Whirlpool MH7110XBB5 Installation Guide

IMPORTANT:

Read and save

these instructions.

IMPORTANT:

Installer:Leave Installation Instructions

with homeowner.

Homeowner: Keep Installation Instructions

for future reference.

Save Installation Instructions for electrical

inspector's use.

Pan' No. 38474W5005676/4358519 Rev. A

Microwave Hood

Combination

Before you start...

Proper installation is the installer's

responsibility. A qualified technician should

install this microwave oven. Make sure you

have everything necessary for correct

installation. It is the responsibility of the

installer to comply with the installation

clearances specified either on the

mounting bracket or in the Installation

Instructions.

'_29-7/8" _i _ 13-'-Z_'_''.//_',

Important: Observe all

governing codes and

ordinances.

Remove all

contents from

the upper

cabinet.

30" min. cabinet

opening width

16"

Electrical ground is

required. See "Electrical

requirements", Panel B.

30" rain. to top of wall

mounting bracket

l

Excessive Microwave Energy Exposure

• Do Not attempt to operate this

microwave oven with the door open.

• Do Not tamper with or defeat the safety

interlocks.

• Do Not place objects between the

microwave oven front face and the

door.

• Do Not allow soil or cleaner residue to

accumulate on sealing surface of

microwave oven door.

• Do Not operate microwave oven if it is

damaged.

• The microwave oven door must close

properly to provide sate operation. Do

Not use microwave oven if door isbent;

hinges and latches are broken or loose;

or door seals, sealing surfaces or glass is

broken.

• The microwave oven should be

adjusted and repaired only by a

qualified repair person.

• Have a qualified repair person check

for microwave leakage if a repair is

made.

• Do Not use microwave oven for

commercial purposes. Thismicrowave

oven isdesigned for household use

only.

Failure to use microwave oven except as

instructed could result in exposure to

excessive microwave energy.

This product issuitable

for use above electricand gas cooking

products 30""wide

or less.

Wall construction should be a minimum of

2" x 4" wood studding and 3/8" thickness

drywall or plaster/lath.

Remove all packaging material from inside

microwave oven. Check the microwave

oven for damage -- see WARNING for

excessive microwave energy exposure. If

any damage is evident, Do Not operate

the microwave oven until it ischecked by

an authorized service technician.

Properly Damage

Place a portion of carton or another

heavy material over the countertop and

range before installing the microwave

hood. Do Not use a plastic cover.

Failure to protect cooking surface or

countertop could result in property

damage.

Parts supplied

for installation:

Check location where microwave oven will

be installed. The wall must be strong

enough to support the microwave weight

of 150 Ibs, plus the weight of any items

placed inside the microwave or the upper

cabinet. The location should be away from

draft areas, such as windows, doors, and

strong heating vents. The microwave oven

should be located for convenient use in the

kitchen.

Tools and materials

needed for

installation:

screwdriver

j__ Phillips

stud finder or

thin nail

/'_ electric drill

carton or another

heavy material

for covering

countertop

318"and 3/4"

wood drill bits

Personal Injury Hazard

Two people are required to lift this

microwave oven.

Failure to use more than one person

during installation may result in personal

injury.

• Thismicrowave oven must be mounted

against and supported by a flat, vertical

wail.

• Thismicrowave oven must be attached

with two lag screws to a minimum of

one, vertical 2" x 4" wall stud.

• Do Not mount microwave oven to an

island or peninsula cabinet.

• The microwave oven top and rear

supporting structure must be capable of

supporting 150 Ib, plus the weight of any

items placed inside the microwave

oven or upper cabinet.

Failure to mount the microwave oven as

instructed could result in personal injury

and/or property damage.

Electrical Shock Hazard

It isthe customer's responsibility:

• To contact a qualified electrical

installer.

• To assure that the electrical installation

isadequate and in conformance with

National Electrical Code, ANSI/NFPA

70 -- latest edition*, and all local codes

and ordinances.

Failure to do so could result in fire,

electrical shock or other personal injury.

==========================================

6, I/4" x 3" bolts

4 spring toggle-heads

4, I/4" x 2" bolts

4, I/4" x 2" lag screws

2 tapping screws

(bright-colored)

2 washers

2filters

1powersupply Special hardware and tools are required for

cord bushing brick or masonry walls.

duct tape

measuring tape

• Care must be taken when drilling holes

into the wall. Electrical wires may be

concealed behind the wall covering

and contact with them could result in

electrical shock.

• Locate any electrical circuits that could

be affected by the installation of this

product and disconnect power circuit.

Failure to do so could result in electrical

shock or other personal injury.

* Copies of the standard listed may be

obtained from:

National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

Panel A

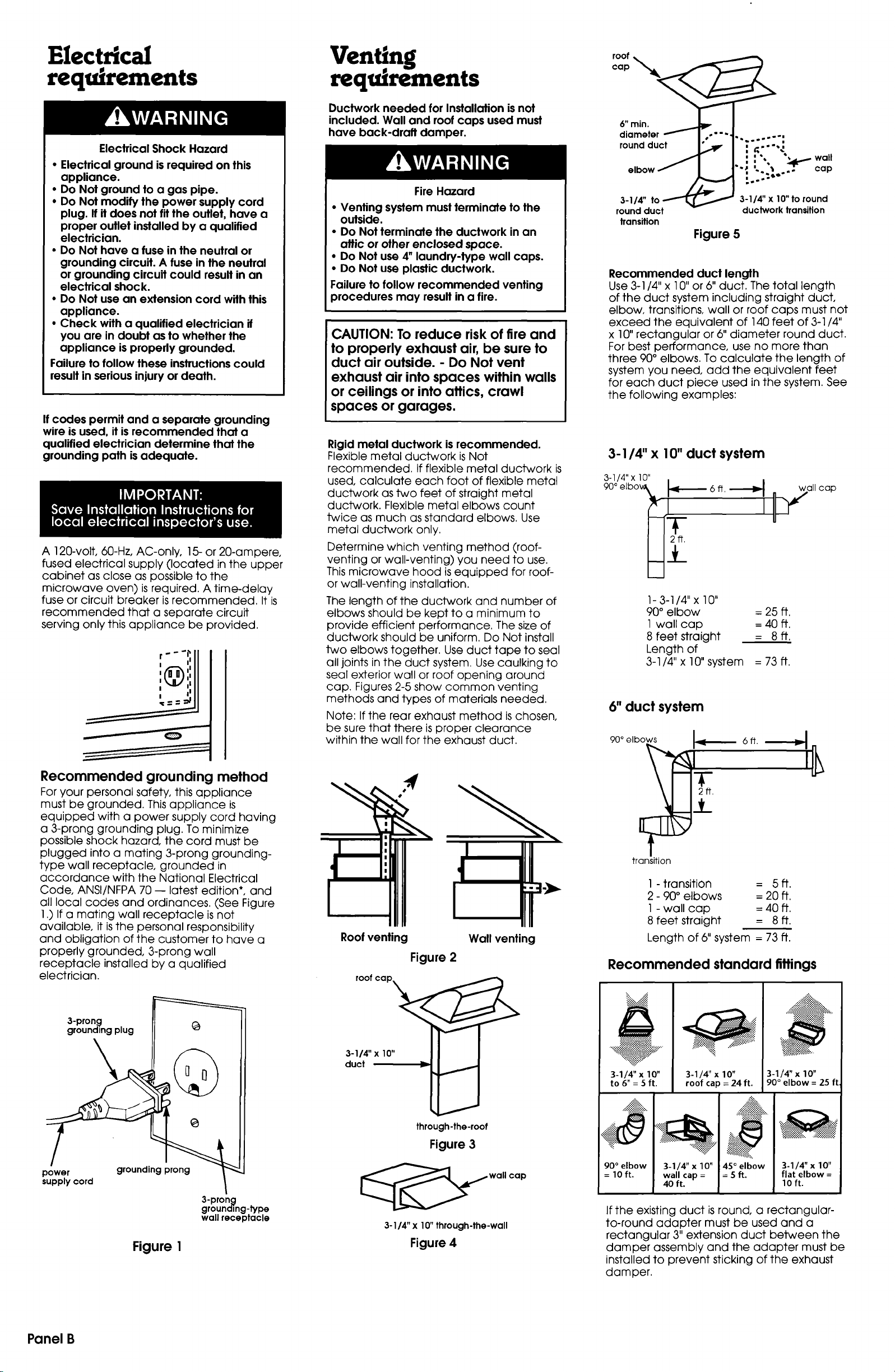

Electrical

Venting

roof

requirements

Electrical Shock Hazard

• Electrical ground is required on this

appliance.

• Do Not ground to a gas pipe.

• Do Not modify the power supply cord

plug. If it does not fit the outlet, have a

proper outlet installed by a qualified

electrician.

• Do Not have a fuse in the neutral or

grounding circuit. A fuse in the neutral

or grounding circuit could result in an

electrical shock.

• Do Not use an extension cord with this

appliance.

• Check with a qualified electrician if

you are in doubt as to whether the

appliance is properly grounded.

Failure to follow these instructions could

result in serious injury or death.

If codes permit and a separate grounding

wire is used, it isrecommended that a

qualified electrician determine that the

grounding path is adequate.

A 120-volt, 60-Hz, AC-only, 15- or 20-ampere,

fused electrical supply (located in the upper

cabinet as close as possible to the

microwave oven) is required. A time-delay

fuse or circuit breaker isrecommended. It is

recommended that a separate circuit

serving only this appliance be provided.

r_

iI

I ii

I_11

I it

I

l il

requirements

Ductwork needed for Installation is not

included. Wall and roof caps used must

have back-draft damper.

Fire Hazard

• Venting system must terminate to the

outside.

• Do Not terminate the ductwork in an

attic or other enclosed space.

• Do Not use 4" laundry-type wall caps.

• Do Not use plastic ductwork.

Failure to follow recommended venting

procedures may result in a fire.

CAUTION: To reduce risk of fire and

to properly exhaust air, be sure to

duct air outside. - Do Not vent

exhaust air into spaces within walls

or ceilings or into attics, crawl

spaces or garages.

Rigid metal ductwork is recommended.

Flexible metal ductwork isNot

recommended. If flexible metal ductwork is

used, calculate each foot of flexible metal

ductwork as two feet of straight metal

ductwork. Flexible metal elbows count

twice as much as standard elbows. Use

metal ductwork only.

Determine which venting method (roof-

venting or wall-venting) you need to use.

This microwave hood isequipped for roof-

or wall-venting installation.

The length of the ductwork and number of

elbows should be kept to a minimum to

provide efficient performance. The size of

ductwork should be uniform. Do Not install

two elbows together. Use duct tape to seal

all joints in the duct system. Use caulking to

seal exterior wall or roof opening around

cap. Figures 2-5 show common venting

methods and types of materials needed.

Note: If the rear exhaust method is chosen,

be sure that there is proper clearance

within the wall for the exhaust duct.

6" min.

diameter

round duct

3-I/4" to

round duct

transition

3-I/4" x 10" to round

ductwork transition

Figure 5

Recommended duct length

Use 3-I/4"x I0"or6"duct.The totallength

ofthe duct system includingstraightduct,

elbow, transitions,wallorroofcaps must not

exceed the equivalentof 140 feetof 3-I/4"

x I0"rectangularor6"diameter round duct.

Forbest performance, use no more than

three 90°elbows.To calculatethe lengthof

system you need, add the equivalentfeet

foreach duct piece used inthe system.See

the followingexamples:

3- I/4" x 10" duct system

3-I/4" x I0"

90° elbo_ _1_6 ft,-_ wall cap

1- 3-1/4" x 10"

90° elbow : 25 ft.

1 wall cap = 40 ft.

8 feet straight = 8 ft.

Length of

3-1/4"" x 10" system = 73 ft.

6" duct system

90° elbows J

6ft.

Recommended grounding method

For your personal safety, this appliance

must be grounded. Thisappliance is

equipped with a power supply cord having

a 3-prong grounding plug. To minimize

possible shock hazard, the cord must be

plugged into a mating 3-prong grounding-

type wall receptacle, grounded in

accordance with the National Electrical

Code, ANSI/NFPA 70 -- latest edition*, and

all local codes and ordinances. (See Figure

1.) If a mating wall receptacle isnot

available, it isthe personal responsibility

and obligation of the customer to have a

properly grounded, 3-prong wall

receptacle installed by a qualified

electrician.

3-pron._

grounding plug

power

supply cord

grounding prong

Figure I

3-prong

grounding-type

wall receptacle

Roof venting Wall venting

Figure 2

roof cap

3-I/4" x 10"

duct

through-the-roof

Figure 3

wall cap

3-I/4" x 10"through-the-wall

Figure 4

transition

1 - transition = 5 ft.

2 - 90° elbows = 20 ft.

1 - wall cap = 40 ft.

8 feet straight = 8 ft.

Length of 6" system = 73 ft.

Recommended standard fittings

:.:.:.:....:.:.:.:.

:-:-:-:-:.:.:-:o:.:..,,..._

..::_::..

..::_:_:]:-:':;.]:.::.--:..

========================

=======================================

---:::::: _:::.}..:-- ....

:.:.:.--:.:_._.:.:.:-.-.:.

......

3-1/4" x 10"

to 6" = 5 ft.

..::iii::..

.-.-.:.:.:.:.:.:.:.:_-.

90 ° elbow

= lOft.

3-1/4" x 10"

roof cap : 24 ft.

3-1/4" x 10"

wall cap =

40 ft.

::.._'::::::::::::::::

_..==...........

45° elbow

=Sft.

If the existing duct is round, a rectangular-

to-round adapter must be used and a

rectangular 3" extension duct between the

damper assembly and the adapter must be

installed to prevent sticking of the exhaust

damper.

3-1/4" x 10"

90 ° elbow = 25 ft

-.......:..

3-1/4" x 10"

flat elbow =

10 ft.

Panel B

Loading...

Loading...