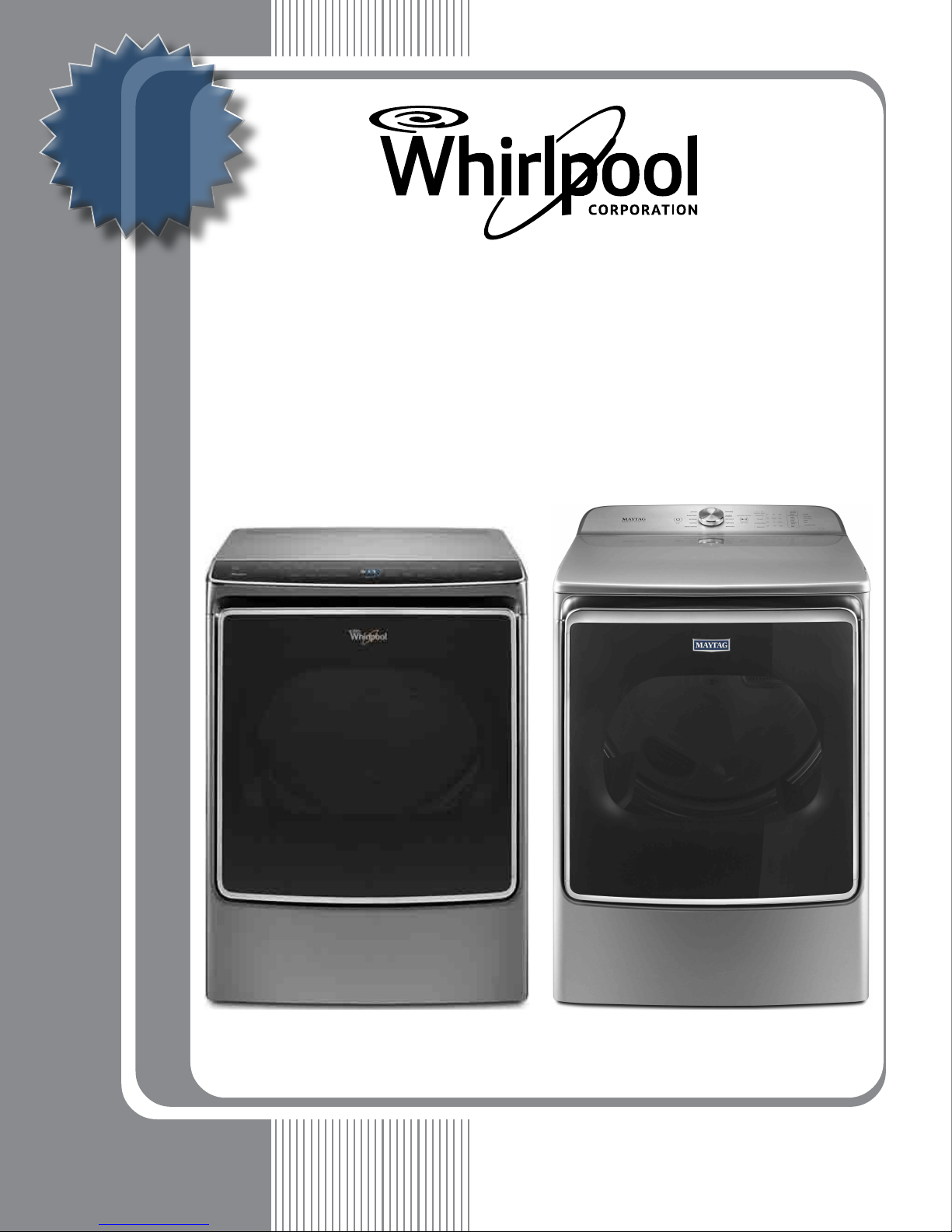

Whirlpool WED9500E, MEDB955F, MGDB955F, WGD9500E Service Manual

Multimedia

Enhanced

L-91

SERVICE MANUAL

WHIRLPOOL & MAYTAG

9.2 CU. FT. STEAM DRYER

WED9500E*, WGD9500E* MEDB955F*, MGDB955F*

*All Colors & Versions

W10881701

FORWARD

This Whirlpool Service Manual, (Part No. W10881701), provides the In-Home Service Professional with

service informaon for the “WHIRLPOOL & MAYTAG 9.2 CU. FT. STEAM DRYER.”

The Wiring Diagram used in this Service Manual is typical and should be used for training purposes

only. Always use the Wiring Diagram supplied with the product tech sheet when servicing the dryer.

For specic operang and installaon informaon on the model being serviced, refer to the “Use and

Care Guide” or “Installaon Instrucons” provided with the dryer.

GOALS AND OBJECTIVES

The goal of this Service Manual is to provide informaon that will enable the In-Home Service

Professional to properly diagnose malfuncons and repair the “WHIRLPOOL & MAYTAG 9.2 CU. FT.

STEAM DRYER.”

The objecves of this Service Manual are to:

• Understand and follow proper safety precauons.

• Successfully troubleshoot and diagnose malfuncons.

• Successfully perform necessary repairs.

• Successfully return the washer to its proper operaonal status.

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made on our

products by anyone other than authorized In-Home Service Professionals.

Copyright © 2016, Whirlpool Corporaon, Benton Harbor, MI 49022

ii

Whirlpool & Maytag 9.2 Cu. Ft. Steam Dryer

n

TABLE OF CONTENTS

WHIRLPOOL & MAYTAG 9.2 CU. FT. STEAM DRYER

SECTION 1 — GENERAL INFORMATION

WASHER SAFETY .................................................................................................................................1-2

GENERAL INFORMATION ...................................................................................................................1-3

MODEL & SERIAL NUMBER LABEL LOCATION....................................................................................1-4

TECH SHEET LOCATION .......................................................................................................................1-4

MODEL AND SERIAL NUMBER NOMENCLATURE ..............................................................................1-5

PRODUCT SPECIFICATIONS ................................................................................................................1-6

SECTION 2 — DIAGNOSTICS & TROUBLESHOOTING

WHIRLPOOL CONTROL PANEL ............................................................................................................2-2

MAYTAG CONTROL PANEL ..................................................................................................................2-3

DIAGNOSTIC GUIDE ............................................................................................................................2-4

SERVICE DIAGNOSTIC MODE .............................................................................................................2-4

ACTIVATING SERVICE DIAGNOSTIC MODE ........................................................................................2-4

KEY ACTIVATION & ENCODER TEST ....................................................................................................2-5

SERVICE TEST MODE...........................................................................................................................2-5

SERVICE TEST MODE CHART ..............................................................................................................2-5

SOFTWARE VERSION DISPLAY ............................................................................................................2-7

FAULT/ERROR CODES..........................................................................................................................2-7

EXITING SERVICE DIAGNOSTIC MODE ...............................................................................................2-7

CUSTOMER FAULT/ERROR CODES CHART ..........................................................................................2-7

SERVICE FAULT/ERROR CODES CHART ...............................................................................................2-8

TROUBLESHOOTING GUIDE .............................................................................................................2-10

NOTES ...............................................................................................................................................2-12

SECTION 3 — COMPONENT TESTING

COMPONENT TESTING: SAFETY INFORMATION ................................................................................3-2

COMPONENT LOCATIONS ..................................................................................................................3-3

WIRING DIAGRAM - ELECTRIC ...........................................................................................................3-4

WIRING DIAGRAM - GAS ....................................................................................................................3-5

COMPONENT TESTING .......................................................................................................................3-6

TEST #1: ACU POWER CHECK ..............................................................................................................3-6

ACU BOARD / CONNECTORS & PINOUTS ...........................................................................................3-7

TEST #2: SUPPLY CONNECTIONS ........................................................................................................3-8

TEST #3: MOTOR CIRCUIT .................................................................................................................3-10

TEST #4: HEAT SYSTEM .....................................................................................................................3-12

TEST #4A: THERMISTORS ..................................................................................................................3-14

TEST #4B: THERMAL FUSE ................................................................................................................3-15

TEST #4C: THERMAL CUTOFF ............................................................................................................3-15

TEST #4D: GAS VALVE .......................................................................................................................3-16

TEST #5: MOISTURE SENSOR ............................................................................................................3-17

TEST #5A: ADJUSTING CUSTOMER-FOCUSED DRYNESS LEVEL........................................................3-18

TEST #6: BUTTONS AND INDICATORS ..............................................................................................3-19

TEST #7: DOOR SWITCH ....................................................................................................................3-20

TEST #8: DRUM LED ..........................................................................................................................3-21

TEST #9: WATER VALVE .....................................................................................................................3-22

TEST #10: SERVICE LEDS ...................................................................................................................3-23

NOTES ...............................................................................................................................................3-24

Whirlpool & Maytag 9.2 Cu. Ft. Steam Dryer

n

iii

SECTION 4 — COMPONENT ACCESS

COMPONENT LOCATIONS ..................................................................................................................4-2

REMOVING THE DOOR ASSEMBLY* ...................................................................................................4-3

REMOVING THE TOP PANEL* .............................................................................................................4-4

REMOVING THE USER INTERFACE* ....................................................................................................4-4

REMOVING THE APPLIANCE CONTROL UNIT (ACU)* ........................................................................4.5

REMOVING THE FRONT PANEL & DOOR SWITCH* ............................................................................4-6

REMOVING THE DRUM LIGHT* ..........................................................................................................4-7

REMOVING THE MOISTURE SENSOR* ...............................................................................................4-7

REMOVING THE BELT, DRUM, AND ROLLERS* ...................................................................................4-8

REMOVING THE DRIVE MOTOR* .....................................................................................................4-10

REMOVING THE THERMAL FUSE & OUTLET THERMISTOR (ELECTRIC)* .........................................4-11

REMOVING THE HEATER ELEMENT (ELECTRIC)* ..............................................................................4-12

REMOVING THE HIGH LIMIT THERMOSTAT & THERMAL CUTOFF (ELECTRIC)* ..............................4-12

REMOVING THE IGNITOR, FLAME SENSOR (GAS)............................................................................4-13

REMOVING THE HIGH-LIMIT THERMOSTAT & THERMAL CUTOFF (GAS) ........................................4-13

REMOVING THE GAS BURNER ASSEMBLY COILS (GAS) ...................................................................4-15

REMOVING THE WATER VALVE* ......................................................................................................4-16

* Video Available Look for this ICON throughout Secon 4

PRODUCT SPECIFICATIONS & WARRANTY INFORMATION SOURCES (inside back cover)

iv

Whirlpool & Maytag 9.2 Cu. Ft. Steam Dryer

n

GENERAL INFORMATION

Section 1:

General Information

This secon provides general safety, parts, and informaon for

the “Whirlpool & Maytag 9.2 Cu. Ft. Steam Dryer.”

n Dryer Safety

n General Info

n Model/Serial Number Locaon

n Tech Sheet Locaon

n Model & Serial Number Nomenclature

n Product Specicaons

Whirlpool & Maytag 9.2 Cu. Ft. Steam Dryer

n

1-1

GENERAL INFORMATION

Dryer Safety

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

You

can be killed or seriously injured if you don't

instructions.

follow

1-2

Whirlpool & Maytag 9.2 Cu. Ft. Steam Dryer

n

GENERAL INFORMATION

General Info

INTRODUCTION

The new Whirlpool and Maytag Steam Dryers represents

industry-leading innovaon with Advanced Moisture Sensing

using three sensors to track moisture and temperature,

adapng drying mes to end the cycle at just the right me.

NEW COMPONENTS

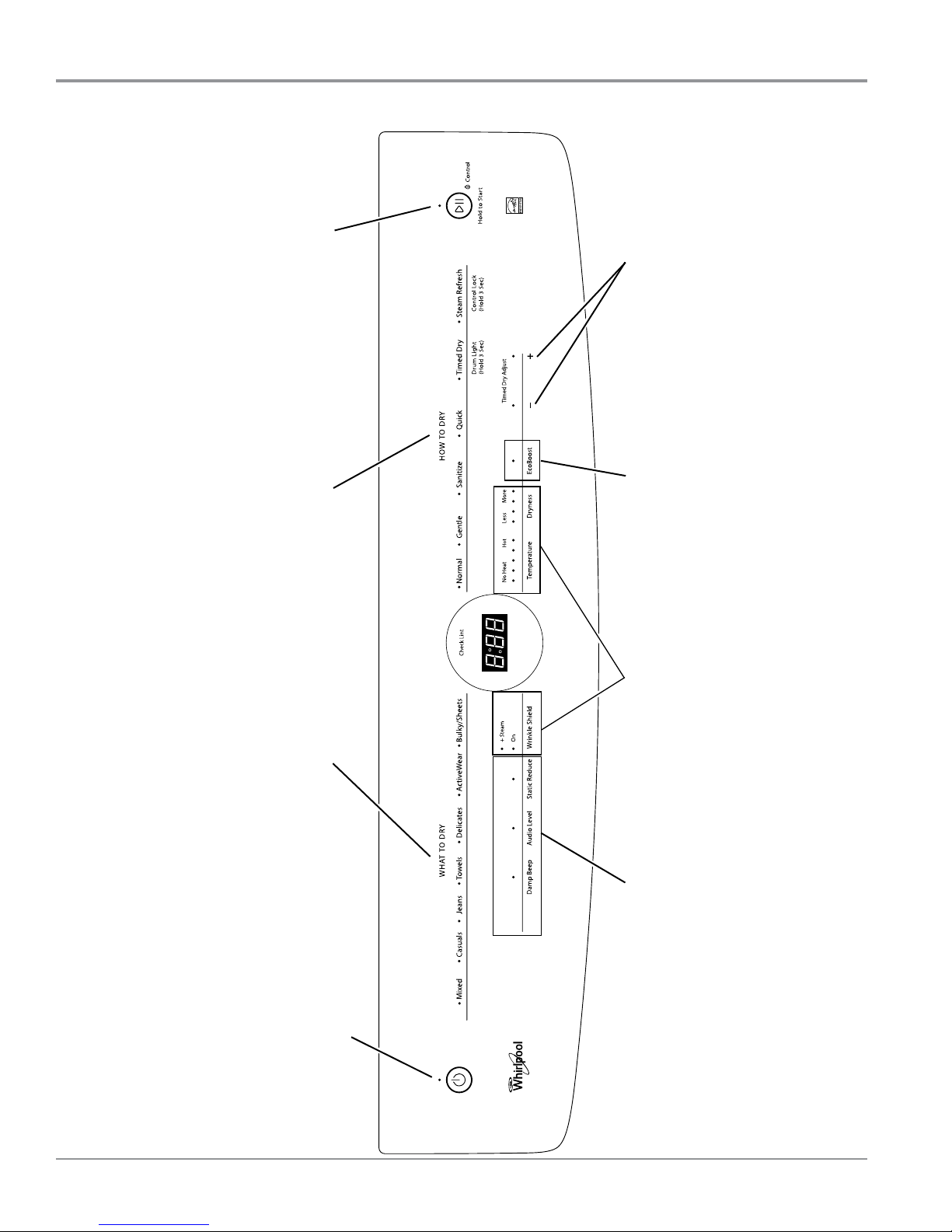

Sleek Under Glass User Interface — the Whirlpool dryer features a new sleek under glass capacive touch user interface that

asks “what’s being dried” followed by “how you want to dry.” First select a cycle from the “What to Dry” (Casuals, Jeans, Towels,

Delicates, AcveWear, and Bulky Sheets) and then select the “How to Dry” (Normal, Gentle, Sanize, Quick, Timed Dry, Steam

Refresh). This new and improved input will help the customer achieve the best combinaon cycle available for the type of items

being dried.

Addional features include 9.2 cu. . capacity, Stainless Steel

Drum, Intuive Touch Controls with Memory, Customized

Fabric Care, and a Steam Refresh Cycle that releases wrinkles

and reduces odors without rewashing.

What to Dry

Figure 1 - User Interface with Intuitive Touch Controls

Extra Large 9.2 cu. . Capacity Drum — Our largest dryer

opening available, the Whirlpool and Maytag dryers have an

extra large drum capacity of 9.2 cu.. The drum’s stainless

steel construcon presents a smooth surface that helps deliver

ulmate gentleness, cradling clothes as they tumble.

How to Dry

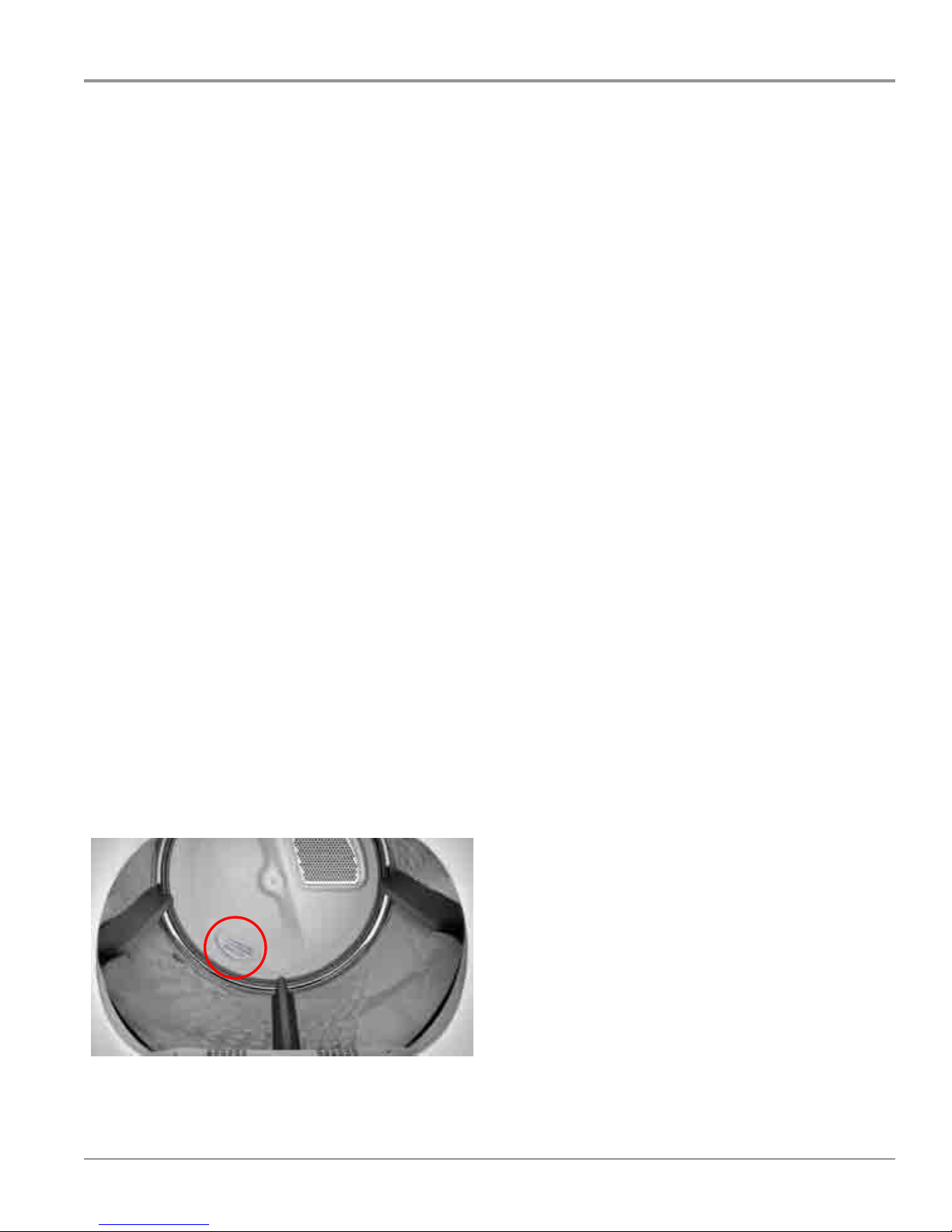

Advanced Moisture Sensing — now using up to four (4)

moisture sensors to track moisture more accurately. Two

moisture sensors in the front of the dryer, located on the lint

screen outlet grill, (see Figure 3 below) and on Maytag models,

two moisture sensors in the back of the dryer, located on the

rear bulkhead, (circled in Figure 2).

Figure 2 - Extra Large Capacity Basket

Figure 3 - Moisture Sensors

Whirlpool & Maytag 9.2 Cu. Ft. Steam Dryer

n

1-3

GENERAL INFORMATION

Model & Serial Number Location

Model & Serial Number

Label Location

Figure 3 - Model / Serial Number

Tech Sheet Location

Tech Sheet Location (Under CCU)

(Whirlpool) Beneath Top Panel

CCU

(Maytag) Beneath Console

1-4

Whirlpool & Maytag 9.2 Cu. Ft. Steam Dryer

n

Figure 4 - Tech Sheet Location

GENERAL INFORMATION

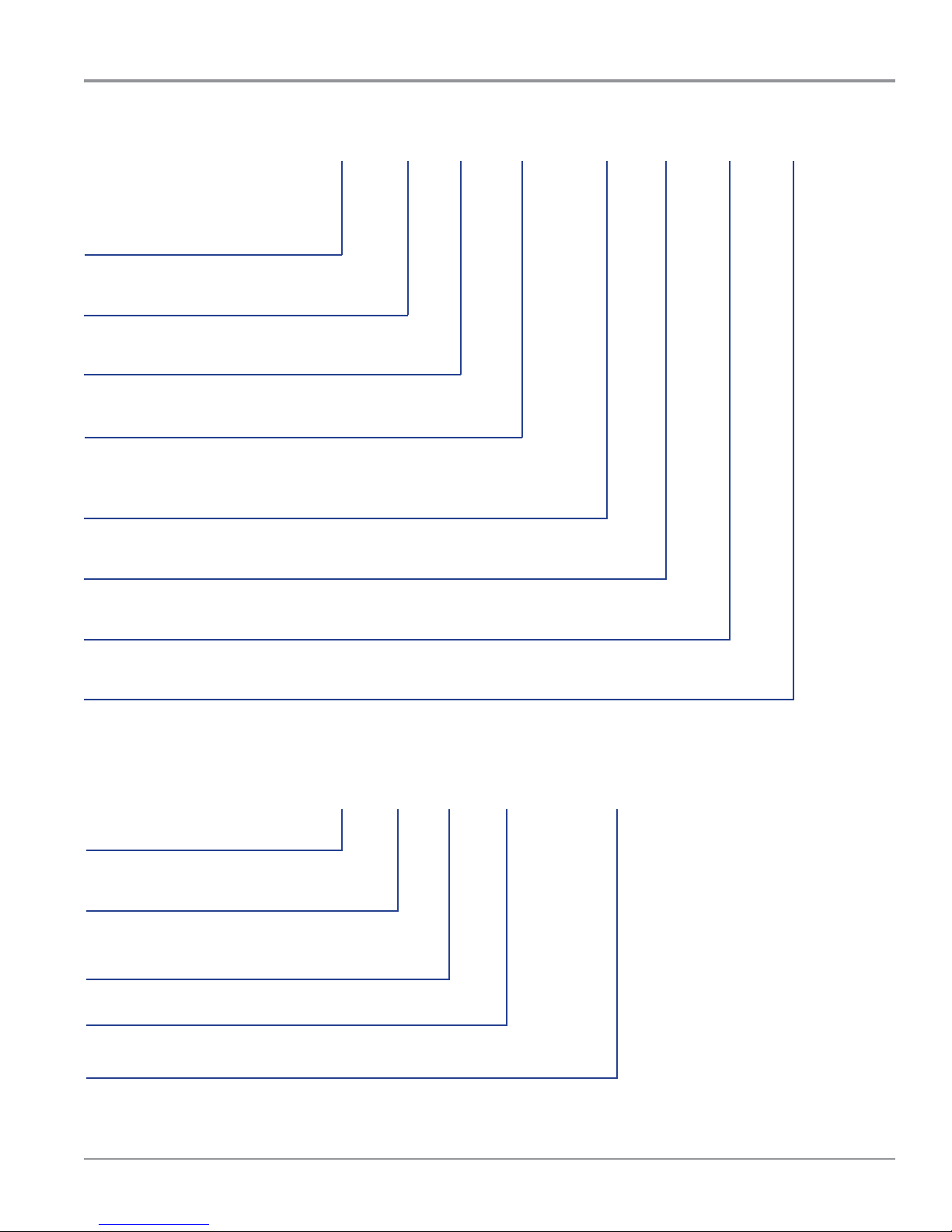

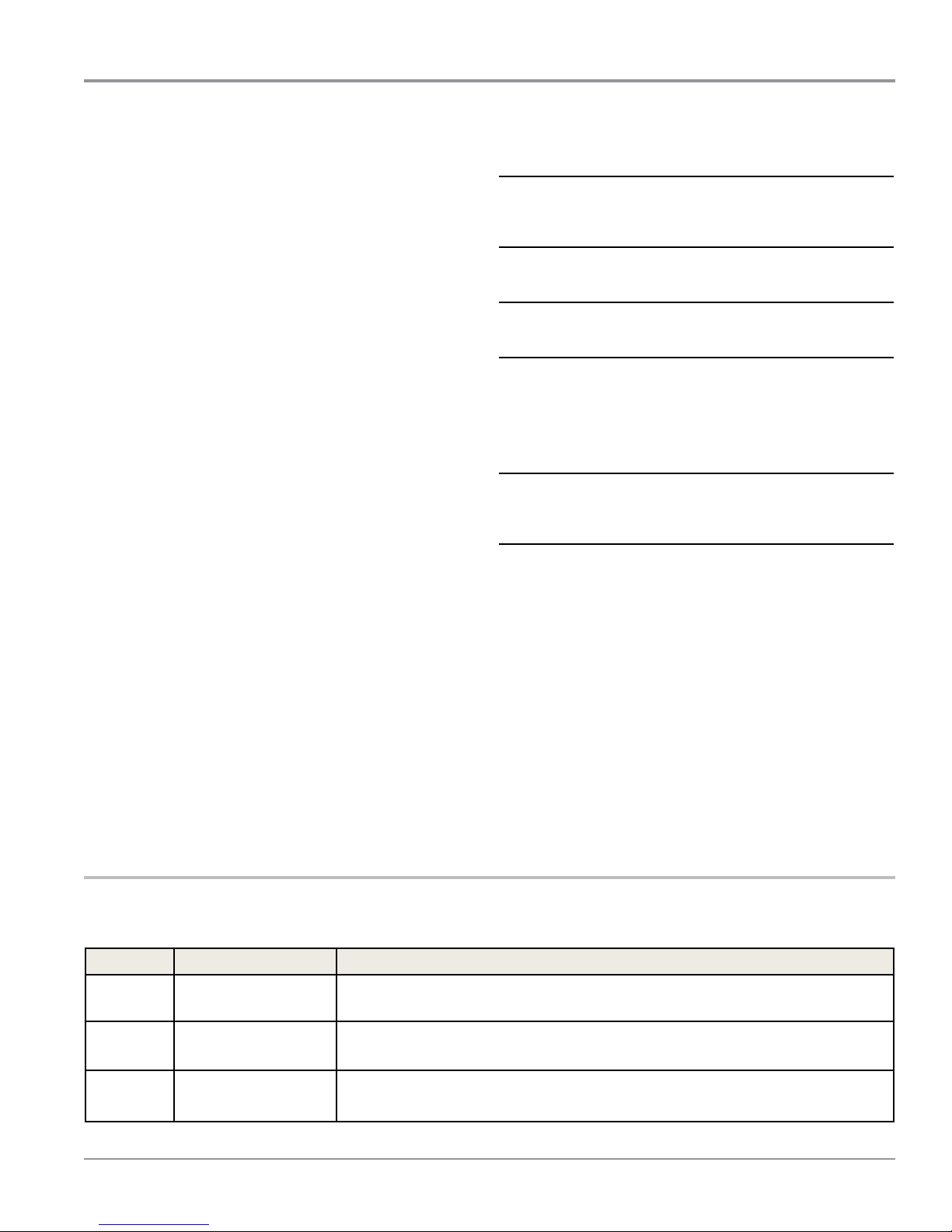

Model & Serial Number Nomenclature

MODEL NUMBER W E

INTERNATIONAL SALES OR

MARKETING CHANNEL

BRAND

W = Whirlpool; M = Maytag

ACCESS

E = Electric Dryer; G = Gas Dryer

PRODUCT

W = Washer; D = Dryer

FEATURE SET

9500 = Whirlpool 9.2 Cu. Ft.

B955 = Maytag 9.2 Cu. Ft.

YEAR OF INTRODUCTION

E = 2015; F = 2016

COLOR CODE

W = White; C = Chrome Shadow

D

9500 E W 0

ENGINEERING CHANGE

0 = Basic Release; 1 = First Revision

SERIAL NUMBER M 4 25 10000

PRODUCTION SITE

M = MARION, OH

YEAR OF PRODUCTION

4 = 2014; 5 = 2015

WEEK OF PRODUCTION

PRODUCT SEQUENCE NUMBER

Whirlpool & Maytag 9.2 Cu. Ft. Steam Dryer

n

1-5

GENERAL INFORMATION

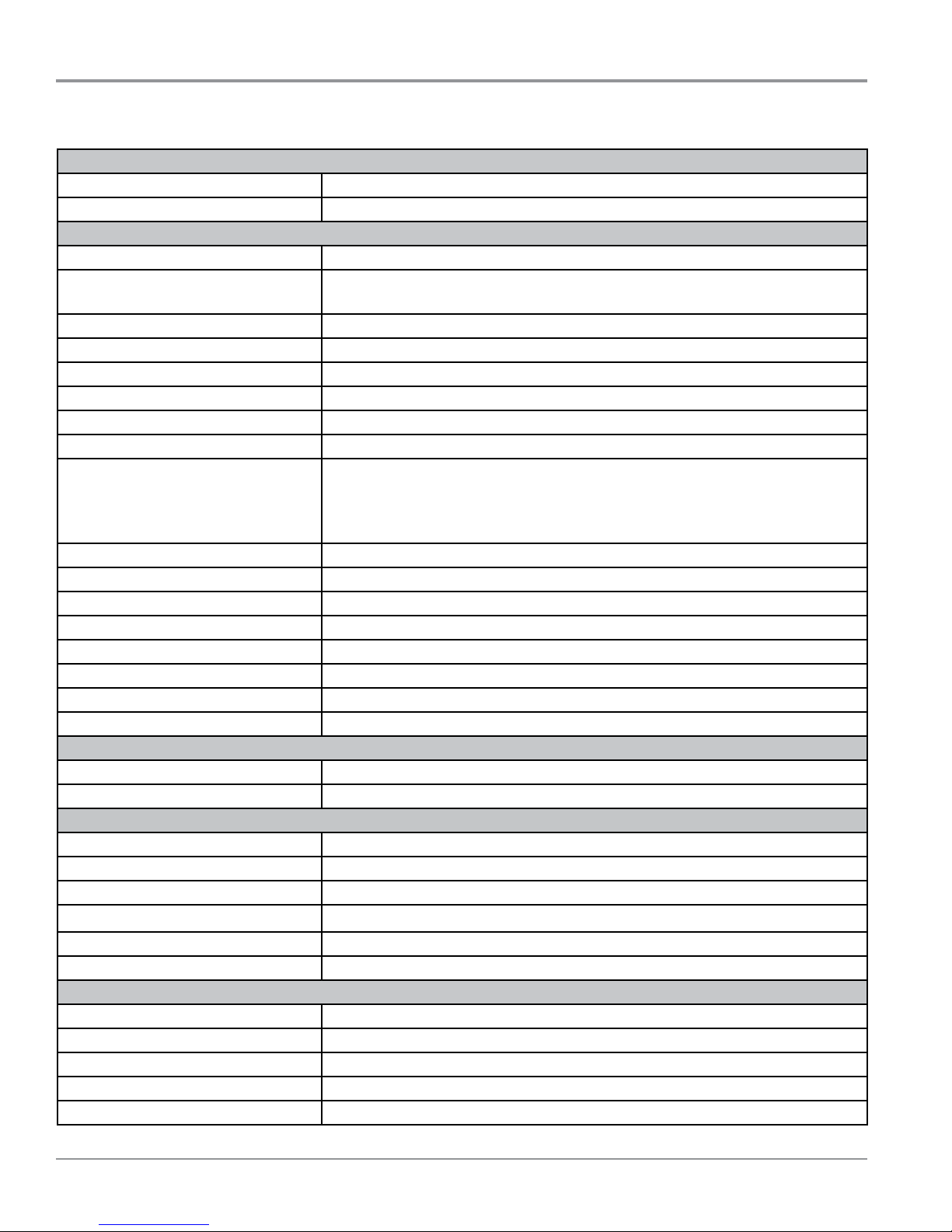

Product Specifications

ELECTRICAL

Fuel Type (Electric) : 240 VAC, 60 Hz, 30 Amp Service

Fuel Type (Gas) : 120 VAC, 60 Hz, 15-20 Amp Service

PRIMARY FEATURES

Capacity : 9.2 cu. .

Control Panel : (Whirlpool) Front / Capacive Touch / Electronic

(Maytag) Rear Panel / Capacive Touch / Cycle Select Knob

Drum Material : Stainless Steel

Drum Design : Quad Baes

Door Style : Side Swing, Reversible, Window

Interior Light : Yes

Energy Star® Qualied : Yes

Steam : Yes

Cycles (Whirlpool) : (What to Dry)

Mixed, Casuals, Jeans, Towels, Delicates, AcveWear, Bulky/Sheets

(How to Dry)

Normal, Gentle, Sanize, Quick, Timed Dry, Steam Refresh

Temperatures : (5) Air Only, Extra Low, Low, Medium, High

Dryness Levels : (4) Less, Low, Medium, More

Lint Filter Indicator : Yes

Automac Dry Control : Yes

EcoBoost™ Energy Saver Yes

Cycle Time Remaining : Yes

Advanced Moisture Sensor : Yes

Sound Package : Yes

INSTALLATION CONSIDERATIONS

Venng Direcon : 4-Way (Le, Right, Boom, Rear)

Maximum Vent Length : 64 .

OPTIONS

Audio Level : Change the sounds from low, medium, high, or o

End of Cycle Signal : Sound when cycle is complete

Damp Dry Signal : Sound when load is damp, but not completely dry

Eco Boost™ : Use a slightly lower heat level to increase energy savings

Stac Reduce : Introduces a small amount of moisture to reduce stac

Wrinkle Shield™ with Steam : Adds up to 150 minutes of periodic tumbling to reduce wrinkling

DIMENSIONS

Height : 41 3/8” (105.1 cm)

Width : 29” (73.66 cm)

Depth : 33 1/2” (85.1 cm)

Depth with door open : 57 5/8” (146.4 cm)

Gross Weight : 191 lbs. (86.64 kg)

1-6

Whirlpool & Maytag 9.2 Cu. Ft. Steam Dryer

n

DIAGNOSTICS & TROUBLESHOOTING

Section 2:

Diagnostics &

Troubleshooting

This secon provides diagnosc, fault codes, and

troubleshoong informaon for the “Whirlpool & Maytag 9.2

Cu. Ft. Steam Dryer.”

n Whirlpool Control Panel

n Maytag Control Panel

n Diagnosc Guide

n Service Diagnosc Mode

n Acvang Service Diagnosc Mode

n Key Acvaon & Encoder Test

n Service Test Mode

n Soware Version Display

n Exing Service Diagnosc Mode

n Fault/Error Codes

n Customer Fault/Error Codes

n Service Fault/Error Codes

n Troubleshoong Guide

n Notes

Whirlpool & Maytag 9.2 Cu. Ft. Steam Dryer

n

2-1

DIAGNOSTICS & TROUBLESHOOTING

FOR SERVICE TECHNICIAN’S USE ONLY

Figure 1 - Key Activation & Encoder Test for Service Diagnostic Mode

For Service Technician Use Only

off “Control” indicator).

to turn off indicator (also turns

START/PAUSE button: press once

its respective indicator.

Timed Dry Adjust “–” or “+”

button: press once to turn off

“Check Lint” display.

Pressing each “HOW TO DRY”

button turns off each corresponding

off the seven-segment display and the

indicator. Pressing “Normal” also turns

the light ring LEDs.

Pressing “Bulky/Sheets” also turns off

Pressing each “WHAT TO DRY” button

turns off each corresponding indicator.

button once to turn off

its respective indicator.

Option buttons: press each

display segment.

Press each modifier button

once to turn off its respective

button once to turn off

its respective indicator.

Option buttons: press each

indicator. Press twice to exit service

Whirlpool Control Panel (features and appearances may vary between models)

2-2

Whirlpool & Maytag 9.2 Cu. Ft. Steam Dryer

n

POWER button: press once to turn off

standby mode.

diagnostic mode and return to

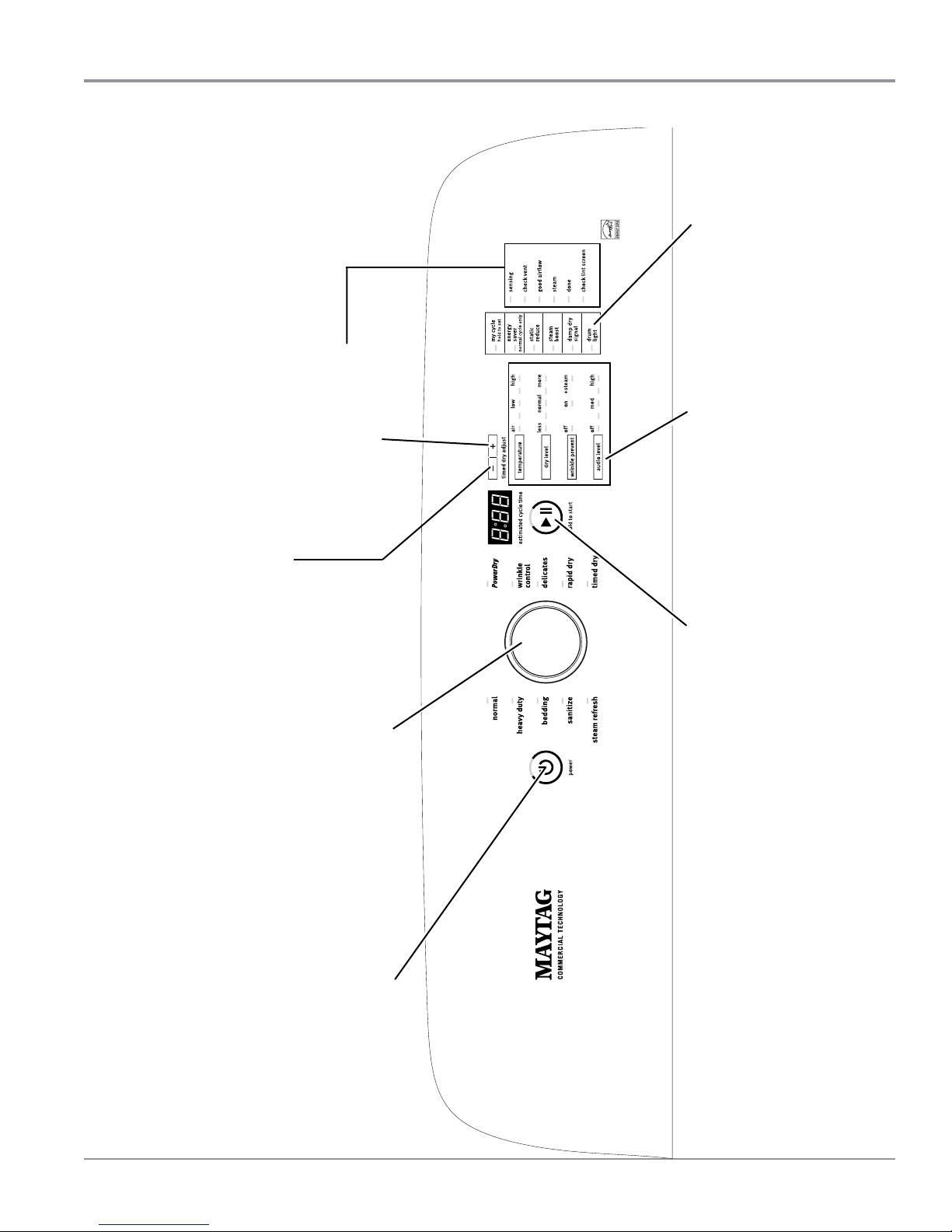

Figure 1 - Key Activation & Encoder Test for Service Diagnostic Mode

For Service Technician Use Only

FOR SERVICE TECHNICIAN’S USE ONLY

DIAGNOSTICS & TROUBLESHOOTING

button once to turn off

its respective indicator.

Option buttons: press each

press once to turn off the

Timed Dry Adjust “+” button:

seven-segment display.

press once to turn off the

Timed Dry Adjust “–” button:

indicator. (Features and

Rotating the cycle selector knob

turns off each corresponding cycle

status LEDs.

appearances vary between models).

display segment.

Press each modifier button

once to turn off its respective

off indicator.

press once to turn

START/PAUSE button:

Maytag Control Panel (features and appearances may vary between models)

to standby mode.

off indicator. Press twice to exit

POWER button: press once to turn

service diagnostic mode and return

Whirlpool & Maytag 9.2 Cu. Ft. Steam Dryer

n

2-3

Figure 2 - Key Activation & Encoder Test for Service Diagnostic Mode

FOR SERVICE TECHNICIAN’S USE ONLY

tripped? Was a regular fuse used? Inform

customer that a time-delay fuse is required.

Is dryer vent properly installed and clear

of lint or obstructions?

VOM (volt-ohm-milliammeter) or DVM

(digital-voltmeter) having a sensitivity of

20,000 1 per volt DC or greater.

dryer unplugged or power disconnected.

diameter probes when checking harness

connectors as the probes may damage

the connectors upon insertion.

before replacing components. Look for

connectors not fully seated, broken or

loose wires and terminals, pin insertion,

or wires not pressed into connectors

far enough to engage metal barbs.

functioning is corrosion or contamination on

connections. Use an ohmmeter to check for

continuity across suspected connections.

SERVICE DIAGNOSTIC MODE

These tests allow service personnel to test

and verify all inputs to the machine control

electronics. You may want to do a quick and

overall checkup of the dryer with these tests

before going to specific troubleshooting tests.

ACTIVATING SERVICE DIAGNOSTIC MODE

1. Be sure the dryer is in standby mode

(plugged in with all indicators off).

2. Select any three (3) buttons (except

POWER) and follow the steps below, using

the same buttons (remember the buttons and

the order that the buttons were pressed):

Within 8 seconds,

• Press and Release the 1st selected button,

• Press and Release the 2nd selected button,

• Press and Release the 3rd selected button;

• Repeat this 3 button sequence 2 more times.

3. If this test mode has been entered

successfully, all indicators on the console

will be illuminated for 5 seconds with “”

showing in the three-digit display and a tone

will sound. If there are no saved fault codes,

all indicators on the console will turn off,

and only the seven segment display will

remain on.

NOTE: The Service Diagnostic mode will time

out after 10 minutes of user inactivity, or shut

down if AC power is removed from the dryer.

DIAGNOSTICS & TROUBLESHOOTING

For Service Technician Use Only

Diagnosc Guide

Before servicing, check the following:

n Make sure there is power at the wall outlet.

n Make sure control lock is not enabled.

n Has a household fuse blown or circuit breaker tripped? Was

a regular fuse used? Inform customer that a me-delay

fuse is required.

n Is dryer vent properly installed and clear of lint or

obstrucons?

n All tests/checks should be made with a VOM (volt-

ohm-milliammeter) or DVM (digital-voltmeter) having a

sensivity of 20,000 Ω per volt DC or greater.

n Resistance checks must be made with dryer unplugged or

power disconnected.

n IMPORTANT: Avoid using large diameter probes when

checking harness connectors as the probes may damage

the connectors upon inseron.

n Check all harnesses and connecons before replacing

components. Look for connectors not fully seated, broken

or loose wires and terminals, pin inseron, or wires not

pressed into connectors far enough to engage metal barbs.

n A potenal cause of a control not funconing is corrosion

or contaminaon on connecons. Use an ohmmeter to

check for connuity across suspected connecons.

Service Diagnosc Mode

These tests allow service personnel to test and verify all inputs

to the machine control electronics. You may want to do a quick

and overall checkup of the dryer with these tests before going

to specic troubleshoong tests.

Acvang Service Diagnosc Mode

1. Be sure the dryer is in standby mode (plugged in with all

indicators o).

2. Select any three (3) buons (except POWER) and follow

the steps below, using the same buons (remember the

buons and the order that the buons were pressed):

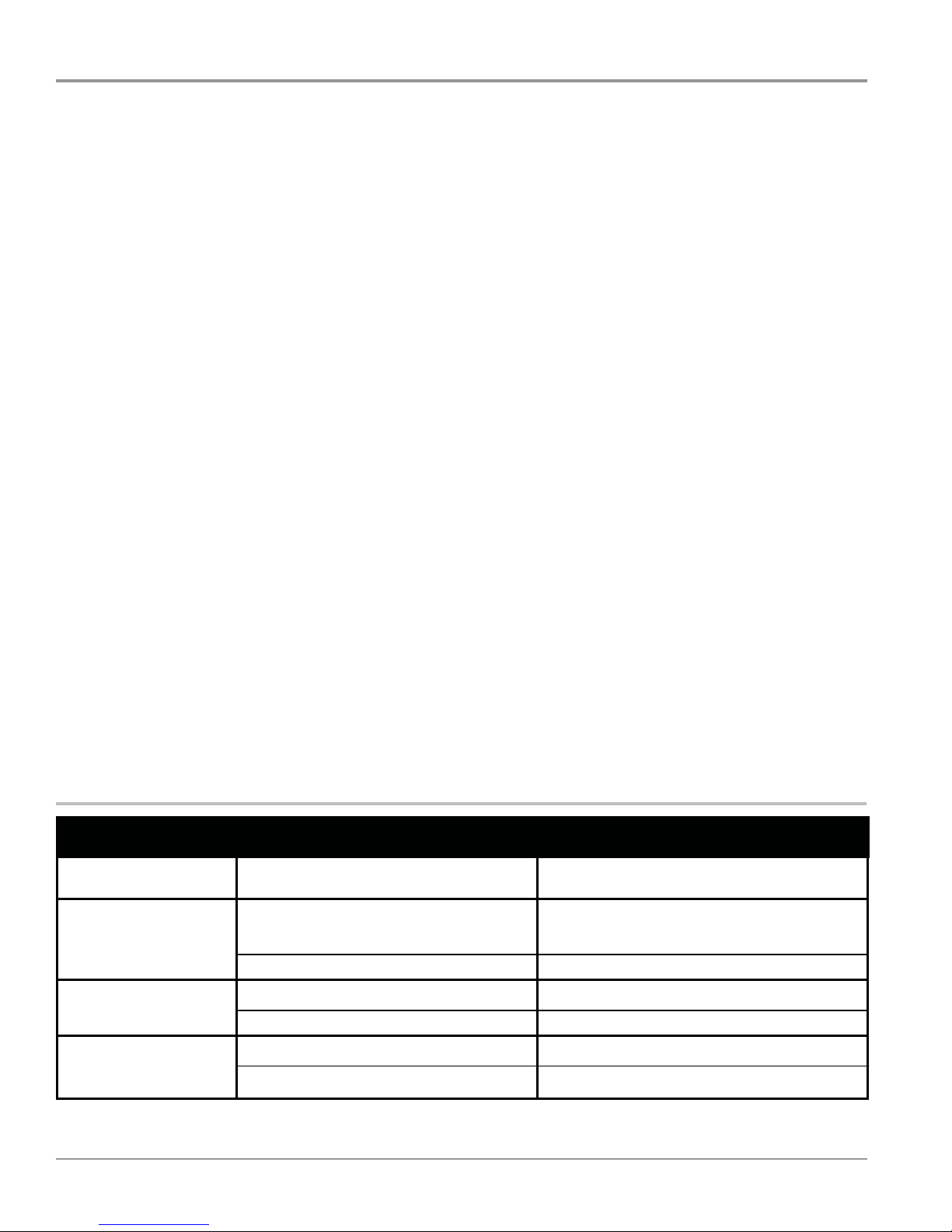

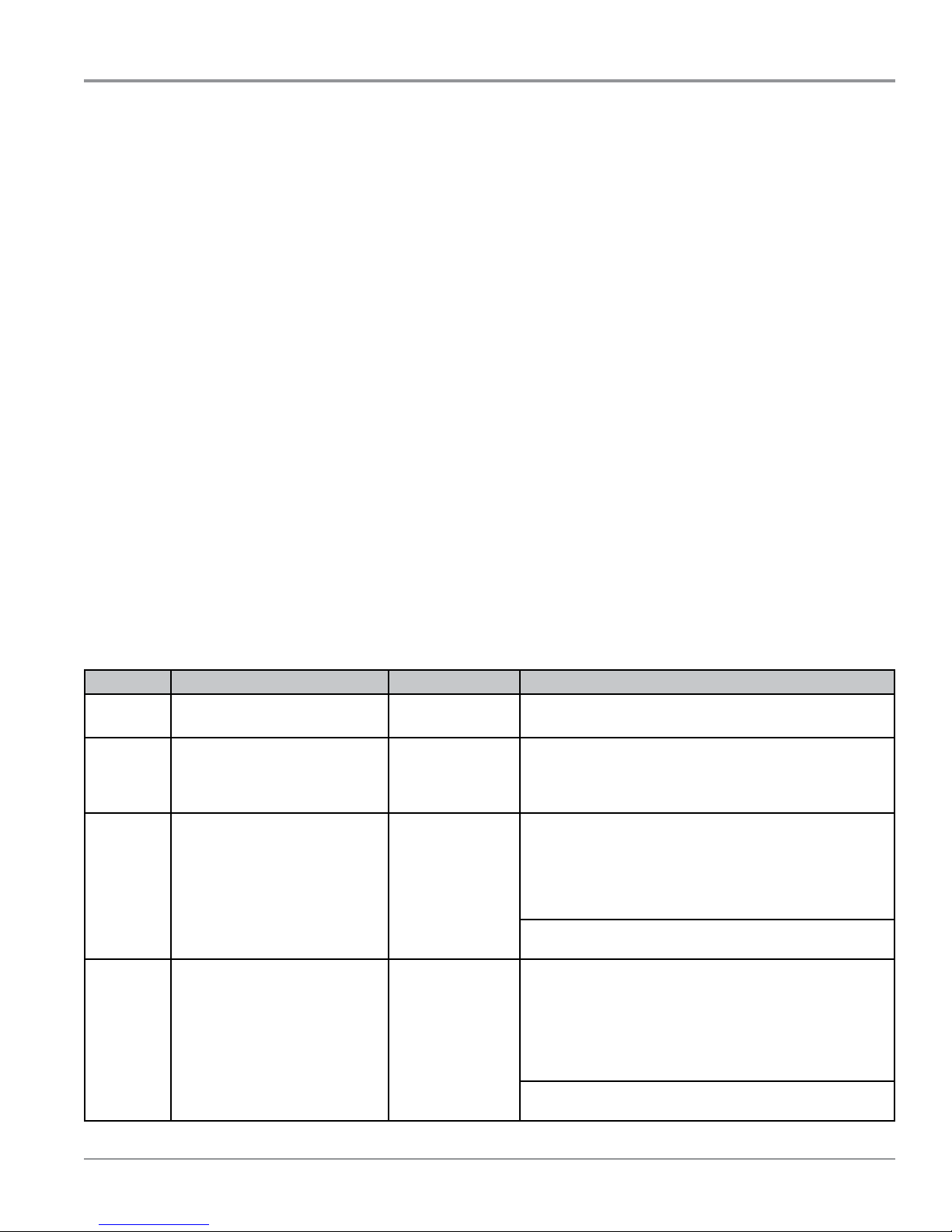

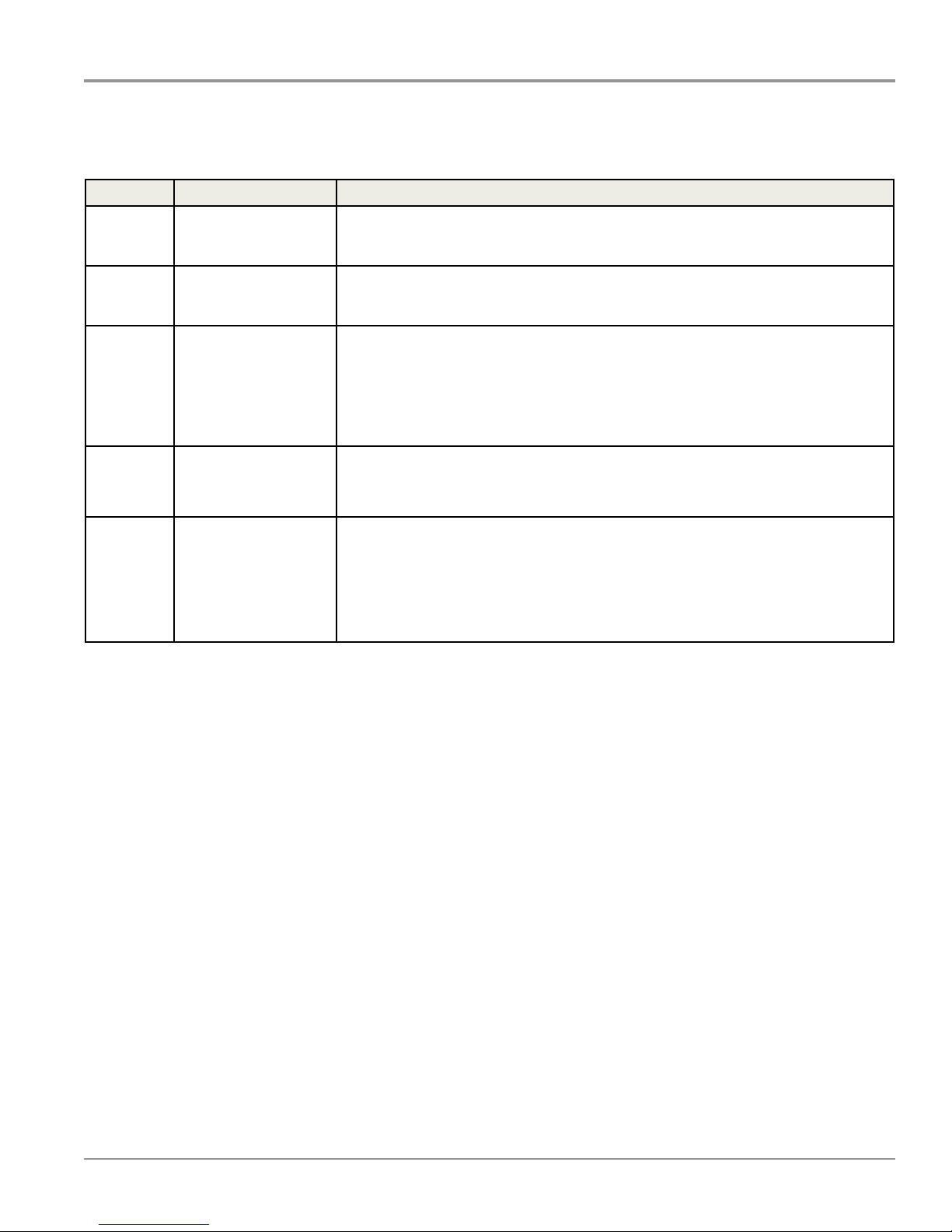

SERVICE DIAGNOSTIC MENU TABLE

Button Press Function Behavior

Within 8 seconds,

• Press and Release the 1st selected buon,

• Press and Release the 2nd selected buon,

• Press and Release the 3rd selected buon;

• Repeat this 3 buon sequence 2 more mes.

3. If this test mode has been entered successfully, all

indicators on the console will be illuminated for 5 seconds

with “888” showing in the three-digit display and a tone

will sound. If there are no saved fault codes, all indicators

on the console will turn o, and only the seven segment

display will remain on.

NOTE: The Service Diagnosc mode will me out aer

10 minutes of user inacvity, or shut down if AC power is

removed from the dryer.

Unsuccessful Activation

If entry into diagnosc mode is unsuccessful, refer to the

following indicaons and acons:

Indicaon 1: None of the indicators or display turn on.

Acon: Select any cycle.

¾ If indicators come on, try to change the funcon for the

three buons used to acvate the diagnosc test mode. If

any buon is unable to change the funcon, something is

faulty with the buon, and it will not be possible to enter

the diagnosc mode using that buon. Replace the user

interface and housing assembly.

¾ If no indicators come on aer selecng the cycle, go to

TEST #1, ACU Power Check, page 3-6.

Indicaon 2: Console indicators begin ashing immediately.

Acon: If console indicators begin ashing on and o

immediately, replace the user interface.

Acvaon with Saved Fault Codes

If there is a saved fault code, it will be ashing in the display.

Review the Fault/Error Codes table on page 2-8 for the

recommended procedure. If there is no saved fault code,

“888” will be displayed.

1st Button - Momentary press

- Press and hold for 5 secs.

2nd Button - Momentary press

- Press and hold for 5 secs.

3rd Button - Momentary press

- Press and hold for 5 secs.

• See “Acvang Service Diagnosc Mode” to acvate these buons. Make sure all of step 3 is complete before acvaon.

2-4

Whirlpool & Maytag 9.2 Cu. Ft. Steam Dryer

n

- Activates Key Activation

& Encoder Test

- Exits Service Diagnostics

- Activates Service Test Mode

- Software Version Display

- Displays Next Error Code

- Clears the Error Codes

DIAGNOSTICS & TROUBLESHOOTING

For Service Technician Use Only

KEY ACTIVATION & ENCODER TEST

NOTE: The Service Diagnosc mode must be acvated before

entering the Key Acvaon & Encoder Test; see procedure on

page 2-4.

Acve Fault Code Display In Key Acvaon & Encoder Test

If the display begins ashing while in the Key Acvaon &

Encoder Test, it is displaying an acve fault code. Acve fault

codes are codes that are currently detected. Only one acve

fault code can be displayed at a me.

Entry Procedure

Press and release the 1st buon used to acvate Service

Diagnosc mode. The following test will be available:

DIAGNOSTIC: Key Activation & Encoder Test

Pressing each buon will turn o its corresponding indicator(s)

or display segment and sound a beep (see gure 1 & 2, pages

2-2 and 2-3.)

Rotang the cycle selector knob (on some models) turns o

each corresponding cycle indicator.

NOTE: A second press of the POWER buon while in Key

Acvaon & Encoder Test mode exits the Service Diagnosc

mode and returns the dryer to standby mode.

¾ If indicators do not turn o and beep aer pressing buons

and rotang the cycle selector knob (on some models), go

to TEST #6: Buons and Indicators, page 3-19.

Exit Procedure

To exit Key Acvaon & Encoder Test, press the POWER buon

once or twice (depending on diagnosc procedure) or press and

hold the rst buon used to acvate Service Diagnosc mode.

SERVICE TEST MODE

NOTE: The Service Diagnosc mode must be acvated before

entering Service Test Mode; see procedure on page 2-4.

NOTE: If, at any point, the user presses the POWER buon or

opens the door during Service Test Mode, the dryer exits to

standby mode.

NOTE: Door must be closed to perform test. Dryer must be

cool before test to run correctly.

Acve Fault Code Display in Service Test Mode

If the display begins ashing while in Service Test Mode, it is

displaying an acve fault code. Acve fault codes are codes

that are currently detected. Only one acve fault code can be

displayed at a me.

Entry Procedure

To enter Service Test Mode, press and release the 2nd buon

used to acvate the Service Diagnosc mode. All LEDs (except

for POWER) turn o, “888” is displayed for 2 seconds, and the

START buon begins to ash.

PERFORM ALL TESTS: Press and release the START buon to

run ALL tests indicated in the chart below and on page 2-6.

VOLTAGE AND WATER SYSTEM-ONLY TESTS: Press and hold

the START buon for 5 seconds aer step 3 to run only the

voltage and water system tests.

Exit Procedure

When the test is complete, press the POWER buon to exit

Service Test Mode and return to standby mode.

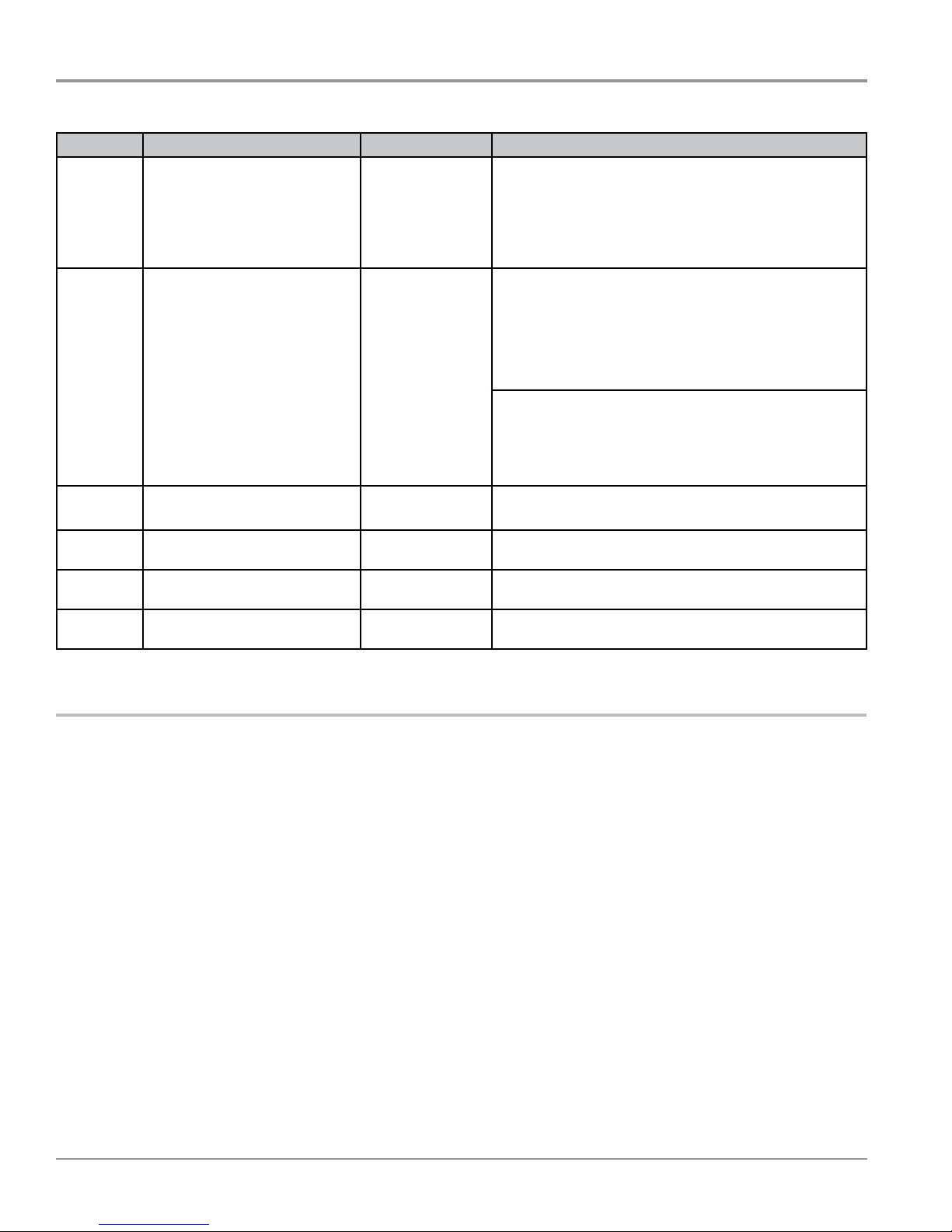

SERVICE TEST MODE CHART

Step # Action Component User Interface Response

1 User enters Service Test Mode

through Service Diagnoscs.

2 Press and release START to

begin the L2 Voltage Check.

3 L2 Voltage Check completes.

Vrms_L2 and Fuel are published

to the UI.

L1 Voltage Check starts

automacally.

4 L1 Voltage Check completes.

Vrms_L1 and Heater_Voltage

are published to the UI.

Check for Warm Machine begins

automacally. Airow begins

detecon algorithm: Status_

Airow = 3 (Detecng).

Press and hold START to jump to

Step 8 and start the Steam Test.

Motor On The display will show “----” unl the voltage is available

Motor On

Heater(s) On

Motor On

Heater(s) On/O

Display shows “888” for 2 seconds. All LEDs (except for

POWER) are o, and the START buon is ashing.

at the UI.

If the START is pressed again or pressed and held before

L2 voltage is available, a tone will sound 3 mes.

If electric (Fuel = Electric): The UI will report ndings

per the “Electric Dryer Results Display” secon where L2

Voltage is available, L1 Voltage is not available, Heater

Voltage is not available, and Airow is not available.

If gas (Fuel = Gas): The display will connue to show

“----”.

If START is pressed again or pressed and held before L1

voltage is available, a tone will sound 3 mes.

If electric (Fuel = Electric): The UI will report ndings

per the “Electric Dryer Results Display” secon where

L2 Voltage is available, L1 Voltage is available, Heater

Voltage is available, and Airow is not available.

If gas (Fuel = Gas): The UI will report ndings per the

“Gas Dryer Results Display” secon where Heater Voltage

is available and Airow is not available.

If a “Detecng Airow” indicator is present, it is displayed

on the UI.

Connued on next page...

Whirlpool & Maytag 9.2 Cu. Ft. Steam Dryer

n

2-5

DIAGNOSTICS & TROUBLESHOOTING

For Service Technician Use Only

Step # Action Component User Interface Response

5 Check for Warm Machine

completes.

Load Mass for Airow begins

automacally.

Press and hold START to jump to

Step 8 and start the Steam Test.

6 Load Mass for Airow

completes. The update for

Status_Airow is published to

the UI.

7 Service Loads Test Complete. Motor O

8 Pressing START begins

STEAM_TEST.

9 Steam Test begins. Water Valve On

10 STEAM_TEST complete. Water Valve O

NOTE: Aer step 3, press and hold the START buon for 5 seconds to jump to the water system test.

Electric dryer performance is opmized for 2-phase, 240 VAC service. If complaint is made regarding electric dryer performance and the L1 to L2 voltage is ~208

VAC, dryer may be connected to a 3-phase service with reduced waage that will decrease dryer performance.

Motor On

Heater(s) On

Motor On/O

Heater(s) On/O

Heater(s) O

Drum Light On

Drum Light O

UI connues to display as in Step 4.

If electric (Fuel = Electric): The UI will report ndings

per the “Electric Dryer Results Display” secon where

L2 Voltage is available, L1 Voltage is available, Heater

Voltage is available, and Airow is available.

If gas (Fuel = Gas): The UI will report ndings per the

“Gas Dryer Results Display” secon where Heater Voltage

is available and Airow is available.

If a “Detecng Airow” LED is present, it is turned o.

If a “Good Airow” LED is present, it also displays when

the Status_Airow = 0.

If a “Check Vent” LED is present, it also displays when the

Status_Airow = 2.

UI & Status LEDs connue to display as in step 6.

“START” is ashing to start the Steam Test.

Display show “h2o” when test is running.

If applicable, UI turns on Drum Light LED. Drum light is

turned on for a maximum of 30 seconds.

Display goes blank and waits for “ServiceTimeout” or

pressing of POWER to go to Standby mode.

Electric Dryer Results Display

The frame rate will be 0.5 seconds per frame. This sequence

will repeat. The text will be right aligned.

Frame 1: L2

Frame 2: When the voltage is available to the UI, it will display

it without illuminang the colon (range 0 to 200).

Frame 3: L1

Frame 4: When the voltage is available to the UI, it will display

it without illuminang the colon (range 0 to 200).

Frame 5: Htr

Frame 6: When the voltage is available to the UI, it will display

it without illuminang the colon (range 0 to 200).

Frame 7: Air

Frame 8: See “Airow Display Secon”.

When the voltage or airow is not yet available to the UI, the

display will show “---”.

2-6

Whirlpool & Maytag 9.2 Cu. Ft. Steam Dryer

n

Gas Dryer Results Display

The frame rate will be 0.5 seconds per frame. This sequence

will repeat. The text will be right aligned.

Frame 1: Htr

Frame 2: When the voltage is available to the UI, it will display

it without illuminang the colon (range 0 to 200).

Frame 3: Air

Frame 4: See “Airow Display Secon”.

When the voltage or airow is not yet available to the UI, the

display will show “---”.

Airow Display:

Value Seng

0 Airow not bad

1 Cannot detect

2 Airow bad; check vent

3 (Default) Detecng

If the result is not yet available, it will be displayed as “---”.

Status_Airow = 0 will be displayed as: “000”.

Status_Airow = 1 will be displayed as: “001”.

Status_Airow = 2 will be displayed as: “002”.

Status_Airow = 3 will be displayed as: “003”.

DIAGNOSTICS & TROUBLESHOOTING

For Service Technician Use Only

SOFTWARE VERSION DISPLAY

NOTE: The Soware Version Display mode will me out aer

10 minutes of user inacvity and return to standby mode.

Entry Procedure

To enter Soware Version Display, press and hold the 2nd

buon used to acvate the Service Diagnosc mode for 5

seconds. Upon entry, the display will automacally cycle

through the following informaon:

• UI soware revision code (U: major revision number, U:

minor revision number, U: test revision number)

• UI GEE revision code (b: major revision number, b: minor

revision number, b: test revision number)

• UI touch parameters revision code (o: major revision

number, o: minor revision number, o: test revision number)

• UI audio soware revision code (A: major revision number,

A: minor revision number, A: test revision number)

• ACU soware revision code (C: major revision number, C:

minor revision number, C: test revision number)

• ACU GEE revision code (h: major revision number, h: minor

revision number, h: test revision number)

• ACU cycle designer revision code (d: major revision

number, d: minor revision number, d: test revision number)

Exit Procedure

Pressing the POWER buon will exit Soware Version Display

and return dryer to standby mode.

FAULT/ERROR CODES

Refer to customer fault/error codes below and service fault/

error codes on page 2-8.

Advancing Through Saved Fault/Error Codes

Procedure for advancing through saved fault codes:

Press and release

the 3rd buon used

to acvate Service

Diagnoscs

Repeat

Repeat

Repeat

.

.

.

Repeat

beep tone

beep tone

beep tone

beep tone

. . .

. . .

. . .

triple beep

second most

recent fault code is

displayed

third most recent

fault code is

displayed

fourth most recent

fault code is

displayed

h most recent

fault code is

displayed

.

.

.

no addional fault

codes are stored--

back to the most

recent fault code

Clearing Fault Codes

To clear stored fault codes, enter Service Diagnosc mode.

Then press and hold the 3rd buon used to enter Service

Diagnosc mode for 5 seconds. Once the stored fault codes

are successfully erased, the seven segment display will show

“888” and a beep will sound.

Fault/Error Code Display Method

Fault codes are displayed by alternately showing F# and E#. All

fault codes have an F# and an E#. The F# indicates the suspect

System/Category. The E# indicates the suspect Component

system.

Up to eight Fault/Error codes may be stored. When the oldest

fault code is displayed, addional presses of the 3rd buon

will result in a triple beep, then display of the most recent fault

code. If each press of the 3rd buon results in a triple beep

and the display shows “888”, no saved fault codes are present.

EXITING SERVICE DIAGNOSTIC MODE

Use either of the two methods below to exit diagnosc mode.

• Pressing and holding the 1st buon used to acvate

the Service Diagnosc mode for 5 seconds.

• Pressing the POWER buon once or twice, depending

on diagnosc procedure.

Customer Fault/Error Codes

Code Description Explanation and Recommended Procedure

PF Power Failure PF indicates that a power failure occurred while the dryer was running.

Press START to connue the cycle, or press POWER to clear the display.

AF Restricted Airow AF indicates low airow that may aect dryer performance. Conrm that airow

system is not blocked. Check lint screen, exhaust duct, exhaust fan.

L2 Low Line Voltage L2 indicates low L2 voltage (less than 30 V) is detected at the ACU.

• Refer to Fault/Error Code “F4E4”, page 2-9, for recommended procedure.

Service Fault/Error Codes on next page...

Whirlpool & Maytag 9.2 Cu. Ft. Steam Dryer

n

2-7

DIAGNOSTICS & TROUBLESHOOTING

For Service Technician Use Only

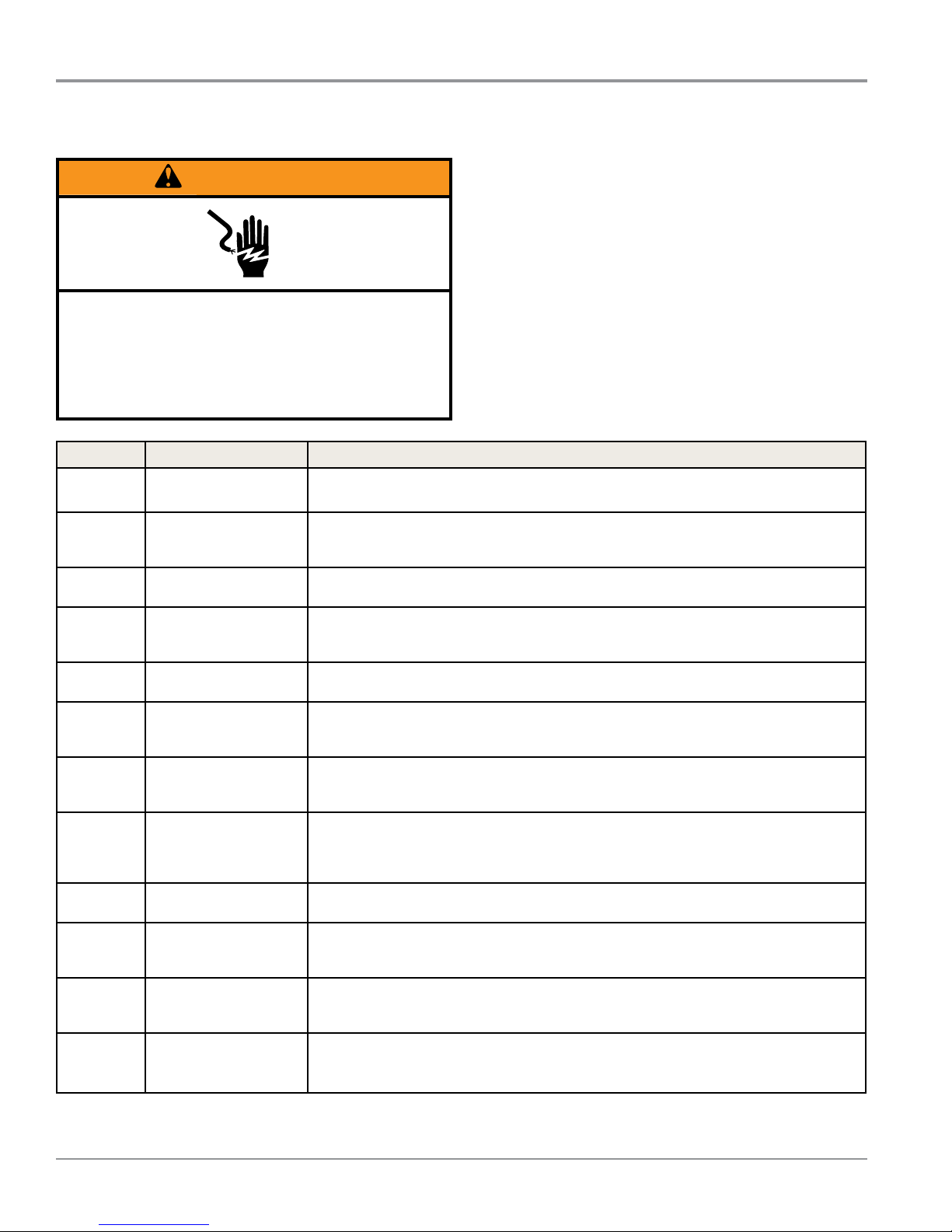

Service Fault/Error Codes

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or

electrical shock.

Code Description Explanation and Recommended Procedure

F1E1 Motor Relay Stuck On

Incorrect Controller

F1E3

F1E5

F2E1

F2E3

F2E4

F2E5

F3E1

F3E2

F3E3

F3E7

F4E1

Installed (on electric

models only)

Parameter Memory

Invalid

User Interface (UI)

Stuck Buon

User Interface (UI)

Mismatch

UI Soware Error:

Incompable

Parameter File

UI Soware Error:

Parameter Memory

Invalid

Exhaust Thermistor

Open/Shorted

Moisture Sensor Open/

Shorted

Inlet Thermistor Open/

Shorted

Rear Moisture Sensor

Open/Shorted (Maytag

Models Only)

Heater 1 Failure or

Connector Problem

Indicates an ACU problem.

• Replace the ACU.

Verify that the part numbers of the ACU and the User Interface are correct for the

dryer model displaying the fault/error code. Replace the ACU and/or UI that does not

match.

ACU parameter le missing: replace the ACU.

Indicates a stuck buon (depressed for over 20 seconds). This fault code will ONLY

appear when in the service diagnosc mode. See TEST #6: Buons and Indicators,

page 3-19.

Indicates a UI and ACU model ID parameter mismatch caused by replacement of

either the UI or ACU with an incorrect part number.

Replace the User Interface.

Replace the User Interface.

Indicates that the exhaust thermistor is open or shorted. If the temperature drops

below 18° F (> 50k ohms), the exhaust thermistor is open. If the temperature is

above 250° F (< 500 ohms), the exhaust thermistor has shorted. May occur if the J14

connector is not plugged into the ACU. See TEST #4a: Thermistors, page 3-14.

Indicates the moisture sensor strip is open or shorted. This fault code will only appear

when in the service diagnosc mode. See TEST #5: Moisture Sensor, page 3-17.

Indicates that the inlet thermistor is open or shorted. If the temperature drops below

18° F (> 245k ohms), the inlet thermistor is open. If the temperature is above 391° F (<

328 ohms), the inlet thermistor has shorted. See TEST #4a: Thermistors, page 3-14.

Indicates the rear moisture sensor strip is open or shorted. This fault code will only

appear when in the service diagnosc mode. See TEST #5: Moisture Sensor, page 3-17.

Indicates no voltage detected at the heater relay.

• Unplug dryer or disconnect power and check that the wires are plugged into the

heater element(s) and the relay(s) on the ACU.

2-8

Whirlpool & Maytag 9.2 Cu. Ft. Steam Dryer

n

Connued on next page...

DIAGNOSTICS & TROUBLESHOOTING

For Service Technician Use Only

Service Fault/Error Codes

Connued from page 2-8

Code Description Explanation and Recommended Procedure

Heater 2 Failure or

F4E2

F4E3 Restricted Airow

F4E4

F4E5 High Limit

F6E2

F6E3

Connector Problem (on

electric models only)

L2 Line Voltage Error

(on electric models

only)

Communicaons Error

UI Cannot Hear ACU

Communicaon Error

ACU Cannot Hear UI

Indicates no voltage detected at the heater relay.

• Unplug dryer or disconnect power and check that the wires are plugged into the

heater element(s) and the relay(s) on the ACU.

Indicates low airow that may aect dryer performance.

• Conrm that airow system is not blocked; check lint screen, exhaust duct, and

exhaust fan.

Indicates low L2 voltage (less than 50 V) is detected at the CCU.

• Check to see if a household fuse has blown or a circuit breaker has tripped.

• Conrm the power cord is properly installed and plugged into the power outlet.

• Unplug dryer or disconnect power and check the relay connecons on the ACU.

• Gas Models Only: Unplug dryer or disconnect power and check the J14 connecon

on the ACU (harness loopback on pins 4 & 5).

Indicates that the temperature threshold of the dryer has been exceeded. This

excessive temperature is usually an indicator of poor airow and is most likely caused

by an exhaust restricon or failure of a component that drives airow such as the

blower wheel.

Communicaon between the ACU and UI has not been detected.

• Unplug dryer or disconnect power.

• Check the harness connuity and connecons between the ACU and UI.

• Check AC and DC supplies. See TEST #1: ACU Power Check, page 3-6.

• Replace the User Interface.

• Replace the ACU.

Whirlpool & Maytag 9.2 Cu. Ft. Steam Dryer

n

2-9

DIAGNOSTICS & TROUBLESHOOTING

For Service Technician Use Only

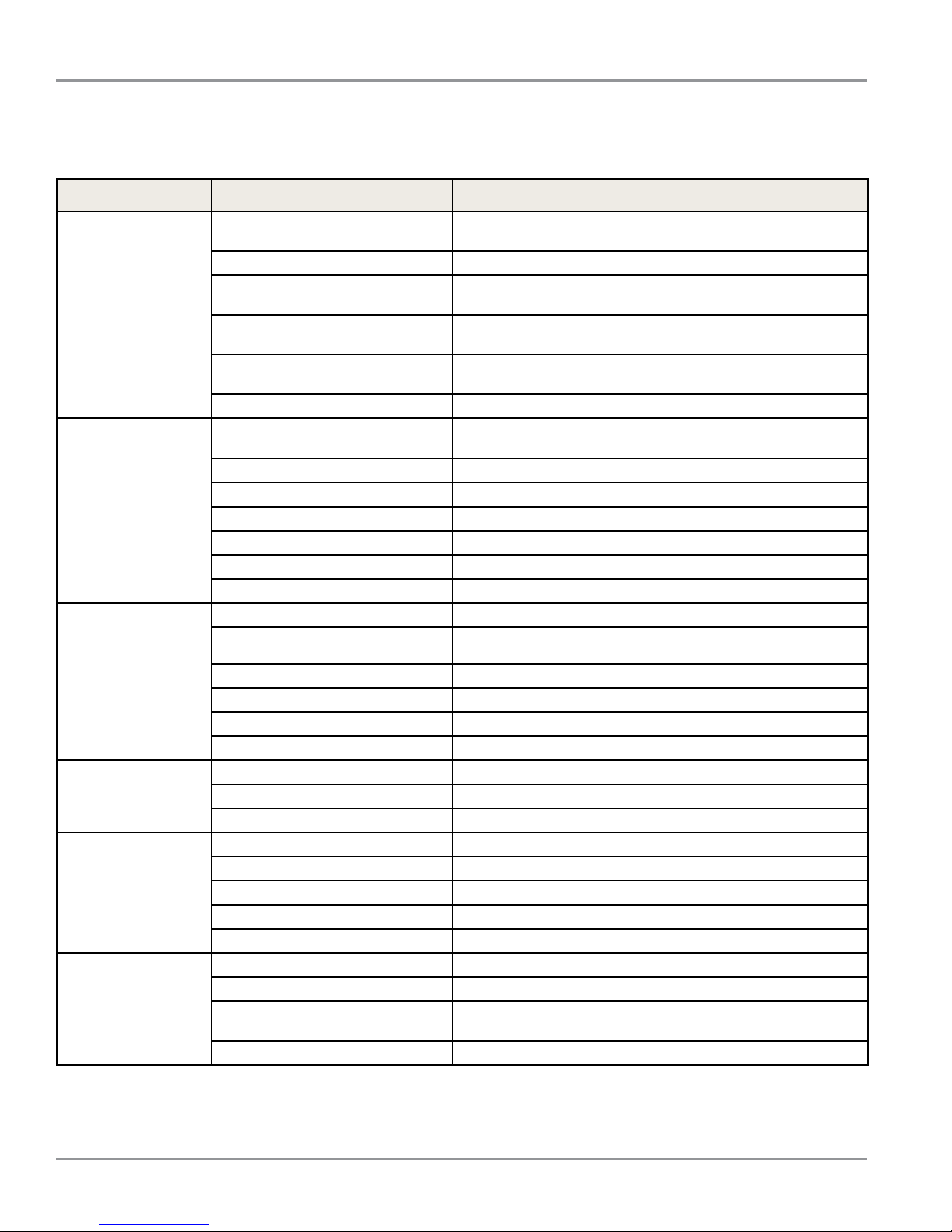

Troubleshoong Guide

NOTE: Always check for error codes rst (page 2-8 and 2-9)

Problem Possible Cause Checks & Tests

Won’t Power Up

• No operaon

• No keypad

response

• No LEDs or display

Will Not Start Cycle

(No response when

START buon is

pressed.)

Will Not Shut O

When Expected

Console Won’t Accept

Selecons

Drum Will Not Spin Drive Belt problem. See Test #3: Motor Circuit, page 3-10.

Will Not Heat Check Installaon. Verify proper dryer installaon.

No power to dryer. Check power at outlet, check circuit breaker, fuses, or juncon

box connecons.

Control Lock feature is enabled. Press and hold STEAM REFRESH for 3 seconds.

Connecon problem between AC

plug and dryer.

Connecon problem between ACU

and UI.

Power supplies not present at

machine electronics.

User Interface problem. See Test #6: Buons & Indicators, page 3-19.

Door not fully closed or striking the

door latch.

Control Lock feature is enabled. Press and hold STEAM REFRESH for 3 seconds.

Door Switch problem. See Test #7: Door Switch, page 3-20.

Drive Belt problem. See Test #3: Motor Circuit, page 3-10.

Thermal Fuse / Motor Problem See Test #3: Motor Circuit, page 3-10.

User Interface problem. See Test #6: Buons & Indicators, page 3-19.

ACU problem. See Test #1: ACU Power Check, page 3-6.

Poor airow. Check lint screen and exhaust vent. Clean if necessary.

Check the Power/Cancel or Start/

Pause buon.

Moisture Sensor problem. See Test #5: Moisture Sensor, page 3-17.

Thermistor problem. See Test #4a: Thermistors, page 3-14.

User Interface problem. See Test #6: Buons & Indicators, page 3-19.

ACU problem. See Test #1: ACU Power Check, page 3-6.

User selected invalid opon. Refer customer to “Use and Care Guide”.

Control Lock feature is enabled. Press and hold STEAM REFRESH for 3 seconds.

User Interface problem. See Test #6: Buons & Indicators, page 3-19.

Thermal Fuse. See Test #4b: Thermal Fuse, page 3-15.

Door switch problem. See Test #7: Door Switch, page 3-20.

Motor problem. See Test #3: Motor Circuit, page 3-10.

ACU problem. See Test #1: ACU Power Check, page 3-6.

Check for L1 and L2. Perform ACU L1 and L2 tests under Service Test Mode.

Heater system malfuncon or open

heater coil.

ACU problem. See Test #1: ACU Power Check, page 3-6.

See Test #2: Supply Connecons, page 3-8.

Check connecons and harness connuity between ACU and UI.

See Test #1: ACU Power Check, page 3-6.

Be sure the door is completely closed, then press and hold the

START buon.

Perform Key Acvaon & Encoder Test.

See Test #4: Heat System, page 3-12

2-10

Whirlpool & Maytag 9.2 Cu. Ft. Steam Dryer

n

Connued on next page...

Loading...

Loading...