Whirlpool LTE6234DQ3 Installation Guide

27IN.(69CM)ELECTRICWAStlER/DRYER

INSTAILATIONINSTRUCTIONS

TableofContents

WASHER/DRYER SAFETY .............................. 1

INSTALLATION INSTRUCTIONS .................... 2

Tools and Parts ............................................. 2

Alternate Parts ............................................... 2

Location Requirements ................................ 2

Drain System ................................................. 3

Electrical Requirements ................................. 4

Electrical Connection .................................... 5

Venting Requirements ................................... 9

Remove Shipping Strap .............................. 10

Install Leveling Legs .................................... 10

Connect the Drain Hose .............................. 10

Connect the Inlet Hoses ............................. 11

Secure the Drain Hose ................................ 11

Plan Vent System ........................................ 12

Install Vent System ...................................... 13

Level Washer/Dryer ..................................... 14

Connect Vent .............................................. 14

Complete Installation .................................. 14

WASHER/DRYERSAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

8542746

INSTAILATIONINSTRUCTIONS

Check that you have everything necessary for correct installation.

Proper installation is your responsibility.

Tools needed:

• #2 Phillips and flat-blade • Knife

screwdriver

• Adjustable wrench that

opens to 1 in. (2.5 cm) or • Vent clamps

9/16in. open-end wrench • Caulking gun and

(for adjusting dryer feet) compound (for installing

• Level new exhaust vent)

• 1/4in. nut driver or socket • Gloves

wrench • Pliers

• Wood block(for leveling) • Scissors

• Ruler or measuring tape • Tin snips (for new vent

• Wire stripper (direct wire installations)

installations)

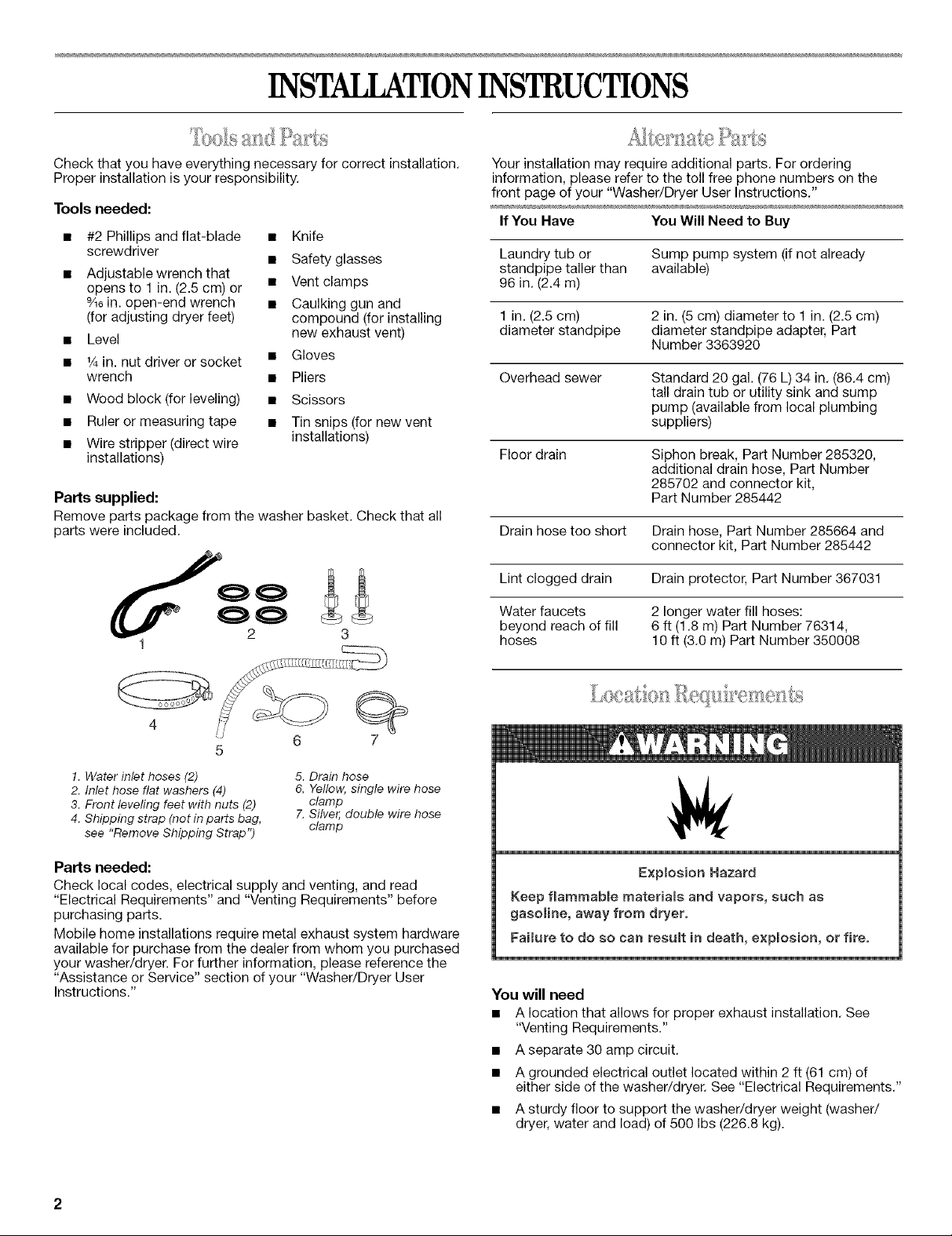

Parts supplied:

Remove parts package from the washer basket. Check that all

parts were included.

• Safety glasses

Your installation may require additional parts. For ordering

information, please refer to the toll free phone numbers on the

front page of your "Washer/Dryer User Instructions."

If You Have You Will Need to Buy

Laundry tub or Sump pump system (if not already

standpipe taller than available)

96 in. (2.4 m)

1 in. (2.5 cm) 2 in. (5 cm) diameter to 1 in. (2.5 cm)

diameter standpipe diameter standpipe adapter, Part

Number 3363920

Overhead sewer Standard 20 gal. (76 L) 34 in. (86.4 cm)

tall drain tub or utility sink and sump

pump (available from local plumbing

suppliers)

Floor drain Siphon break, Part Number 285320,

additional drain hose, Part Number

285702 and connector kit,

Part Number 285442

Drain hose too short Drain hose, Part Number 285664 and

connector kit, Part Number 285442

Lint clogged drain Drain protector, Part Number 367031

Water faucets 2 longer water fill hoses:

beyond reach of fill 6 ft (1.8 m) Part Number 76314,

hoses 10 ft (3.0 m) Part Number 350008

6 7

!. Water inlet hoses (2)

2. Inlet hose flat washers (4)

3. Front leveling feet with nuts (2)

4. Shipping strap (not in parts bag,

see "Remove Shipping Strap")

Parts needed:

Check local codes, electrical supply and venting, and read

"Electrical Requirements" and "Venting Requirements" before

purchasing parts.

Mobile home installations require metal exhaust system hardware

available for purchase from the dealer from whom you purchased

your washer/dryer. For further information, please reference the

"Assistance or Service" section of your "Washer/Dryer User

Instructions."

5. Drain hose

6. Yellow, single wire hose

clamp

7. Silver, double wire hose

clamp

Explosion Hazard

Keep flammable materiaBs and vapors, such as

gasoline, away from dryer.

Failure to do so can result in death, expmosion, or fire.

You will need

• A location that allows for proper exhaust installation. See

"Venting Requirements."

• A separate 30 amp circuit.

• A grounded electrical outlet located within 2 ft (61 cm) of

either side of the washer/dryer. See "Electrical Requirements."

• A sturdy floor to support the washer/dryer weight (washer/

dryer, water and load) of 500 Ibs (226.8 kg).

• Alevelfloorwithamaximumslopeof1in.(2.5cm)under

entirewasher/dryer.Clothesmaynottumbleproperlyand

automaticsensorcyclesmaynotoperatecorrectlyifdryeris

notlevel.Installingoncarpetisnotrecommended.

• Awaterheatersettodeliver120°F(49°C)watertothewasher.

• Hotandcoldwaterfaucetslocatedwithin4ft(1.2m)ofthe

hotandcoldwaterfillvalves,andwaterpressureof5-100psi

(34.5-689.6kPa).

Thewasher/dryermustnotbeinstalledorstoredinanareawhere

itwillbeexposedtowaterand/orweather.

Donotoperateyourwasherintemperaturesatorbelow32°F

(0°C).Somewatercanremaininthewasherandcancause

damageinlowtemperatures.See"Washer/DryerCare"inyour

"Washer/DryerUserInstructions"forwinterizinginformation.

Donotoperateyourdryerattemperaturesbelow45°F(7°C).At

lowertemperatures,thedryermightnotshutoffattheendofan

automaticcycle.Thiscanresultinlongerdryingtimes.

Checkcoderequirements.Somecodeslimit,ordonotpermit,

installationofthewasher/dryeringarages,closets,mobilehomes,

orsleepingquarters.Contactyourlocalbuildinginspector.

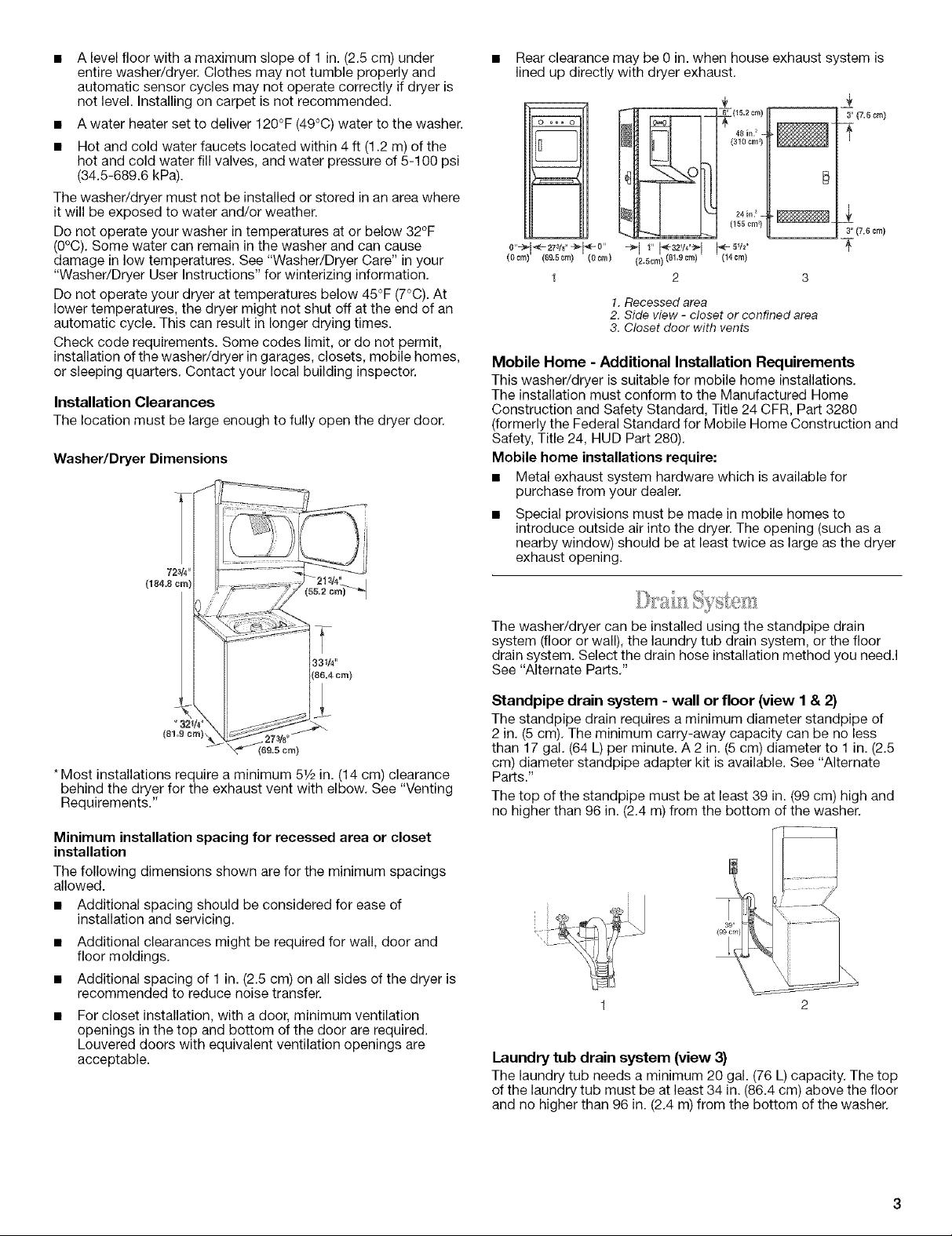

Installation Clearances

The location must be large enough to fully openthe dryer door.

Washer/Dryer Dimensions

723/4"

(184=8cm)

Rear clearance may be 0 in. when house exhaust system is

lined up directly with dryer exhaust.

_(15=2era) 3"(7=6cm)

(3!0 cm _)

(155 cra)

(0era 69=5em 0¢rn) (2.5cm) (81=9cm)

2

1. Recessed area

2. Side view - closet or confined area

3. Closet door with vents

Mobile Home - Additional Installation Requirements

This washer/dryer is suitable for mobile home installations.

The installation must conform to the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction and

Safety, Title 24, HUD Part 280).

Mobile home installations require:

• Metal exhaust system hardware which is available for

purchase from your dealer.

• Special provisions must be made in mobile homes to

introduce outside air into the dryer. The opening (such as a

nearby window) should be at least twice as large as the dryer

exhaust opening.

(14cm)

3" (7=_¢m)

* Most installations require a minimum 51/2in. (14 cm) clearance

behind the dryer for the exhaust vent with elbow. See "Venting

Requirements."

Minimum installation spacing for recessed area or closet

installation

The following dimensions shown are for the minimum spacings

allowed.

• Additional spacing should be considered for ease of

installation and servicing.

• Additional clearances might be required for wall, door and

floor moldings.

• Additional spacing of 1 in. (2.5 cm) on all sides of the dryer is

recommended to reduce noise transfer.

For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilation openings are

acceptable.

The washer/dryer can be installed using the standpipe drain

system (floor or wall), the laundry tub drain system, or the floor

drain system. Select the drain hose installation method you need.I

See "Alternate Parts."

Standpipe drain system - wall or floor (view I & 2)

The standpipe drain requires a minimum diameter standpipe of

2 in. (5 cm). The minimum carry-away capacity can be no less

than 17 gal. (64 L) per minute. A 2 in. (5 cm) diameter to 1 in. (2.5

cm) diameter standpipe adapter kit is available. See "Alternate

Parts."

The top of the standpipe must be at least 39 in. (99 cm) high and

no higher than 96 in. (2.4 m) from the bottom of the washer.

Laundry tub drain system (view 3}

The laundry tub needs a minimum 20 gal. (76 L) capacity. The top

of the laundry tub must be at least 34 in. (86.4 cm) above the floor

and no higher than 96 in. (2.4 m) from the bottom of the washer.

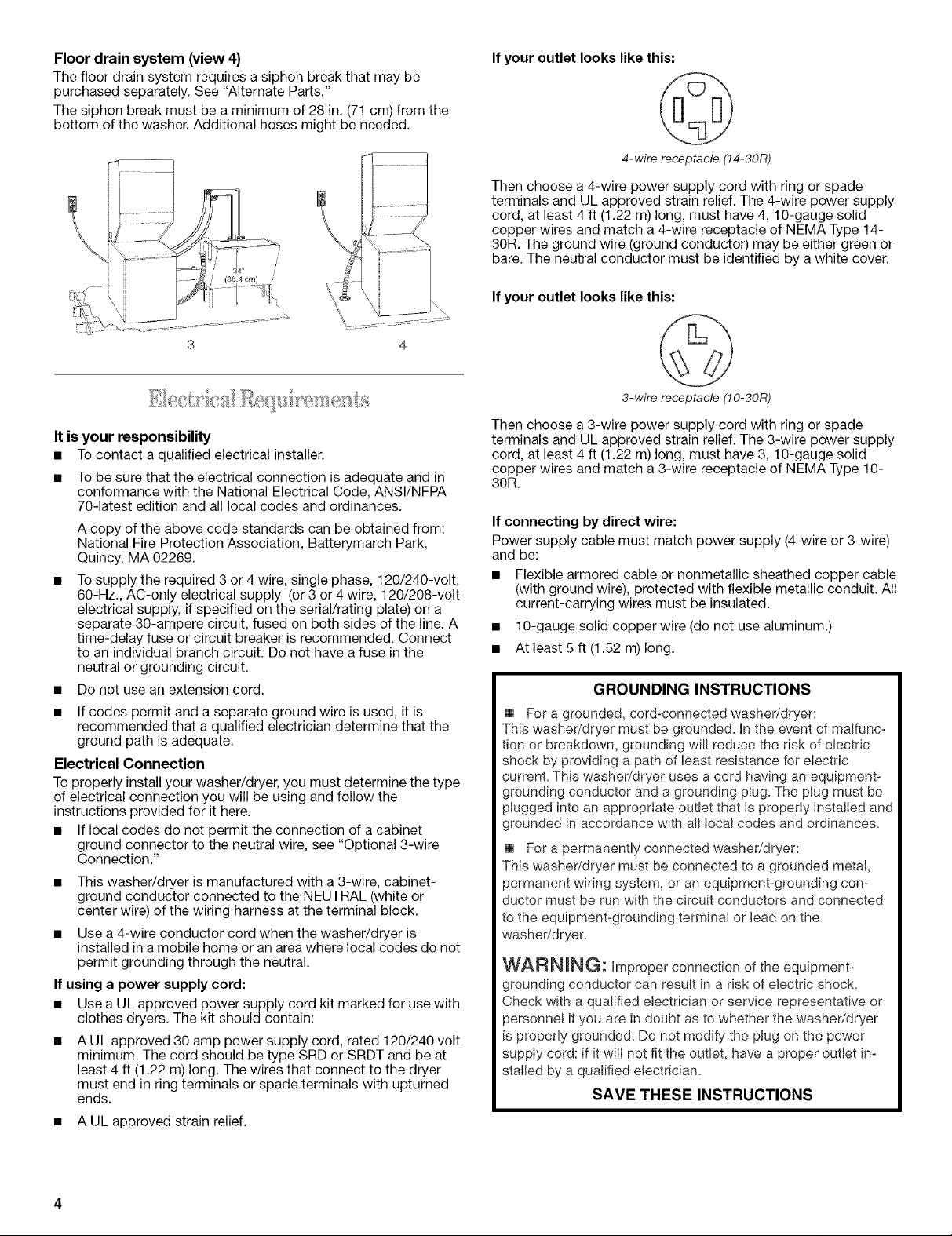

Floor drain system (view 4)

The floor drain system requires a siphon break that may be

purchased separately. See "Alternate Parts."

The siphon break must be a minimum of 28 in. (71 cm) from the

bottom of the washer. Additional hoses might be needed.

It is your responsibility

• To contact a qualified electrical installer.

• To be sure that the electrical connection is adequate and in

conformance with the National Electrical Code, ANSI/NFPA

70-latest edition and all local codes and ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association, Batterymarch Park,

Quincy, MA 02269.

• To supply the required 3 or 4 wire, single phase, 120/240-volt,

60-Hz., AC-only electrical supply (or 3 or 4 wire, 120/208-volt

electrical supply, if specified on the serial/rating plate) on a

separate 30-ampere circuit, fused on both sides of the line. A

time-delay fuse or circuit breaker is recommended. Connect

to an individual branch circuit. Do not have a fuse in the

neutral or grounding circuit.

• Do not use an extension cord.

• If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

Electrical Connection

To properly install your washer/dryer, you must determine the type

of electrical connection you will be using and follow the

instructions provided for it here.

• If local codes do not permit the connection of a cabinet

ground connector to the neutral wire, see "Optional 3-wire

Connection."

• This washer/dryer is manufactured with a 3-wire, cabinet-

ground conductor connected to the NEUTRAL (white or

center wire) of the wiring harness at the terminal block.

• Use a 4-wire conductor cord when the washer/dryer is

installed in a mobile home or an area where local codes do not

permit grounding through the neutral.

If using a power supply cord:

• Use a UL approved power supply cord kit marked for use with

clothes dryers. The kit should contain:

• A UL approved 30 amp power supply cord, rated 120/240 volt

minimum. The cord should be type SRD or SRDT and be at

least 4 ft (1.22 m) long. The wires that connect to the dryer

must end in ring terminals or spade terminals with upturned

ends.

• A UL approved strain relief.

If your outlet looks like this:

4-wire receptacle (14-30R)

Then choose a 4-wire power supply cord with ring or spade

terminals and UL approved strain relief. The 4-wire power supply

cord, at least 4 ft (1.22 m) long, must have 4, 10-gauge solid

copper wires and match a 4-wire receptacle of NEMA Type 14-

30R. The ground wire (ground conductor) may be either green or

bare. The neutral conductor must be identified by a white cover.

If your outlet looks like this:

3-wire receptacle (10-30R)

Then choose a 3-wire power supply cord with ring or spade

terminals and UL approved strain relief. The 3-wire power supply

cord, at least 4 ft (1.22 m) long, must have 3, 10-gauge solid

copper wires and match a 3-wire receptacle of NEMA Type 10-

30R.

If connecting by direct wire:

Power supply cable must match power supply (4-wire or 3-wire)

and be:

• Flexible armored cable or nonmetallic sheathed copper cable

(with ground wire), protected with flexible metallic conduit. All

current-carrying wires must be insulated.

• 10-gauge solid copper wire (do not use aluminum.)

• At least 5 ft (1.52 m) long.

GROUNDING INSTRUCTIONS

[] For a grounded, cord-connected washer/dryer:

This washer/dryer must be grounded. Hnthe event of malfunc-

tion or breakdown, grounding will reduce the risk of electric

shock by providing a path of least resistance for electric

current. This washer/dryer uses a cord having an equipment-

grounding conductor and a grounding plug. The plug must be

plugged into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

[] For a permanently connected washer/dryer:

This washer/dryer must be connected to a grounded metal,

permanent wiring system, or an equipment-grounding con-

ductor must be run with the circuit conductors and connected

to the equipment_grounding terminal or lead on the

washer/dryer.

WARNING: Hmproper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative or

personnel if you are in doubt as to whether the washer/dryer

is properly grounded. Do not modify the plug on the power

supply cord: if it wiiI not fit the outlet, have a proper outlet in-

stalled by a qualified electrician.

SAVE THESE INSTRUCTIONS

PowerSupplyCord DirectWire

Fire Hazard

Use a new UL approved 30 amp power supply cord,

Use a UL approved strain retief.

Disconnect power before making emectrical connections.

Connect neutram wire (white or center wire) to center

terminal (silver),

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 suppmy wires to remaining

2 terminals (gored).

Securemy tighten aimeJectrical connections,

Failure to do so can resumt in death, fire, or

emectrical shock,

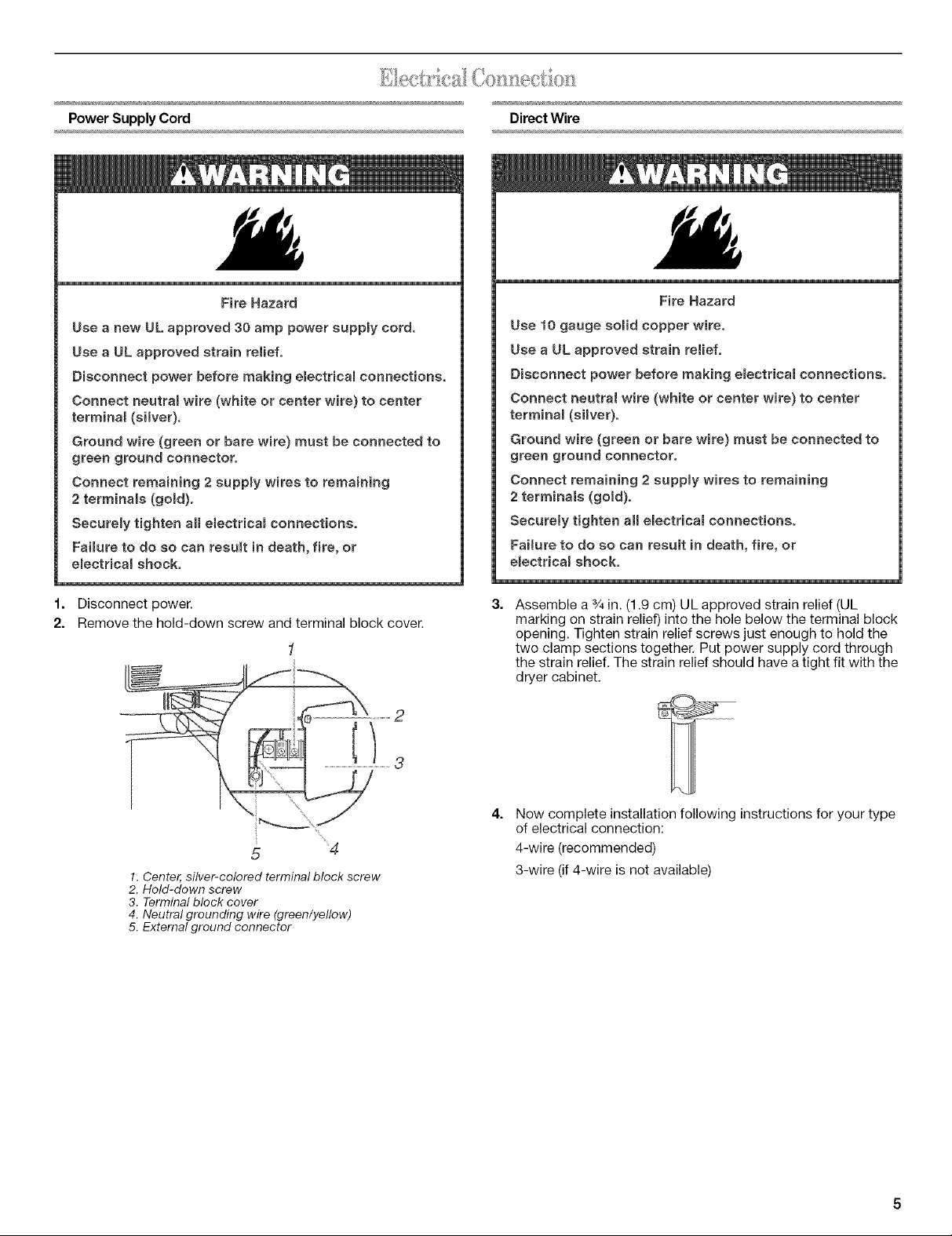

1. Disconnect power.

2. Remove the hold-down screw and terminal block cover.

I

2

Fire Hazard

Use t0 gauge somid copper wire,

Use a UL approved strain retief,

Disconnect power before making emectricamconnections.

Connect neutral wire (white or center wire) to center

terminal (simver).

Ground wire (green or bare wire) must be connected to

green ground connector,

Connect remaining 2 suppmy wires to remaining

2 terminals (gold).

Securely tighten aimemectrica{ connections.

Failure to do so can result in death, fire, or

electrica_ shock.

3. Assemble a 3/,in. (1.9 cm) UL approved strain relief (UL

marking on strain relief) into the hole below the terminal block

opening. Tighten strain relief screws just enough to hold the

two clamp sections together. Put power supply cord through

the strain relief, The strain relief should have a tight fit with the

dryer cabinet.

5

1.Center,silver-colored terminal block screw

2.Hold-down screw

3. Terminalblock cover

4. Neutralgrounding wire(green/yellow)

5. Externalground connector

Now complete installation following instructions for your type

of electrical connection:

4-wire (recommended)

3-wire (if 4-wire is not available)