Whirlpool LDE7800W1 Installation Guide

ill_'h.lllilliIDll ill,_'h'ntliIDllS

ElectricDryer

Before you begin ...

read the following instructions completely and carefully.

They will simplify the installation.

AFTER COMPLETING THE INSTALLATION, SAVE THESE INSTRUCTIONS FOR FUTURE USE.

IMPORTANT: OBSERVE ALL GOVERNING CODES AND ORDINANCES

Where to install the dryer -

Your dryer should, of course, be installed in a location that

is convenient for you; however, there are other factors

which should be considered before selecting the permanent

location.

Codes Requirements - There are some codes which

prohibit or restrict installation of clothes dryers in

garages, closets, mobile homes and sleeping quarters. If

m doubt about the location you have chosen, check with

your local building inspector.

Utilities - Connections to proper electric supply

should be available. See page 3.

Exhaust - A four (4) inch metal exhaust duct is rec-

ommended. Is there one available or can one be installed

to meet requirements in pages 4, 5 and 6?

Physical Characteristics - The site must be large enough

_o--r_ dr--_ _ a-T_-w room to fulLy open the dryer

door. The floor must be able to support the weight and

the dryer must be protected from the weather. If the

temperature where the dryer is to be installed is not

above 45 o F, the dryer may not shut off when automatic

cycles are used.

CAUTION:

• It is the personal responsibility of the customer to

ensure that gasoline, paint, thinners and other flam-

mable materials are not used or stored near the dryer.

Fumes from these materials could result in fire or

explosion.

• Never install the dryer up against draperies or curtains

and be sure to keep any and all items from falling or

collecting behind the dryer.

• Replace all access or service panels before operating

dryer.

ELI CT£ICAL REQUIREMENTS

1. A three-wire or four-wire single phase 120/240 volt 60

Hz AC only electrical supply (or three-wire or four-wire

120/208 volt if specified on nameplate) is required on a

separate 30 ampere circuit, fused on both sides of the line

(time-delay fuse or circuit breaker is recommended). Do

NOT fuse neutral.

2. THE DRYER MUST BE CONNECTED WITH COPPER

WIRE ONLY. Aluminum wire must not be used to avoid

potentially unsatisfactory connections.

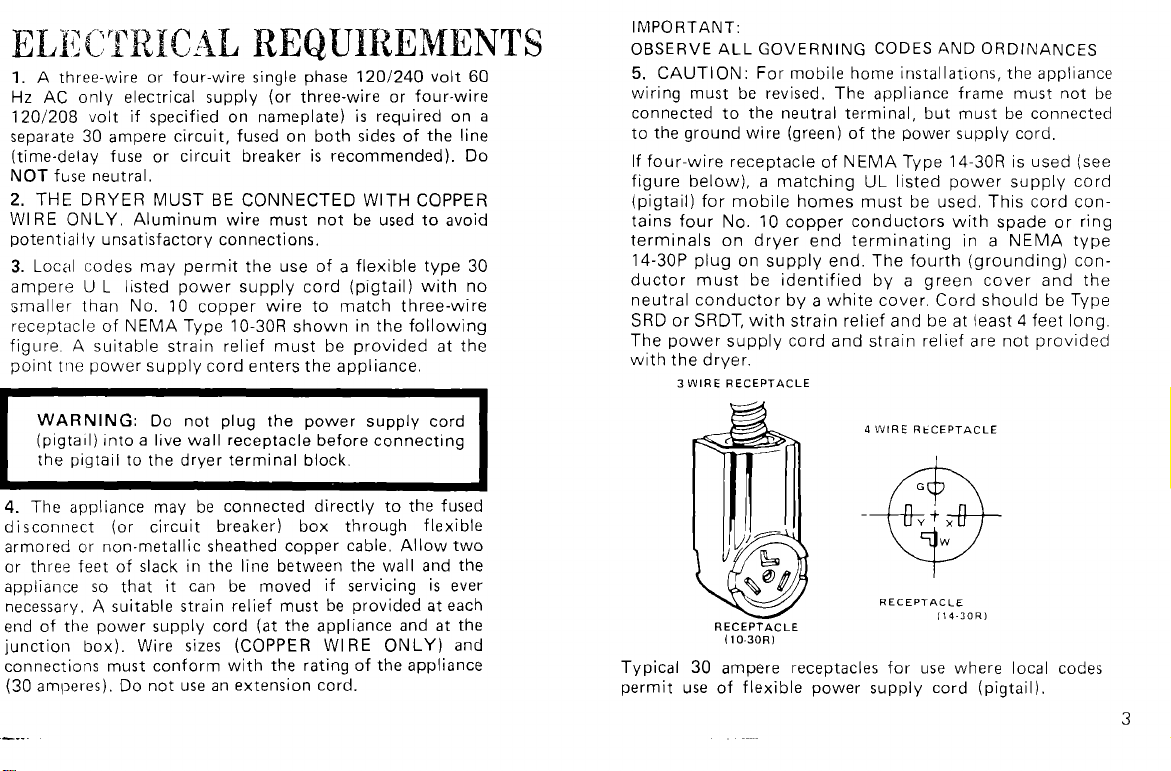

3. Local codes may permit the use of a flexible type 30

ampere U L listed power supply cord (pigtail) with no

smaller than No. 10 copper wire to match three-wire

receptacle of NEMA Type 10-30R shown in the following

figure. A suitable strain relief must be provided at the

point the power supply cord enters the appliance.

IMPORTANT:

OBSERVE ALL GOVERNING CODES AND ORDINANCES

5. CAUTION: For mobile home installations, the appliance

wiring must be revised. The appliance frame must not be

connected to the neutral terminal, but must be connected

to the ground wire (green) of the power supply cord.

If four-wire receptacle of NEMA Type 14-30R is used (see

figure below), a matching UL listed power supply cord

(pigtail) for mobile homes must be used. This cord con-

tains four No. 10 copper conductors with spade or ring

terminals on dryer end terminating in a NEMA type

14-30P plug on supply end. The fourth (grounding) con-

ductor must be identified by a green cover and the

neutral conductor by a white cover. Cord should be Type

SRD or SRDT, with strain relief and be at least 4 feet long.

The power supply cord and strain relief are not provided

with the dryer.

3WIRE RECEPTACLE

the pigtail to the dryer terminal block

WARNING: Do not plug the power supply cord 4WIRERI:CEPTACL_

(pigtail) into a live wall receptacle before connectingefusb_d

• The appliance may be connected directly to the

isconnect (or circuit breaker) box through fl "

armored or non-metallic sheathed copper cable. Allow two

or three feet of slack in the line between the wall and the

appliance so that it can be moved if servicing is ever

necessary. A suitable strain relief must be provided at each RECEPTACLE

end of the power supply cord (at the appliance and at the RECEPTACLE

junction box). Wire sizes (COPPER WIRE ONLY) and 11o-3om

connections must conform with the rating of the appliance Typical 30 ampere receptacles for use where local codes

(30amperes). Do not use an extension cord. permit use of flexible power supply cord (pigtail),

I

114-30R)

3

.... T r_

EXitA[ S I SYSTEM REQUIREMENTS

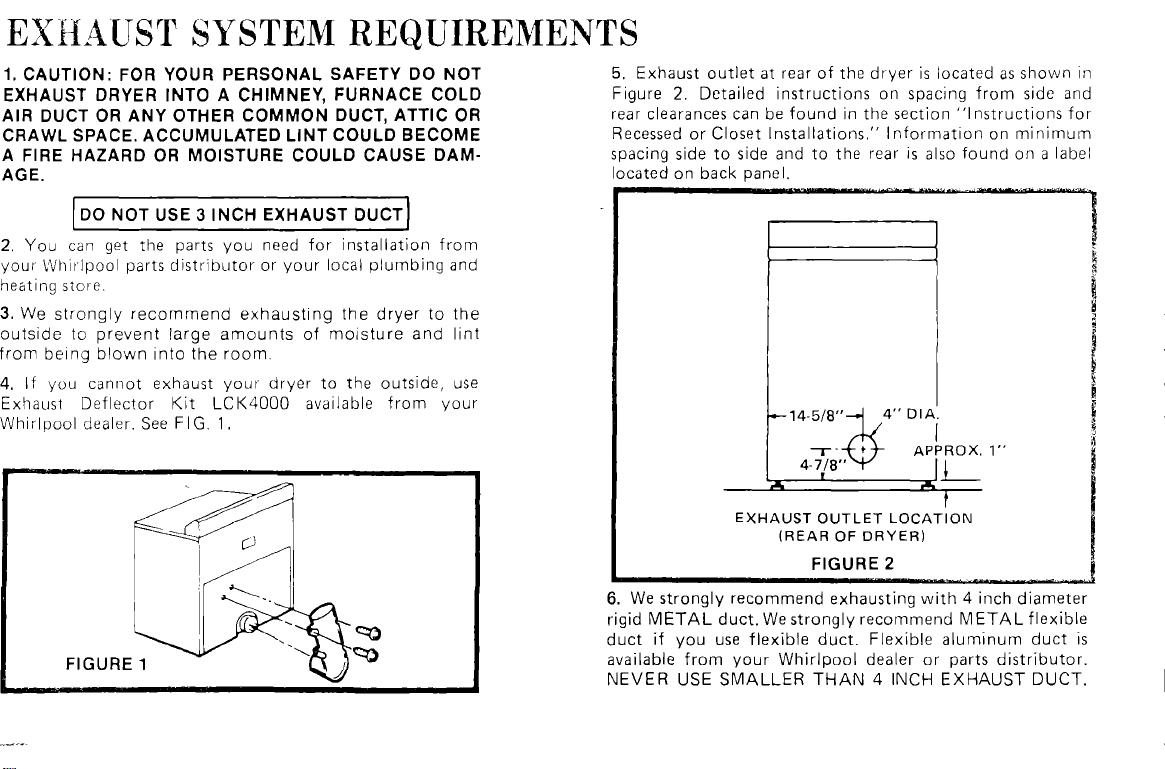

1. CAUTION: FOR YOUR PERSONAL SAFETY DO NOT

EXHAUST DRYER INTO A CHIMNEY, FURNACE COLD

AIR DUCT OR ANY OTHER COMMON DUCT, ATTIC OR

CRAWL SPACE. ACCUMULATED LINT COULD BECOME

A FIRE HAZARD OR MOISTURE COULD CAUSE DAM-

AGE.

DO NOT USE 3 INCH EXHAUST DUCT I

2. You can get the parts you need for installation from

your Whirlpool parts distributor or your local plumbing and

heating store.

3. We strongly recommend exhausting the dryer to the

outside to prevent large amounts of moisture and lint

from being blown into the room.

4. If you cannot exhaust your- dryer to the outside, use

Exhaust Deflector Kit LCK4000 available from your

Whirlpool dealer. See FIG. 1.

FIGURE 1

i

5, Exhaust outlet at rear of the dryer is located as shown in

Figure 2. Detailed instructions on spacing from side and

rear clearances can be found in the section "Instructions for

Recessed or Closet Installations," Information on minimum

spacing side to side and to the rear is also found on a label

located on back panel,

_14-5_____/8'_4" DIA.I

4-7/-"8 "1"/ APPROX. 1"

, l!

A _

EXHAUST OUTLET LOCATION

(REAR OF DRYER)

FIGURE 2

6. We strongly recommend exhausting with 4 inch diameter

rigid METAL duct. We strongly recommend METAL flexible

duct if you use flexible duct. Flexible aluminum duct is

available from your Whirlpool dealer or parts distributor.

NEVER USE SMALLER THAN 4 INCH EXHAUST DUCT.

_4

l

7.Theexhaustmayberoutedup,down,left,rightor

straightthroughthewall.

8.Theexhaustductshouldterminatewithanexhaust

hoodtopreventbackdrafts.Theoutletofthehoodmust

beatleast12inchesfromthegroundoranyobstruction.A

Iouveredexhausthood,PartNumber279399isavailable

fromyourWhirlpooldealerorpartsdistributor.Anexhaust

hoodwitha2!/,inchoutletcreatesmorebackpressure,but

maybeusedwithshortersystems.Neveruseanexhaust

hoodwithamagneticlatch.

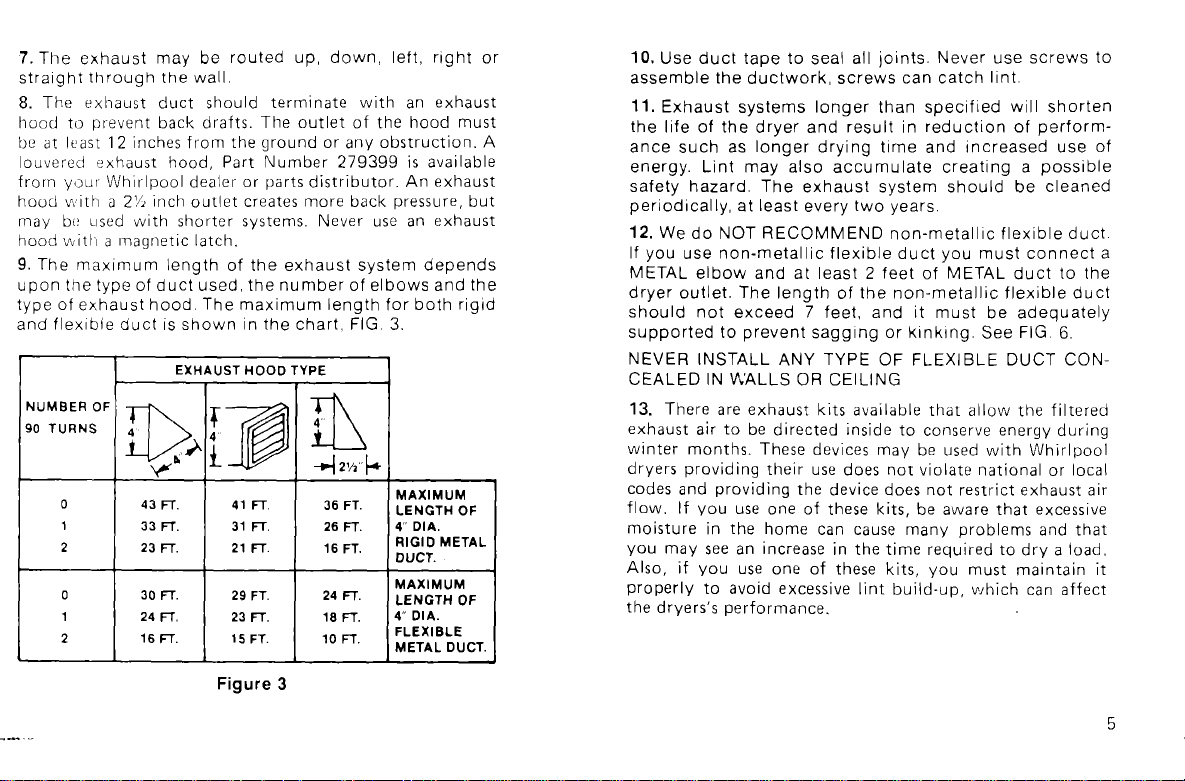

9.Themaximumlengthoftheexhaustsystemdepends

uponthetypeofductused,thenumberofelbowsandthe

typeofexhausthood.Themaximumlengthforbothrigid

andflexibleductisshowninthechart,FIG.3.

EXHAUST HOOD TYPE

NUMBER OF

90 TURNS

.L

0

1

2

0

1

2

43FT.

33FT.

23 FT.

30 FT.

24 FT,

16FT.

41 FT. 36 FT.

31 FT. 26 FT.

21 FT. 16FT.

29 FT. 24 FT.

23FT. 18FT.

15 FT. 10 FT.

MAXIMUM

LENGTH OF

4" DIA.

RIGID METAL

DUCT.

MAXIMUM

LENGTH OF

4" DIA.

FLEXIBLE

METAL DUCT.

10, Use duct tape to seal all joints. Never use screws to

assemble the ductwork, screws can catch lint.

11. Exhaust systems longer than specified will shorten

the life of the dryer and result in reduction of perform-

ance such as longer drying time and increased use of

energy. Lint may also accumulate creating a possible

safety hazard. The exhaust system should be cleaned

periodically, at least every two years.

12. We do NOT RECOMMEND non-metallic flexible duct.

If you use non-metallic flexible duct you must connect a

METAL elbow and at least 2 feet of METAL duct to the

dryer outlet. The length of the non-metallic flexible duct

should not exceed 7 feet, and it must be adequately

supported to prevent sagging or kinking. See FIG. 6.

NEVER INSTALL ANY TYPE OF FLEXIBLE DUCT CON-

CEALED IN VVALLS OR CEILING

13. There are exhaust kits available that allow the filtered

exhaust air to be directed inside to conserve energy during

winter months. These devices may be used with Whirlpool

dryers providing their use does not violate national or local

codes and providing the device does not restrict exhaust air

flow. If you use one of these kits, be aware that excessive

moisture in the home can cause many problems and that

you may see an increase in the time required to dry a toad.

Also, if you use one of these kits, you must maintain it

properly to avoid excessive lint build-up, which can affect

the dryers's performance.

Figure 3

Loading...

Loading...