cooking unit on. When cooking is

complete, turn cooking unit off,

remove utensils from cooking

surface, and push button on top

of retractable downdraft vent.

The blower will turn off and the

retractable section of the vent will

return to the closed position.

If a spill occurs on the cooktop

that allows liquids to seep inside

the downdraft, you must turn the

downdraft off immediately. It is

possible to cause damage to the

downdraft if water is allowed

inside the downdraft while it is

operating.

• Immediately turn OFF the

downdraft at the speed control

located on the right-hand side

of the downdraft.

• Turn OFF the power supply to

the downdraft at the circuit

breaker box or fuse box.

• Allow plenty of time for the

downdraft to dry naturally. Do

not open the downdraft to

remove the water.

Cleaning

Surface of downdraft vent: Clean

with soap and water. Do Not use

scouring powder or abrasive

solutions.

Filter or filters (depending on

model): Frequently remove and

clean the filters in the retractable

section of the downdraft vent.

This will improve the operating

efficiency of the downdraft vent

system.

1. Remove the filter(s) and clean

them in the dishwasher or in a

hot detergent solution.

Do Not use the downdraft vent

when the filter(s) is not in place.

2. Reinstall the clean filter(s),

making sure that they are pushed

in as far as they will go.

Note: Downdraft vent will not

operate if filter(s) is not in proper

position. If the handle(s) is not

fully locked, the vent may retract

but not raise back up.

Page 13

If retractable downdraft vent

does not operate after clean

filters have been reinstalled:

Push the filter in as far as it will

go. When the filter is removed,

the microswitch behind the filter

is inactivated. This safety feature

stops the blower and raising

mechanism until the filter is

properly reinstalled.

Note: Instructions are included with

each kit.

For model series

KIRD & YKIRD 801, 802

30" (76.2 cm) one-piece trim:

Part No. 8171304 (white)

Part No. 8171305 (black)

Part No. 8171306 (biscuit)

For model series

KIRD & YKIRD 861, 862

36" (91.4 cm) one-piece trim:

Part No. 8171310 (white)

Part No. 8171311 (black)

Part No. 8171312 (biscuit)

For model series

KIRD & YKIRD 821, 822

42" (106.7 cm) one-piece trim:

Part No. 8171316 (white)

Part No. 8171317 (black)

Part No. 8171318 (biscuit)

For model series

GZ & YGZ 7930

30" (76.2 cm) one-piece trim:

Part No. 8171300 (white)

Part No. 8171301 (black)

For model series

GZ & YGZ 7736

36" (91.4 cm) one-piece trim:

Part No. 8171302 (white)

Part No. 8171303 (black)

Accessories

available from your dealer

microswitches behind filters

models with two filters

left metal

filter

right metal

filter

locking handles

models with one filter

filter

Part No. 4329225/4360363

© 1999 Whirlpool Corporation

Benton Harbor, Michigan 49022

microswitches

behind filter

Page 14

Référence rapide

Table des matières :

Pages

Avant de commencer...

Alimentation électrique

Dimensions du produit

Dimensions du placard

Ouverture à découper

Système de décharge -

Ventilateur intérieur

Les étapes de l’installation

Système de décharge Ventilateur extérieur

Les étapes de l’installation

Utilisation et entretien

Accessoires

Instructions d’installation et

Guide d’utilisation et d’entretien

Système rétractable

d’aspiration par le bas

76,2 cm (30 po)

91,4 cm (36 po)

106,7 cm (42 po)

IMPORTANT :

Lire et conserver

ces instructions.

IMPORTANT :

Installateur : Remettre les instructions

d’installation au propriétaire de l’appareil.

Propriétaire : Conserver les instructions

d’installation pour consultation ultérieure.

Conserver les instructions d’installation à

l’intention de l’inspecteur local des installations

électriques.

Pièce n°

4329225/4360363

2

3

4

4

5

6

7- 9

9

11

12

13

10 -

Page 15

Avant de commencer...

C’est à l’installateur qu’incombe la

responsabilité d’une installation

correcte. Vérifier que tout le matériel

nécessaire pour une installation

correcte est disponible. C’est à

l’installateur qu’incombe la

responsabilité de respecter les

dégagements de séparation spécifiés

sur la plaque signalétique. La plaque

signalétique (avec numéro de modèle

et numéro de série) est située à

l’avant du système d’aspiration, audessus de la boîte de connexion.

Évaluer l’emplacement où le système

d’aspiration doit être installé.

L’emplacement d’installation doit être

éloigné des sources de courants d’air

comme fenêtres, portes, ventilateurs

et bouches de chauffage. Avant de

découper une ouverture dans un plan

de travail, vérifier qu’il n’y aura

aucune obstruction au niveau des

placards, du dosseret et du

colombage du mur à l’intérieur des

placards.

ASSURER L’ÉTANCHÉITÉ AU NIVEAU

DE CHAQUE OUVERTURE DÉCOUPÉE

DANS LE PLANCHER OU LE MUR

POUR L’INSTALLATION DU SYSTÈME

D’ASPIRATION.

Important : Respecter les

prescriptions de tous les codes

et règlements en vigueur.

Pièces fournies

pour l’installation :

Pièces nécessaires

pour l’installation :

Outillage nécessaire pour l’installation :

tournevis

Phillips

tournevis lame plate

pistolet d’application

pour produits de

calfeutrage et

d’étanchéité

ruban adhésif

pour conduits

cisaille de

ferblantier

pince

crayon

scie sauteuse

ou scie à

chantourner

perceuse

mèche à bois 1/8 po

niveau

pince à dénuder

ou couteau

utilitaire

2

Une liaison électrique entre la terre et

le système est nécessaire. Voir à la

page 3 « Alimentation électrique ».

Lors de l’installation du système

d’aspiration, on devra éliminer le tiroir

du placard et installer le panneau de

façade du tiroir d’une manière

permanente sur le placard.

Note : On installe le système

d’aspiration directement derrière la

table de cuisson. Installer d’abord le

système d’aspiration.

Le système d’aspiration n’est pas

conçu pour l’utilisation dans une

résidence mobile.

Configuration des placards : Le

système d’aspiration est conçu pour

être utilisé dans un placard de 61 cm

(24 po) (profondeur). Pour certaines

installations, un plan de travail de

plus de 63,5 cm (25 po) est

nécessaire. Voir le tableau de la page

5. La profondeur maximum des

placards muraux est de 33 cm (13 po).

Les placards muraux installés de part

et d’autre du système d’aspiration

doivent être placés à 45,7 cm (18 po)

au-dessus de la table de cuisson.

Avant d’effectuer un découpage,

consulter les instructions d’installation

de la table de cuisson, et déterminer

la distance minimale entre le bord

avant du plan de travail et le bord

avant de la table de cuisson. La

distance horizontale minimale entre

les placards muraux est identique à la

largeur du système d’aspiration

installé.

Lors de l’installation d’un système

d’aspiration rétractable de 91,4 cm

(36 po) ou 106,7 cm (42 po) avec des

modules « Create-A-Cooktop », on

doit installer le support optionnel à

l’avant du système d’aspiration. Pour

les détails, voir les étapes de

l’installation.

clé à cliquet avec

douille 9,5 mm (3/8 po)

gants

mètre-ruban

lunettes de

sécurité

• 1 garniture supérieure

• 2 embouts

• 2 pieds de support inférieurs

• 2 brides d’appui sur comptoir

• 2 brides de fixation sous comptoir

• 1 sachet de vis et boulons

• 1 couvercle métallique

• 1 volet de réglage du tirage

• brochures

• support optionnel et deux vis -

seulement pour modèles de 91,4 cm

(36 po) ou 106,7 cm (42 po)

• 2 connecteurs de conduit 12,7 mm

(1/2 po) - homologation U.L. ou

ACNOR ; (3 connecteurs sont

nécessaires si le moteur monté à

l’extérieur est utilisé)

• 1 capuchon bouche de décharge murale

pour moteur monté à l’intérieur

• système d’aspiration

• câble d’alimentation

• câble d’alimentation pour ventilateur

monté à distance (option)

Risque possible de décès ou de blessure

grave si vous ne suivez pas les instructions.

DANGER

AVERTISSEMENT

Votre sécurité et celle des autres

est très importante.

Nous donnons de nombreux messages de

sécurité importants dans ce manuel et sur

votre appareil ménager. Assurez-vous de

toujours lire tous les messages de sécurité

et de vous y conformer.

Voici le symbole de sécurité.

Ce symbole d’alerte de sécurité

vous signale les dangers susceptibles de causer le décès et des

blessures graves à vous et à d’autres.

Tous les messages de sécurité seront

précédés du symbole d’alerte de sécurité

et du mot « DANGER » ou « AVERTISSEMENT ». Ces mots signifient :

Tous les messages de sécurité identifient le

danger et vous disent comment réduire le

risque de blessure, et ce qui peut se produire

en cas de non-respect des instructions.

Risque certain

de décès ou de blessure

grave si vous ne suivez pas les instructions.

Page 16

3

AVERTISSEMENT - POUR RÉDUIRE

LE RISQUE D’INCENDIE, CHOC

ÉLECTRIQUE OU BLESSURE,

RESPECTER LES INSTRUCTIONS

SUIVANTES :

Tout travail d’installation ou câblage

électrique doit être réalisé par une

personne qualifiée, et respecter des

prescriptions de tous les codes et

normes applicables, y compris les

codes du bâtiment et de protection

contre les incendies. Le

fonctionnement de cet appareil peut

modifier la circulation de l’air et

affecter le fonctionnement d’un

appareil utilisant un combustible.

Respecter les directives du fabricant

de l’équipement de chauffage et les

prescriptions des normes de

sécurité - comme celles publiées par

la National Fire Protection

Association (NFPA) et l’American

Society of Heating, Refrigeration

and Air Conditioning Engineers

(ASHRAE) - et les prescriptions des

autorités réglementaires locales.

Lors d’opérations de découpage et

de perçage dans un mur ou plafond,

veiller à ne pas endommager les

câblages électriques ou

canalisations qui peuvent s’y

trouver.

Le conduit d’évacuation associé à un

ventilateur doit toujours décharger

l’air à l’extérieur.

AVERTISSEMENT - Pour réduire le

risque d’incendie, utiliser

uniquement des conduits

métalliques.

Alimentation électrique

Important : Respecter les

prescriptions de tous les codes et

règlements en vigueur.

C’est au client qu’incombe la

responsabilité de :

• Contacter un électricien qualifié

pour l’installation.

• Veiller à ce que l’installation

électrique soit réalisée d’une

manière adéquate et en conformité

avec les prescriptions du Code

national des installations

électriques ANSI/NFPA 70 - dernière

édition*, ou des normes ACNOR

C22.1.94 / Code canadien des

installations électriques (partie 1) et

C22.2 N° 0-M91 - dernière édition**,

et avec les prescriptions de tous les

codes et règlements locaux en

vigueur.

Si un conducteur distinct de liaison à

la terre est utilisé lorsque le code le

permet, on recommande qu’un

électricien qualifié vérifie que la

liaison à la terre est adéquate.

Ne pas utiliser une tuyauterie de gaz

pour la liaison à la terre.

En cas d’incertitude quant à la qualité

de la liaison à la terre de la hotte,

consulter un électricien qualifié.

Ne pas installer un fusible en série

avec le conducteur neutre ou le

conducteur de liaison à la terre.

IMPORTANT :

Conserver les instructions

d’installation à l’intention de

l’inspecteur local des installations

électriques.

E.Un connecteur de conduit de

12,7 mm (1/2 po) (homologation UL

ou ACNOR) doit être installé à

chaque extrémité du câble

d’alimentation (sur le système

d’aspiration et sur la boîte de

connexion).

A.Le système d’aspiration doit

être alimenté par un circuit

indépendant 120 volts, 60 Hz, CA

seulement, 15 A, protégé par fusible

sur les deux côtés de la ligne. On

recommande l’emploi de fusibles ou

disjoncteurs temporisés. La capacité

de protection du fusible doit satisfaire

les prescriptions du code local et être

compatible avec la demande de

courant de l’appareil indiquée sur la

plaque signalétique placée à l’avant

du système d’aspiration, au-dessus

du couvercle de la boîte de

connexion.

B.LE SYSTÈME D’ASPIRATION

VERS LE BAS DOIT ÊTRE RACCORDÉ

UNIQUEMENT AVEC DES

CONDUCTEURS DE CUIVRE.

C.Le calibre des conducteurs et

les connexions doivent satisfaire les

prescriptions du Code national des

installations électriques ANSI/NFPA

70 - dernière édition*, ou des normes

ACNOR C22.1.94 / Code canadien des

installations électriques (partie 1) et

C22.2 N° 0-M91 - dernière édition**,

et les prescriptions de tous les codes

et règlements locaux en vigueur.

D.Le système d’aspiration vers

le bas devrait être raccordé

directement au coupe-circuit avec

fusible ou disjoncteur par

l’intermédiaire d’un câble flexible de

conducteurs de cuivre, à blindage

métallique ou à gaine non métallique.

Veiller à ajouter une longueur de

câble suffisante pour qu’il soit

possible de déplacer l’appareil lors de

toute intervention d’entretien.

F. Un schéma de câblage

accompagne l’appareil ; on le trouve

au-dessus du couvercle de la boîte de

connexion.

* National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

** Canadian Standard Association

178 Rexdale Boulevard

Etobicoke (Toronto), Ontario M9W 1R3

Page 17

4

Dimensions du placard

Dimensions du produit

garniture supérieure pour

modèle 76,2 cm (30 po),

modèle 91,4 cm (36 po)

modèle 106,7 cm (42 po)

9,5 mm (3/8 po)

21 cm (8 1⁄4 po)

hauteur de

déploiement/

rétraction

4,8 cm

(1 7/8 po)

66,4 cm

(26 1/8 po)

54 cm

(2 1/8 po)

MOTEUR DE

VENTILATEUR

INTERNE

MOTEUR DE VENTILATEUR

MONTÉ À L’EXTÉRIEUR

15,9 mm

(5/8 po)

10,2 cm

(4 po)

20,3 cm

(8 po)

22,9 cm (9 po)

Diamètre

40,6 cm

(16 po)

20,3 cm

(8 po)

40,6 cm

(16 po)

15,9 mm

(5/8 po)

23,8 cm

(9 3/8 po)

40,6 cm

(16 po)

40,6 cm

(16 po)

10,5 cm +A

(4 1/8 po)

44,6 cm

(17 9/16 po)

43,7 cm

(17 3/16 po)

A = 12,7 mm

(1/2 po) min.

59,8 cm

(23 9/16 po)

9,5 mm

(3/8 po)

axe central de

l’ouverture pour la

table de cuisson

8,3 cm x 25,4 cm

(3 1/4 po x 10 po)

Pour les dimensions de

l’ouverture à découper pour

la table de cuisson, voir les

instructions du fabricant.

Utiliser les dimensions

applicables à l’installation

particulière.

Dimensions de l’ouverture à découper

indiquées seulement pour les modèles à

ventilateur interne.

Un circuit doté d’un ventilateur extérieur

doit être raccordé à un conduit de 22,9 cm

(9 po). Pour ce système, la position des

ouvertures à découper dépendra des

caractéristiques spécifiques de

l’installation.

Placer la boîte de

connexion dans l’angle

inférieur droit arrière du

placard.

ouvertures découpées

représentées pour

conduit de 8,3 x 25,4 cm

(3 1/4 x 10 po)

68,6 cm (27 po) pour modèle de 76,2 cm (30 po)

83,8 cm (33 po) pour modèle de 91,4 cm (36 po)

99,1 cm (39 po) pour modèle de 106,7 cm (42 po)

Page 18

5

Dimensions de l’ouverture à découper pour la table de cuisson

69,9 cm (27 1/2 po) pour modèle de 76,2 cm (30 po)

85,1 cm (33 1/2 po) pour modèle de 91,4 cm (36 po)

100,3 cm (39 1/2 po) pour modèle de 106,7 cm (42 po)

Voir les dimensions

dans le tableau

ci-dessous.

A = 12,7 mm

(1/2 po)

min.

axe central de l’ouverture

à découper pour la table

de cuisson

Pour certains modèles, on doit

avoir un plan de travail de plus

de 63,5 cm (25 po); voir les

dimensions de l’ouverture dans

le tableau ci-dessous.

6,4 mm

(1/4 po)

6,4 mm

(1/4 po)

4,8 cm

(1-7/8 po)

table de cuisson

dosseret

système

d’aspiration

plan de travail

12,7 mm

(1/2 po)

min.

12,7 mm (1/2 po)

minimum

*

L’installation avec un système d’aspiration nécessite la présence d’un plan de travail de plus de 63,5 cm (25 po) et de placards de

plus de 61 cm (24 po).

Pour éviter toute erreur, on

recommande de tracer sur le plan

de travail avant le découpage les

ouvertures nécessaires pour la table

de cuisson et le système

d’aspiration.

Pour les détails de l’installation et

toutes les dimensions à respecter,

voir les instructions d’installation de

la table de cuisson.

IMPORTANT : Pour ces installations,

un plan de travail avec rebord avant

est déconseillé.

épaisseur du dosseret

19,1 mm (3/4 po) max.

séparation de 12,7 mm

(1/2 po) min. avec

dosseret ou mur

arrière

E

H

D

C

G

Profondeur hors-tout de

la table de cuisson et du

système d’aspiration vers

le bas

B

A

Profondeur

min. nécessaire

du plan de

travail

F

Largeur hors-tout de la table

de cuisson et du système

d’aspiration vers le bas

Modèles de Taille de la Modèles de

table de cuisson table de cuisson systèmes d'aspiration A B C D E F G H

KGCT305G KGCS105G 76,2 cm KIRD801HSS KIRD802HSS

73,7 cm 69,9 cm 49,8 cm 5,4 cm 4,4 cm 79,7 cm 58,4 cm 63,5 cm

(30 po) KIRD801XSS KIRD802XSS

(29 po) (27 1/2 po) (19 5/8 po) (2 1/8 po) (1 3/4 po) (31 3/8 po) (23 po) (25 po)

KECC501G*KECC502G*76,2 cm KIRD801HSS KIRD802HSS

74,9 cm 69,9 cm 52,1 cm 5,4 cm 5,1 cm 80 cm 59,1 cm 65,7 cm

KECC507G*KECC508G*(30 po) KIRD801XSS KIRD802XSS

(29 1/2 po) (27 1/2 po) (20 1/2 po) (2 1/8 po) (2 po) (31 1/2 po) (23 1/4 po) (25 7/8 po)

KECS100G

*

76,2 cm KIRD801HSS KIRD802HSS

73,3 cm 69,9 cm 48,3 cm 6,4 cm 8,6 cm 80 cm 58,4 cm 65,1 cm

(30 po) KIRD801XSS KIRD802XSS

(28 7/8 po) (27 1/2 po) (19 po) (2 1/2 po) (3 3/8 po) (31 1/2 po) (23 po) (25 5/8 po)

SCS3004G SCS3014G, 76,2 cm GZ7930XGS

73,7 cm 69,9 cm 49,8 cm 5,4 cm 4,4 cm 79,7 cm 58,4 cm 63,5 cm

GLT3014G (30 po) GZ7930XHS

(29 po) (27 1/2 po) (19 5/8 po) (2 1/8 po) (1 3/4 po) (31 3/8 po) (23 po) (25 po)

RCC3024G*GJC3034G*76,2 cm GZ7930XGS

74,9 cm 69,9 cm 52,1 cm 5,1 cm 5,1 cm 76,2 cm 58,4 cm 65,4 cm

(30 po) GZ7930XHS

(29 1/2 po) (27 1/2 po) (20 1/2 po) (2 po) (2 po) (30 po) (23 po) (25 3/4 po)

RCS3004G*RCS3014G*76,2 cm GZ7930XGS

73,3 cm 69,9 cm 48,3 cm 6,4 cm 7,6 cm 80 cm 58,4 cm 64,8 cm

YRCS3014G

*

(30 po) GZ7930XHS

(28 7/8 po) (27 1/2 po) (19 po) (2 1/2 po) (3 po) (31 1/2 po) (23 po) (25 1/2 po)

KGCT365G KECT366G 91,4 cm KIRD861HSS KIRD862HSS

89,5 cm 85,9 cm 49,8 cm 5,4 cm 4,4 cm 95,3 cm 58,4 cm 63,5 cm

KGCS166G (36 po) KIRD861XSS KIRD862XSS

(35 1/4 po) (33 1/2 po) (19 5/8 po) (2 1/8 po) (1 3/4 po) (37 1/2 po) (23 po) (25 po)

KECC562G*KECC567G*91,4 cm KIRD861HSS KIRD862HSS

90,2 cm 85,9 cm 52,1 cm 5,4 cm 5,1 cm 95,3 cm 59,1 cm 68,3 cm

KECC568G

*

(36 po) KIRD861XSS KIRD862XSS

(35 1/2 po) (33 1/2 po) (20 1/2 po) (2 1/8 po) (2 po) (37 1/2 po) (23 1/4 po) (26 7/8 po)

KECS161G

*

91,4 cm KIRD861HSS KIRD862HSS

88,9 cm 85,9 cm 48,3 cm 6,4 cm 8,6 cm 95,6 cm 58,4 cm 65,1 cm

(36 po) KIRD861XSS KIRD862XSS

(35 po) (33 1/2 po) (19 po) (2 1/2 po) (3 3/8 po) (37 5/8 po) (23 po) (25 5/8 po)

SCS3614G 91,4 cm GZ7936XGS

89,5 cm 85,9 cm 49,8 cm 5,4 cm 4,4 cm 95,3 cm 58,4 cm 63,5 cm

(36 po) GZ7936XHS

(35 1/4 po) (33 1/2 po) (19 5/8 po) (2 1/8 po) (1 3/4 po) (37 1/2 po) (23 po) (25 po)

GLT3614XG 91,4 cm GZ7936XGS

89,5 cm 85,9 cm 49,8 cm 5,4 cm 4,4 cm 93 cm 58,4 cm 63,5 cm

(36 po) GZ7936XHS

(35 1/4 po) (33 1/2 po) (19 5/8 po) (2 1/8 po) (1 3/4 po) (36 5/8 po) (23 po) (25 po)

GJC3634G

*

91,4 cm GZ7936XGS

90,2 cm 85,9 cm 52,1 cm 5,1 cm 5,1 cm 91,4 cm 58,4 cm 65,4 cm

(36 po) GZ7936XHS

(35 1/2 po) (33 1/2 po) (20 1/2 po) (2 po) (2 po) (36 po) (23 po) (25 3/4 po)

RCS3614G

*

91,4 cm GZ7936XGS

88,9 cm 85,9 cm 48,3 cm 6,4 cm 7,6 cm 95,6 cm 58,4 cm 65,1 cm

(36 po) GZ7936XHS

(35 po) (33 1/2 po) (19 po) (2 1/2 po) (3 po) (37 5/8 po) (23 po) (25 5/8 po)

KGCS127G 106,7 cm KIRD821HSS

108,6 cm

99,4 cm 49,8 cm 5,4 cm 4,4 cm

113 cm

58,4 cm 63,5 cm

(42 po) KIRD822HSS

(42 3/4 po)

(39 1/8 po) (19 5/8 po) (2 1/8 po) (1 3/4 po)

(44 1/2 po)

(23 po) (25 po)

Page 19

Conduit Longueur

Diam. 15,2 cm (6 po) 8,9 m (35 pieds)

8,3 cm x 25,4 cm 8,9 m (35 pieds)

(3 1/4 x 10 po)

6

Prescriptions

concernant le

système d’évacuation

Le système doit décharger l’air à

l’extérieur.

Ne pas terminer le conduit

d’évacuation au-dessus d’un plafond

ou dans un autre espace fermé.

Ne pas utiliser une bouche de

décharge murale de 10,2 cm (4 po)

normalement utilisée pour un

équipement de buanderie.

Ne pas utiliser de conduit flexible

métallique ou de plastique.

Les conduits nécessaires ne sont pas

fournis.

Une bouche de décharge n’est pas

fournie avec le moteur monté à

l’intérieur.

Déterminer la méthode d’évacuation à

utiliser. Le circuit d’évacuation doit

acheminer l’air évacué à l’extérieur, à

travers le mur ou à travers le toit.

Minimiser la longueur du circuit et le

nombre de coudes afin de maximiser

la performance.

La taille du conduit d’évacuation doit

être uniforme.

Ne pas raccorder deux coudes

ensemble.

Au niveau de chaque jointure du

système de décharge, assurer

l’étanchéité avec du ruban adhésif

pour conduit.

Au point de passage de la bouche de

décharge à travers le plancher ou le

mur, assurer l’étanchéité avec un

produit de calfeutrage.

Ne pas couper les solives ou les

poteaux du colombage. Si un poteau

ou une solive se trouve à l’endroit de

passage du conduit d’évacuation, on

doit construire une structure de

support.

On déconseille l’emploi de conduit

d’évacuation flexible. En cas

d’utilisation de conduit d’évacuation

flexible, on doit tenir compte du fait

que la longueur effective de un pied

de conduit flexible correspond à

61 cm (2 pi) de conduit métallique

rigide. La longueur effective d’un

coude de conduit flexible est le

double de la longueur effective d’un

coude standard.

NOTE : Avant de découper les

ouvertures de passage du conduit

d’évacuation, vérifier que les

dégagements de sécurité appropriés

seront respectés dans le mur ou le

plancher.

Longueur recommandée pour le

conduit d’évacuation

Moteur d’ventilateur

monté à l’intérieur

Exigences de l’installation

Installation sur un îlot

Installation dans un placard

conduit

d’évacuation

vers le bas

conduit

d’évacuation

vers le bas

conduit d’évacuation

par l’arrière

conduit d’évacuation

par la gauche

conduit d’évacuation

par la droite

a

a

a

a

a

a

a

aa

a

aa

aaa

a

a

a

a

a

a

a

aa

a

a

aa

a

a

a

a

a

aa

aa

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

aa

aaa

a

a

a

a

a

a

a

aa

a

a

aa

a

a

a

a

a

aa

a

Circuit d’évacuation installé sous

une dalle de béton (utilisation de

tuyaux de PVC pour égout)

bouche de

décharge

murale

raccord PVC

diam.

15,2 cm (6 po)

raccord PVC

diam.

15,2 cm (6 po)

tuyau PVC/

égout diam.

15,2 cm (6 po)

tuyau PVC/

égout diam.

15,2 cm (6 po)

conduit métallique diam. 15,2 cm (6 po)

Gravier ou sable

bien tassé, tout

autour du tuyau.

Gravier ou sable

bien tassé, tout

autour du tuyau.

raccord de

transition

raccord de

transition

conduit

métallique diam.

15,2 cm (6 po)

conduit

métallique diam.

15,2 cm (6 po)

raccord

PVC diam.

15,2 cm (6 po)

raccord

PVC diam.

15,2 cm (6 po)

dalle de

béton

dalle de

béton

tuyau PVC/

égout diam.

15,2 cm (6 po)

tuyau PVC/

égout diam.

15,2 cm (6 po)

coude 90°

PVC/égout,

diam. 15,2 cm

(6 po)

coude 90° PVC/

égout, diam.

15,2 cm (6 po)

coude 90°

PVC/égout,

diam. 15,2 cm

(6 po)

40,6 cm (16 po)

maximum

30,5 cm (12 po)

minimum

30,5 cm (12 po)

minimum

SBCCI

a

a

a

a

a

a

a

aa

a

aa

aa

a

a

a

a

a

a

a

a

aa

a

a

aa

a

a

a

a

a

aa

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

aa

aaa

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

aa

a

fosse de

fenêtre

15.2 cm

(6 po) min.

Option - Circuit d’évacuation installé

sous une dalle de béton, dans une fosse

de fenêtre.

Ne pas décharger les gaz de combustion

d’une table de cuisson à gaz dans une

fosse de fenêtre

SBCCI

Longueur maximale du conduit

d’évacuation

Pour obtenir la meilleure performance,

ne pas incorporer plus de trois coudes à

90°. S’il y a plus de un coude, veiller à

ce que deux coudes soient séparés par

une section rectiligne d’au moins 61 cm

(24 po). Ne pas connecter deux coudes

ensemble. On recommande l’emploi de

conduit rond plutôt que rectangulaire,

particulièrement s’il est nécessaire

d’incorporer des coudes. Si l’emploi

d’une section de conduit rectangulaire

est nécessaire, effectuer la transition

dès que c’est possible avec du conduit

rond de diam. 15,2 cm (6 po).

Détermination de la longueur

nécessaire du système :

Pour calculer la longueur effective du

système de décharge, on doit tenir

compte de la longueur équivalente de

chaque composant du système. Voir

l’exemple pour un circuit d’évacuation

de conduit rond de diam. 15,2 cm (6 po).

Dans le cas d’un ventilateur monté à

l’intérieur ou à l’extérieur, la longueur

effective totale du conduit

d’évacuation ne doit pas dépasser la

valeur maximale indiquée dans le

tableau « Longueur maximale du

conduit d’évacuation ». (Voir le

tableau de cette page pour un

ventilateur monté à l’intérieur ; voir la

page 9 pour un ventilateur monté à

l’extérieur.)

bouche de

décharge

murale

Obturer avec un produit de calfeutrage

l’espace autour de la bouche de

décharge murale à l’intérieur du

raccord de PVC.

Page 20

7

Danger de poids excessif

Deux personnes ou plus doivent

déplacer et installer la hotte.

Le non-respect de cette

instruction peut causer une

blessure au dos ou d’autres

blessures.

AVERTISSEMENT

Circuit d’évacuation de

conduit rond, diam.

15,2 cm (6 po)

1,8 m (6 pi)

0,6 m (2 pi)

coudes à 90°

raccord de

transition

Longueur maximum = 8,9 m (35 pi)

1 - bouche de décharge

murale = 0 m (0 pi)

2,4 m (8 pi) section

rectiligne = 2,4 m (8 pi)

2 coudes à 90° = 3 m (10 pi)

Raccord de transition = 1,4 m (4,5 pi)

Longueur effective

totale de conduit de

diam. 15,2 cm (6 po) = 6,9 m (22,5 pi)

Raccords standard

recommandés

transition

8,3 cm x 25,4 cm

(3 1/4 x 10 po) à

diam. 15,2 cm (6 po)

= 1,4 m (4,5 pi)

Coude à 90° =

1,5 m (5 pi)

Coude à 45° =

0,8 m (2,3 pi)

transition

diam. 15,2 cm (6 po)

à 8,3 cm x 25,4 cm

(3 1/4 x 10 po) =

0,3 m (1 pi)

1.Porter des gants et des

lunettes de sécurité. Placer une feuille

de carton ou un autre matériau de

protection sur une surface plane pour

l’assemblage du circuit d’évacuation.

Retirer de l’emballage les sachets de

pièces, le système d’aspiration et le

ventilateur. Retirer du système

d’aspiration et du ventilateur tous les

matériaux d’emballage, rubans

adhésifs et films de protection.

3.Fixer sur le système d’aspiration

les embouts de gauche et de droite).

Utiliser 1 vis pour chaque embout.

2.Fixer sur le système

d’aspiration les brides d’appui sur le

plan de travail (côté gauche et côté

droit). Utiliser 1 vis pour chaque

bride.

5.Insérer prudemment le

système d’aspiration dans l’ouverture

découpée dans le plan de travail. On

recommande que deux personnes

participent à cette opération, du fait

du poids du système. Veiller à placer

le système d’aspiration parallèlement

aux côtés de l'ouverture découpée;

les brides de montage doivent

prendre appuisur le plan de travail.

6.Faire descendre les pieds

jusqu’au plancher du placard. Placer

un niveau contre l’avant de la base

du système d’aspiration; ajuster

selon le besoin pour que le système

soit parfaitement vertical. Avec un

crayon, marquer le sommet de

chaque pied sur le système

d’aspiration. Marquer ensuite la

position des trous des pieds de

support sur le plancher du placard.

Retirer le système d’aspiration de

l’ouverture découpée. Percer des

avant-trous à l’emplacement de

chaque vis sur le plancher du

placard. Aligner le sommet des pieds

avec les marques de repérage tracées

au crayon sur le système

d’aspiration. Serrer les vis de fixation

des pieds.

7.Déterminer la direction de

décharge de l’air par le ventilateur

installé dans le placard (vers le bas,

vers l’arrière, vers la gauche ou vers

la droite).

Décharge vers le bas :

Le système d’aspiration est configuré

à l’usine pour la décharge vers le bas;

par conséquent, aucune modification

n’est nécessaire. Passer à l’étape 8.

Décharge par la gauche et par la

droite :

a. Ôter les 4 écrous hex. fixant la

boîte du ventilateur sur la base du

système d’aspiration. Ôter le

ventilateur.

b. Faire pivoter le ventilateur de 90°

vers la gauche ou vers la droite pour

que la sortie du ventilateur coïncide

avec la direction de décharge désirée.

c. Fixer de nouveau la boîte du

ventilateur sur la base du système

d’aspiration avec 4 écrous hex.

Décharge vers l’arrière :

a. Ôter les 4 écrous hex. fixant la

boîte du ventilateur sur la base du

système d’aspiration. Ôter le

ventilateur.

b. Noter la configuration

d’installation du câble d’alimentation

sous les agrafes de plastique à

l’intérieur de la base du système.

Extraire prudemment le câble des