Whirlpool MH6140XKQ/B, MH6141XKQ/B, MHE14XKQ/B User Manual

CONSUMER SERVICES TECHNICAL

EDUCATION GROUP PRESENTS

MICROWAVE

OVEN HOOD

COMBINATION

KM-27

JOB AID

Part No. 8178053

FORWARD

This Job Aid, “Whirlpool Microwave Oven Hood Combination,” (Part No.8178053 ), provides the

technician with information on the operation and service of the Whirlpool Microwave Oven Hood

Combination. It is to be used as a training Job Aid and Service Manual. For specific information

on the model being serviced, refer to the “Use and Care Guide,” or “Tech Sheet” provided with the

microwave oven.

The Wiring Diagrams and Strip Circuits used in this Job Aid are typical and should be used for

training purposes only. Always use the Wiring Diagram supplied with the product when servicing

the unit.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair the Microwave Oven Hood Combination.

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the microwave oven to proper operational status.

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made

on our products by anyone other than Authorized Factory Service Technicians.

Copyright © 2001, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

TABLE OF CONTENTS

Page

GENERAL............................................................................................................................... 1-1

Important Safety Information ................................................................................................ 1-1

Warning To Service Technicians ......................................................................................... 1-2

Precautions To Be Observed Before And During Servicing To Avoid

Possible Exposure To Excessive Microwave Energy ....................................................... 1-3

R.F. Leakage Test................................................................................................................ 1-4

Whirlpool Model & Serial Number Designations .................................................................. 1-5

Model & Serial Number Label And Tech Sheet Locations ................................................... 1-6

Specifications ....................................................................................................................... 1-7

Whirlpool Microwave Oven Warranty ................................................................................. 1-11

THEORY OF OPERATION ..................................................................................................... 2-1

The Vent Motor Mounting Positions ..................................................................................... 2-1

The Oven Thermostat & Vent Motor Capacitor .................................................................... 2-2

The Vent & Turntable Motors ............................................................................................... 2-3

COMPONENT ACCESS ......................................................................................................... 3-1

Component Locations .......................................................................................................... 3-1

Removing The Turntable Motor & Cooktop Lamp Assembly ............................................... 3-2

Removing The Control Panel & Control Board .................................................................... 3-4

Removing The Door Switches.............................................................................................. 3-6

Removing The Oven Lamp Assembly.................................................................................. 3-7

Removing The Oven Thermostat, Line Fuse, & Power Cord ............................................... 3-8

Removing The Vent Motor Capacitor, The High

Voltage Capacitor, & Rectifier ......................................................................................... 3-10

Removing The High Voltage Transformer.......................................................................... 3-11

Removing The Magnetron.................................................................................................. 3-12

Removing The Vent Motor ................................................................................................. 3-13

Removing The Oven Door, The Switch Actuators,

And The Outer Glass ...................................................................................................... 3-14

COMPONENT TESTING ........................................................................................................ 4-1

Touch Panel Continuity ........................................................................................................ 4-1

The Turntable & Vent Motors ............................................................................................... 4-2

The Vent Motor Capacitor, Line Fuse, Oven Thermostat,

& Door Switch ................................................................................................................... 4-3

The High Voltage Capacitor & Rectifier ............................................................................... 4-4

The High Voltage Transformer ............................................................................................. 4-5

The Magnetron ..................................................................................................................... 4-6

WIRING DIAGRAM & STRIP CIRCUITS ............................................................................... 5-1

Wiring Diagram .................................................................................................................... 5-1

Strip Circuits ......................................................................................................................... 5-2

- iii -

— NOTES —

- iv -

GENERAL

IMPORTANT SAFETY INFORMATION

Your safety and the safety of others is very important.

Important safety messages have been provided in this Job Aid. Always read and obey all

safety messages.

This is the safety alert symbol.

This symbol alerts you to hazards that can kill or hurt you

and others.

All safety messages will be preceded by the

safety alert symbol and the word “WARNING.”

All safety messages will identify the hazard, tell

you how to reduce the chance of injury, and tell

you what can happen if the instructions are not

followed.

WARNING

ELECTRICAL SHOCK HAZARD

Disconnect power before servicing.

Replace all panels before operating.

Failure to do so could result in death or

electrical shock.

IMPORTANT SAFETY

INSTRUCTIONS

Before touching any oven component or wiring, always unplug the oven from its power

source and discharge the capacitor by using a

20,000 ohm discharge resistor or use an insulated plastic handle screwdriver to short across

the capacitor terminals.

Check that the unit is grounded before troubleshooting. Be careful of the high voltage circuits.

Discharge any static charge from your body by

touching ground before handling any part of

the circuitry on the control board. Electrostatic

discharge may damage the control circuit.

Do not touch oven components or wiring during

operation. Attach meter leads with alligator

clips when making operational tests.

For continued protection against radiation

emission, replace only with these types of

switches: Primary (Interlock) Switch: SZM-V16FA-63 or VP-533A-OF; Secondary (Interlock)

Switch: SZM-V01-FA-32; Interlock (Monitor)

Switch: SZM-VI6-FA-62 or VP-532A-OF; Oven

Lamp Switch: SZM-V6-FA-31 or VP-331 AOD.

It is neither necessary nor advisable to attempt

measurement of high voltage.

Attaching the adaptor ground terminal to the

wall receptacle cover screw does not ground

the appliance unless the cover screw is metal

and not insulated and the wall receptacle is

grounded through the house wiring.

ELECTROSTATIC DISCHARGE

(ESD) SENSITIVE ELECTRONICS

ESD problems are present everywhere. ESD

may damage or weaken the electronic control assembly. The new control assembly

may appear to work well after repair is finished, but failure may occur at a later date

due to ESD stress.

• Use an antistatic wrist strap. Connect

the wrist strap to a green ground connection point or unpainted metal in the

appliance; or touch your finger repeatedly to a green ground connection point

or unpainted metal in the appliance.

• Before removing the part from its package, touch the antistatic bag to a green

ground connection point or unpainted

metal in the appliance.

• Avoid touching electronic parts or terminal contacts. Handle the electronic

control assembly by the edges only.

• When repackaging the failed electronic

control assembly in an antistatic bag,

observe the above instructions.

1-1

WARNING TO SERVICE TECHNICIANS

To avoid possible exposure to microwave radiation or energy, visually check the oven for

damage to the door and door seal before

operating any oven. Use a microwave survey

meter to check the amount of leakage before

servicing. In the event the R.F. Ieakage exceeds 4 mw/cm2 at 5 cm, appropriate repair

must be made before continuing to service the

unit. Check interlock function by operating the

door latch. The oven cook cycle should cut off

before the door can be opened.

The door and latching assembly contains the

radio frequency energy within the oven. The

door is protected by three safety interlock

switches. Do not attempt to defeat them.

Under no circumstances should you try to

operate the oven with the door open.

• Proper operation of microwave ovens requires that the magnetron be properly

assembled to the waveguide and cavity.

Never operate the magnetron unless it is

properly installed.

• Be sure the “RF” seal is not damaged and

is assembled around the magnetron dome

properly when installing the magnetron.

• Routine service safety procedures should

be exercised at all times.

• Untrained personnel should not attempt

service without a thorough review of test

procedures and safety information contained in this Job Aid.

Whirlpool microwave ovens have a monitoring

system designed to assure proper operation of

the safety interlock systems.

The interlock monitor switch will immediately

cause the oven fuse to blow if the door is

opened and the primary door interlock switch

and/or the secondary interlock switch contacts

fail in a closed position.

CAUTION: Replace a blown fuse with a 20

ampere class H fuse only.

Test the upper and lower door interlock

switches, cook relay and interlock monitor

switch (middle switch) for proper operation as

described in the component test procedures,

before replacing the blown oven fuse.

Do not attempt to repair sticking contacts

of any interlock switch, safety switch, or

Cook (Latch) relay. The components must

be replaced.

Any indication of sticking contacts during component tests requires replacement of that component to assure reliability of the safety interlock system.

If the fuse is blown, the Monitor, Primary,

and Secondary interlock switches must be

replaced. Be sure they are properly connected.

1-2

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING

SERVICING TO AVOID POSSIBLE EXPOSURE

TO EXCESSIVE MICROWAVE ENERGY

A. Do not operate or allow the oven to be

operated with the door open.

B. Make the following safety checks on all

ovens to be serviced before activating the

magnetron or other microwave source,

and make repairs as necessary:

1)Interlock Operation

2)Proper Door Closing

3)Seal and Sealing Surfaces (Arcing,

Wear, and Other Damage)

4)Damage to or Loosening of Hinges and

Latches

5)Evidence of Dropping or Abuse

C. Before turning on the microwave power

for any service test or inspection within the

microwave generating components, check

the magnetron, wave guide or transmission line, and cavity for proper alignment,

integrity, and connections.

D. Any defective or misadjusted components

in the interlock, monitor, door seal, and

microwave generation and transmission

systems shall be repaired, replaced, or

adjusted, using procedures described in

this Job Aid, before the oven is released to

the owner.

E. A microwave leakage check to verify com-

pliance with Federal Performance Standard should be performed on each oven

prior to release to the owner.

F. Do not attempt to operate the oven if the

door glass is broken.

1-3

R.F. LEAKAGE TEST

EQUIPMENT

• Electromagnetic energy leakage monitor

(NARDA 81 00B, HOLADAY H 1501 ).

• 275 ±15 ML glass beaker.

TEST

On every service call, checks for microwave

energy emission must be made according to

the following manner.

1. Remove the cooking rack from the oven

cavity, if the microwave oven is so

equipped.

2. Place a 275 ±15 ML (9.3 oz.) glass of

water in the center of the oven bottom.

3. Select "HIGH" cook power, turn the micro-

wave oven on, and test for R.F. Ieakage at

the following locations:

a)Around the cabinet at the front.

b)Around the door.

c) Across the console panel.

d)Horizontally across the door.

e)Vertically across the door.

f) Diagonally across the door.

g)Across the air vents.

h)Across the rear air vent.

i) All lockseams.

j) Weld at bottom.

k) Bottom plate.

I) Oven feet.

4. The scan speed is one inch per second.

When checking for R.F. Ieakage, use an approved R.F. measuring device to assure less

than 4 mw/cm2 emission at 5 cm distance with

a maximum scan rate of 2.54 cm/second, in

compliance with U.S. Government Department

of Health, Education and Welfare 21CFR1030,

performance Standard for Microwave Ovens.

NOTE: Enter leakage readings in space BEFORE and AFTER on the service document.

All microwave ovens exceeding the emission

level of 4 mw/cm2 must be reported to Dept. of

Service for microwave ovens immediately and

the owner should be told not to use the microwave oven until it has been repaired completely.

If a microwave oven is found to operate with the

door open, report to Dept. of Service, the

manufacturer and CDRH* immediately. Also

tell the owner not to use the oven.

The interlock monitor switch acts as the final

safety switch protecting the customer from

microwave radiation. If the interlock monitor

switch operated to blow the fuse when the

interlocks failed, you must replace all interlock

switches with new ones, because the contacts

of those interlock switches may be melted and

welded together.

If safety interlock/monitor switch replacement,

or adjustment, is required, you must reconnect

the circuit, and perform a continuity check on

the monitor circuit.

All repairs must be performed in such a manner

that microwave energy emissions are minimal.

Address for CDRH is:

Office of Compliance (HFZ-342) Center for

Devices and Radiological Health

2098 Gaither Road

Rockville, MD 20850

* CDRH: Center for Devices and Radiological Health,

Food and Drug Administration.

A properly operating door and seal assembly

will normally register small emissions, but they

must be no greater than 4 mw/cm2 to allow for

measurement uncertainty.

1-4

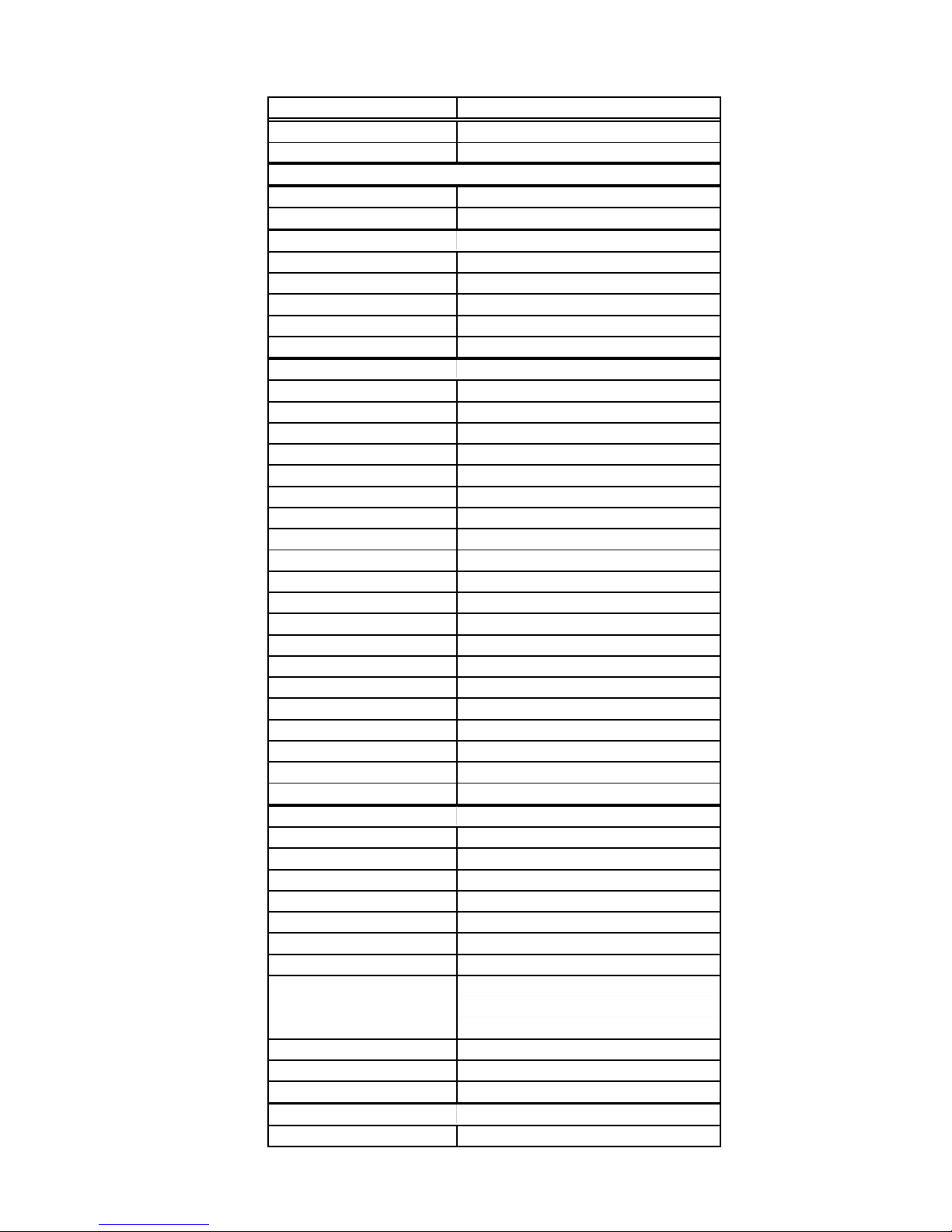

WHIRLPOOL MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER

MODEL NUMBER M H 6 14 0 X K Q 0

INTERNATIONAL SALES IND.

OR MARKETING CHANNEL

IF PRESENT

PRODUCT GROUP

G = WHIRLPOOL GOLD

M = MICROWAVE

PRODUCT IDENTIFICATION

B = BROWNER

C = CONVECTION

G = GRILL / CRISPER

H = OTR HOOD COMBO

K = KITS

M = GOLD CONVECTION

S = STIRRER FAN

T = TURNTABLE

MODEL VARIATIONS

0 - 9

CUBIC FEET

04 = .4 CU. FT. 10 = 1.0 CU. FT.

06 = .6 CU. FT. 12 = 1.2 CU. FT.

07 = .7 CU. FT. 14 = 1.4 CU. FT.

08 = .8 CU. FT. 15 = 1.5 CU. FT.

09 = .9 CU. FT. 16 = 1.6 CU. FT.

FEATURE LEVEL

0 = 30˝ KIT (IF KIT)

2 = 22˝ KIT (IF KIT)

4 = 24˝ KIT (IF KIT)

5 = SENSORED MODEL

7 = 27˝ KIT (IF KIT)

FEATURE CODE

C = CSA APPROVED

S = CARRY IN WARRANTY (EFFECTIVE 02/96)

X = IN HOME WARRANTY (EFFECTIVE O2/96)

YEAR OF INTRODUCTION

J = 2000, K = 2001, L = 2002

COLOR CODE

B = BLACK, Q = WHITE, T = BISCUIT

ENGINEERING CHANGE (0, 1, 2, ETC.)

SERIAL NUMBER

SERIAL NUMBER FG L 2 5 54321

MANUFACTURING SITE

FG = FINDLAY, OH

YEAR OF PRODUCTION

K = 2000, L = 2001

WEEK OF PRODUCTION

25TH WEEK

PRODUCT SEQUENCE NUMBER

1-5

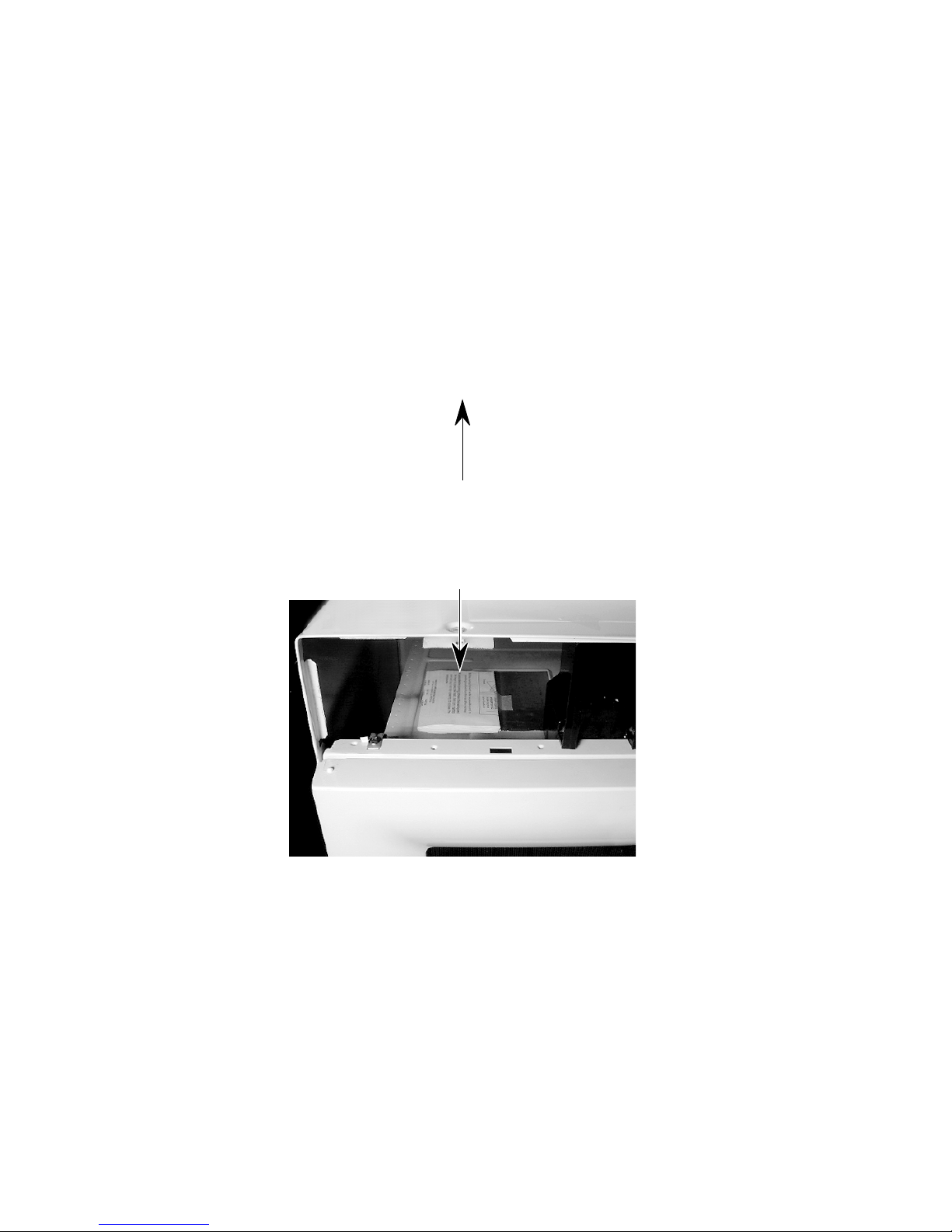

MODEL & SERIAL NUMBER LABEL

AND TECH SHEET LOCATIONS

The Model/Serial Number label and Tech Sheet locations are shown below.

Model & Serial

Number Location

Tech Sheet Location

(Behind Grille)

1-6

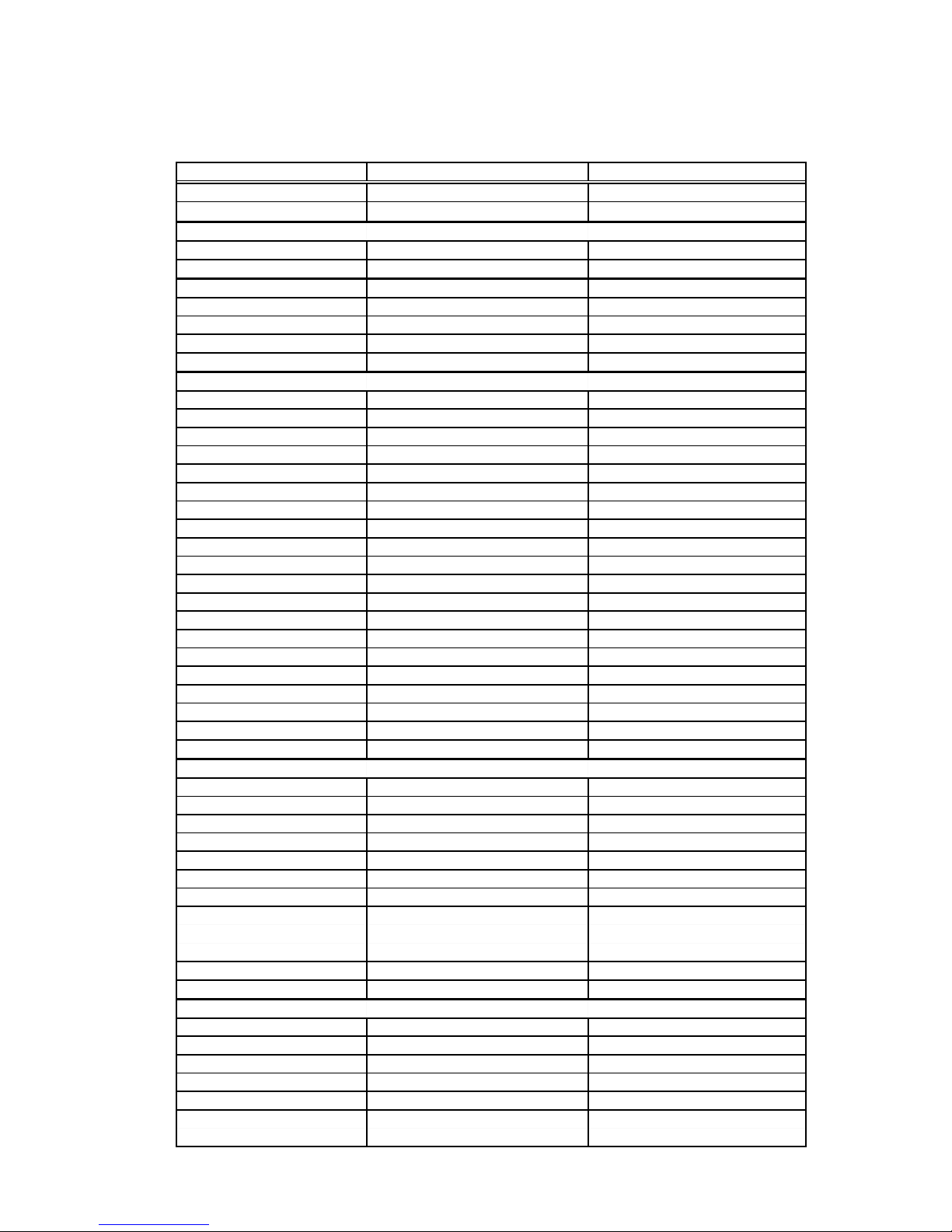

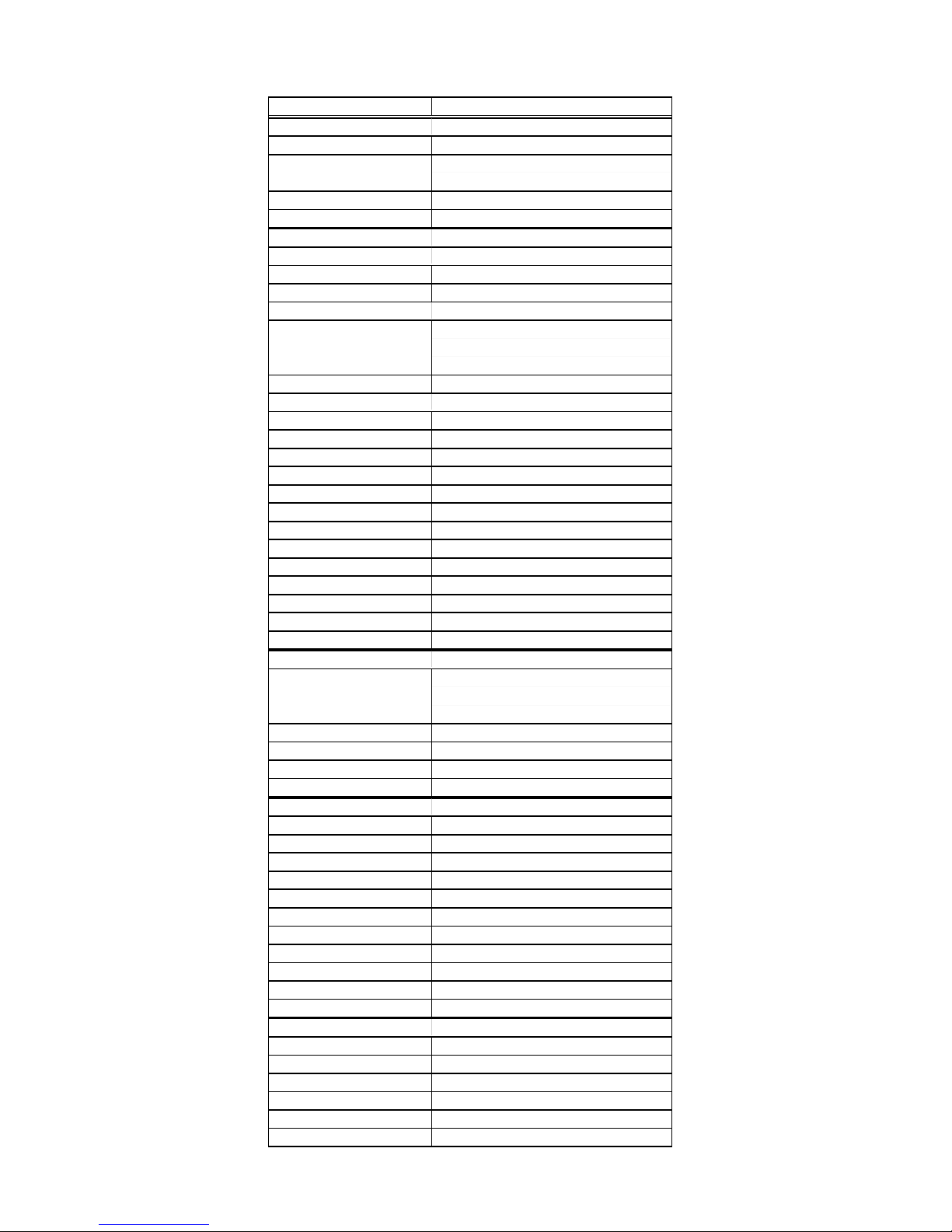

WHIRLPOOL

SPECIFICATIONS

MODEL

Size-Configuration

Feature Level/Series

DIMENSIONS / SPECIFICATIONS

Outside Dimensions 29-15/16" W x 16-7/16" H x 15-3/8" D 29-15/16" W x 16-7/16" H x 15-3/8" D

Interior Cavity Dimensions 19-7/8" W x 8-15/16" H x 14-3/16" D 19-7/8" W x 8-15/16" H x 14-3/16" D

CONTROL SYSTEM

Timer Electronic Electronic

Limits 99 Min. 99 Sec. 99 Min. 99 Sec.

Scale Linear (Digital) Linear (Digital)

Display 7 Digit Display Scroll VFD 7 Digit Display Scroll VFD

OTHER FEATURES

Stoppable Turntable No No

Child Lock Yes - Start / Enter Button Yes - Start / Enter Button

Variable Power (Cook Power) Yes Yes

Type Electronic Electronic

Range 10% - 100% 10% - 100%

Scale Digital Digital

Levels Ten Ten

Auto On Yes - 56 degrees C Yes - 56 degrees C

Cooktop Light Yes - One (1) Yes - One (1)

On Yes Yes

Night Yes Yes

Manual Off Yes Yes

Auto Off No No

Wattage 30 Watts 30 Watts

Light Cover Glass Glass

Start Indication "Touch Start" Scroll display "Touch Start" Scroll display

Probe Temp Indication N / A N / A

Weight Indication "Lbs" "Lbs"

Clock Set "ENTER TIME OF DAY" "ENTER TIME OF DAY"

Independent Minute Timer "ENTER TIME IN MIN AND SEC" "ENTER TIME IN MIN AND SEC"

INTERIOR

Size 19-7/8" W x 8-15/16" H x 14 -5/32" D 19-7/8" W x 8-15/16" H x 14 -5/32" D

Capacity 1.4 Cubic Feet 1.4 Cubic Feet

Finish Epoxy Powder Coat Epoxy Powder Coat

Cooking Power 950 Watts (1EC-705 Rating) 950 Watts (1EC-705 Rating)

Ventilation Forced Air Forced Air

Shelf Spillguard Sealed-In Spillguard Sealed-In

Bi-Level Rack No No

Interior Light Yes-Automatic turns on when oven Yes-Automatic turns on when oven

Turntable Diameter 12-3/4" 12-3/4"

Stoppable Turntable No No

EXTERIOR

Window Water Clear Glass Water Clear Glass

Window Size 18-1/4" W x 7-1/2" H 18-1/4" W x 7-1/2" H

Door / Window Graphics Whirlpool Logo on Door; upper left corner Whirlpool Logo on Door; upper left corner

Outer Door Stamped Steel with tempered cover Stamped Steel with tempered cover

Handle/Latch Pull to open Pull to open

Seals Three Stage Three Stage

(Capacitive, Reflective & Absorbive) (Capacitive, Reflective & Absorbive)

MH6140XKQ/B MH6141XKQ/B

1.4 cu ft 1.4 cu ft

Basic Non Sensor Basic Non Sensor

door is open or oven is operating door is open or oven is operating

30 watts (2000 hr. life) 30 watts (2000 hr. life)

1-7

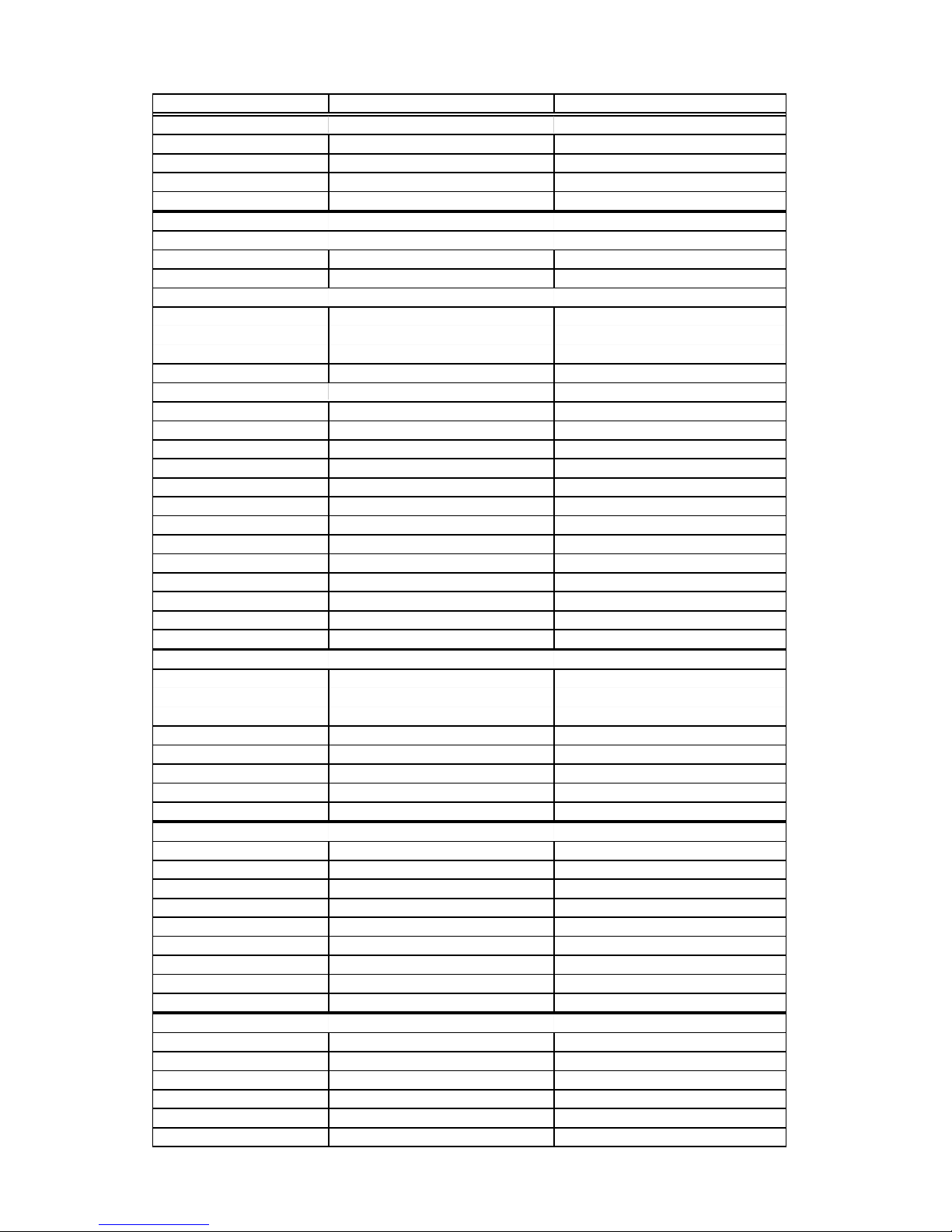

MODEL

EXTERIOR FEATURES

Outside Dimensions 29-15/16" W x 16-7/16" H x 15-3/8" D 29-15/16" W x 16-7/16" H x 15-3/8" D

Control and Door Frames One Piece Molded One Piece Molded

Cooktop Light w/Touch Control One Lamp - 30 Watt Easy Access One Lamp - 30 Watt Easy Access

Power Cord Length 3.28 Ft. 3.28 Ft.

MISCELLANEOUS

MICROWAVE SYSTEM

Distribution Regular Side Feeding Regular Side Feeding

Magnetron Standard Standard

SAFETY FEATURES

Interlock Three Door/Latch Operated Three Door/Latch Operated

Thermal Protectors One (1) - Oven Cavity One (1) - Oven Cavity

VENTILATION SYSTEM

Type Convertible Convertible

Duct Outlet Size 10 " W x 3-1/4 "H 10 " W x 3-1/4 "H

Recirculation CFM 148 (Hi with Charcoal Filter) 148 (Hi with Charcoal Filter)

Horizontal CFM (Hi-Low) 223CFM / 112 CFM 223CFM / 112 CFM

Vertical CFM (Hi-Low) 220 CFM / 110 CFM 220 CFM / 110 CFM

Touch Control (2-speed) Two Speed (Hi / Low) Yes - High / Low

Auto ON - High Speed

Noise Level 43 dBA (Microwave Only) 43dBA (Microwave Only)

Damper Yes Yes

Grease Filter Yes - (2) Yes (2)

Charcoal Filter Yes - (1) Yes - (1)

Blower Type Twin Squirrel Cage Twin Squirrel Cage

Shipped Recirculating Mode Recirculating Mode

OTHER SPECIFICATIONS

Electrical 120V, Single Phase, 60 Hz, 120V, Single Phase, 60 Hz,

Domestic Use Only Yes Yes

Agency Approvals FCC, DHHS, U.L. Listed FCC, DHHS, U.L. Listed

Approx. Shipping Weight 58 lbs. 58 lbs.

Approx. Net Weight 52 lbs. 52 lbs.

Carton Dimensions 33-7/16" W x 19-5/16" H x 19-17/32" D 33-7/16" W x 19-5/16" H x 19-17/32" D

LITERATURE

Use & Care Guide 8183890 / 3828W5A1876 (English) 8183890 / 3828W5A1876 (English)

Job Aid 8178053 8178053

Cooking Guide 8183893 / 3850W3D032B (English) 8183893 / 3850W3D032B (English)

Installation Instructions 8183895 / 3828W5U0125 (English) 8183895 / 3828W5U0125 (English)

Upper Cabinet Template 8183896 / 4922W5A025A (English) 8183896 / 4922W5A025A (English)

Wall Template No No

Warranty In Use & Care Guide In Use & Care Guide

Carton Tag Std. - On Carton Corner Std. - On Carton Corner

Tech Sheet 8183894 / 3840W3T001G (English) 8183894 / 3840W3T001G (English)

ACCESSORIES

Filler Kit 4158311 4158311

Charcoal Filter 8183916 / 2B72706D 8183916 / 2B72706D

Grease Filter 4358853 / 2B72705B 4358853 / 2B72705B

Exhaust Damper Assembly Yes (1 Set) Yes (1 Set)

Trim Kit No No

Hardware for Installation Yes (1 Set) Yes (1 Set)

MH6140XKQ/B MH6141XKQ/B

Switches (1 Power Interrupt, Switches (1 Power Interrupt,

1 Monitor, 1 Low Voltage 1 Monitor, 1 Low Voltage

o

C Yes - 56oC

Yes - 56

1500 Watts, For Use With 1500 Watts, For Use With

20 Amp Circuit 20 Amp Circuit

1-8

ROPER

MODEL

Size-Configuration

Feature Level/Series Basic Non Sensor

DIMENSIONS / SPECIFICATIONS

Outside Dimensions 29-15/16" W x 16-7/16" H x 15-3/8" D

Interior Cavity Dimensions 19-7/8" W x 8-15/16" H x 14-3/16" D

CONTROL SYSTEM

Timer No

Type N / A

Limits N / A

Scale N / A

Display 7 Digit Display Scroll VFD

OTHER FEATURES

Stoppable Turntable No

Clock Yes

Child Lock Yes - Start / Enter Button

Variable Power (Cook Power) Yes

Type Electronic

Range 10% - 100% (increments of 10%)

Scale

Levels

Operation Direct Entry

Ventilation Forced Air

Exhaust Fan Yes

High Yes (220 CFM) - Vertical

Low Yes (110 CFM) - Vertical

Manual Off Yes

Auto Off No

Auto On Yes - 56 degrees C

Cooktop Light Yes - One (1)

On Yes (30 Watts)

Night Yes (17 Watts)

Manual Off Yes

INTERIOR

Size 19-7/8" W x 8-15/16" H x 14 -3/16" D

Capacity 1.4 Cubic Feet

Finish Epoxy Powder Coat

Cooking Power 950 Watts (1EC-705 Rating)

Ventilation Forced Air

Shelf No

Bi-Level Rack No

Yes-Automatic turns on when oven

Interior Light

Turntable Diameter 12-3/4"

Stoppable Turntable No

Turntable Roller Yes

EXTERIOR

Window Size 17" W x 6-7/8" H

door is open or oven is operating

MHE14XKQ/B

1.4 cu ft

Digital

Ten (10)

30 watt (2000 hr. life)

1-9

MODEL

EXTERIOR FEATURES

Outside Dimensions

Wrapper Material

Cooktop Light w/Touch Control One Lamp - 30 Watt Easy Access

Power Cord Length 3.28 Ft.

MISCELLANEOUS

MICROWAVE SYSTEM

Distribution Side Feed

Magnetron Standard

SAFETY FEATURES

Interlock

Thermal Protectors One (1) for Oven Cavity

VENTILATION SYSTEM

Type Convertible

Duct Outlet Size 10 " W x 3-1/4 "H

Recirculation CFM 148 (Hi with Charcoal Filter)

Horizontal CFM (Hi-Low) 223CFM / 112 CFM

Vertical CFM (Hi-Low) 220 CFM / 110 CFM

Touch Control (2-speed) Two Speed (Hi / Low)

Auto ON - Low Speed

Noise Level 53.5 dBA (Ventilation Mode)

Damper Yes

Grease Filter Yes - (2)

Charcoal Filter Yes - (1)

Blower Type Twin squirrel cage

Shipped Recirculating Mode

OTHER SPECIFICATIONS

Electrical

Domestic Use Only Yes

Agency Approvals FCC, DHHS, U.L. Listed

Approx. Shipping Weight 58 lbs.

Approx. Net Weight 52 lbs.

LITERATURE

Use & Care Guide Whpl # 8183914 / 3828W5A1906 (English)

Cooking Guide Whpl # 8183915 / 3850W3D032D (English)

Installation Instructions 8183895 / 3828W5U0125 (English)

Upper Cabinet Template 8183896 / 4922W5A025A (English)

Wall Template No

Warranty In Use & Care Guide

Carton Tag Std. - On Carton Corner

Model Serial Plate Location Upper Front Frame

Cooking Guide Location Upper Front Frame

Tech Sheet 8183894 / 3840W3T001G (English)

Job Aid 8178053

ACCESSORIES

Filler Kit 4158311

Charcoal Filter 8183916 / 2B72706D

Grease Filter 4358853 / 2B72705B

Exhaust Damper Assembly Yes (1 Set)

Trim Kit No

Hardware for Installation Yes (1 Set)

29-15/16" W x 16 7/16" H x 15-3/8"" D

For Black Model: Black Textured VCM

For White Model: PCM NON-Textured Steel

MHE14XKQ/B

Three Door/Latch Operated

Switches (1 Power Interrupt,

1 Monitor, 1 Low Voltage)

o

Yes - 56

C

120V, Single Phase, 60 Hz,

1500 Watts, For Use With

20 Amp Circuit

1-10

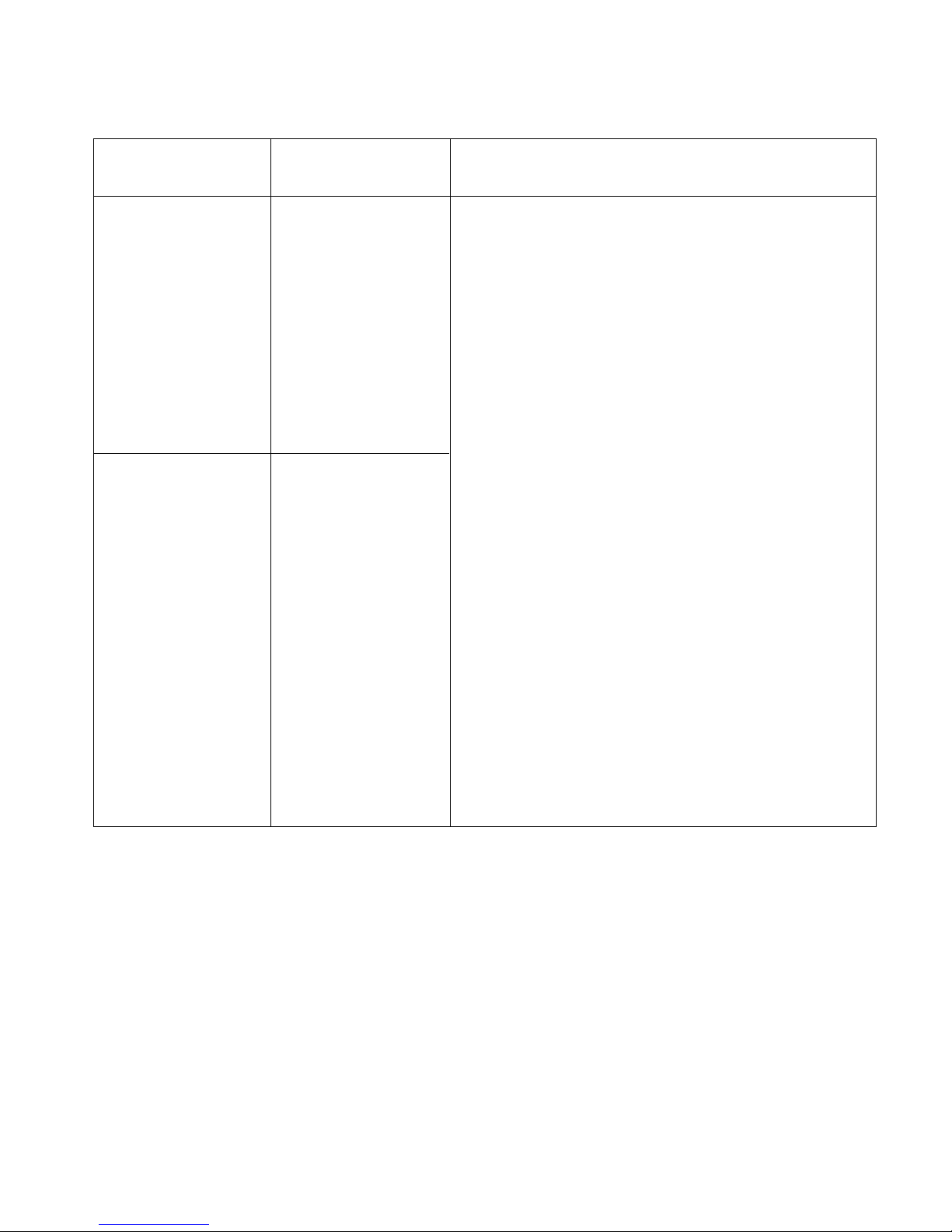

WHIRLPOOL MICROWAVE OVEN WARRANTY

LENGTH OF

WARRANTY:

ONE-YEAR FULL

WARRANTY

From Date of

Purchase.

LIMITED FOURYEAR WARRANTY Second

through fifth year

from Date of

Purchase.

WHIRLPOOL

WILL PAY FOR:

FSP ® Replacement parts and

repair labor costs

to correct defects

in materials or

workmanship.

Service must be

provided by a

Whirlpool-designated servicing

company.

FSP ® Replacement magnetron

tube on microwave

ovens if defective

in materials or

workmanship.

WHIRLPOOL

WILL NOT PAY FOR:

A. Service calls to:

1. Correct the installation of the microwave

oven.

2. Instruct you how to use the microwave

oven.

3. Replace house fuses or correct house

wiring.

4. Replace owner-accessible light bulbs.

B. Repairs when microwave oven is used in

other than normal single-family household

use.

C. In-home service. Your microwave oven must

be taken to a Whirlpool-designated service

company, except when your microwave oven

is installed over an approved oven using an

approved built-in kit.

D. Damage to the microwave oven resulting

from accident, alteration, misuse, abuse, fire,

flood, acts of God, or use of products not

approved by Whirlpool Corporation.

E. Any labor costs during the limited warranty.

F. Repairs to parts or systems resulting from

unauthorized modifications made to the

appliance.

G. Replacement parts or repair labor costs for

units operated outside the United States.

WHIRLPOOL CORPORATION SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. Some states do not allow the exclusion or limitation of incidental or

consequential damages, so this exclusion or limitation may not apply to you. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to

state.

Outside the United States, this warranty does not apply. Contact your authorized Whirlpool dealer to determine if another warranty applies.

If you need service, see the “Requesting Assistance or Service” in the Use & Care Guide, or by

calling our Customer Interaction Center telephone number, 1-800-253-1301, from anywhere in

the U.S.A.

1-11

Loading...

Loading...