Whirlpool RS160LXT, RY160LXT, RS160LXTQ, RY160LXTQ, RS160LXTB User manual

...

CONSUMER SERVICES TECHNICAL

EDUCATION GROUP PRESENTS

SLIDE-IN ELECTRIC

RANGE

JOB AID

Part No. 8178710

KR-38

Models RS160LXT*, RY160LXT*

FORWARD

This Whirlpool Job Aid “Slide in Electric Range” (Part No. 8178710), provides the In-Home Service

Professional with information on the installation, operation, and service of the Slide in Electric

Range. For specic information on the model being serviced, refer to the “Use and Care Guide,”

or “Wiring Diagram” provided with the cooktop.

The Wiring Diagrams used in this Job Aid are typical and should be used for training purposes

only. Always use the Wiring Diagram supplied with the product when servicing the Slide in Electric

Range.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide information that will enable the In-Home Service Professional

to properly diagnose malfunctions and repair the Slide in Electric Range.

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the Slide in Electric Range to its proper operational status.

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made on

our products by anyone other than authorized In-Home Service Professionals.

Copyright © 2008, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

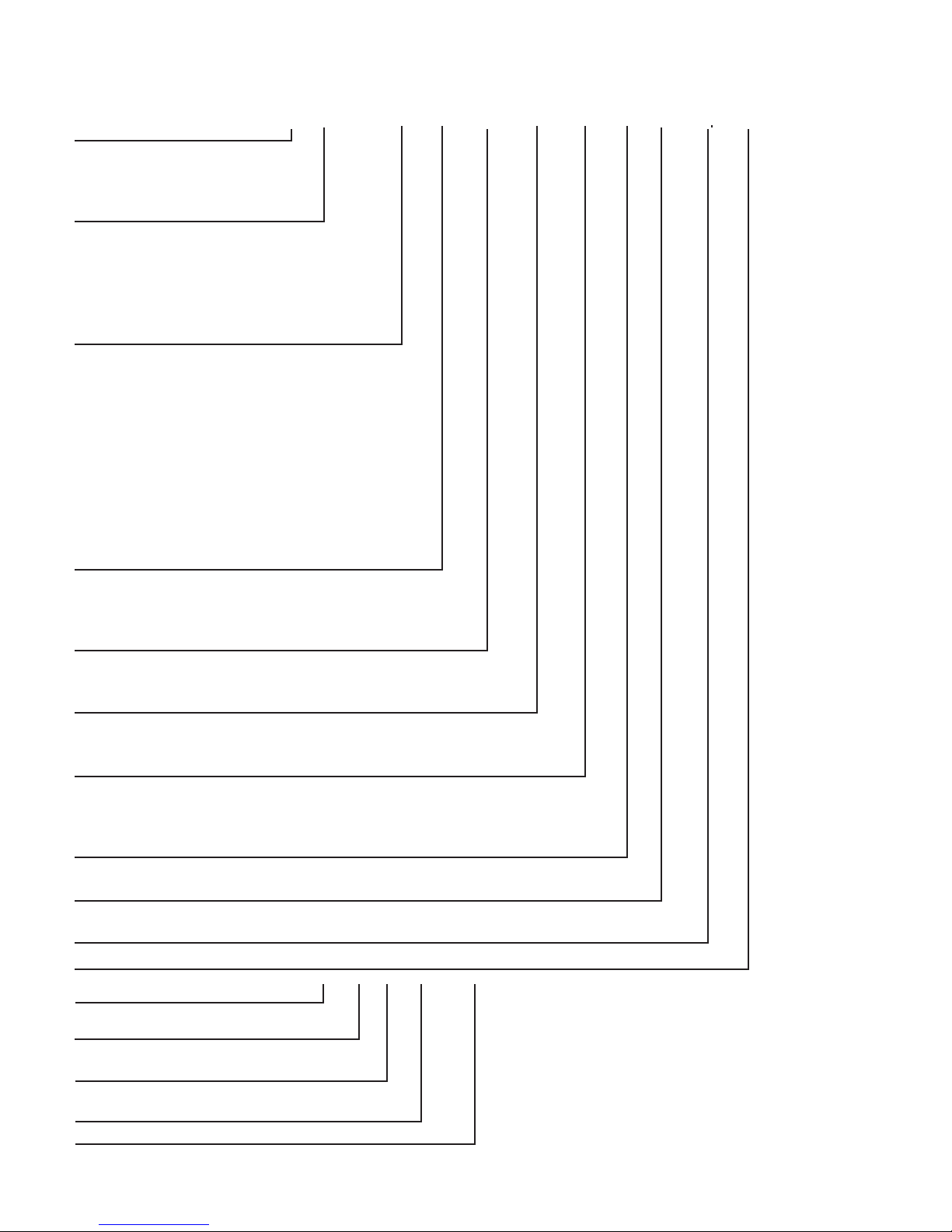

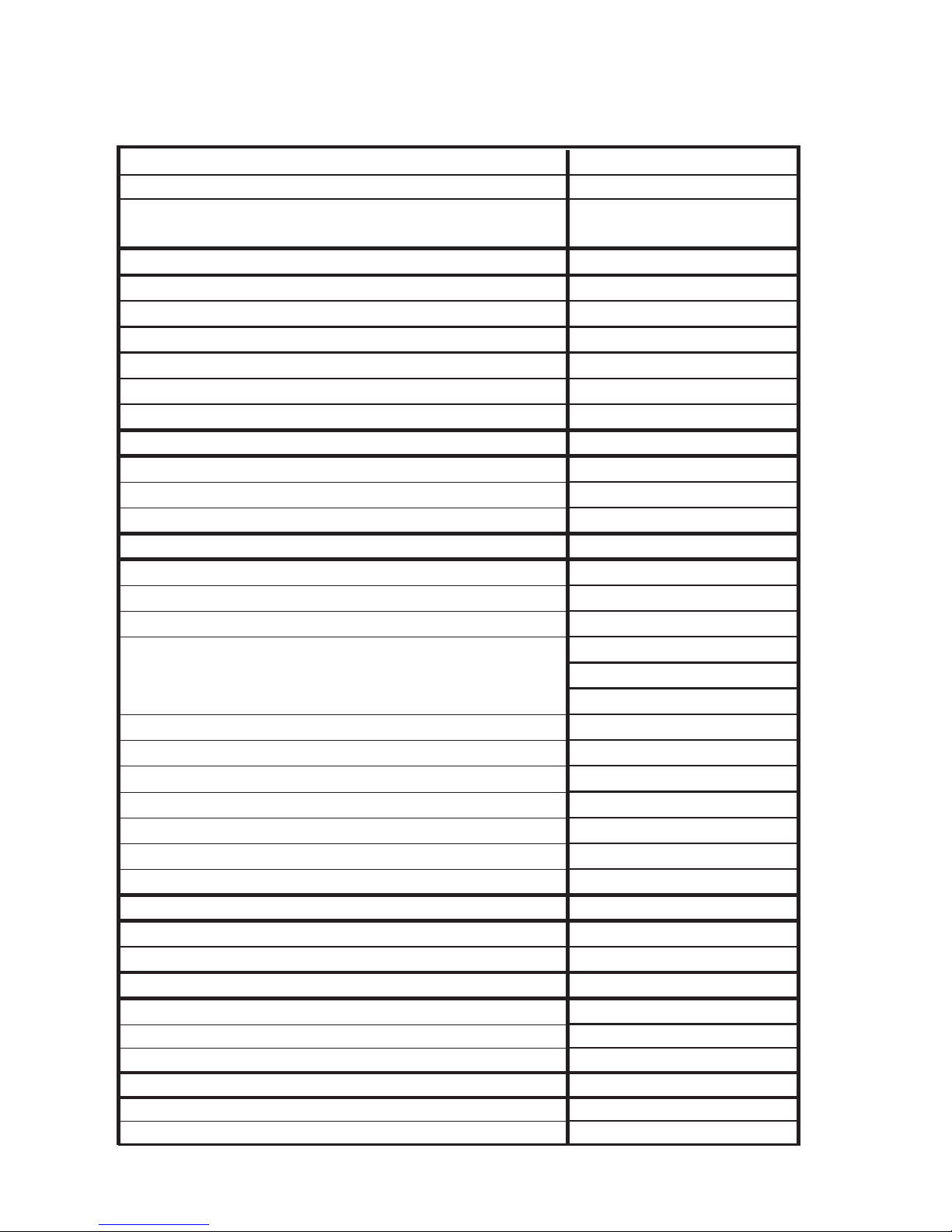

TABLE OF CONTENTS

Page

GENERAL .............................................................................................................................. 1-1

Slide in Range Safety......................................................................................................... 1-1

Model & Serial Number Designations ................................................................................ 1-2

Model & Serial Number Label And Wiring Diagram Locations ........................................... 1-3

Specications ..................................................................................................................... 1-4

INSTALLATION INFORMATION ............................................................................................ 2-1

Installation Requirements................................................................................................... 2-1

Location Requirements ...................................................................................................... 2-2

Product Dimensions ........................................................................................................... 2-3

Cabinet Dimensions ........................................................................................................... 2-3

Electrical Requirements ..................................................................................................... 2-4

Installation Instructions....................................................................................................... 2-6

PRODUCT OPERATION ....................................................................................................... 3-1

Display ............................................................................................................................... 3-1

Cancel ................................................................................................................................ 3-1

Clock .................................................................................................................................. 3-1

Control Lock ....................................................................................................................... 3-2

Oven Temperature Control ................................................................................................. 3-2

COMPONENT ACCESS ................................................................................................... 4-1

Component Locations ........................................................................................................ 4-1

Removing The EOC Assembly ........................................................................................... 4-2

Removing An LED and Innite Switch................................................................................ 4-3

Removing Cooktop and Coil Element Receptacles ........................................................... 4-4

Removing Rear Panel ........................................................................................................ 4-6

Removing A Cooling Fan And Oven Light Socket .............................................................. 4-7

Removing Broil Element..................................................................................................... 4-8

Removing Bake Element.................................................................................................... 4-9

Removing The Oven Temperature Sensor ....................................................................... 4-10

Removing The Oven TOC .................................................................................................4-11

Removing Door Latch Assembly ...................................................................................... 4-12

Removing And Reinstalling The Oven Door ..................................................................... 4-14

Removing An Oven Hinge ................................................................................................ 4-15

Removing The Decorative Glass, Oven Door Handle And The Oven Door Glass ........... 4-16

Removing Oven Door Seal .............................................................................................. 4-18

- iii -

COMPONENT TESTING ........................................................................................................ 5-1

Innite Switch ..................................................................................................................... 5-1

Oven Temperature Sensor ................................................................................................. 5-2

Oven TOD .......................................................................................................................... 5-2

Bake Element ..................................................................................................................... 5-3

6 Inch & 8 Inch Coil Elements ............................................................................................ 5-3

Broil Element ...................................................................................................................... 5-4

Cooling Fan Motor.............................................................................................................. 5-4

Door Latch Assembly Switch.............................................................................................. 5-5

DIAGNOSTICS & TROUBLESHOOTING ............................................................................. 6-1

Error Codes ........................................................................................................................ 6-1

"Quick Test" Mode for Electronic Range Control ................................................................ 6-4

Hidden Functions ............................................................................................................... 6-5

WIRING DIAGRAMS ............................................................................................................. 7-1

Cooktop Control Circuit ...................................................................................................... 7-2

Oven Control Circuit ........................................................................................................... 7-2

- iv -

GENERAL

DANGER

WARNING

SLIDE-RANGE SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on the appliance.

Always read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word

“DANGER” or “WARNING.” These words mean:

You can be killed or seriously injured if you don’t

immediately follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance

of injury, and tell you what can happen if the instructions are not followed.

1-1

MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER R Y 1 6 0 L X T W 0

PRODUCT IDENTIFICATION

R = ELECTRIC RANGES

S = GAS RANGES

G = WHIRLPOOL GOLD

PRODUCT IDENTIFICATION

A = ACCESSORY K = KITS

B = BUILT-IN M = MV COMBO

C = COOK TOP S = SET-IN

E = EYE-LEVEL W = GAS SLIDE-IN

F = FREE-STANDING Y = ELEC SLIDE-IN

MODEL SIZE

0 = 20" OR 24" FREE-STANDING

1 = 24" OR 27" BUILT-IN OVEN (BEFORE 1996)

1 = 30" IMPERIAL SERIES FREESTANDING

(1996 AND LATER)|

2 = 30" BUILT-IN OVEN (BEFORE 1996)

2 = 30" FREE-STANDING(1996 AND LATER)

3 = 30" FREE-STANDING

4 = 40" FREE-STANDING

5 = 36" FREE-STANDING

6 = 30" SET-IN RANGES

OVEN TYPE (DOES NOT APPLY TO COUNTERTOPS)

0 THRU 3 = STANDARD PORCELAIN

2 THRU 5 = CONTINUOUS CLEAN (BEFORE 1996)

4 THRU 9 = PYROLYTIC SELF-CLEAN

FE ATURE/ VARI AT I O NS

ELECTRIC

0,1,2,5,7 = COIL ELEMENTS

DOOR TYPE

B = SOLID BLACK GLASS 0 = METAL OVEN DOOR

L = LARGE WINDOW P = STANDARD WINDOW GLASS

FEATURE CODE

E = ELECTRONIC IGNITION (GAS ONLY) X = NOT DEFINED

S = STANDING IGNITION (GAS ONLY)

C = COLOR COORDINATED GLASS (BEFORE 1998)

YEAR OF INTRODUCTION

T = 2007

COLOR CODE

W = White

ENGINEERING CHANGE (NUMERIC)

SERIAL NUMBER FM U 24 01234

DIVISION RESPONSIBILITY

FM = CLEVELAND

YEAR OF PRODUCTION

U = 2007

WEEK OF PRODUCTION

24 = 24TH WEEK

PRODUCT SEQUENCE NUMBER

1-2

MODEL & SERIAL NUMBER LABEL

AND WIRING DIAGRAM LOCATIONS

The Model/Serial Number label and Wiring Diagram locations are shown below.

Wiring Diagram Location

(On Back Side Of Storage Drawer)

Model & Serial Number

Label Location

1-3

SPECIFICATIONS

RS160LXT, RY160LXT

Color Q (wht), B (Blk), S (SS)

Slide-In

30” Electric Coil, Pyro

COOKTOP

lioCecafruS gnikooC

4stnemelE fo rebmuN

emorhC slwoB pirD

FL ,RR)nrut 3( lioC "6

RL ,FR)nruT 4( lioC "8

2sthgiL rotacidnI

Controls

DELyalpsiD fo epyT

1remiT nehctiK

seYtuO kcoL lortnoC

OVEN

naelC fleSnaelC fo epyT

seYnaelC yaleD

oNnoitcevnoC

seYedoM htabbaS

seYmraW peeK

seYdloH & kooC

launaMmsinahceM kcoL rooD

oNgniliorb rood desolC

seYtnemele liorB desseceR

6sessaP fo rebmuN tnemelE liorB

oNdedulcnI naP liorB

launaMthgiL

nevO

Oven light type

Incandescent

Control Panel

4sbonK fo rebmuN

rekcoRhctiwS thgiL nevO

DOOR

dtSwodniW

SS no SS/ssalGhsiniF

seYsselemarF

Drawer

seYrewarD egarotS

tniaPhsiniF rewarD egarotS

Model

Model Description

1-4

INSTALLATION INFORMATION

INSTALLATION REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation. Read and follow the instructions

provided with any tools listed here.

Tools Needed

Tape measure•

Level•

Phillips screwdriver•

Flat-blade screwdriver•

Wrench or pliers•

3/8" nut driver•

Hand or electric drill•

1/8" (3.2 mm) drill bit•

Parts supplied

Check that all parts are included.

3 - 10–32 hex nuts (attached to terminal •

block)

3 - Terminal lugs•

2 - Oven racks•

2 - #12 x 1 5/8" screws (for mounting anti-tip •

bracket)

Anti-tip bracket (taped inside storage draw-•

er)

Anti-tip brackets must be securely mounted

toback wall or oor.Thickness of oor may

require longer screws to anchor

brackettosub-oor.Longerscrewsareavailable from your local hardware store.

Parts needed

If using a power supply cord:

A UL listed power supply cord kit marked for •

use with ranges.

The cord should be rated at 250 volts minimum,

40 amps or 50 amps that is marked for use with

nominal 1 3/8" (3.5 cm) diameter connection

opening and must end in ring terminals or open end spade terminals with upturned ends.

A UL listed strain relief.•

Check local codes. Check existing electrical

supply. See “Electrical Requirements” on page

2-5. It is recommended that all electrical connections should be made by a licensed, quali-

edelectricalinstaller.

2-1

Location Requirements

IMPORTANT: Observe all governing codes

and ordinances.

It is the installer’s responsibility to comply •

withinstallationclearancesspeciedonthe

model/serial rating plate. The model/serial

rating plate is located on the right-hand side

of the oven frame behind the storage drawer

panel.

The range should be located for convenient •

use in the kitchen.

Toeliminatetheriskofburnsorrebyreach-•

ing over heated surface units, cabinet storage space located above the surface units

should be avoided. If cabinet storage is to be

provided, the risk can be reduced by installing a range hood that projects horizontally a

minimum of 5" (12.7 cm) beyond the bottom

of the cabinets.

Cabinet opening dimensions that are shown •

must be used. Given dimensions are minimum

clearances.

Theooranti-tipbracketmustbeinstalled.•

To install the antitip bracket shipped with

the range, see “Install Anti-Tip Bracket”

section.

Grounded electrical supply is required. See •

“Electrical Requirements” section.

IMPORTANT: To avoid damage to your cabinets, check with your builder or cabinet supplier

to make sure that the materials used will not discolor, delaminate or sustain other damage. This

oven has been designed in accordance with the

requirements of UL and CSA International and

complies with the maximum allowable wood

cabinet temperatures of 194°F (90°C).

Mobile Home - Additional Installation Requirements

Mobile home installations require:

When this range is installed in a mobile •

home,itmustbesecuredtotheoorduring

transit. Any method of securing the range

is adequate as long as it conforms to the

standards listed above.

Four-wire power supply cord or cable must •

be used in a mobile home installation. The

appliance wiring will need to be revised. See

“Electrical Connection” on page 2-5.

The installation of this range must conform

to the Manufactured Home Construction and

Safety Standard, Title 24 CFR, Part 3280 (formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24, HUD Part

280). When such standard is not applicable, the

Standard for Manufactured Home Installations,

ANSI A225.1/NFPA 501A or with local codes.

2-2

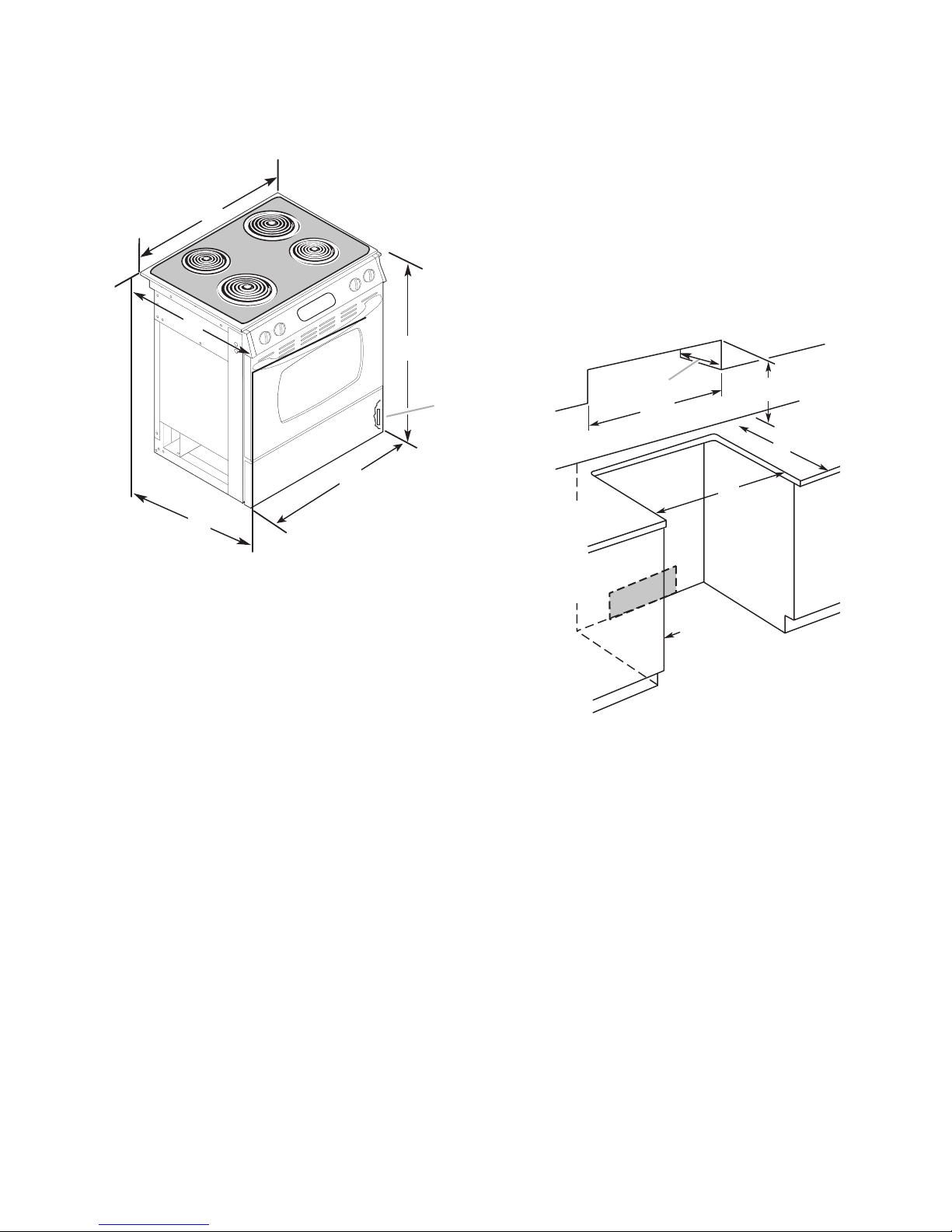

Product Dimensions

A. " (78 cm)

B. 35 " (90.8 cm) height to underside

of cooktop edge with leveling legs

screwed all the way in*

C. Model/serial number plate (located

behind the storage drawer on the

right-hand side of the oven frame

D. 29 " (75.9 cm)

E. 28 " (75.9 cm) from

handle to stando at back

of range**

F. 23 " (60.3 cm)

countertop notch to rear

of cooktop

C

B*

A

D

E**

F

A. 13" (33 cm) upper cabinet

depth

B. 30" (76.2 cm) min. opening

width

C. For minimum clearance to the

top of the cooktop,

see NOTE*.

D. 23 " (58.1 cm) opening

depth

E. 30" (76.2 cm) min. opening

width

F. Junction box - 5.5" (14 cm)

min. from either cabinet,

10" (25.4 cm) max. from oor

Outlet must be ush.

Nothing located in shaded

area can extend more than

2" (5.1 cm) from wall or range

will not slide all the way back.

G. Cabinet door or hinge should

not extend into cutout.

A

B

C

D

E

F

G

Cabinet Dimensions

Cabinet opening dimensions shown are for 25"

(64 cm) countertop depth, 24" (61 cm) base

cabinet depth and 36" (91.4 cm) countertop

height.

If installing a range hood or microwave hood

combination above the range, follow the range

hood or microwave hood combination installation instructions for dimensional clearances

above the cooktop surface.

*Range can be raised approximately 1" (2.5

cm) by adjusting the leveling legs.

**When installed in a 24" (61 cm) base cabinet

with 25" (63.5 cm) countertop; front of oven

door protrudes 2 1/2" (6.4 cm) beyond 24" (61

cm) base cabinet.

NOTE: 24" (61 cm) minimum when bottom of

wood or metal cabinet is protected by not less

than1/4"(0.64cm)ame retardantmillboard

covered with not less than No. 28 MSG sheet

steel, 0.015" (0.4 mm) stainless steel, 0.024" (0.6

mm) aluminum or 0.020" (0.5 mm) copper.

30" (76.2 cm) minimum clearance between the

top of the cooking platform and the bottom of

an unprotected wood or metal cabinet

2-3

Electrical Requirements

If codes permit and a separate ground wire is

used,itisrecommendedthataqualiedelectrical installer determine that the ground path

is adequate and wire gauge is in accordance

with local codes.

Do not use an extension cord.

Be sure that the electrical connection and wire

size are adequate and in conformance with the

National Electrical Code, ANSI/ NFPA 70-latest

edition and all local codes and ordinances.

Allow 2 to 3 ft (61.0 cm to 91.4 cm) of slack •

in the line so that the range can be moved if

servicing is ever necessary.

A UL listed conduit connector must be pro-•

vided at each end of the power supply cable

(at the range and at the junction box).

Wire sizes and connections must conform •

with the rating of the range (40 amps).

The wiring diagram is located on the un-•

derside of the storage drawer or below the

warming drawer in a clear plastic bag.

If using a power supply cord:

A copy of the above code standards can be

obtained from:

National Fire Protection Association

One Battery march Park

Quincy, MA 02269

Electrical Connection

To properly install your range, you must determine the type of electrical connection you will

be using and follow the instructions provided

for it here.

Range must be connected to the proper •

electricalvoltageandfrequencyasspecied

on the model/serial number rating plate. (The

model/serial number rating plate is located

on the oven frame behind the storage drawer

panel.)

When a 4-wire or 3-wire, single phase 120/240 •

volt, 60 Hz, AC only electrical supply is available, a 50-amp maximum circuit protection is

required(or,ifspeciedonthemodel/serial

rating plate, when a 4-wire or 3-wire single

phase 120/208 volt 60 Hz, AC only electrical

supply is available, a 40- or 50-amp maximum

circuit protection is required), fused on both

sides of the line.

A time-delay fuse or circuit breaker is recom-•

mended.

The range can be connected directly to the •

fused disconnect (or circuit breaker box)

through exible or nonmetallic sheathed,

copper or aluminum cable. See “Electrical

Connection.”

A UL listed power supply cord kit marked for •

use with ranges. The cord should be rated

at 250 volts minimum, 40 amps or 50 amps

that is marked for use with nominal 1 3/8"

(3.5 cm) diameter connection opening and

must end in ring terminals or open-end spade

terminals with upturned ends.

A UL listed strain relief.•

If connecting to a 4-wire system:

This range is manufactured with the ground

connected to the cabinet. The ground must be

revised so the green ground wire of the 4-wire

power supply cord is connected to the cabinet.

See “Electrical Connection.”

Grounding through the neutral conductor is

prohibited for new branch-circuit installations

(1996 NEC); mobile homes; and recreational

vehicles, or an area where local codes prohibit

grounding through the neutral conductor.

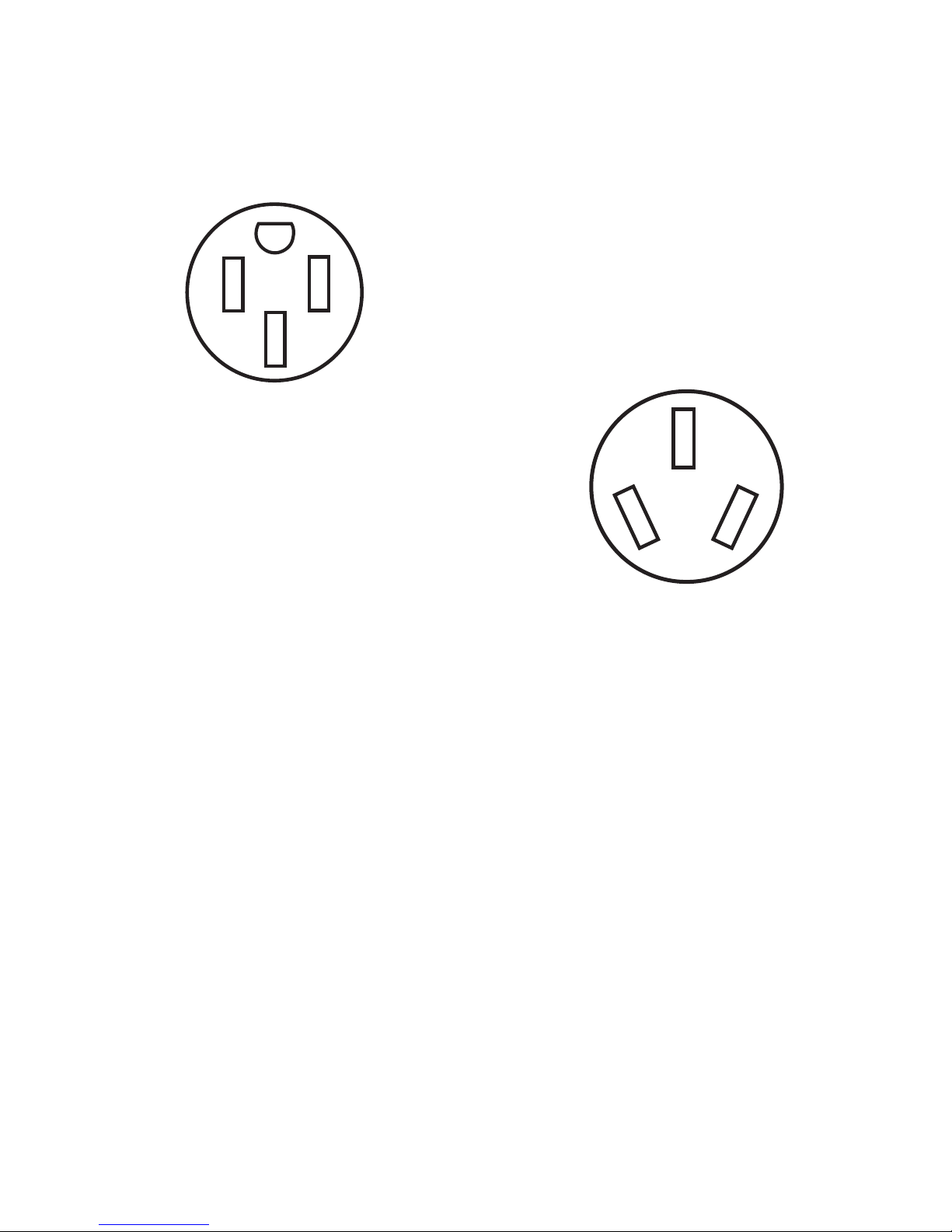

When a 4-wire receptacle of NEMA Type 14-50R

is used, a matching UL listed, 4-wire, 250 volt,

40-amp, range power supply cord (pigtail) must

be used. This cord contains 4 copper conductors

with ring terminals or open-end spade terminals

with upturned ends, terminating in a NEMA Type

14-50R plug on the supply end.

T h e f o u r t h ( g r o u n d i n g ) c o n d u c t o r m u s t b e i d e n t i -

edbyagreenorgreen/yellowcoverandthe

neutral conductor by a white cover.

2-4

The cord should be Type SRD or SRDT with a

4-wire receptacle (14-50R)

3-wire receptacle (10-50R)

UL listed strain relief and be at least 4 ft (1.22

m) long.

The minimum conductor sized for the copper

4-wire power cord are:

If connecting to a 3-wire system:

Local codes may permit the use of a UL listed,

3-wire, 250 volt, 40-amp range power supply

cord (pigtail). This cord contains 3 copper conductors with ring terminals or open-end spade

terminals with upturned ends, terminating in a

NEMA Type 10-50P plug on the supply end.

Connectors on the appliance end must be provided at the point the power supply cord enters

the appliance. This uses a 3-wire receptacle of

NEMA Type 10-50R.

40-amp circuit

2 No.-8 conductors

1 No.-10 white neutral

1 No.-8 green grounding

2-5

INSTALLATION INSTRUCTIONS

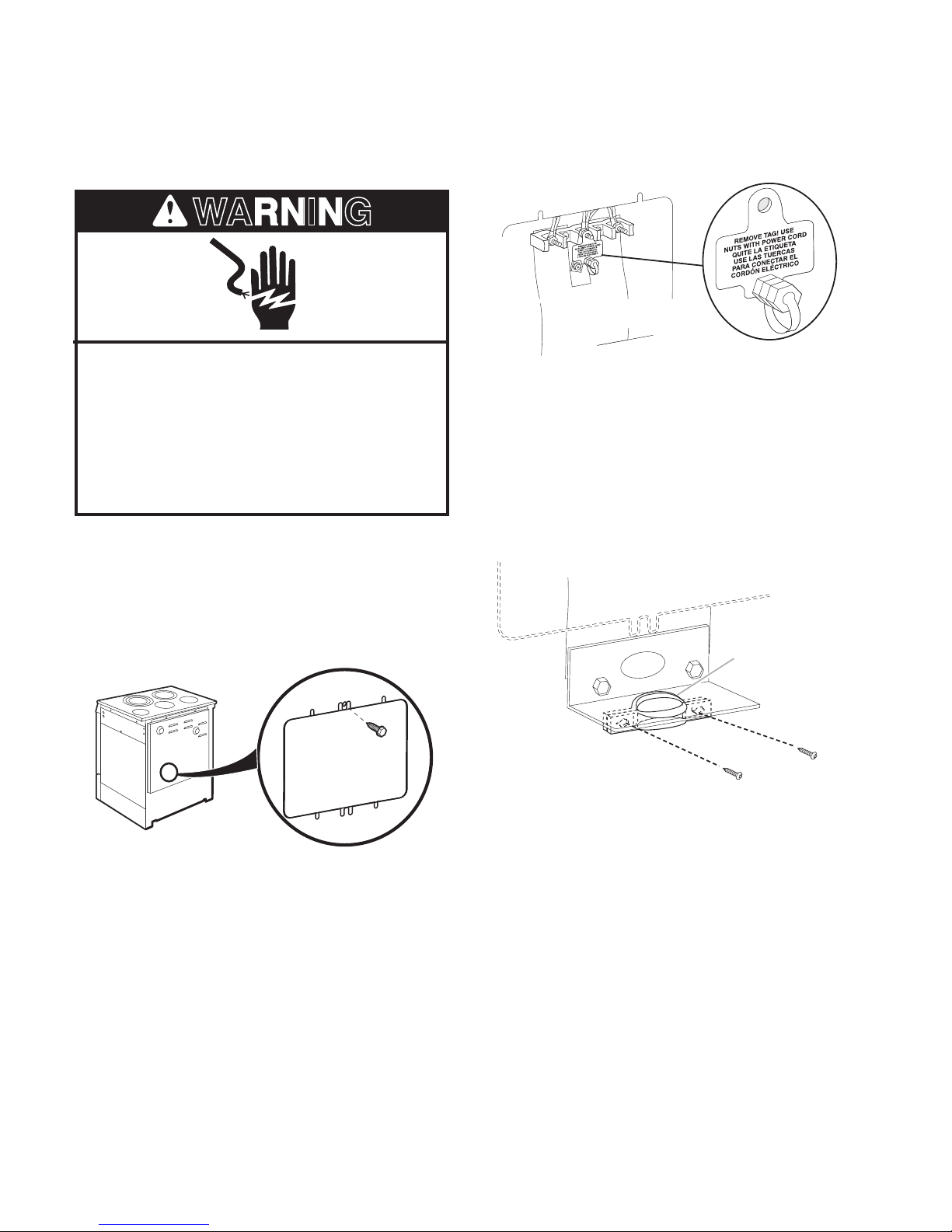

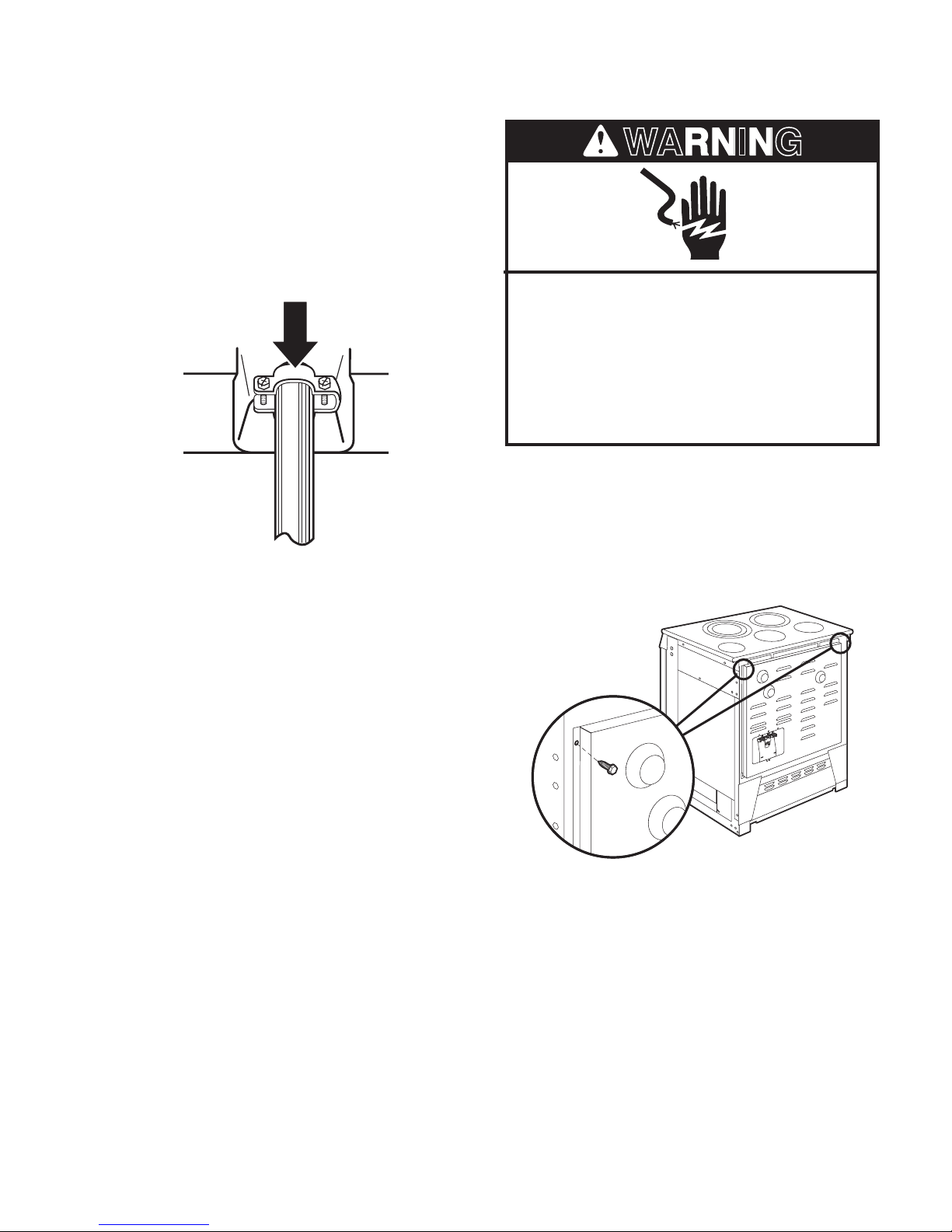

WARNING

A. UL listed strain relief

A

Electrical Connection

Power Supply Cord

Electrical Shock Hazard

Disconnect power before servicing.

Use a new 40 amp power supply cord.

Plug into a grounded outlet.

Failure to follow these instructions can

result in death, re, or electrical shock.

1. Disconnect power.

2. Use Phillips screwdriver to remove the

terminal block cover screw located on the

back of the range. Pull cover down and

toward you to remove cover.

4. Add strain relief.

Style 1: Power supply cord strain relief

Assemble a UL listed strain relief in the •

opening.

3. Remove plastic tag holding three 10-32

hex nuts from the middle post of the terminal block.

2-6

WARNING

Feed the power supply cord through the •

R

E

M

O

V

E

T

A

G

!

U

S

E

N

UTS

W

I

T

H

PO

W

E

R

C

O

R

D

Q

U

I

T

E

L

A

E

T

I

Q

U

E

T

A

U

S

E

LA

S

T

U

E

R

C

A

S

P

A

RA

C

O

NE

CT

A

R

E

L

C

O

R

D

Ó

N

EL

É

C

T

R

I

C

O

R

E

M

O

V

E

T

A

G

!

U

S

E

N

UTS

W

I

T

H

PO

W

E

R

C

O

R

D

Q

U

I

T

E

L

A

E

T

I

Q

U

E

T

A

P

A

RA

C

O

NE

CTA

R

E

L

C

O

R

D

Ó

N

EL

É

C

T

R

I

C

O

opening in the cord/conduit plate on bottom

of range. Allow enough slack to easily attach

the wiring to the terminal block.

Tighten strain relief screw against the power •

supply cord.

Direct Wire

Electrical Shock Hazard

Disconnect power before servicing.

Use 8 gauge copper wire.

Electrically ground cooktop.

Failure to follow these instructions can

result in death, re, or electrical shock.

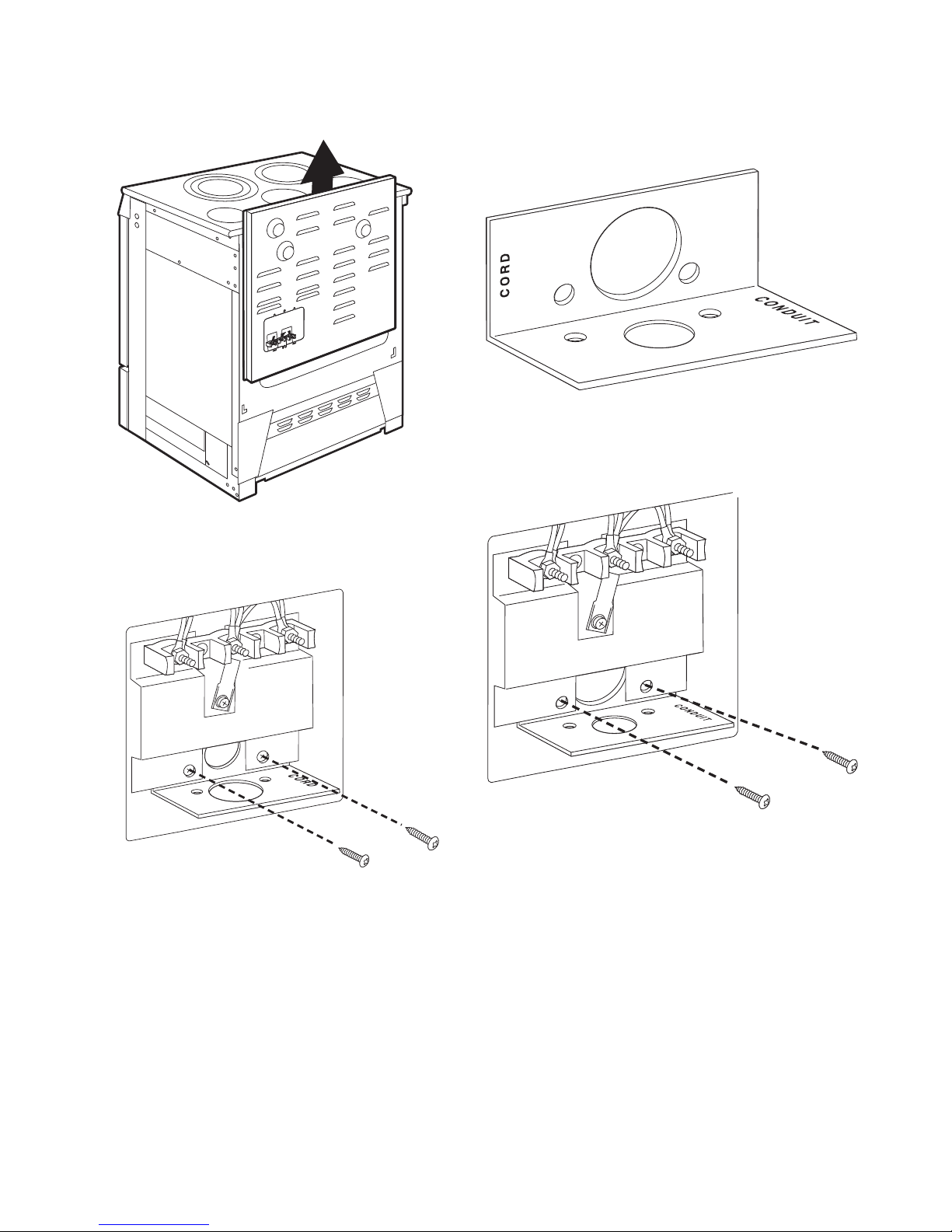

Style 2: Direct wire strain relief

Use Phillips screwdriver to remove screws •

from panel on back of range.

2-7

Lift range back panel up and off.•

R

EM

O

V

E

T

A

G

!

U

S

E

N

U

T

S

W

I

T

H

P

O

W

E

R

C

O

R

D

Q

U

I

T

E

L

A

E

T

I

Q

U

E

TA

U

S

E

L

A

S

T

U

E

R

C

A

S

PA

R

A

C

O

NE

C

T

A

R

E

L

C

OR

D

Ó

N

E

L

É

C

T

R

I

C

O

R

EM

O

V

E

T

A

G

!

U

S

E

N

U

T

S

W

I

T

H

P

O

W

E

R

C

O

R

D

Q

U

I

T

E

L

A

E

T

I

Q

U

E

T

A

P

A

R

A

C

O

N

E

C

T

A

R

E

L

C

O

R

D

Ó

N

E

L

É

C

T

R

I

C

O

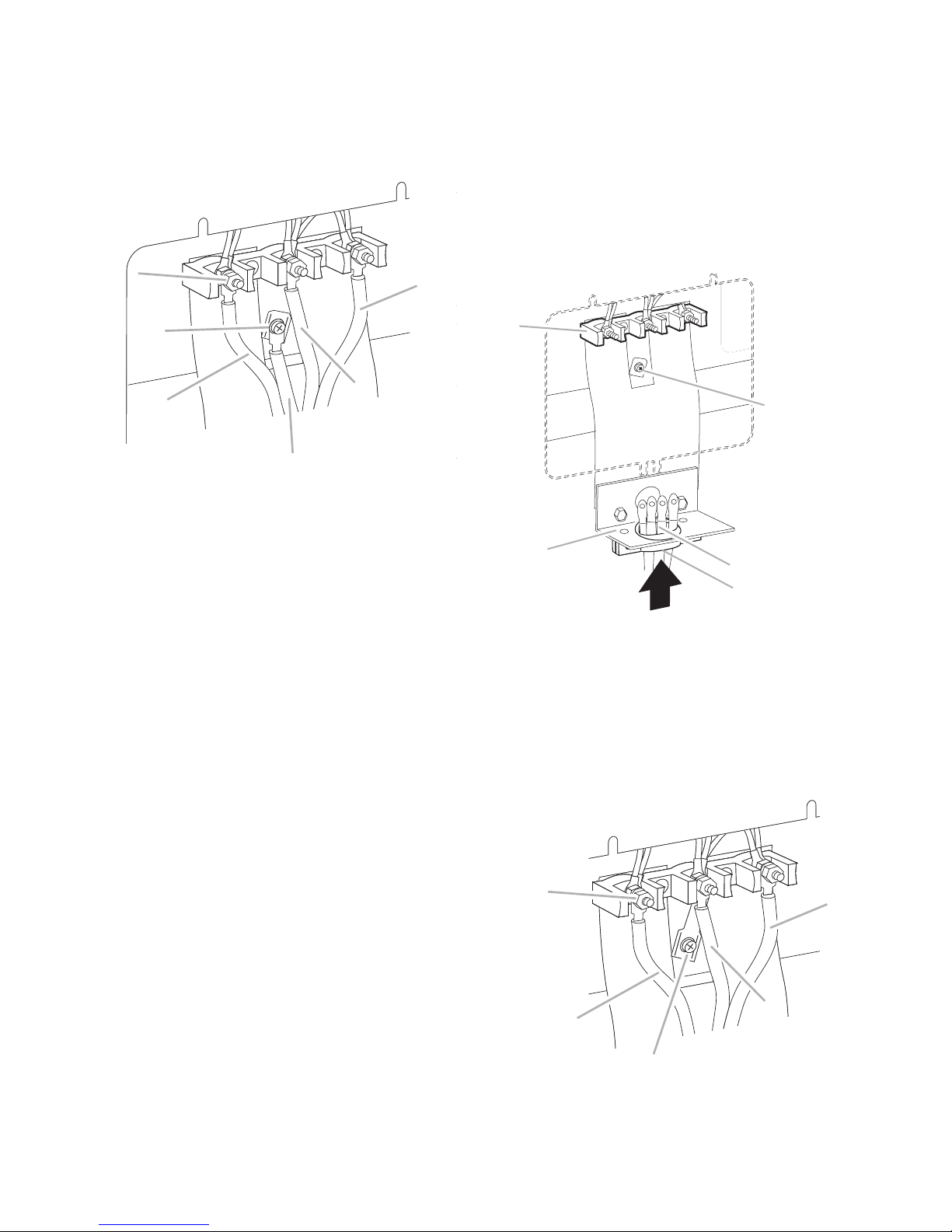

Use Phillips screwdriver to remove screws •

and slide cord/conduit plate down and out.

Position cord/conduit plate as shown in the •

following illustration.

Replace cord/conduit plate and insert •

screws.

2-8

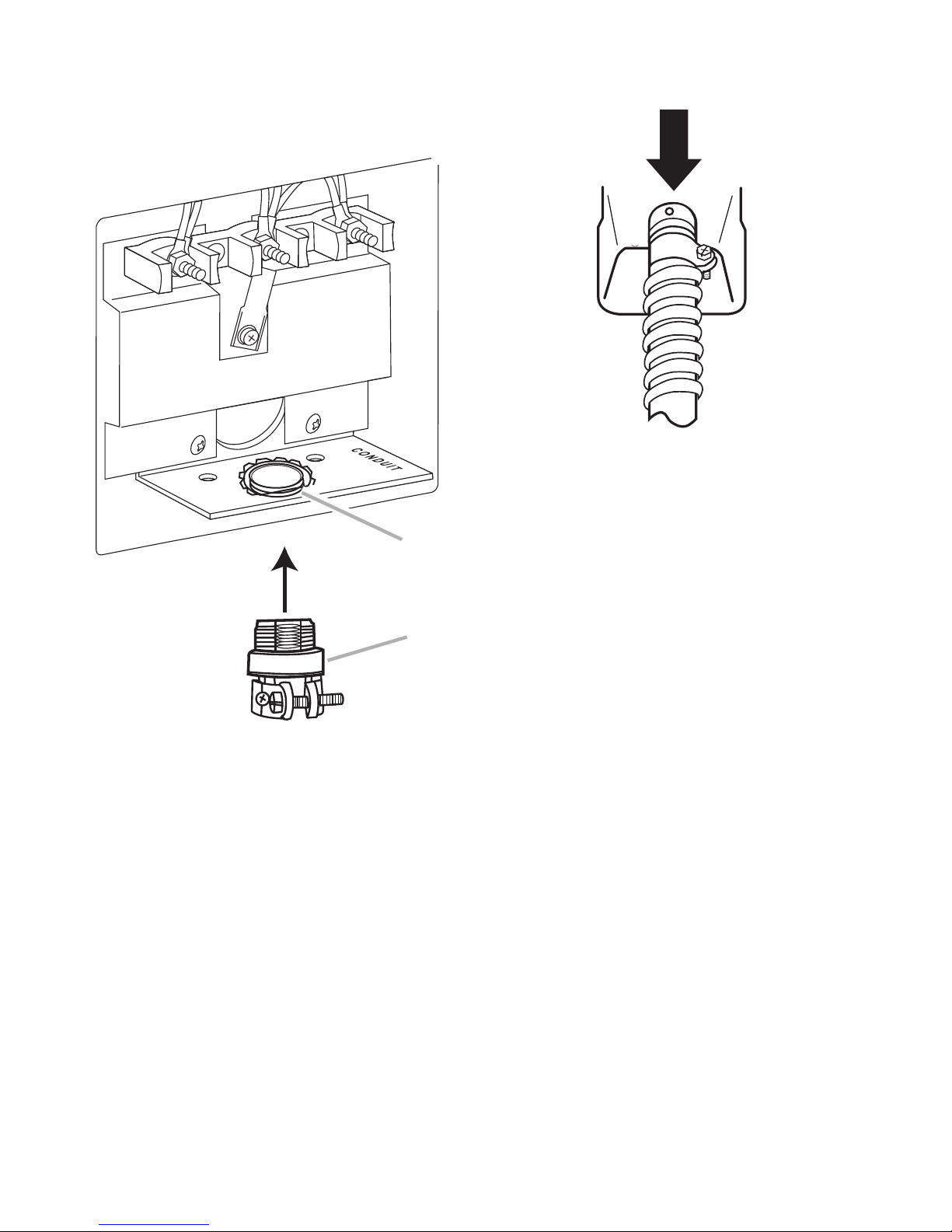

Assemble a UL listed conduit connector in •

A. Removable retaining nut

B. Strain relief

A

B

the opening.

5. Replace back panel and screws on rear of

range.

6. Complete installation following instructions

for your type of electrical connection:

Feedtheexibleconduitthroughthestrain•

relief, allowing enough slack to easily attach

wiring to the terminal block.

Tightenstrainreliefscrewagainsttheex-•

ible conduit.

4-wire (recommended)

3-wire (if 4-wire is not available)

2-9

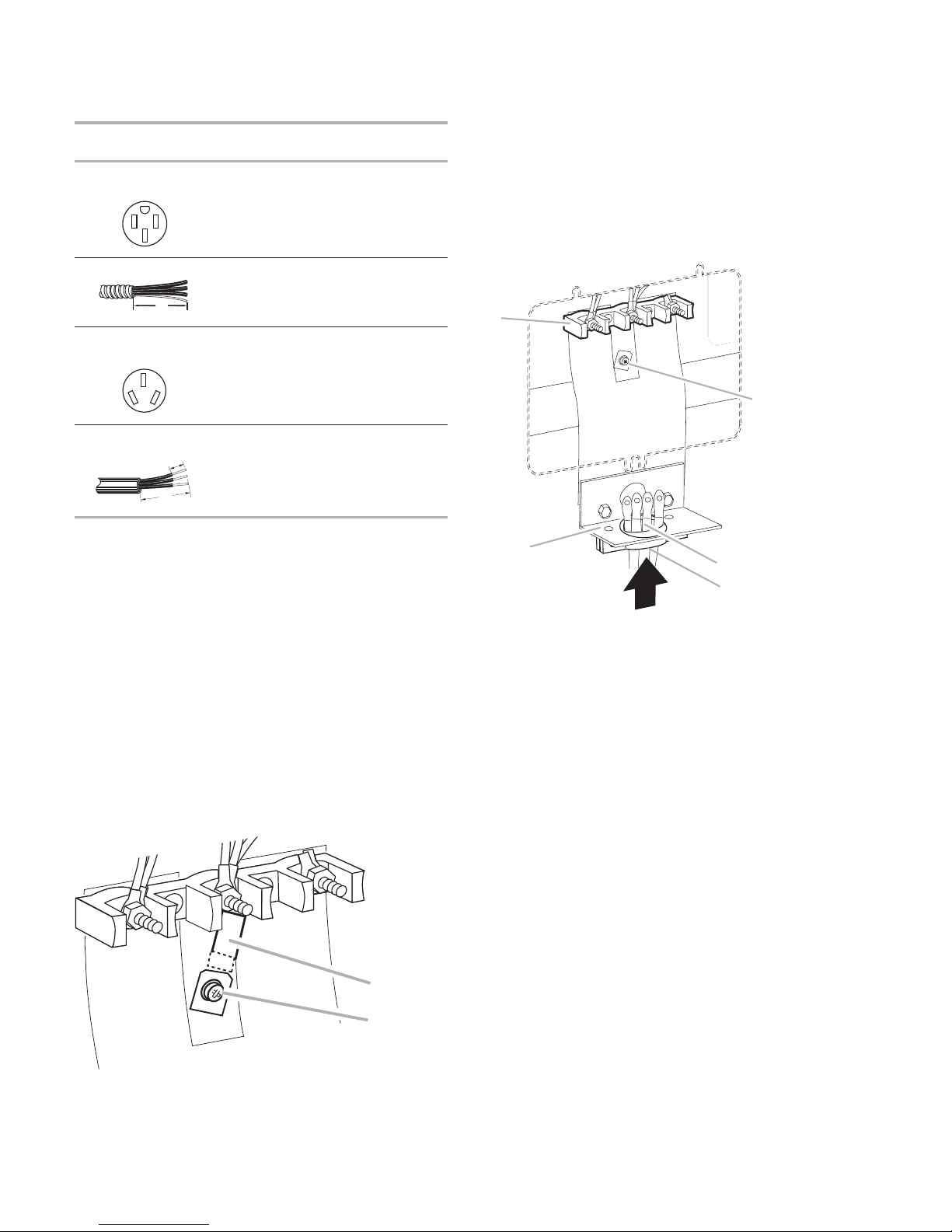

Electrical Connection Options

If your home has: And you will be

connecting to:

Go to Section:

4-wire receptacle

(NEMA type 14-50R)

A UL listed,

250-volt

minimum,

40-amp, range

power supply

cord

4-wire connection:

Power supply cord

4-wire direct A fused

disconnect or

circuit breaker

box

4-wire connection:

Direct wire

3-wire receptacle

(NEMA type 10-50R)

A UL listed,

250-volt

minimum,

40-amp, range

power supply

cord

3-wire connection:

Power supply cord

3-wire direct A fused

disconnect or

circuit breaker

box

3-wire connection:

Direct wire

(12.7 cm)

5"

3"

(7.6 cm)

1"

(2.5 cm)

A. Metal ground strap

B. Ground-link screw

A

B

A. Terminal block

B. Ground-link screw

C. Cord/conduit plate

D. Power supply cord wires

E. Strain Relief

A

B

C

D

E

2. Use Phillips screwdriver to remove the

ground-link screw from the back of the

range. Save the ground-link screw.

3. Feed the power supply cord through the

opening in the cord/conduit plate on bottom of range. Allow enough slack to easily

attach the wiring to the terminal block.

4-wire connection: Power Supply Cord

Use this method for:

New branch-circuit installations (1996 •

NEC)

Mobile homes•

Recreational vehicles•

I n a n a r e a w h e r e l o c a l c o d e s p r o h i b i t g r o u n d -•

ing through the neutral

1. Part of metal ground strap must be cut out

and removed.

4. Use Phillips screwdriver to connect the

green ground wire from the power supply cord to the range with the ground-link

screw. The ground wire must be attached

rst.

2-10

5. Use 3/8" nut driver to connect the neutral

A. 10–32 hex nut

B. Ground-link screw

C. Line 1 (black)

D. Green ground wire

E. Neutral (center) wire

F. Line 2 (red)

A

B

C

F

D

E

A. Terminal block

B. Ground-link screw

C. Cord/conduit plate

D. Power supply cord wires

E. Strain Relief

A

B

C

D

E

A. 10–32 hex nut

B. Line 1 (black)

C. Ground-link screw

D. Neutral (white) wire

E. Line 2 (red)

A

B

C

D

E

(white) wire to the center terminal block

post with one of the 10–32 hex nuts.

3-wire connection: Power Supply Cord

Use this method only if local codes permit connecting chassis ground conductor to neutral

wire of power supply cord.

1. Feed the power supply cord through the

opening in the cord/conduit plate on bottom of range. Allow enough slack to easily

attach the wiring to the terminal block.

6. Connect line 1 (black) and line 2 (red) wires

to the outer terminal block posts with 10-32

hex nuts.

7. Securely tighten hex nuts.

NOTE: For power supply cord replacement, only

use a power cord rated at 250 volts minimum,

40 amps or 50 amps that is marked for use

with nominal 3/8" (3.5 cm) diameter connection opening, with ring terminals and marked

2. Use 3/8" nut driver to connect the neutral

(white) wire to the center terminal block post

with one of the 10–32 hex nuts.

for use with ranges.

8. Replace terminal block access cover.

2-11

Loading...

Loading...