Whirlpool LE6098XTQ1 Installation Guide

IMPORTANT"

Read and save

these instructions.

IMPORTANT:

Installer: Leave Installation Instructions

with the homeowner,

Homeowner: Keep Installation Instructions

for future reference.

Save Installation Instructions for local

electrical inspector's use.

_affrNo. 3397597 Rev. C

Electric Dryer

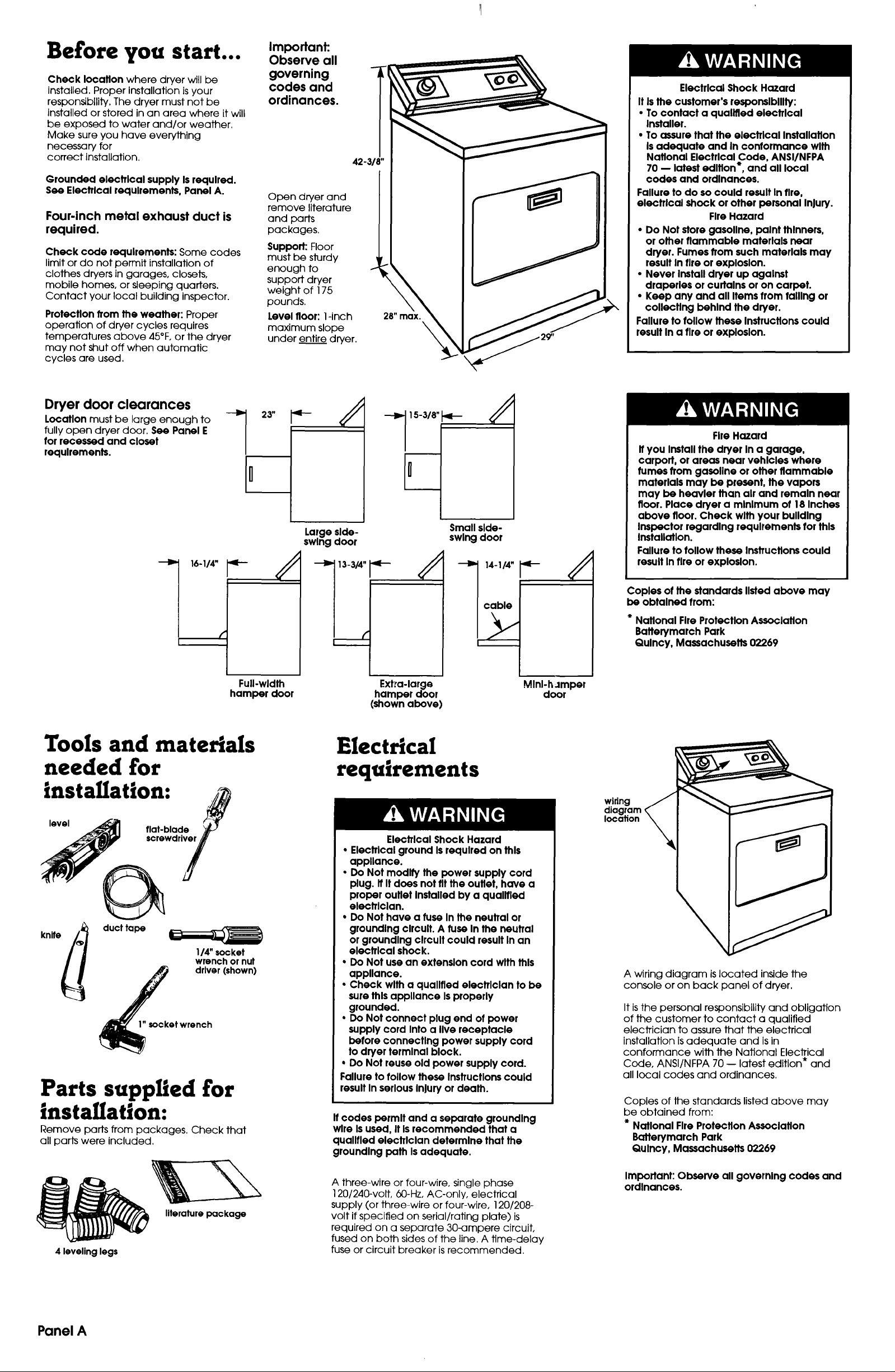

Before you start...

Check locationwhere dryerwillbe

installed.Properinstallationisyour

responsibility.The dryermust not be

installedorstored inan area where itwill

be exposed towater and/or weather.

Make sureyou have everything

necessary for

correctinstallation.

Grounded electrical supply Isrequlred.

See Elecfrlcal requirements, Panel A.

Four-inch metal exhaust duct is

required.

Check code requirements:Some codes

limitor do not permit installationof

clothesdryersingarages, closets,

mobile homes, orsleepingquarters.

Contact your localbuildinginspector.

Protectionfrom the weather: Proper

operation ofdryercycles requires

temperatures above 45°F,orthe dryer

may not shutoffwhen automatic

cyclesare used.

Important:

Observe all

governing

codes and

ordinances.

Open dryer and

remove literature

and parts

packages.

Support: Floor

must be sturdy

enough to

support dryer

weight of 175

pounds.

Level floor: l-inch

maximum slope

under entiredryer.

42-3/8"

28" max.

Electrical Shock Hazard

It Isthe customer's responslblllty:

• To contact a qualified electrical

Installer.

• To assurethat the electrical Installatlon

Isadequate and Inconformance wlth

National Electrlcal Code, ANSl/NFPA

70 -- latestedltlon*, and all local

codes and ordlnances.

Fallureto do so could resultIn tire,

electrlcal shock or other personal Injury.

FlreHazard

• Do Not store gasollne, paint thlnners,

or other flammable materlals near

dryer. Fumesfrom such materials may

resultIn flre or exploslon.

• Never Installdryer up agalnst

draperies or curtalnsor on carpet.

• Keep any and all Itemsfrom falllng or

collecting behlnd the dryer.

\

Fallureto follow these Instructionscould

resultIn a fire or exploslon.

Dryer door clearances

Locatlon must be largo enough to

fully open dryer door, See Panel E

for recessed and closet

requlrements.

16-I/4"

f

Full-wldth

hamper door

Large slde-

swlng door

Extra-large

hamper door

(shown above)

Smallslde-

swlngdoor

14-1/4"

cable

Mlnl-h.lmper

door

FireHazard

Ifyou Installthe dryer In a garage,

carport, or areas near vehlcles where

fumesfrom gasoline or otherflammable

materlals may be present, the vapors

may be heavler than alr and remaln near

floor.Place dryer a mlnlmum of 18 Inches

above floor. Check wlth your bulldlng

Inspector regardlng requlrements for thls

Installatlon.

Fallureto follow these Instructlonscould

resultIn fire or exploslon.

Coples of the standards llstedabove may

be obtalned from:

* National FlreProtection Assoclaflon

Batterymarch Park

Qulncy, Massachusetts 02269

Tools and materials

needed for

installation:

level

duct tape

knife_

_ socket wrench

flat-blade

screwdriver

114"socket

wrench or nut

driver (shown)

Parts supplied for

installation:

Remove parts from packages. Check that

all parts were included.

Electrical

requirements

Electrlcal Shock Hazard

• Electrical ground Is requlred on thls

appllance.

• Do Not modify the power supply cord

plug. IfIt does not fit the outlet, have a

proper outlet Installed by a qualIfled

elecfrlclan.

• Do Not have a fuseIn the neutral or

grounding clrcult. A fuse In the neutral

or groundlng clrcult could resultIn an

electrlcal shock.

• Do Not use an extenslon cord wlth thls

appllance.

• Check wlth a quallfled elecfrlclan to be

sure thlsappllance Is properly

grounded.

• Do Not connect plug end of power

supply cord Into a llve receptacle

before connectlng power supply cord

to dryer termlnal block.

• Do Not reuse old power supply cord.

Fallure tofollow these Instructlonscould

resultIn serlousInjury or death.

Ifcodes permlt and a separate groundlng

wlre Isused, It Isrecommended that a

quallfled electrlclan determlne that the

groundlng path Isadequate.

wiring

diagram

location

A wiring diagram is located inside the

console or on back panel of dryer.

It is the personal responsibility and obligation

of the customer to contact a qualified

electrician to assure that the electrical

installation isadequate and is in

conformance with the National Electrical

Code, ANSI/NFPA 70 -- latest edition* and

all local codes and ordinances.

Copies of the standards listed above may

be obtained from:

* Natlonal Flre ProtectlonAssoclaflon

Batterymarch Park

Qulncy, Massachusetts02269

4 leveling legs

Panel A

literature package

A three-wire or four-wire, single phase

120/240-volt, 60-Hz, AC-only, electrical

supply (or three-wire or four-wire, 120/208-

volt if specified on serial/rating plate) is

required on a separate 30-ampere circuit,

fused on both sides of the line. A time-delay

fuse or circuit breaker is recommended.

Important: Observe all governlng codes and

ordlnances.

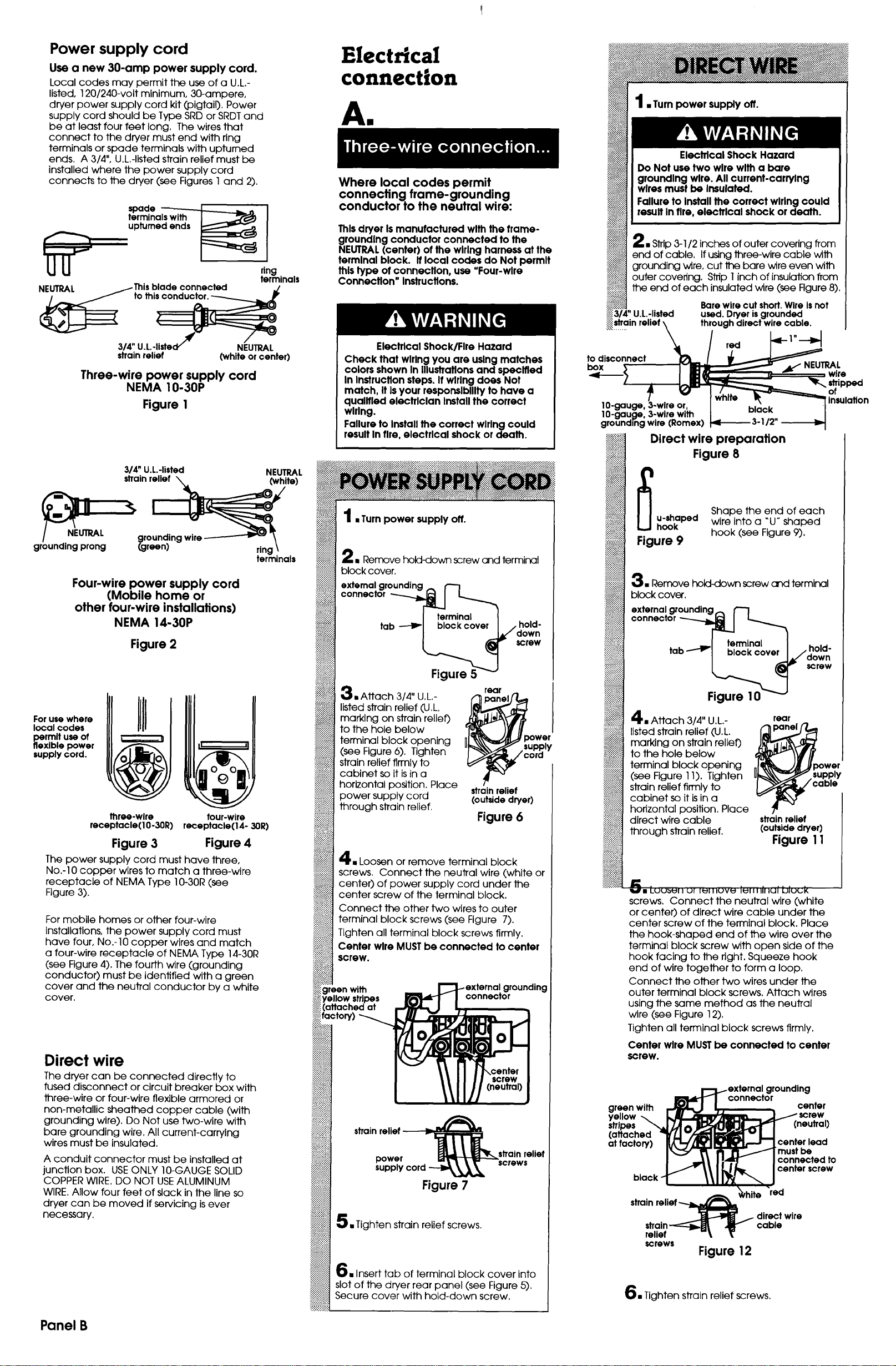

Power supply cord

Use a new 30-amp power supply cord.

Local codes may permit the use of a U.L.-

listed, 120/240-volt minimum, 30-ampere,

dryer power supply cord kit (pigtail). Power

supply cord should be Type SRD or SRDT and

be at least four feet long. The wires that

connect to the dryer must end with ring

terminals or spade terminals with upturned

ends. A 3/4"", U.D-listed strain relief must be

installed where the power supply cord

connects to the dryer (see Figures 1 and 2).

spade _., I

terminalswith J _i::_

_uptumedends _ .

3/4" U.L.-llsteJ NEUTRAL

strainrelief (white or center)

Three-wire power supply cord

NEMA 10-30P

Figure I

3/4" U.L.-listed NEUTRAL

strain relief (white)

J

ring

terminals

Electrical

connection

Where local codes permit

connecting frame-grounding

conductor to the neutral wire:

Thisdryer Ismanufactured wlth the frame-

groundlng conductor connected to the

NEUTRAL(center) of the wlrlngharness at the

termlnal block. If local codes do Not permlt

this type of connection, use "Four-wlre

Connection" Instructions.

Electrical Shock/Flre Hazard

Check that wlrlng you are using matches

colors shown In lllustratlons and speclfled

In Instruction steps. If wlrlng does Not

match, It Isyour responslblllty to have a

qualifled electrlclan Install the correct

wlrlng.

Fallure to Install the correct wlrlng could

result In flre, electrlcal shock or death.

!!i!i!i!iiiiiiiiii

I • Turnpower supply off.

Electrical Shock Hazard

Do Not use two wlre wlth a bare

groundlng wlre. All current-carrylng

wiresmustbe Insulated.

Failureto Installthe correct wiring could

resultIn tire, electrical shock or death.

2 • Skip 3-1/2 inches of outer covering from

end of cable. If using three-wire cable with

grounding wire, cut the bare wire even with

outer covering. Strip 1inch of insulation from

the end of each insulated wire (see Figure 8).

_i_i_i314"U.L.-listed

iiiiii_ain relief

Bare wire cut short. Wire is not

used. Dryer is grounded

through direct wire cable.

red

to disconnect

box

10-gauge, 3-wlre or,

10-gauche,3-wirewith

grounding wire (Romex) -- /2"

iliiii!iii_!ii Directwire preparation

iii!!!iiiiiill Figure8

::::::::::::::::::

NEUTRAL

,wire

•,. stripped

of

insulation

/ NElL groundingwire

grounding prong (green)

Four-wire power supply cord

(Mobile home or

other four-wire installations)

NEMA 14-30P

Figure 2

For use where

local codes

permit use of

flexible power

supply cord.

three-wire four-wire

receptacle(10-30R) receptacle(14- 30R)

It tI

Figure 3 Figure 4

The power supply cord must have three,

No.-10 copper wires to match a three-wire

receptacle of NEMA Type 10-30R (see

Figure 3).

For mobile homes or other four-wire

installations, the power supply cord must

have four, No.-10 copper wires and match

a four-wire receptacle of NEMA Type 14-30R

(see Figure 4). The fourth wire (grounding

conductor) must be identified with a green

cover and the neutral conductor by a white

cover.

Direct wire

The dryer can be connected directly to

fused disconnect or circuit breaker box with

three-wire or four-wire flexible armored or

non-metallic sheathed copper cable (with

grounding wire). Do Not use two-wire with

bare grounding wire. All current-carrying

wires must be insulated.

A conduit connector must be installed at

junction box. USE ONLY 10-GAUGE SOLID

COPPER WIRE. DO NOT USEALUMINUM

WIRE. Allow four feet of slack in the line so

dryer can be moved if servicing isever

necessary.

Panel B

ring

terminals

I •Turnpower supply off.

..-.-.-.-.-.-.

:.:.:.:.:.:.:.

iiiiiiiiii_ii!:.:.

..............

::::::::::::::

_= • Remove hold-down screw and terminal

:.:.:.:.:.:.:.

.............

,.............

block cover.

:.:.:.:.:.:.:

.......,.....

.,...........

.............

.............

::::::::;:;:::

2o"rn o round ng-

:_:_i[_:_:::

!iiiiliiiiiiili_i

isisisis!_i_isl

.:.:.:.:.:.:.

_rmi

tab ----I_I blockcover I .,hold-

iiljiiiiiiiiii

i!i!i!ili;iii!i

::::;::::::::;:

iiiiiliiiii:..

3 • Attach 3/4" U,L,-

ii!i!ii!!!iii_:_

...............

;:::::;::::::_

listed strain relief (U.L.

iiiiiiiiiiii!i

marking on strain relief)

i.'.":i:i:i:J:i

:::::::::::::

to the hole below

...............

...............

,.............

...............

:::::::::::::

terminal block opening power

...............

;::::::::::::::

...............

(see Figure 6). Tighten supply

:::::::::::::::

:.:.:.:.:.:.:

strain relief firmly to

i!iiiiiii!!ii!

cabinet so it is in a

iiiiiiiiiiiiii

iiii!iiiiiiiil

horizontal position. Place

:.:.:.:.:.:.:

power supply cord

i}!iiiiiii!i

through strain relief.

:.:-:.:-:,:.

.:-:.:-:,:-:

:.:.:.:-:-:-,

::::::::::::::::

iiiiiiiiiiiii_i_i_

.:.:.:.:.:.:.:

A

_::::;:::::

:.:.:.:.:.:...

............

_1_• Loosen or remove terminal block

iiiiiiiiiiii::

:.:.:.:.:.:.

,...........

screws. Connect the neulTal wire (white or

...........

,.......,...

,...........

center) of power supply cord under the

strainrelief

(outsidedryer)

Figure 6

center screw of the terminal block.

Connect the other two wires to outer

terminal block screws (see Figure 7).

Tighten all terminal block screws firmly.

Center wlre MUST be connected to center

screw.

iiiiiiiigreenwith

iiiii}iyellowstripes

!iiiii!i(affachedat

iiiiiiiifactory)

i:i:i:i:..

i:i:i:i:!:!:i:

,:.:.:.:.:.:.:

:.:.:.:.:.:.:

:.:.:.:.:.:.:

:.:.:.:.:.:.:

::::::::::::

...........

...........

...........

iiiii!!!ili!

:.:.:.:.:.:..,

..........

iiii!iii!iiiii

::::::::::::::

.:-:-:-:.:-:.

:-:.:.:.:-:.

::::;:::::::::::::

_J

i!ii!ii!ii!!iiiiil

!i!i!ii!iiiiiiiiii

.;-:-:.:-:.:-:

:.>>:.>>

.:.:.:.:.:.:

:.:.:.:.:.:.:

.:.:.:.:.:.:

:.:.:-:.:,:.:

,:.:.:.:.:.:

:.:.:.:.:.:.:

.:.:.:.:.:.:.

:.:.:.:.:.:.:

.:.:.:.:.:.:.

:.:.:.:.:.:.:

,...........,

,,,....,.,...

,,.,.....,...

,:.:.:.:.:.:,

:.:-:.:,:.:.:

ii iiiiii!iiii

:.:.:.:.:.:,

,.,..,......

:.:.:.:.;.;.:

:.:.:.:.:-:.:

:.:.:.:.:.:.:

,:.:.:.:.:.:.

,...........

...........

iiiiiiiiiiii::

..........

:.:,:.:,:.:

,...,.....,

:.:.:.:.:.:..

,..,.........,

!i!i!i!iiiii!i

::::::::::::

::!:!:!:!:i:.,

strain

power

supplycord

Figure 7

5 • Tighten strain relief screws.

g• Insert tab of terminal block cover into

slot of the dryer rear panel (see Figure 5).

Secure cover with hold-down screw.

connector

r_r

grounding

strainrelief

screws

d=°Ww"

Shape the end of each

wire into a "U" shaped

hook (see Figure 9).

:-:.:.:.:-:.

.......-.-.

Figure 9

:::::::::::::::::::::::

.............-.

:::::::::::::::-.

.........-...-,

...............

.............-...

........,.,.,_-.

.:.:.:.:.:.:.:.:.

::::::::::::::::.

,................

u-shaped

hook

_,_= Remove hold-down screw and terminal

block cover.

external grounding _,

i!!iiiiiiii!_i.-.

,.,.-.-.-...-..,

..-.-.-.-.-.

i:_:_:_:!:_:_:::

:::::::::::::::::::::::

:.:.:.:.:.:.:.:.:.

:!:i:i:i:i:i:i:i

i!

:-:.:.:.:.:,:

:.:.:.:.:.:.:.:.:.

.:.:.:.:.:-:-:-:-:

..-- -.-.-.-.-.

_1_=Attach 3/4" U.L.-

:.:-:-:-:-:.:-:.

.:.:.:.:.:.:.:.:

listed strain relief (U.L.

,.-.-.,...........

...............-

,.................

::::::::::::::::::

marking on strain relief)

_::::::::::::::::

:.:-:.:.:.:.:.:.:.

.:.:-:-:.:.:.:.:.:

to the hole below

i-:'_:i:':i:i-:

terminal block opening

,:.:.:.:.:.:.:.:.:

..............

::::::::::::

(see Figure 11). Tighten

:.:.:.:.:.:.:.

,:.:.:.:.:.:.:

strain relief firmly to

cabinet so it isin a

iiiiiiiii!iiiiiii

i!i_i_ii::i::i::i::i

horizontal position. Place

direct wire cable

through strain relief.

tab---'_l L'_i;_,=,,, I., hold-

- I .......... ...J4(_ clown

Figure I0 -""

strainrelief

(outside dryer)

screws. Connect the neutral wire (white

or center) of direct wire cable under the

center screw of the terminal block. Place

the hook-shaped end of the wire over the

terminal block screw with open side of the

hook facing to the right. Squeeze hook

end of wire together to form a loop.

Connect the other two wires under the

outer terminal block screws. Attach wires

using the same method as the neutral

wire (see Figure 12).

Tighten all terminal block screws firmly.

Center wlre MUSTbe connected to center

screw.

grounding

red

/ direct wire

green with

yellow

stripes

(attached

at factory)

black

strainrelief

connector

strain--_------l_ ,r cable

relief - \ _"

screws

Figure 12

6= Tighten strain relief screws.

rear

power

supply

Figure 11

center

(neutral)

;enter lead

must be

connected to

center screw

ble

Loading...

Loading...