Whirlpool LCE4332PQ User Manual

CONSUMER SERVICES TECHNICAL

EDUCATION GROUP PRESENTS

22″ COMPACT

AUTOMATIC

WASHER

L-74

MODEL LCE4332PQ

JOB AID

Part No. 8178436

FORWARD

This Whirlpool Job Aid “22″ Compact Automatic Washer” (Part No. 8178436), provides the

technician with information on the installation, operation, and service of the 22″ Compact

Automatic Washer. It is to be used as a training Job Aid and Service Manual. For specific

information on the model being serviced, refer to the “Use and Care Guide,” or “Tech Sheet”

provided with the washer.

The Wiring Diagram and Strip Circuits used in this Job Aid are typical and should be used for

training purposes only. Always use the Wiring Diagram supplied with the product when servicing

the unit.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair the Whirlpool 22″ Compact Automatic Washer.

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the washer to its proper operational status.

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made

on our products by anyone other than Authorized Service Technicians.

Copyright © 2004, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

TABLE OF CONTENTS

Page

GENERAL............................................................................................................................... 1-1

Safety First......................................................................................................................... 1-1

Model & Serial Number Designations ................................................................................ 1-2

Model & Serial Number Label And Tech Sheet Locations................................................. 1-3

Specifications..................................................................................................................... 1-4

Whirlpool Compact Washer Warranty ............................................................................... 1-5

INSTALLATION INFORMATION ........................................................................................... 2-1

Installation Requirements .................................................................................................. 2-1

Permanent Installation Instructions.................................................................................... 2-5

Portable Installation Instructions ...................................................................................... 2-10

PRODUCT OPERATION ........................................................................................................ 3-1

Theory Of Operation .......................................................................................................... 3-1

Washer Use ....................................................................................................................... 3-3

COMPONENT ACCESS ......................................................................................................... 4-1

Component Locations ........................................................................................................ 4-1

Removing The Pressure Switch, Water Inlet Valves, Lid Switch,

Interface And Electronic Control Boards......................................................................... 4-2

Removing The Basket ....................................................................................................... 4-6

Removing The Tub ............................................................................................................ 4-8

Removing The Brake And Gearcase Assemblies............................................................ 4-11

Removing The Capacitor And Drive Motor ...................................................................... 4-14

Removing The Brake Actuator Assembly ........................................................................ 4-16

Removing The Drain Pump ............................................................................................. 4-18

COMPONENT TESTING ........................................................................................................ 5-1

Pressure Switch ................................................................................................................. 5-1

Water Inlet Valve Solenoids............................................................................................... 5-2

Drive Motor Capacitor ........................................................................................................ 5-2

Brake Actuator ................................................................................................................... 5-3

Drive Motor ........................................................................................................................ 5-4

Drain Pump ........................................................................................................................ 5-4

DIAGNOSTICS & TROUBLESHOOTING .............................................................................. 6-1

Diagnostics ........................................................................................................................ 6-1

Time Charts .................................................................................................................... 6-2

Self Diagnostic Failure—Alarm Codes ........................................................................... 6-3

Service Routine .............................................................................................................. 6-4

Troubleshooting Guide ...................................................................................................... 6-6

WIRING DIAGRAM & STRIP CIRCUITS ............................................................................... 7-1

Wiring Diagram .................................................................................................................. 7-1

Strip Circuits ...................................................................................................................... 7-2

- iii -

— NOTES —

- iv -

GENERAL

SAFETY FIRST

Your safety and the safety of others is very important.

We have provided many important safety messages in this Job Aid and on the appliance. Always

read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word

“DANGER” or “WARNING.” These words mean:

You can be killed or seriously injured if you don’t

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance

of injury, and tell you what can happen if the instructions are not followed.

immediately follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

1-1

MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER

MODEL NUMBER

Product Group

C = Laundry, Commercial

L = Laundry, Domestic

G = Laundry, Gold

Product Identification

A = Commercial A/W

B = Large Capacity A/W, 24" -U.S.

C = 22" Compact A/W

D = Electric Dryer, 120 volt

E = Electric Dryer, 240 volt

G = Gas Dryer

H = Electric Dryer, (Brazilian)

L = Large Capacity A/W, 27" U.S.

K = Kit

M = Reg. Capacity A/W - Mexico

P = 24" Compact A/W

S = Stack Commercial Dryer or

Super Capacity 27" A/W

T = Thin Twin

X = 96 Ex. Large Capacity A/W 27"

Z = 5KG A/W 22" - Brazil

Feature Code/Variation Lines

E = Electronic or N = No Match

Electric Thin Twin G = Gas Thin Twin

P = Pushbutton C = Clean Touch

R = Rotary L = Special

T = Circuit City W = Web

S = Water Saver V = Variation Line

Q = Rotary Quiet

Cycles - Domestic (1 - 9)

A/W (1 - 6) = Washer Speed Combinations

Washer (1 - 8) = Wash/Spin Combinations

Washer (1 - 5) = Water Levels

Year of Introduction

P = 2004

Color Code

W = White, N = Almond,

Q = White on White, Z = Almond on Almond

Engineering Change (numeric)

LCE4332PQ0

SERIAL NUMBER

SERIAL NUMBER

DIVISION RESPONSIBILITY

C = Clyde, OH

R = Multibras Rio Claro, Brazil

YEAR OF PRODUCTION

R = 2004

WEEK OF PRODUCTION

01 = 1st Week

PRODUCT SEQUENCE NUMBER

CR R 01 00102

1-2

MODEL & SERIAL NUMBER LABEL

AND TECH SHEET LOCATIONS

The Model/Serial Number label and Tech Sheet locations are shown below.

Model & Serial

Number Label Location

Tech Sheet Location

(Behind Front Of Cabinet)

1-3

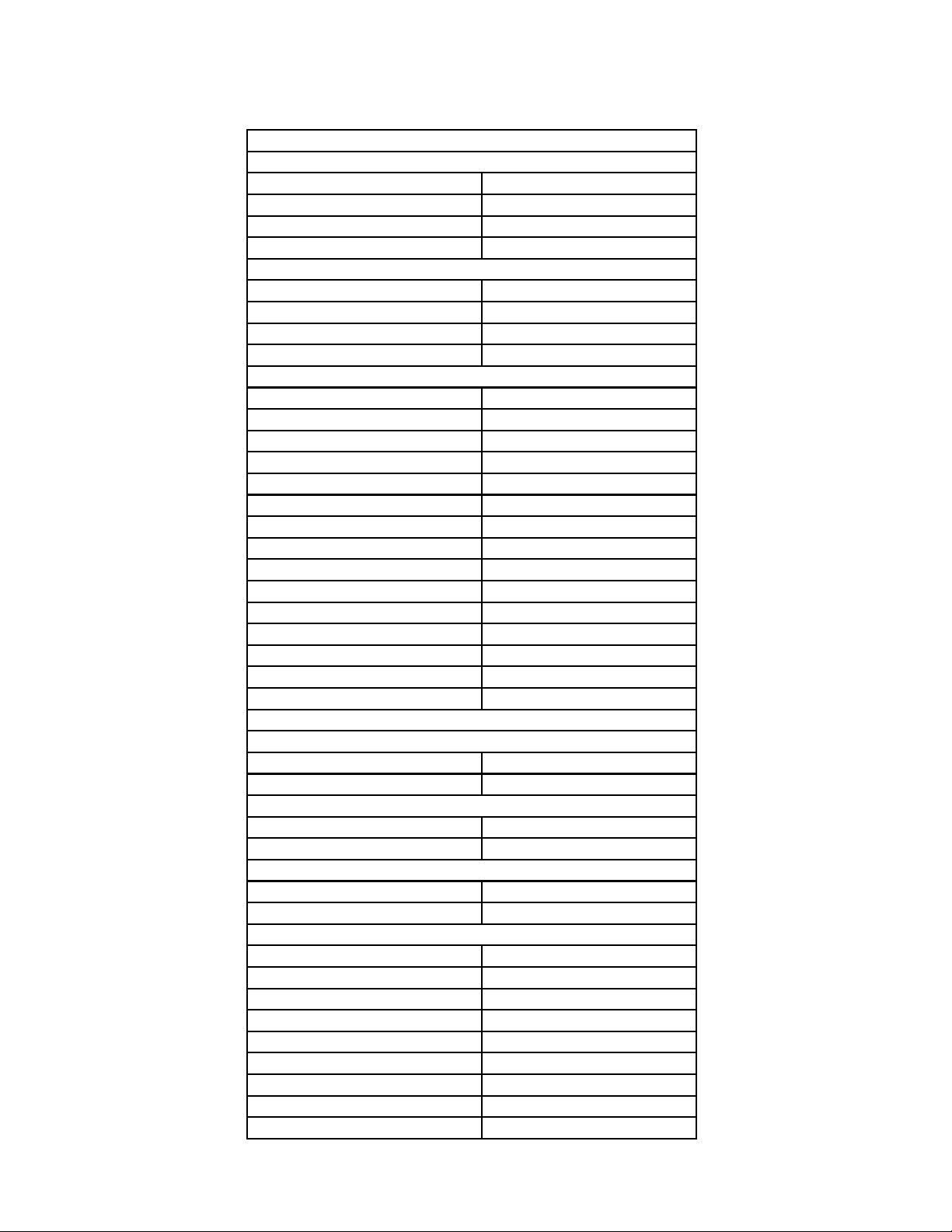

SPECIFICATIONS

WASHER MODEL LCE4332PQ0

WASHING SYSTEM

Washing System Agitator

Agitator Type Single Action

Basket Spinning (High) 750 rpm

Dispenser Yes - 1 drawer

Strokes Per Minute

Heavy Duty (Max) 64 spm

Normal (Max) 68 spm

Quick Wash (Max) 64 spm

Delicate (Max) 35 spm

ELECTRICAL

Nominal Voltage 120 VAC

Voltage Range 100 - 130 VAC

Frequency 60 Hz

Current (Rated) 5 amps

Motor

Power 1/4 HP

Rotation 1625 rpm

Current (Rated) 3 amps

Type PSC - Bi-directional

Drain Pump

Power 36 Watts

Current 0.8 amps

Flow 24 liters/minute

Capacitance

Circuit Breaker 15 amps (recommended)

HYDRAULIC

Max. Water Consumption (All Cycles)

High 33 gal./124 l

Medium 17 gal./64 l

Water Pressure

Maximum 690 kPa/100 psi

Minimum 34.5 kPa/5 psi

Water Level

High Just below balance ring

Medium 5 rows below balance ring

DIMENSIONS

Net Weight 86.4 lbs. (39.2 kg)

Height 38.2 in. (970 mm)

Width 22.2 in. (565 mm)

Depth 24.6 in. (625 mm)

Height W/Lid Open 51.1 in. (1300 mm)

Weight W/Package 94.8 lbs. (43 kg)

Height W/Package 41.7 in. (1060 mm)

Depth W/Package 26.6 in. (675 mm)

Width W/Package 25 in. (635 mm)

45 µF

1-4

WHIRLPOOL COMPACT WASHER WARRANTY

ONE-YEAR FULL WARRANTY

For one year from the date of purchase, when this washer is operated and maintained according to

instructions attached to or furnished with the product, Whirlpool Corporation will pay for FSP replacement

parts and repair labor costs to correct defects in materials or workmanship. Service must be provided by

a Whirlpool designated service company.

SECOND THROUGH FIFTH YEAR LIMITED WARRANTY

ON TOP, LID, AND GEARCASE ASSEMBLY

For the second through the fifth year from the date of purchase when this washer is operated and

maintained according to instructions attached to or furnished with the product, Whirlpool Corporation will

pay for FSP replacement parts for any top and lid rust and any part of the gearcase assembly, if defective

in materials or workmanship.

SECOND THROUGH TENTH YEAR LIMITED WARRANTY ON OUTER TUB

For the second through the tenth year from the date of purchase when this washer is operated and

maintained according to instructions attached to or furnished with the product, Whirlpool Corporation will

pay for FSP replacement parts for the outer tub should it crack or fail to contain water, if defective in

materials or workmanship.

Whirlpool Corporation will not pay for:

1. Service calls to correct the installation of your washer, to instruct you how to use your washer, or to

replace house fuses or correct house wiring or plumbing.

2. Repairs when your washer is used in other than normal, single-family household use.

3. Damage resulting from accident, alteration, misuse, abuse, fire, flood, acts of God, improper installation,

not in accordance with local electrical and plumbing codes, or use of products not approved by Whirlpool

Corporation.

4. Any labor costs during the limited warranty periods.

5. Replacement parts or repair labor costs for units operated outside the United States and Canada.

6. Pickup and delivery. This product is designed to be repaired in the home.

7. Repairs to parts or systems resulting from unauthorized modifications made to the appliance.

8. In Canada, travel or transportation expenses for customers who reside in remote areas.

WHIRLPOOL CORPORATION AND WHIRLPOOL CANADA INC.

SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Some states and provinces do not allow the exclusion or limitation of incidental or consequential damages

so this exclusion or limitation may not apply to you. This warranty gives you specific legal rights and you

may also have other rights which vary from state to state or province to province.

Outside the 50 United States and Canada, this warranty does not apply. Contact your authorized

Whirlpool dealer to determine if another warranty apples.

If you need service first see “Troubleshooting” in the “Use & Care Guide.” Additional help can be found by

checking “Assistance or Service” or call our Customer Interaction Center at 1-800-253-1301 from

anywhere in the U.S.A., or write: Whirlpool Brand Home Appliances, Customer Interaction Center, 553

Benson Road, Benton Harbor, MI 49022-2692. In Canada, call Whirlpool Canada Inc. at 1-800-807-6777.

1-5

— NOTES —

1-6

INSTALLATION INFORMATION

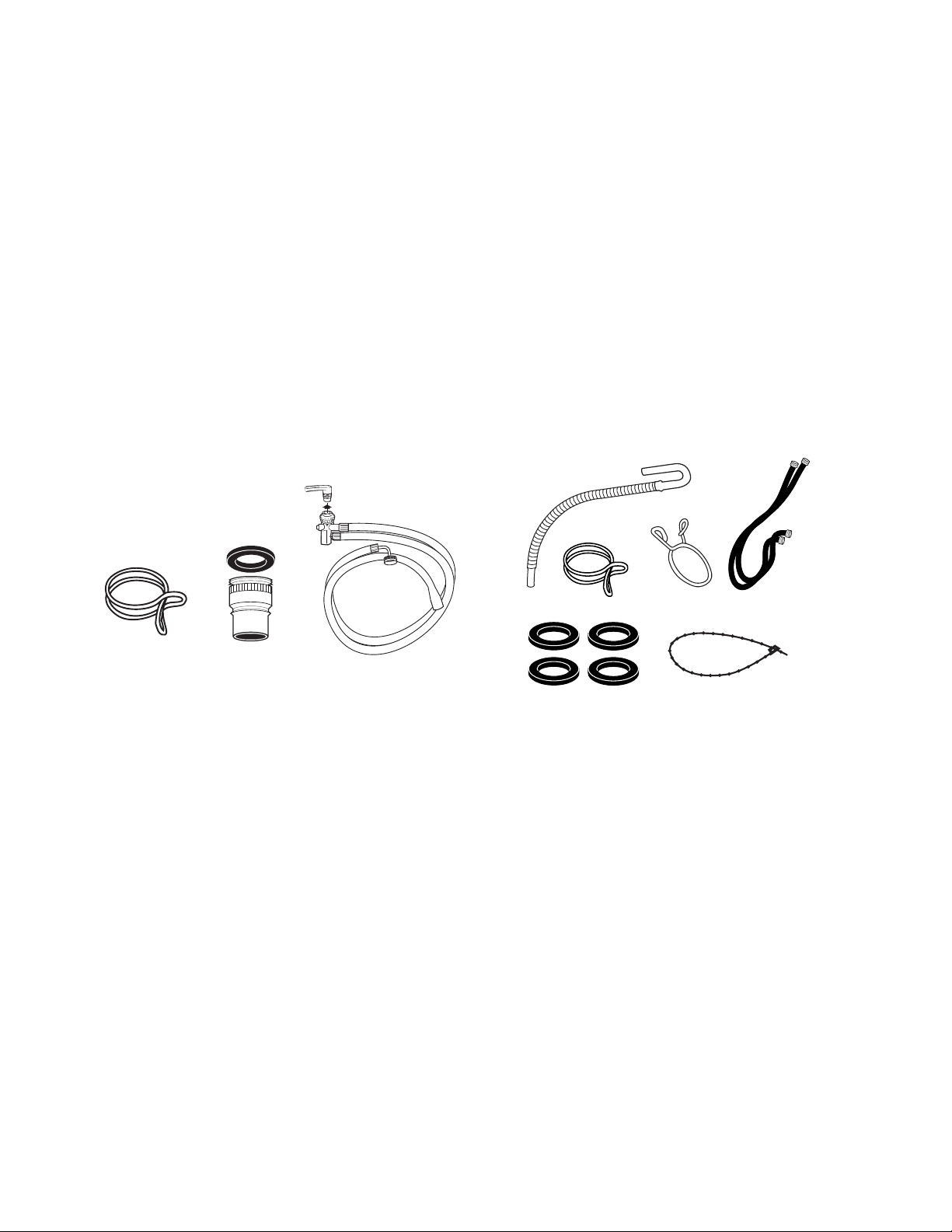

A. Drain hose

B. Silver, double-wire hose clamp

(for the botto m of the drain hose)

C. Yellow, single-w ire hose clamp

(for the top of the drain hose)

D. Water inlet hoses (2)

E. Flat water inlet hose

washers (4)

F. Beaded tie strap

A

BC

D

E

F

INSTALLATION REQUIREMENTS

TOOLS AND PARTS

Assemble the required tools and parts before

starting installation. Read and follow the instructions provided with any tools listed here.

The parts supplied are in the washer basket.

Portable Installation

Tools needed:

• Pliers that open to 1-9/16″ (3.95 cm)

• Utility knife

• Flashlight (optional)

Parts supplied:

Permanent Installation

Tools needed:

• Pliers that open to 1-9/16″ (3.95 cm)

• Flashlight (optional)

• Adjustable or open end wrench 9/16″

(14 mm)

• Level

• Wood block

• Utility knife

• Measuring tape

Parts supplied:

A

A. Silver, double-wir e hose clamp (for the bottom of the

drain hose)

B. Faucet adapter

C. Fill-and-drain hose

B

C

NOTE: To change a permanent installation to

a portable installation, kit #285768 is required.

NOTE: To change a portable installation to a

permanent installation, kit #4396746 is required.

2-1

Alternate Parts

Your installation may require additional parts.

For ordering information, please refer to the

“Assistance or Service” section of the “Use &

Care Guide.”

If You Have: You Will Need to Buy:

Laundry tub or Sump pump system (if not

standpipe taller already available)

than 72″ (183 cm)

1″ (2.5 cm) diameter 2″ (5 cm) diameter to 1″

standpipe diameter standpipe adapter

#3363920

Overhead sewer Standard 20 gal. (76 L) 39″

(99 cm) tall drain tub or

utility sink, sump pump and

connectors (available from

local plumbing suppliers)

Floor drain Siphon break, #285320;

additional drain hose,

#3357090 and connector kit,

#285442

Water faucets 2 longer water fill hoses:

beyond reach of 6 ft (1.8 m) #76314,

fill hoses 10 ft (3.0 m) #350008

Drain hose too Drain hose, #388423 and

short hose kit, #285442

Drain hose that is Hose kit, #285442

too long

Lint clogged drain Drain protector, #367031

• Hot and cold water faucets located within

3-1/2 ft (1.1 m) of the hot and cold water fill

valves, and water pressure of 5-100 psi

(34.5-690 kPa).

• A level floor with a maximum slope of 3/4″

(2.0 cm) under entire washer. Installing the

washer on carpeting is not recommended.

• A sturdy floor to support the washer weight

(washer, water and load) of 260 lbs (118 kgs).

Do not store or operate your washer in temperatures at or below 32°F (0°C). Some water

can remain in the washer and can cause damage in low temperatures. See “Washer Care”

in the “Use & Care Guide” for winterizing information.

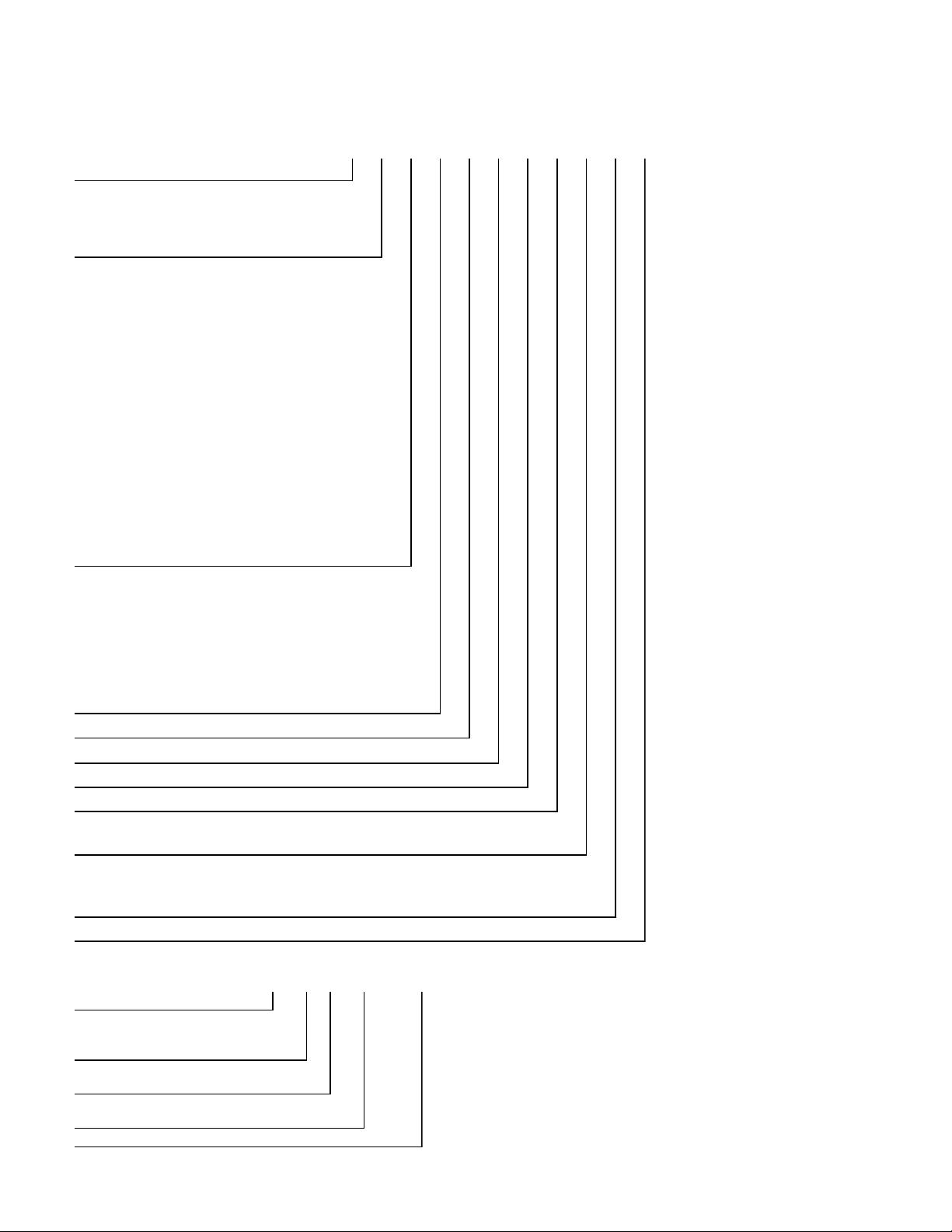

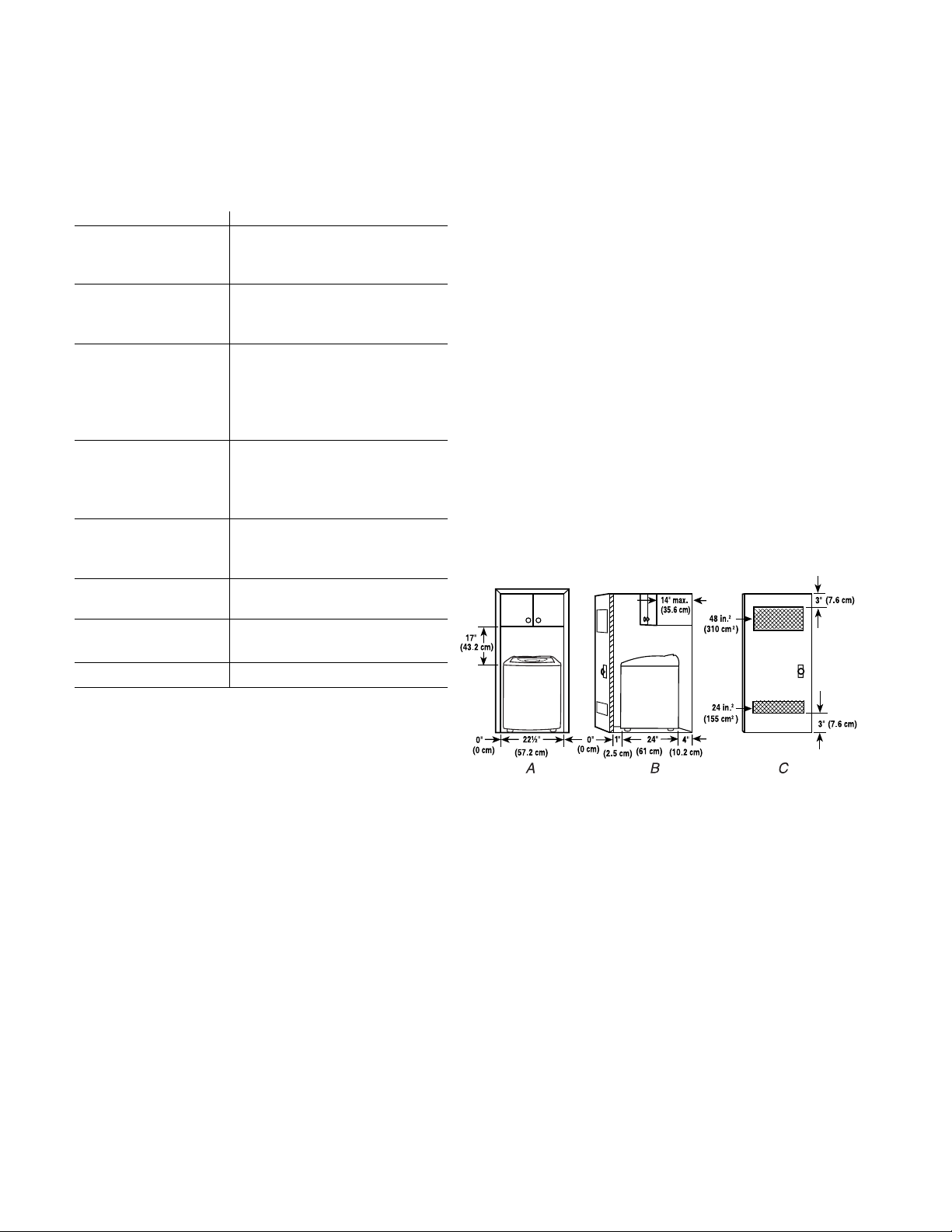

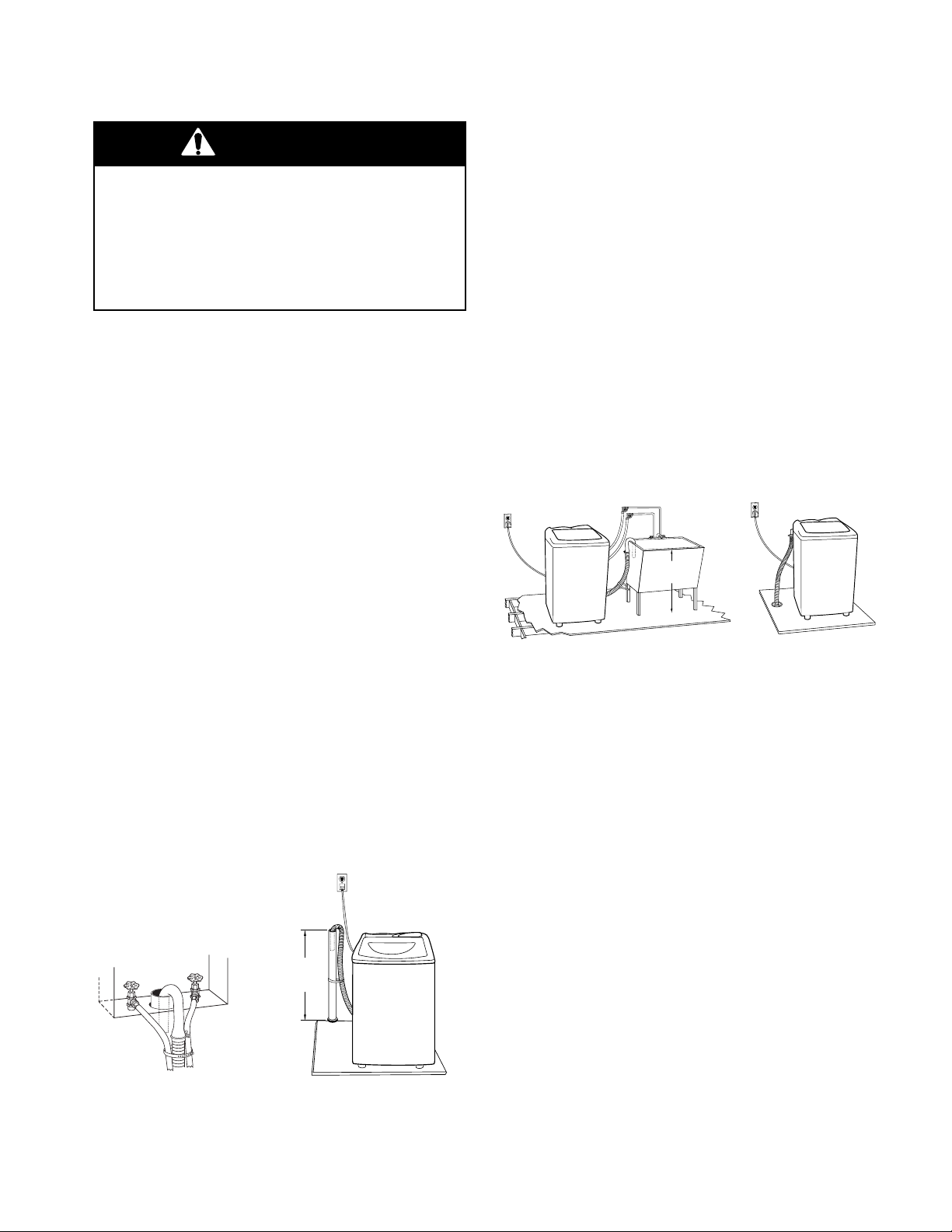

Recessed area or closet installation

The dimensions shown are for the recommended spacing allowed, except the closet

door ventilation openings. The dimensions

shown for the closet door ventilation openings

are the minimum required.

LOCATION REQUIREMENTS

Selecting the proper location for your washer

improves performance and minimizes noise

and possible washer “walk.”

Your washer can be installed in a basement,

laundry room, closet, or recessed area (see

“Drain System”).

IMPORTANT: Do not install or store the washer

where it will be exposed to the weather.

Proper installation is your responsibility.

You Will Need:

• A water heater set to deliver 120°F (49°C)

water to the washer.

• A grounded electrical outlet located within

5 ft (1.5 m) of where the power cord is

attached to the back of the washer (see

“Electrical Requirements”).

A. Front view

B. Side view

C. Closet door with vents

• Additional spacing should be considered for

ease of installation and servicing.

• Additional clearances may be required for

wall, door and floor moldings.

• Additional spacing of 1″ (2.5 cm) on all sides

of the washer is recommended to reduce

noise transfer.

• If a closet door is installed, the minimum air

openings in the top and bottom of the door

are required. Louvered doors with air openings in the top and bottom are acceptable.

• Companion appliance spacing should also

be considered.

2-2

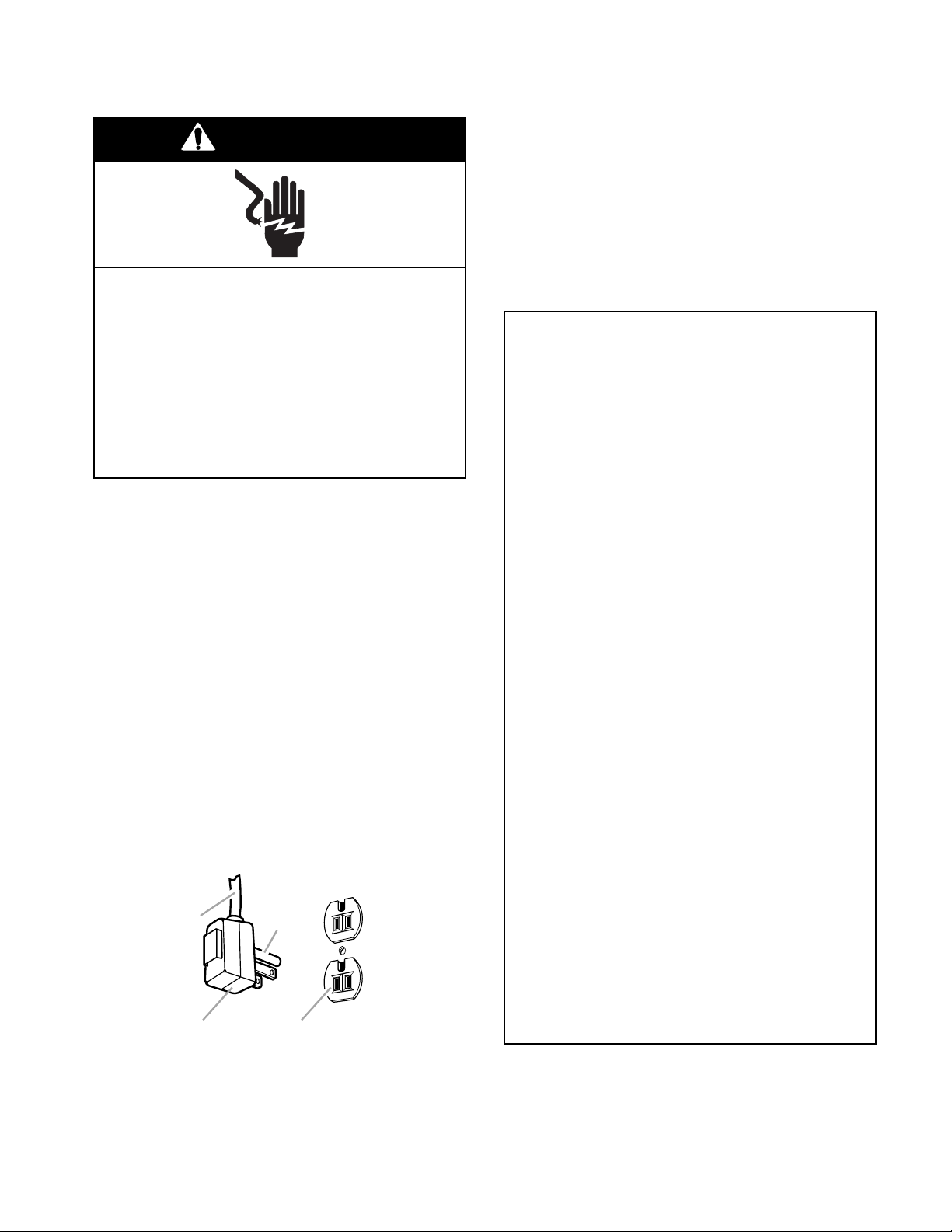

ELECTRICAL REQUIREMENTS

t

WARNING

Electrical Shock Hazard

• If codes permit and a separate ground wire

is used, it is recommended that a qualified

electrician determine that the ground path is

adequate.

• Do not ground to a gas pipe.

• Check with a qualified electrician if you are

not sure the washer is properly grounded.

• Do not have a fuse in the neutral or ground

circuit.

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

• A 120-volt, 60-Hz., AC-only, 15- or 20-ampere, fused electrical supply is required. A

time-delay fuse, or circuit breaker, is recommended. It is recommended that a separate

circuit serving only this appliance be provided.

• This washer is equipped with a power supply

cord having a 3 prong grounding plug.

• To minimize possible shock hazard, the cord

must be plugged into a mating, 3 prong,

grounding-type outlet, grounded in accordance with local codes and ordinances. If a

mating outlet is not available, it is the personal responsibility and obligation of the

customer to have the properly grounded

outlet installed by a qualified electrician.

GROUNDING INSTRUCTIONS

For a grounded, cord-connected

washer:

This washer must be grounded. In the event

of a malfunction or breakdown, grounding

will reduce the risk of electrical shock by

providing a path of least resistance for electric current. This washer is equipped with a

cord having an equipment-grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is

properly installed and grounded in accordance with all local codes and ordinances.

WARNING: Improper connection of the

equipment-grounding conductor can result

in a risk of electric shock. Check with a

qualified electrician or serviceman if you are

in doubt as to whether the appliance is

properly grounded.

Do not modify the plug provided with the

appliance. If it will not fit the outlet, have a

proper outlet installed by a qualified electrician.

B

A

A. 3 p rong grounding plug

B.

Power supply cord

C. Ground prong

D.

3 prong grounding-type outle

C

D

For a permanently connected washer:

This washer must be connected to a grounded

metal, permanent wiring system, or an equipment-grounding conductor must be run with

the circuit conductors and connected to the

equipment-grounding terminal or lead on the

appliance.

2-3

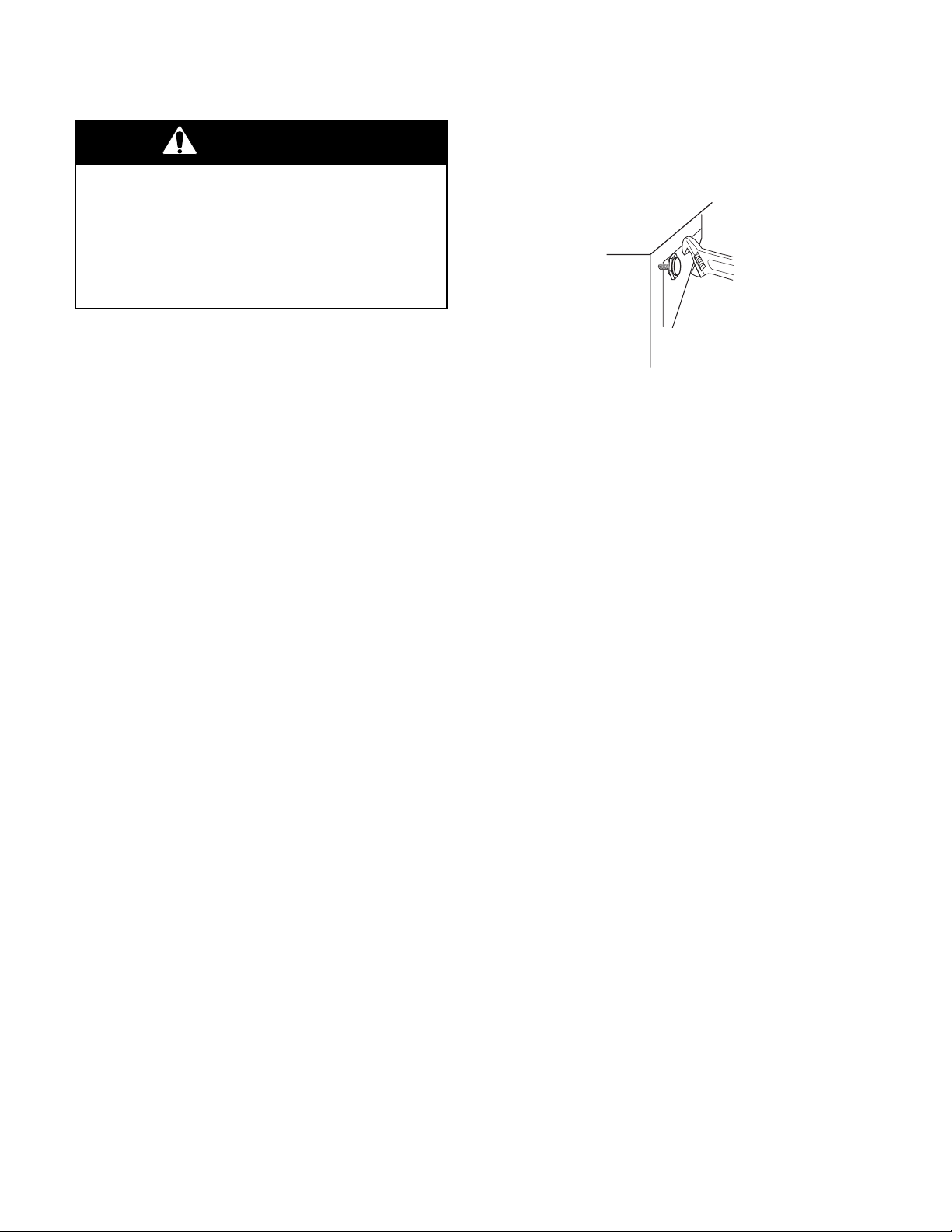

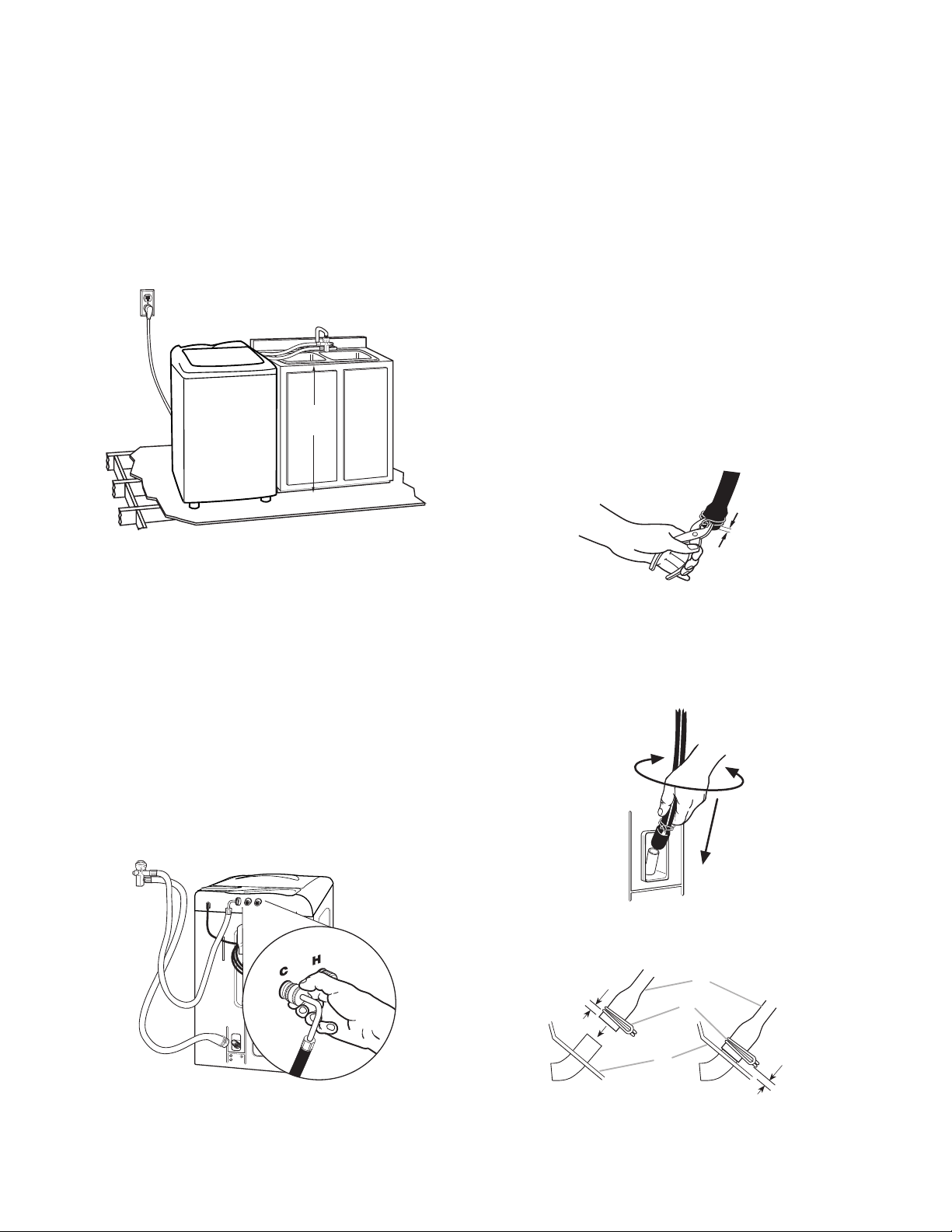

REMOVE SHIPPING MATERIAL

WARNING

Excessive Weight Hazard

Use two or more people to move and

install washer.

Failure to do so can result in back or

other injury.

Before you install your washer, remove all

shipping material.

4. For permanently installed compact

washers only, use an adjustable wrench

to turn the washer legs out approximately

3/4″ (2.0 cm). This is the recommended

setting. Later adjustment may be needed.

1. To protect the floor, place two corner posts

from the shipping material on the floor in

back of the washer.

2. Firmly grasp the body of the washer and

gently lay it on the corner posts.

3. Remove plastic foam packaging from under washer.

5. Stand the washer up.

6. Remove the tape from the washer lid.

Open the washer lid and remove the foam

shipping piece, parts bag, and hoses from

the washer basket. Close the lid.

NOTE: If you are using a permanent installation, proceed to page 2-5. If you are using a

portable installation, proceed to page 2-10.

2-4

39"

(99 cm)

AB

PERMANENT INSTALLATION INSTRUCTIONS

WARNING

Excessive Weight Hazard

Use two or more people to move and

install washer.

Failure to do so can result in back or

other injury.

BEFORE YOU START

• To prevent floor damage, set the washer

onto cardboard before moving across floor.

• Move the washer to within approximately 3 ft

(90 cm) of the final location.

DRAIN SYSTEM

The washer can be installed using the standpipe

drain system (floor or wall), the laundry tub

drain system, or the floor drain system. Select

the drain hose installation method you need.

Laundry tub drain system (view A)

The laundry tub requires a minimum carryaway capacity of 13 gal. (49.2 L) per minute.

The top of the laundry tub must be at least 39″

(99 cm) above the floor and no higher than 72″

(183 cm) from the bottom of the washer.

Floor drain system (view B)

The floor drain system requires a siphon break

that may be purchased separately (see “Alternate Parts” on page 2-2).

The siphon break must be a minimum of 28″

(71 cm) from the bottom of the washer. Additional hoses might be needed.

The minimum carry-away capacity can be no

less than 13 gallon (49.2 L) per minute.

Standpipe drain system - wall or floor

(views A & B)

The standpipe drain requires a minimum diameter standpipe of 2″ (5 cm). The minimum

carry-away capacity can be no less than

13 gallons (49.2 L) per minute. A 2″ (5 cm)

diameter to 1″ (2.5 cm) diameter standpipe

adapter kit is available (see “Alternate Parts”

on page 2-2).

The top of the standpipe must be at least

39″ (99 cm) high and no higher than 72″ (183 cm)

from the bottom of the washer.

39"

(99 cm)

CONNECT DRAIN HOSE

Proper connection of the drain hose will protect

your floors from damage due to water leakage.

To prevent the drain hose from coming off or

leaking, it must be installed per the following

instructions.

IMPORTANT: To ensure proper installation,

this procedure must be followed exactly.

1. Check the drain hose to see that it is the

proper length.

2. Wet the inside of the straight end of the

drain hose with tap water. IMPORTANT:

Do not use any lubricant other than water.

AB

2-5

3. Squeeze the ears of the silver, doublewire clamp with pliers to open it. Place the

clamp over the straight end of the drain

hose 1/4″ (6 mm) from the end.

4. Open the clamp and twist the hose back

and forth while pushing down onto the

drain connector at the bottom of the washer.

Continue until the hose contacts the cabinet.

For standpipe or laundry tub drain systems

1. Open the yellow, single-wire clamp with

pliers, and slide it over the hooked end of

the drain hose to secure the rubber and

corrugated sections together.

A

B

A. Hooked end

B. Drain hose

2. Place the hooked end of drain hose into

the laundry tub, or standpipe. Rotate the

hook to eliminate kinks.

To prevent drain water from going back into the

washer:

5. Place the clamp over the area marked

“CLAMP,” and release the clamp.

1/4"

(6 mm)

C

A. Drain hose

B. Clamp

C. Cabinet

A

B

1/4"

(6 mm)

• Do not straighten the hooked end of drain

hose.

• Do not force excess drain hose into the

standpipe. The hose should be secure, but

loose enough to provide a gap for air.

• Do not lay excess drain hose in the bottom of

the laundry tub.

• For floor drain installation, see kit number

required under “Alternate Parts” on page

2-2.

2-6

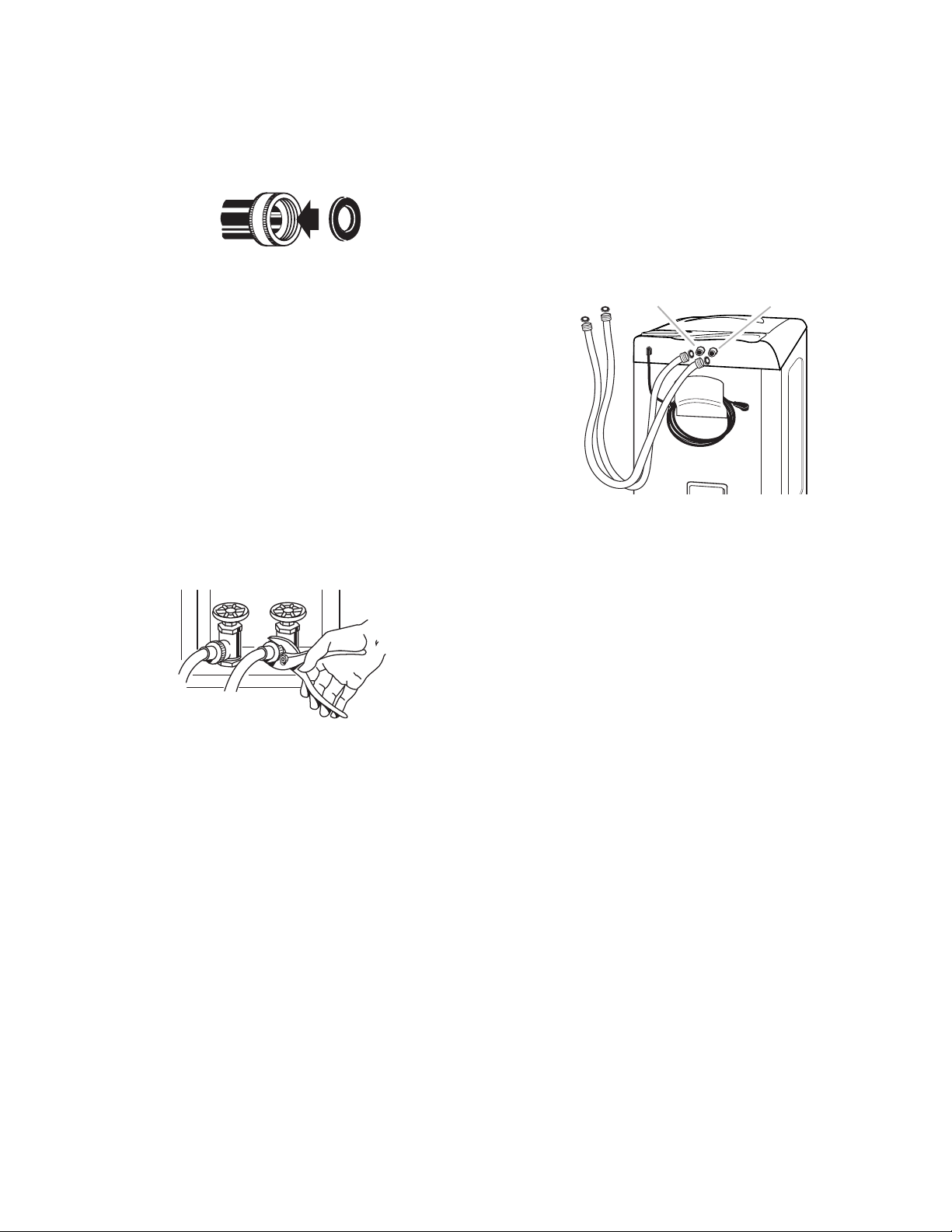

CONNECT THE INLET HOSES

1. Insert the new flat washers (supplied) into

each end of the inlet hoses. Firmly seat the

washers in the couplings.

A B

A. Coupling

B. Washer

7. Attach the hose with the red coupling to

the HOT (right) inlet valve. Attaching the

red coupling first makes it easier to tighten

connection with pliers. Screw the coupling

on by hand until it is seated on the washer.

Using pliers, tighten the couplings with an

additional two-thirds turn. NOTE: Do not

overtighten the couplings, or damage to

the valves may result.

A

B

2. Make sure the washer basket is empty.

3. Attach the hose with the red coupling to

the hot water faucet. Screw the coupling

on by hand until it is seated on the washer.

4. Attach the hose with the blue coupling to

the cold water faucet. Screw the coupling

on by hand until it is seated on the washer.

5. Using pliers, tighten the couplings an additional two-thirds turn. NOTE: Do not

overtighten the couplings, or damage to

the valves may result.

6. Run water through both faucets and inlet

hoses, into a bucket or laundry tub, to get

rid of particles in the water lines that might

clog the inlet valve screens.

C

H

A. Cold water inlet valve (blue)

B. Hot water inlet valve (red)

8. Attach the hose with the blue coupling to

the COLD water (left) inlet valve. Screw

the coupling on by hand until it is seated on

the washer. Using pliers, tighten the couplings with an additional two-thirds turn.

NOTE: Do not overtighten the couplings,

or damage to the valves may result.

2-7

9. Turn on the water faucets and check for

leaks. A small amount of water might enter

the washer. You will drain this later.

NOTE: Replace inlet hoses after 5 years of use

to reduce the risk of hose failure. Record the

hose installation or replacement dates for future reference.

• If you connect only one water hose, you must

cap off the remaining water inlet port.

• Periodically inspect and replace the hoses if

bulges, kinks, cuts, wear, or leaks are found.

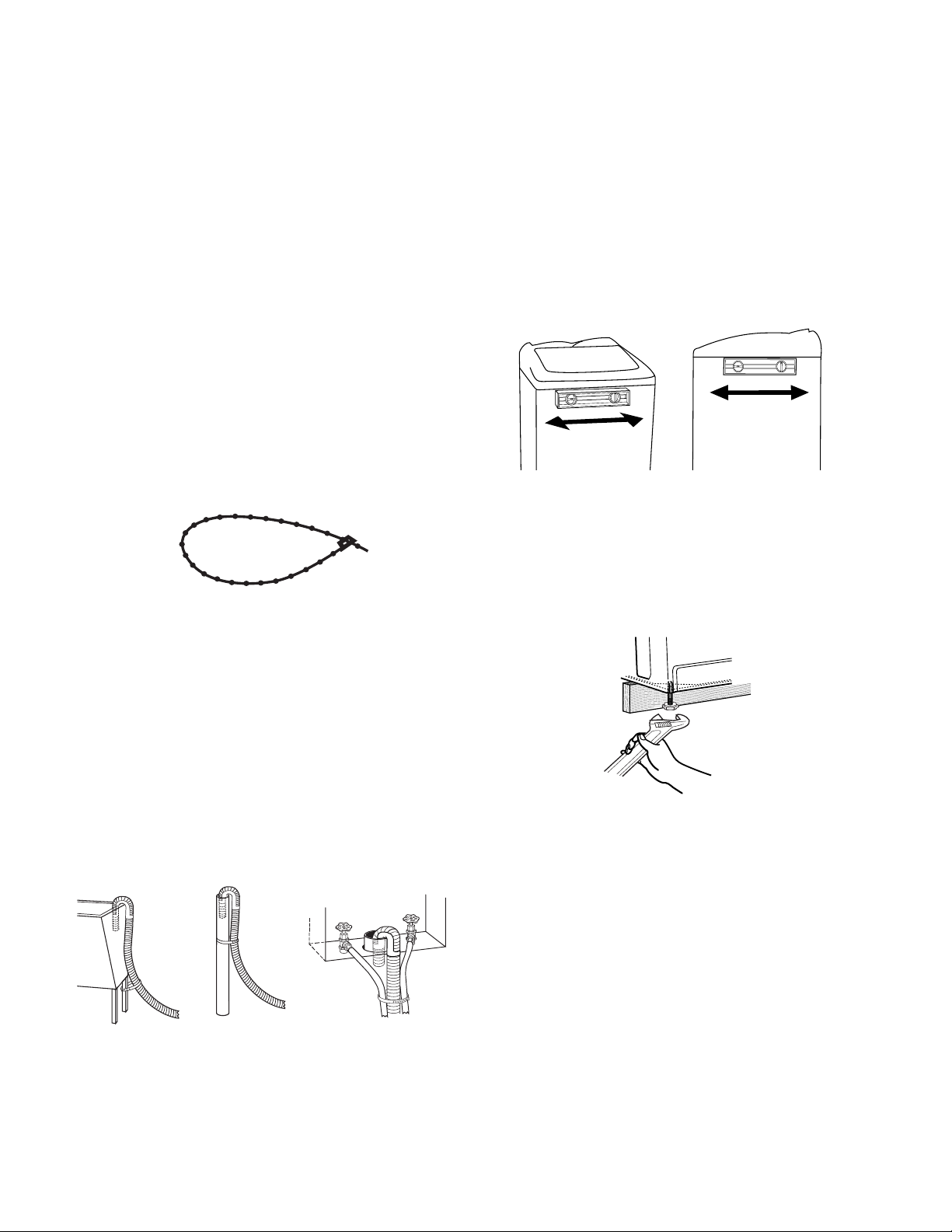

SECURE DRAIN HOSE

1. Drape the power cord over the console.

2. Move the washer to its final location and

remove any cardboard used to move

washer.

LEVEL THE WASHER

Properly leveling the washer will help prevent

excessive noise and vibration. To level the

washer:

1. Move the washer to its final location.

2. Check to see if the washer is level. Check

from side-to-side and from front-to-back

by lining up the level with the top edge of

the washer cabinet where it meets the

washer top.

3. Locate the beaded tie strap (supplied).

Beaded Tie Strap

4. Wrap the drain hose to the laundry tub leg

or standpipe with the tie strap (see illustrations A and B).

If the washer faucets and the drain

standpipe are recessed, place the hooked

end of the drain hose in the standpipe (see

illustration C). Tightly wrap the tie strap

around the water inlet hoses and the drain

hose.

Do not force excess drain hose back into the

rear of the washer.

3. If the washer is not level, prop up the front

of the washer with the wood block and

adjust the feet up or down as necessary. If

the washer is against a wall, move the

washer out slightly before tipping back.

Repeat this step until washer is level.

A

B C

2-8

COMPLETE INSTALLATION

1. Check the electrical requirements on page

2-3, and make sure that you have the

correct electrical supply and the recommended grounding method.

2. Check to be sure that all the parts are now

installed. If there is an extra part, go back

through the steps to see which step was

skipped.

3. Check to be sure you have all of your tools.

4. Dispose or recycle all packaging materials. Keep the expanded foam plug for use

if the washer should be transported.

5. Check to be sure the water faucets are on.

6. Check for leaks around faucets and inlet

hoses.

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

7. Plug into a grounded 3 prong outlet.

8. Read the “Washer Use.”

9. To test the washer:

a) Measure and add 1/2 the normal rec-

ommended amount of detergent to the

washer.

b) Close the lid.

c) Select any cycle, and then press the

START/OFF keypad.

d) Allow the washer to complete one

whole cycle.

2-9

PORTABLE INSTALLATION INSTRUCTIONS

DRAIN SYSTEM

The washer must drain into a sink or laundry

tub with a carry-away capacity of 7 gallons

(26.6 L) per minute. The top of the tub must be

at least 27″ (68.6 cm) above floor, and no

higher than 48″ (121.9 cm) from the bottom of

the washer.

27"

(68.6 cm)

CONNECT FILL-AND-DRAIN HOSE

Connect Drain Hose

To prevent the fill-and-drain hose from leaking,

it must be installed per the following instructions.

IMPORTANT: To ensure proper installation,

this procedure must be followed exactly.

1. Wet the inside end of the fill-and-drain

hose with tap water. IMPORTANT: Do not

use any lubricant other than water.

2. Squeeze the ears of the silver, doublewire clamp with pliers to open the clamp.

3. Place the clamp over the straight end of

the drain hose so it is 1/4″ (6 mm) from the

end.

(6 mm)

1/4"

Proper connection of the fill-and-drain hose will

protect your floors from damage due to water

leakage. To connect the hoses:

Connect Fill Hose

Attach the fill-and-drain hose to the cold water

(left) inlet valve. Tighten coupling by hand. Use

pliers to make an additional two-thirds turn.

NOTE: Do not overtighten the couplings, or

damage to the valves may result.

The hot water (right) inlet valve is capped.

Leave this valve capped.

4. Open the clamp. Twist the hose back and

forth while pushing down onto drain connector at the bottom of the washer. Continue until hose contacts the cabinet.

5. Place the clamp over the area marked

“CLAMP,” and release it.

1/4"

(6 mm)

A

B

1/4"

C

(6 mm)

2-10

A. Drain hose

B. Clamp

C. Cabinet

Loading...

Loading...