Whirlpool MH6300XM1, MH6300XM0 Installation Guide

MICROWAVE

HOOD

COMBINATION

P°]°

IMPORTANT

INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE HOMEOWNER

HOMEOWNER: RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE.

aveOvens,Compactors, RoomAir Conditioners, Dehumidifiers,AutomaticWashers,Clothes Dryers,Freezers,Refrigerator-Freezers,IceMakers,Dishwa

READ AND SAVE THESE INSTRUCTIONS

Before you begin, read the following instructions

completely and carefully. If followed, they will

simplify the installation job.

IMPORTANT: OBSERVE ALL GOVERNING

CODES AND ORDINANCES

FOR USE OVER WHIRLPOOL

CONVENTIONAL GAS AND ELECTRIC

RANGE COOKTOPS

THAT DO NOT HAVE A GRILLE.

MOUNTING TEMPLATES

This product cannot be properly installed without

using the mounting templates.

Locate and study templates before beginning

installation.

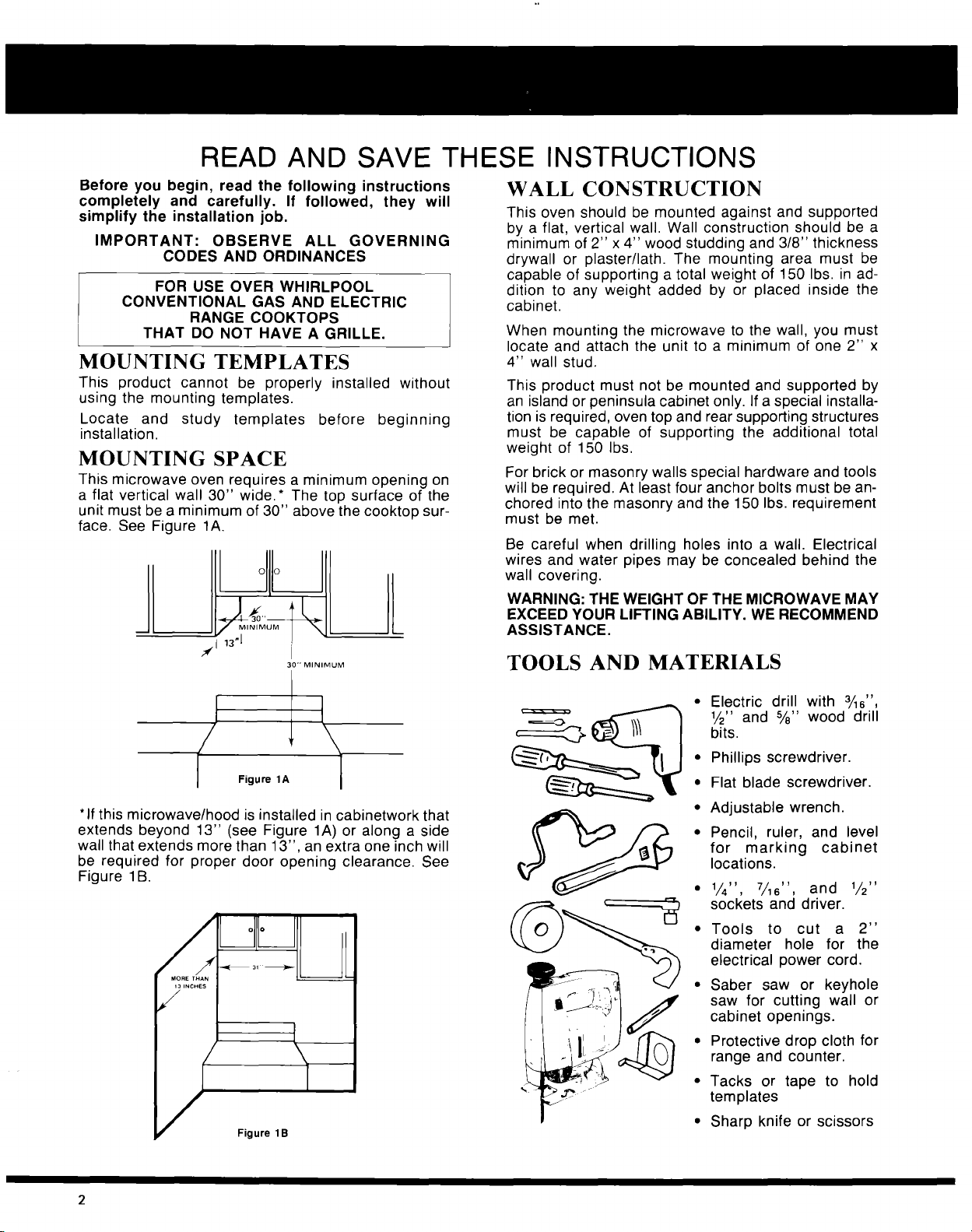

MOUNTING SPACE

This microwave oven requires a minimum opening on

a flat vertical wall 30" wide.* The top surface of the

unit must be a minimum of 30" above the cooktop sur-

face. See Figure 1A.

Io11

._1 13"l [

WALL CONSTRUCTION

This oven should be mounted against and supported

by a flat, vertical wall. Wall construction should be a

minimum of 2" x 4" wood studding and 3/8" thickness

drywall or plaster/lath. The mounting area must be

capable of supporting a total weight of 150 Ibs. in ad-

dition to any weight added by or placed inside the

cabinet.

When mounting the microwave to the wall, you must

locate and attach the unit to a minimum of one 2" x

4" wall stud.

This product must not be mounted and supported by

an island or peninsula cabinet only. If a special installa-

tion is required, oven top and rear supporting structures

must be capable of supporting the additional total

weight of 150 Ibs.

For brick or masonry walls special hardware and tools

will be required. At least four anchor bolts must be an-

chored into the masonry and the 150 Ibs. requirement

must be met.

Be careful when drilling holes into a wall. Electrical

wires and water pipes may be concealed behind the

wall covering.

WARNING: THE WEIGHT OF THE MICROWAVE MAY

EXCEED YOUR LIFTING ABILITY. WE RECOMMEND

ASSISTANCE,

TOOLS AND MATERIALS

*If this microwave/hood is installed in cabinetwork that

extends beyond 13" (see Figure 1A) or along a side

wall that extends more than 13", an extra one inch will

be required for proper door opening clearance. See

Figure 1B.

• Electric drill with y16 ,

1/2" and 5/s" wood drill

bits.

• Flat blade screwdriver.

• Phillips screwdriver.

• Adjustable wrench.

for marking cabinet

_(__ • Pencil, ruler, and level

locations.

• 1/,, 7/ ,, and 1/2"

/4 , /16 ,

sockets and driver.

• Tools to cut a 2"

diameter hole for the

electrical power cord.

• Saber saw or keyhole

saw for cutting wall or

cabinet openings.

• Protective drop cloth for

range and counter.

• Tacks or tape to hold

templates

• Sharp knife or scissors

3/ _

ELECTRICAL REQUIREMENTS

LOCATE THE POLARIZED OUTLET IN REAR WALL

ABOVE UNIT, VISIBLE THROUGH CABINET DOORS

ABOVE UNIT. (DISCONNECT ELECTRIC SUPPLY

BEFORE SERVICING).

A 120 Volt, 60 Hz, AC only, 15 or 20 Ampere fused elec-

trical supply is required (time delay fuse or circuit

breaker is recommended). It is recommended that a

separate circuit servicing only this appliance be pro-

vided. DO NOT use an extension cord.

WARNING: Improper connection of the equipment

grounding conductor can result in a

risk of electrical shock.

RECOMMENDED GROUNDING

METHOD

B. Outside Venting through the rear surface

of the unit.

C. Inside Venting of this oven requires Whirlpool recir-

culating filter kit#RCH6000, Part #788000. Contact

your Whirlpool Dealer to obtain this kit before pro-

ceeding. Separate instructions are included in the

recirculating filter kit.

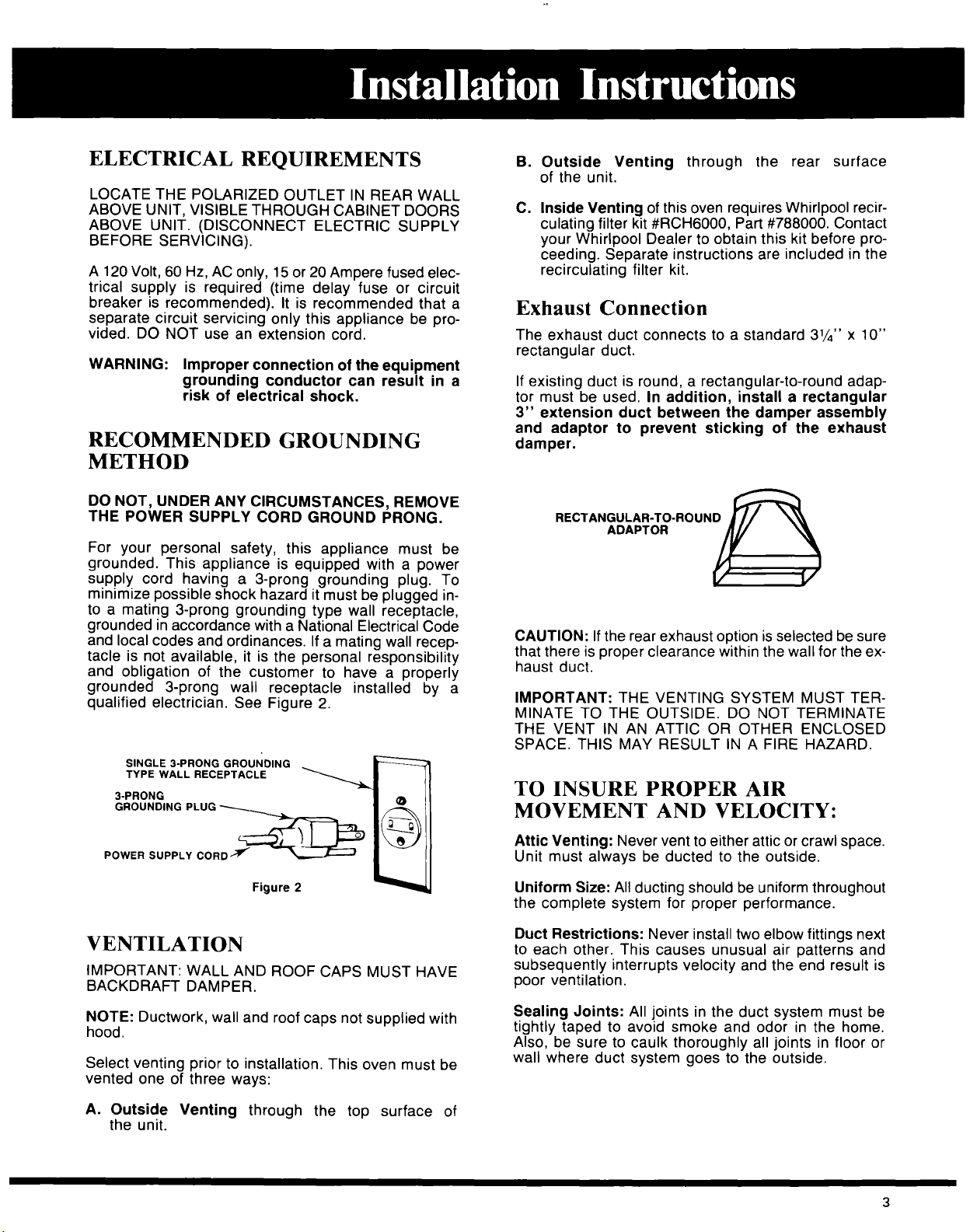

Exhaust Connection

The exhaust duct connects to a standard 31/4'' x 10"

rectangular duct.

If existing duct is round, a rectangular-to-round adap-

tor must be used. In addition, install a rectangular

3" extension duct between the damper assembly

and adaptor to prevent sticking of the exhaust

damper.

DO NOT, UNDER ANY CIRCUMSTANCES, REMOVE

THE POWER SUPPLY CORD GROUND PRONG.

For your personal safety, this appliance must be

grounded. This appliance is equipped with a power

supply cord having a 3-prong grounding plug. To

minimize possible shock hazard it must be plugged in-

to a mating 3-prong grounding type wall receptacle,

grounded in accordance with a National Electrical Code

and local codes and ordinances. If a mating wall recep-

tacle is not available, it is the personal responsibility

and obligation of the customer to have a properly

grounded 3-prong wall receptacle installed by a

qualified electrician. See Figure 2.

SINGLE 3-PRONG GROUNDING

TYPE WALL RECEPTACLE

3-PRONG

Figure 2

VENTILATION

IMPORTANT: WALL AND ROOF CAPS MUST HAVE

BACKDRAFT DAMPER.

RECTANGULAR-TO-ROUND

ADAPTOR__

CAUTION: If the rear exhaust option is selected be sure

that there is proper clearance within the wall for the ex-

haust duct.

IMPORTANT: THE VENTING SYSTEM MUST TER-

MINATE TO THE OUTSIDE. DO NOT TERMINATE

THE VENT IN AN ATTIC OR OTHER ENCLOSED

SPACE. THIS MAY RESULT IN A FIRE HAZARD.

TO INSURE PROPER AIR

MOVEMENT AND VELOCITY:

Attic Venting: Never vent to either attic or crawl space.

Unit must always be ducted to the outside.

Uniform Size: All ducting should be uniform throughout

the complete system for proper performance.

Duct Restrictions: Never install two elbow fittings next

to each other. This causes unusual air patterns and

subsequently interrupts velocity and the end result is

poor ventilation.

NOTE: Ductwork, wall and roof caps not supplied with

hood.

Select venting prior to installation. This oven must be

vented one of three ways:

A. Outside Venting through the top surface of

the unit.

Sealing Joints: All joints in the duct system must be

tightly taped to avoid smoke and odor in the home.

Also, be sure to caulk thoroughly all joints in floor or

wall where duct system goes to the outside.

3

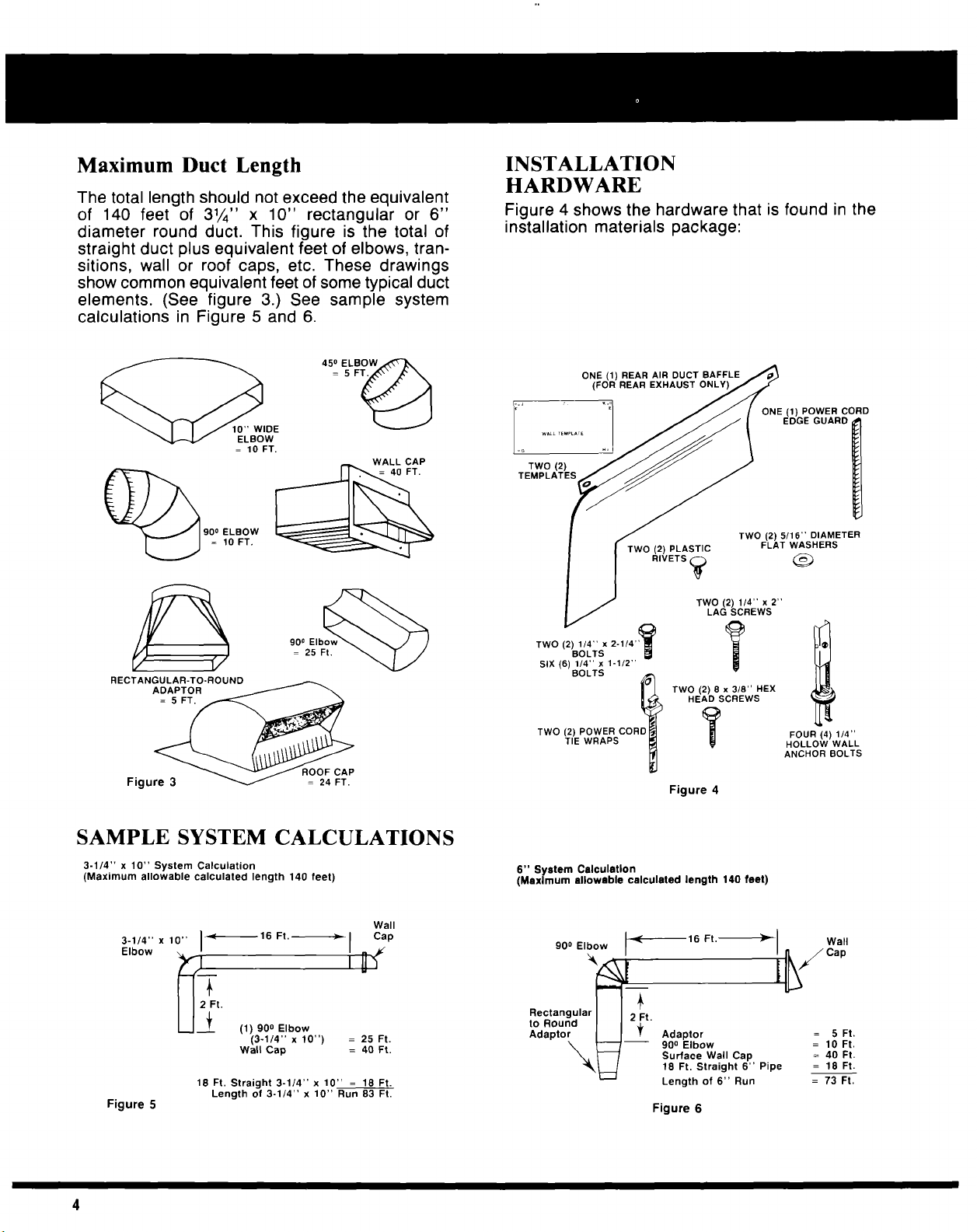

Maximum Duct Length

The total length should not exceed the equivalent

of 140 feet of 31//4'' x 10" rectangular or 6"

diameter round duct. This figure is the total of

straight duct plus equivalent feet of elbows, tran-

sitions, wall or roof caps, etc. These drawings

show common equivalent feet of some typical duct

elements. (See figure 3.) See sample system

calculations in Figure 5 and 6.

INSTALLATION

HARDWARE

Figure 4 shows the hardware that is found in the

installation materials package:

10" WIDE

ELBOW

= 10FT.

90 o ELBOW

= 10FT,

'_°2_'b;_

RECTANGULAR-TO-ROUND

ADAPTOR _

Figure 3 _ - 24 FT.

_'_"_ ROOF CAP

45 o E LBOW ,_'_'_

= 5F_

__ WALL CAP

ONE (1) REAR AIR DUCT BAFFLE

(FOR REAR EXHAUST ONLY),,,,f_

_J " 'I /_'////ONE_'_OW_,"ROORO

J TWO (2) 5/16" DIAMETER

[ TWO (2) PLASTIC FLAT WASHERS

J LAG SCREWS

Two12_BOLTS1,4".2-.."_=

SIX (6) 1/4" x 1-1/2"

TWO (2) 8 x 3/8" HEX

HEAD SCREWS

TIE WRAPS

Figure 4

i

FOUR (4) _4"

HOLLOW WALL

ANCHOR BOLTS

SAMPLE SYSTEM CALCULATIONS

3.1/4" x 10" System Calculation

(Maximum allowable calculated length 140 feet)

Wall

3-1/4" x 10"

Elbow

Figure 5

_€'_ 16 Ft. "--_-'>_ [ Cap

t.

(1) 90 o Elbow

(3-1/4" x 10") = 25 Ft.

Wail Cap = 40 Ft.

18 Ft. Straight 3-1/4" x 10" = 18 Ft.

Length of 3-1/4" x 10" Run 83 Ft.

6" System Calculation

(Maximum allowable calculated length 140 feet)

900 Elbow

Rectang ula r:_lk_J _Ft.

d

Adaptor = 5 Ft.

900 Elbow = 10 Ft.

Surface Wall Cap = 40 Ft.

18 Ft. Straight 6" Pipe = 18 Ft.

Length of 6" Run = 73 Ft.

Figure 6

Loading...

Loading...