Whirlpool L-63 User Manual

CONSUMER SERVICES TECHNICAL

EDUCATION GROUP PRESENTS

27”

ELECTRIC & GAS

L-63

DRYERS

Part No. 4322260

JOB AID

I

INTRODUCTION

This Job Aid, “27 “ ELECTRIC & GAS DRYERS,” (Part No. 4322260), provides specific information on

the installation, service and repair of Whirlpool 27” dryers.

“27” ELECTRIC & GAS DRYERS” has been compiled to provide the most recent information on

design, features, troubleshooting, service and repair procedures.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair Whirlpool 27” electric or gas dryers.

The objectives of the Job Aid are:

The service technician will -

• Understand proper safety precautions.

• Successfully troubleshoot and diagnose malfunction.

• Successfully perform necessary repairs.

• Successfully return the dryer to proper operational status.

CORPORATIO N

WHIRLPOOL CORPORATION ASSUMES NO RESPONSIBILITY

FOR ANY REPAIRS MADE ON OUR PRODUCTS BY ANYONE

OTHER THAN AUTHORIZED SERVICE TECHNICIANS.

© 1997 Whirlpool Corporation, Benton Harbor, MI 49022

PB

TABLE OF CONTENTS

INTRODUCTION.................................................................................................................. II

TABLE OF CONTENTS ...................................................................................................... III

SECTION ONE

GENERAL INFORMATION

Electric Requirements .................................................................................................. 1

Exhaust Requirements for Electric and Gas Dryers .................................................. 5

Gas Requirements for Gas Dryers .............................................................................. 6

Recessed and Closet Installation Instructions........................................................... 8

SECTION TWO

THEORY OF OPERATION

Controls and Cycles....................................................................................................................9

Electronic Dryer Control...........................................................................................................10

Heated Air Circulation...............................................................................................................11

SECTION THREE

COMPONENT ACCESS .................................................................................................... 13

Removing the Console ..........................................................................................................13

Removing the Timer ..............................................................................................................14

Removing the Clean touch Switch Assembly........................................................................14

Removing the Push to Start Button .......................................................................................14

Removing the Buzzer ............................................................................................................14

Removing the Electronic Control Board ................................................................................14

Removing the Dryer Top........................................................................................................14

Replacing the Drum Lamp.....................................................................................................15

Removing the Door Switch....................................................................................................15

Removing the Toe Panel .......................................................................................................15

Removing the Blower Wheel .................................................................................................16

Replacing the Blower Housing ..............................................................................................16

Replacing the Motor ..............................................................................................................17

Replacing the Operating Thermostat and Bias Heater..........................................................17

Replacing the Thermal Fuse .................................................................................................17

Replacing the Heating Element.............................................................................................18

Replacing the Burner Assembly ............................................................................................18

Replacing the High Limit Thermostat and Thermal Cutoff ....................................................18

Replacing the Heat Duct Assembly.......................................................................................18

Removing the Dryer Door......................................................................................................19

Removing the Front Panel.....................................................................................................19

Removing the Belt and Drum ................................................................................................20

Replacing the Front Support Rollers and Shafts ...................................................................20

Replacing the Grille Assembly ..............................................................................................20

Removing the Rear Bulkhead Assembly...............................................................................21

Reattaching the Rear Bulkhead ............................................................................................21

III

SECTION FOUR

TROUBLESHOOTING AND DIAGNOSIS

Troubleshooting Guide.............................................................................................................23

Electronic Dryer Control Testing .............................................................................................24

SECTION FIVE

TECH TIPS

Wiring Diagrams........................................................................................................................25

Strip Circuits..............................................................................................................................27

Model/Serial Number Plate Location .......................................................................................30

Model/Serial Number Designations .........................................................................................30

Product Specification and Warranty Information Source......................................................30

PB

V

Section One

GENERAL INFORMATIONGENERAL INFORMATION

GENERAL INFORMATION

GENERAL INFORMATIONGENERAL INFORMATION

ELECTRICAL REQUIREMENTS

Electrical Requirements for Gas Dryers

Important: Observe all governing codes and ordinances.

Electrical ground is required on this product.

! WARNING

Electrical Shock Hazard

Check with a qualified electrician if you are in doubt as to whether the appliance

is properly grounded. Do Not modify the power supply cord plug. If it will not fit

the outlet, have a proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in a risk

of electrical shock.

Do Not use an extension cord with this appliance. Such use may result in a fire,

electrical shock or other personal injury.

Do Not have a fuse in the neutral or grounding circuit. This could result in a risk

of electrical shock.

A 120 volt, 60 Hz, AC only 15 or 20 Ampere fused electrical supply is required. A time-delay fuse or

circuit breaker is recommended. It is recommended that a separate circuit serving only this appliance

be provided.

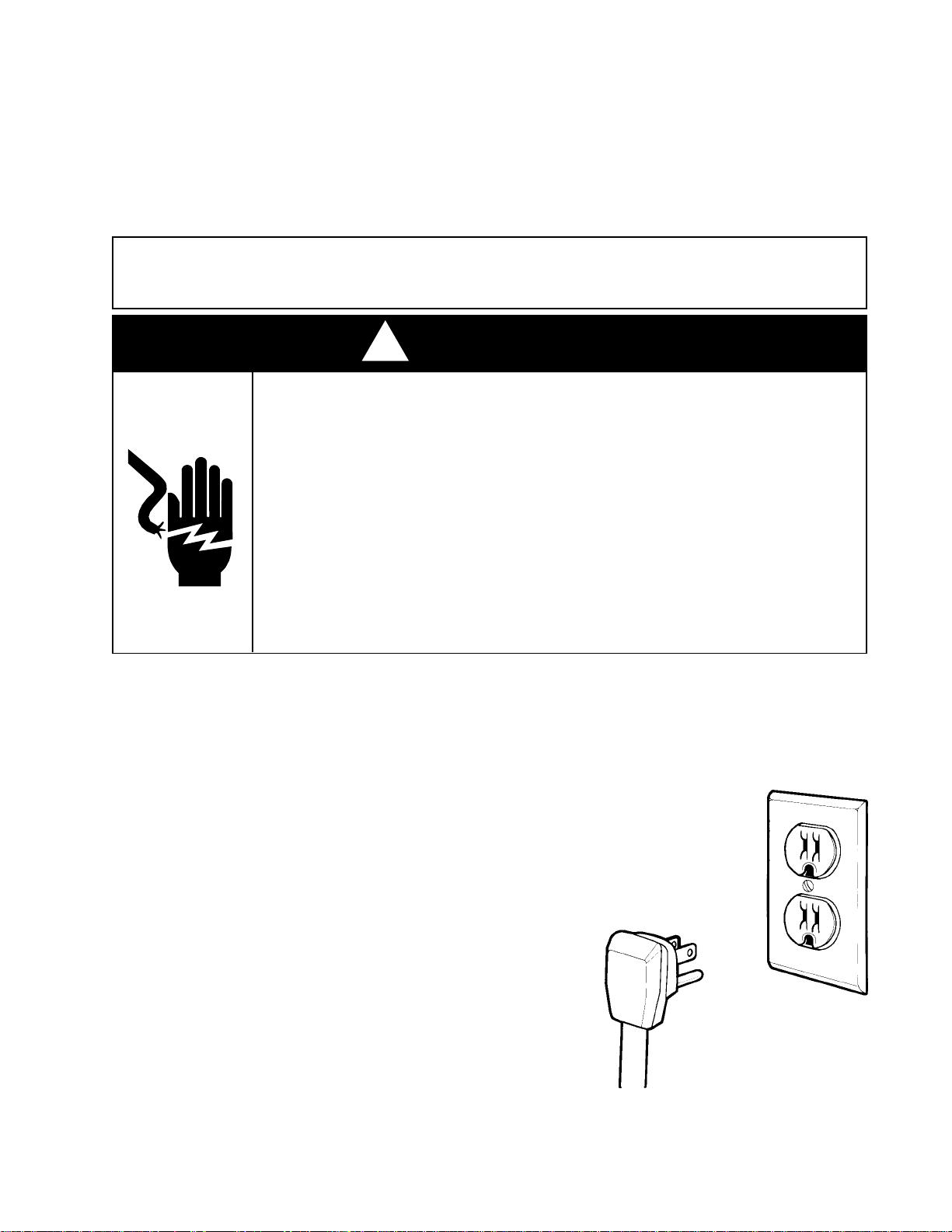

Recommended Grounding Method

Electrical ground is required on this appliance.

DO NOT, UNDER ANY CIRCUMSTANCES,

REMOVE THE POWER SUPPLY CORD GROUND

PRONG.

For your personal safety, this appliance must be

grounded. This appliance is equipped with a power

supply cord having a 3-prong grounding plug. (Fig. 1) To

minimize possible shock hazard, the cord must be

plugged into a mating 3-prong grounding type wall

receptacle, grounded in accordance with the National

Electrical Code, ANSI/NFPA 70-1987 or the latest code

and local ordinances. If a mating wall receptacle is not

available, it is the personal responsibility and obligation

of the customer to have a properly grounded 3-prong

wall receptacle installed by a qualified electrician.

3-prong

groundingplug

➘➘

➘

➘➘

3-prong

groundingtype wall

receptacle

➘➘

➘➘

➘

grounding

prong

power

➘➘

➘

➘➘

supply cord

Fig. 1

➘➘

➘

➘➘

1

Electrical Requirements for Electric Dryers

Important: Observe all governing codes and ordinances.

Electrical ground is required on this product.

! WARNING

Electrical Shock Hazard

Check with a qualified electrician if you are in doubt as to whether the appliance

is properly grounded. Do Not modify the power supply cord plug. If it will not fit

the outlet, have a proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in a risk

of electrical shock.

Do Not have a fuse in the neutral or grounding circuit. This could result in a risk

of electrical shock.

Do Not plug the power supply cord (pigtail) into any receptacle before connecting

the pigtail to the dryer terminal block. This could result in a risk of electrical

shock.

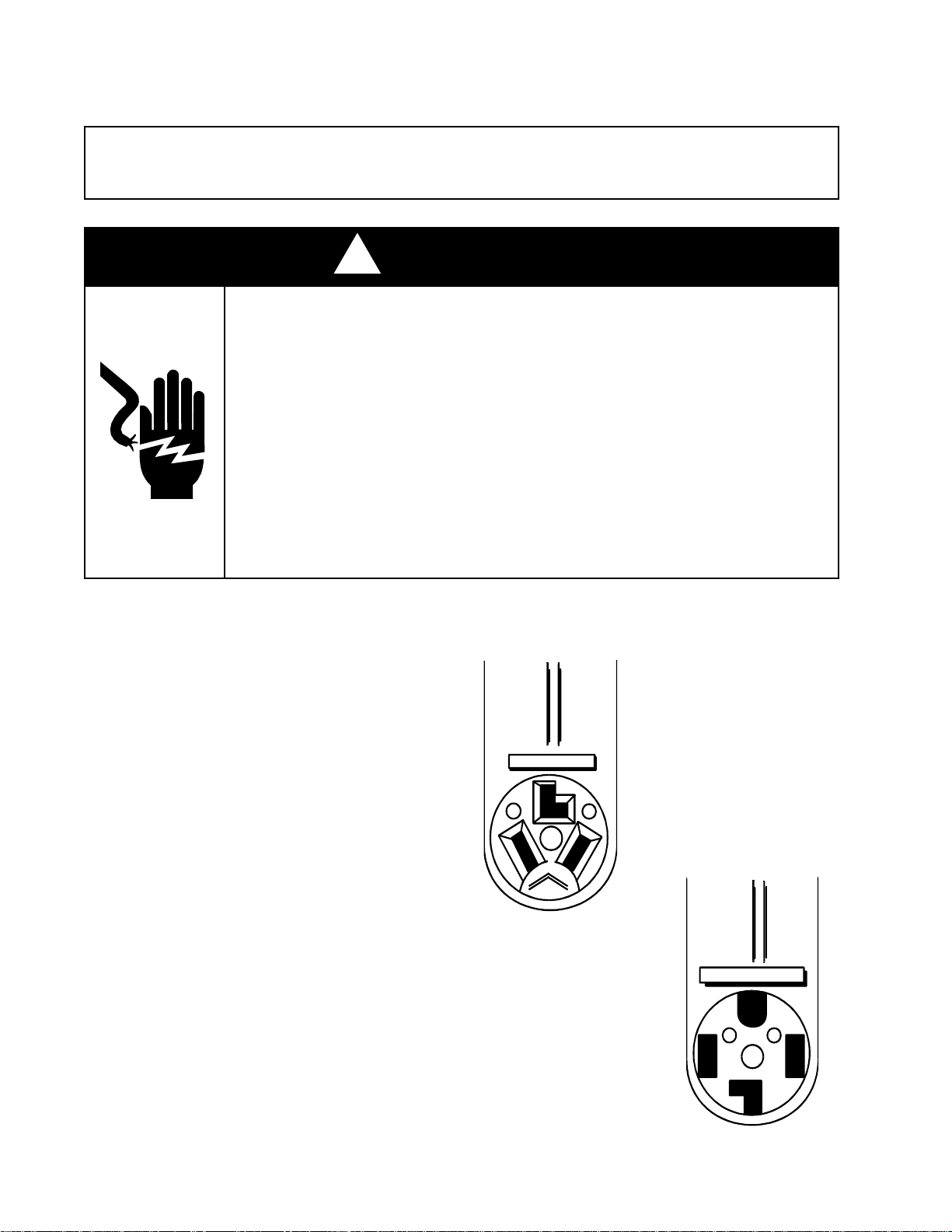

Electrical Connection

A. A three-wire (Fig. 2) or four-wire (Fig. 3),

single phase, 120/240 volt, 60 Hz, AC only

electrical supply is required on a separate

30-ampere circuit, fused on both sides of

the line. A time-delay fuse or circuit

breaker is recommended.

B. Most local codes permit the use of flexible,

30-amp rated, power supply cord (pigtail).

The power cord must be plugged into a

mating 30-amp receptacle (NEMA type

10-30R). A U.L.- listed strain relief must

be installed where the power cord enters

the dryer.

C. THE DRYER MUST BE CONNECTED

WITH 10-GAUGE MINIMUM COPPER

WIRE ONLY. Do Not use aluminum wire

which could cause a fire.

D. The power supply cord (pigtail) can be

removed and the appliance can be connected directlyto an individual 30-ampere

fuse circuit breaker box through flexible

armored or nonmetallic sheathed, 10gauge minimum copper cable. It is the

personal responsibility and obligation of

Fig. 3

Fig. 2

2

the customer to contact a qualified electrician to assure that the electrical installation is

adequate and is in conformance with National Electrical Code ANSI/NFPA 70-1987 (or the

latest edition) and local codes and ordinances.

Important: Allow slack in the line between the wall and the appliance so that it can be

move if servicing is ever necessary.

A U.L.-listed strain relief must be provided at each end of the power supply cable (at the appliance and

at the junction box). Wire sizes (10-gauge COPPER WIRE ONLY) and connections must conform with

the 30-ampere circuit rating.

E. For mobile home installation, the three-wire power supply cord must be removed and the

appliance wiring must be revised. The appliance frame must not be connected to the neutral

terminal, but must be connected to the grounding wire (green) of the power supply cord.

See Alternate electrical connection - mobile home installation, for detailed instructions.

If a four-wire receptacle of NEMA type 14-30R is available, a matching power supply cord (pigtail)

must be used. This cord contains No. 10-gauge copper conductors with spade or ring terminals on the

dryer end and terminating in a NEMA type 14-30P plug on supply end. The fourth (grounding) must be

identified by a green cover and the neutral conductor by a white cover. Cord should be at least three

feet long. The four-wire power supply cord and strain relief are not provided with the dryer.

! WARNING

Electrical Shock Hazard

Disconnect power supply cord from the electric supply before making these

changes. Use a new power supply cord.

Failure to do so may result in electrical shock.

Grounding Instructions

This appliance must be connected to a grounded metal, permanent wiring system; or an equipmentgrounding conductor must be run with the circuit conductors and connected to the equipment-grounding

terminal or lead on the appliance.

Electrical grounding is required on this appliance.

This appliance is manufactured with the neutral terminal connected to the frame.

Make sure power supply is turned off.

A. If local codes permit connection of the frame-grounding conductor to the neutral wire of the power

supply cord:

1. Loosen the terminal block cover hold-down screw. Swing cover open to the right.

2. Attach a U.L.-listed strain relief to the dyer through the power supply cord hole. Place the

power supply cord or direct wire through the strain relief.

3. Connect the neutral wire on the power supply cord to the center, silver-colored terminal of the

terminal block and connect the other wires to the outer terminals.

3

4. IF YOUR POWER SUPPLY CORD OR DIRECT WIRING HAS PLAIN WIRE ENDS, FOLLOW

THESE STEPS:

a. Strip outer covering back 3 inches from the end exposing the 3 wires.

b. Strip the insulation back 1 inch from the end of each wire. Form the bare wire to “U”

shaped hook.

c. Loosen, do not remove, the center, silver-colored screw of the terminal block.

d. Slide the end of the neutral (white or center) wire under the screw head with the open side

of the hook on the right. Squeeze the wire together to form a loop.

e. Tighten the screw firmly.

f. Connect the remaining 2 wires to the outer screws the same way. Tighten screws firmly.

5. Close the terminal block cover and tighten screw.

6. Tighten screws on strain relief.

B. If local codes DO NOT permit frame grounding to the neutral wire of the power supply cord:

1. Loosen the terminal block cover hold-down screw. Swing cover open to the right.

2. Attach a U.L.-listed strain relief to the dryer through the power supply cord hole. Place the

power supply cord or direct wire through the strain relief.

3. Remove the grounding wire (green) from the external grounding connector and fasten under

center silver-colored terminal block screw.

4. Connect the neutral wire of the power supply cord to the center silver-colored terminal of the

terminal block and connect the other wires to the outer terminals.

5. Connect a separate copper grounding wire (No. 10 minimum) to a grounded cold water pipe

by means of a clamp and then to the frame of the appliance at the external grounding connector.

Use Part No. 685463 grounding wire and clamp assembly. Do Not ground to a gas supply

pipe or hot water pipe. Do not connect the power supply cord to electric power supply until

appliance is permanently grounded.

6. Close the terminal block cover and tighten screw.

7. Tighten screws on strain relief.

C. If connecting to a four-wire electrical system (mobile home):

1. Loosen the terminal block cover hold-down screw. Swing cover open to the right.

2. Attach a U.L.-listed strain relief to the dryer through the power supply cord hole. Place the

power supply cord or direct wire thought the strain relief.

3. Remove the grounding wire (green/yellow) from the external grounding connector and fasten

under the center, silver-colored terminal block screw.

4. Connect the grounding wire (green) of the power supply cord to the external grounding connector.

5. Connect the neutral wire (white) of the power supply cord to the center, silver-colored terminal

of the terminal block and connect the other wires to the outer terminals.

6. Close the terminal block cover and tighten screw.

7. Tighten screws on strain relief.

4

Exhaust Requirements for Gas and Electric Dryers

! WARNING

Fire Hazard

Do Not use nonmetal, flexible duct. Do Not use metal duct smaller that four inches in diameter. Do

Not use exhaust hoods with magnetic latches. Improper air supply for exhausting may result in a

fire. Check that exhaust system is not longer than specified. Exhaust systems longer than specified

will:

• Accumulate lint

• Shorten the life of the product

• Reduce performance and result in longer drying times and increased energy usage.

Failure to follow these specifications may result in a fire.

Do Not exhaust dryer into a chimney, furnace cold air duct, attic or crawl space, or any other duct

used for venting. Clean the exhaust system every other year. Do Not install flexible duct under

wall, ceiling or floor materials. Accumulated lint could result in a fire or cause moisture damage.

Four inch Rigid Metal Duct is preferred. Four-inch flexible metal duct may be used.

Metal flexible duct must be fully extended and supported when the dryer is in its final position. DO

NOT KINK OR CRUSH THE DUCT. The metal flexible duct must be completely open to allow adequate

exhaust air to flow.

Plan installation to use the fewest number of elbows and turns. Allow as much room as possible when

using elbows or making turns. Bend duct gradually to avoid kinking. Remove excess flexible duct to

avoid sagging and kinking that may result in reduced air flow.

Use duct tape to seal all joints.

The Exhaust duct can be routed down, left, right, or straight out the back of the dryer. Space

requirements are provided in the Installation Instructions.

Minimum length of rear exhaust system depends upon the type of duct used, number of elbows and

the type of exhaust hood. The maximum length for both rigid and flexible ducts is shown in chart.

Side or bottom exhaust maximum length is 16 feet with two external elbows.

Exhausting the dryer outside is preferred.

Four inch Rigid Metal Duct is preferred. Four-inch flexible metal duct may be used.

Metal flexible duct must be fully extended and supported when the dryer is in its final position. DO

NOT KINK OR CRUSH THE DUCT. The metal flexible duct must be completely open to allow adequate

exhaust air to flow.

5

If the dryer is installed in a confined area such as a bedroom, bathroom, or closet, it must be

exhausted to the outside and provisions must be made for enough air for combustion and ventilation.

Check governing codes and ordinances. Also refer to the Recessed Installation Instructions.

An Exhaust hood should cap the exhaust duct to prevent exhausted air from returning to the dryer.

The outlet of the hood must be a least 12 inches from the ground or any object that may be in the path

of the exhaust.

Four-inch outlet hood is preferred, however, a 2 1/2 inch outlet exhaust hood may be used with

systems ten feet or less. (This outlet creates greater back pressure than other hood types.)

Exhaust kits are available that direct filtered exhaust air inside to conserve energy during the winter

months. Before installing, check that using this type of kit does not violate local codes and ordinances.

Using one of these kits may result in excessive moisture in the home. This may cause problems and

could increase the drying time. The filter must be cleaned regularly to avoid excessive lint buildup

which can affect the dryer’s performance.

Mobile home installation. This appliance is suitable for mobile home installations. The installation of

the dryer must conform to the Manufactured Home Construction and Safety Standard, Title 24 CFR,

Part 3280 (formerly the Federal Standard for Mobile Homes Constructions and Safety, Title 24, HUD

Part 280, 1975) or the latest edition.

Mobile home exhaust requirements: The dryer must have an outside exhaust. If the dryer is

exhausted through the floor and the area under the mobile home is enclosed, the exhaust system

must terminate outside the enclosed area. Extension beyond the enclosure will prevent lint and

moisture buildup under the mobile home.

Secure dryer: For mobile home use, gas dryers must be securely fastened to the floor. Whirlpool Kit

No. 346764 is available at your local parts distributor or Whirlpool Service Center.

For best efficiency the exhaust system should be designed

to conform to the specifications in the Whirlpool Exhaust Guide,

Part No. LIT603197-B. (Fig. 4)

Fig. 4

Gas Requirements for Gas Dryers

Important: Observe all governing codes and ordinances.

! WARNING

Fire Hazard

Connect dryer to a regulated gas supply. L.P. gas supply must not exceed

a pressure of 13” water column. This must be checked by a qualified

person before installing the dryer. Use new, flexible tubing. Old tubing

may leak. All connections must be wrench-tightened. Do Not check for

gas leaks using an open flame. Failure to follow these instructions could

result in a fire or explosion.

6

Loading...

Loading...