CONSUMER SERVICES TECHNICAL

EDUCATION GROUP PRESENTS

L-61

Washers and Dryers with Fifth Generation

Solid State Electronic Control Systems

Fabric/Cycles Time Load Size Temperature Options Status

Heavy

Regular

Perm Press

Delicate

Hand Wash

Soak

On

Select

14

Heavy

12

10

Normal

8

6

Light

4

Delay Hours

Extra Large

Medium

Small

Wash/Rinse

Hot/Warm

Hot/Cold

Warm/Warm

Warm/Cold

Cold/Cold

SelectSelectSelect

Super Wash

Extra Rinse

Rinse & Spin-High

Rinse & Spin-Low

Spin Only - High

Select

LockOut

Fill/Wash

Rinse

Final Spin

LockOut

Cancel

Start

Delay

Cycles/Temps

Reg/Heavy-High

Perm Press-Med

Delicate-Low

Fluff Air-No Heat

Tumble Press-Med

Damp Dry-High

On

Select

Very Dry

More Dry

*Reg Dry

Less Dry

Least Dry

or Timed

90 Min

70 Min

50 Min

30 Min

10 Min

Select

OptionsAutomatic

Cycle Signal

Finish Guard

Select

LockOut

Status

Drying

Cool Down

Finish Guard

LockOut

Cancel

Start

JOB AID

Part No. 4321848

INTRODUCTION

This Job Aid,

No. 4321848 provides specific instruction for servicing the control system of Whirlpool-built three

speed direct drive washers and gas and electric dryers equipped with fifth generation fully solid state

electronic controls. These controls were introduced on Whirlpool washer model LSE9355BZO and

dryer model LE/GE9848BZO and KitchenAid washer model KAWE977BWHO and dryer model KE/

GYW977BWHO.

The Job Aid should be used in conjunction with the companion video tape ,

Fifth Generation Solid State Electronic Controls,”

All mechanical aspects of these units are identical to Whirlpool-build Direct Drive Washers and Gas

and Electric Dryers except as noted in ths Job Aid. For a complete description of repair procedures

refer to the Job Aids,

L-58, Part No. 4314557. Companion videos are also available for these Job Aid.

“Washers and Dryers with Fifth Generation Solid State Electronic Controls,”

“Washers and Dryers with

Part No. 4321849.

“Direct Drive Washers”

L-55, Part No. 787930 and

“Dryer Mechanical Systems"

L-61, Part

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide specific information that will enable the service technician to

repair and maintain Whirlpool-built washers and dryers equipped with fifth generation solid state

electronic controls.

The objectives of this Job Aid are:

,

The service technician will -

• Understand the function of the solid state electronic controls

• Perform and interpret the diagnostic tests for the solid state electronic controls

TO THE INSTRUCTOR/INDEPENDENT STUDENT

This Job Aid is designed to be used with the video tape,

Genreration Solid State Electronic Control Systems,”

you will see a symbol that looks like this:

“Washers and Dryers with Fifth

Part No. 4321849. As you use this Job Aid

>>

It instructs you to view certain sections of the video tape. The section numbers you should view

appear in the lower left corner of the screen.

This symbol (

appar at the end of various sections of the Job Aid. You will need a pencil to complete these exercises.

.) appears next to the heading,. “Confirmation Of Understanding Exercises” which

WHIRLPOOL CORPORATION ASSUMES NO RESPONSIBILITY

FOR ANY REPAIRS MADE ON OUR PRODUCTS BY ANYONE

OTHER THAN AUTHORIZED SERVICE TECHNICIANS

© 1995 Whirlpool Corporation, Benton Harbor, Michigan

TABLE OF CONTENTS

INTRODUCTION III

TABLE OF CONTENTS IV

SECTION 1 - EQUIPMENT AND SAFETY 1

SECTION 2 - INSTALLATION CONSIDERATIONS 3

SECTION 3 - THEORY OF OPERATION 7

Automatic Electronic Three Speed Direct Drive Washers 7

Electronic Electric and Gas Dryers 9

SECTION 4 - SERVICING WASHERS AND DRYERS 11

Automatic Electronic Three Speed Direct Drive Washers 11

Component Location and Access 11

Testing and Diagnosis 12

Servicing Procedures 18

Solid State Electronic Controls 18

Water Level Transducer 18

Electronic Electric and Gas Dryers 19

Component Locations and Access 19

Testing and Diagnosis 20

Servicing Procedures 23

Solid State Electronic Controls 23

SECTION 5 - TECH TIPS 25

Testing Procedures for Water level Transducer 25

Testing Procedures for LED Indicators 25

Product Speficiation and Warranty Information 25

Wiring Diagrams 26

-- NOTES --

>>

View Section 1 of the Video Tape

Section 1

EQUIPMENT AND SAFETYEQUIPMENT AND SAFETY

EQUIPMENT AND SAFETY

EQUIPMENT AND SAFETYEQUIPMENT AND SAFETY

EQUIPMENT

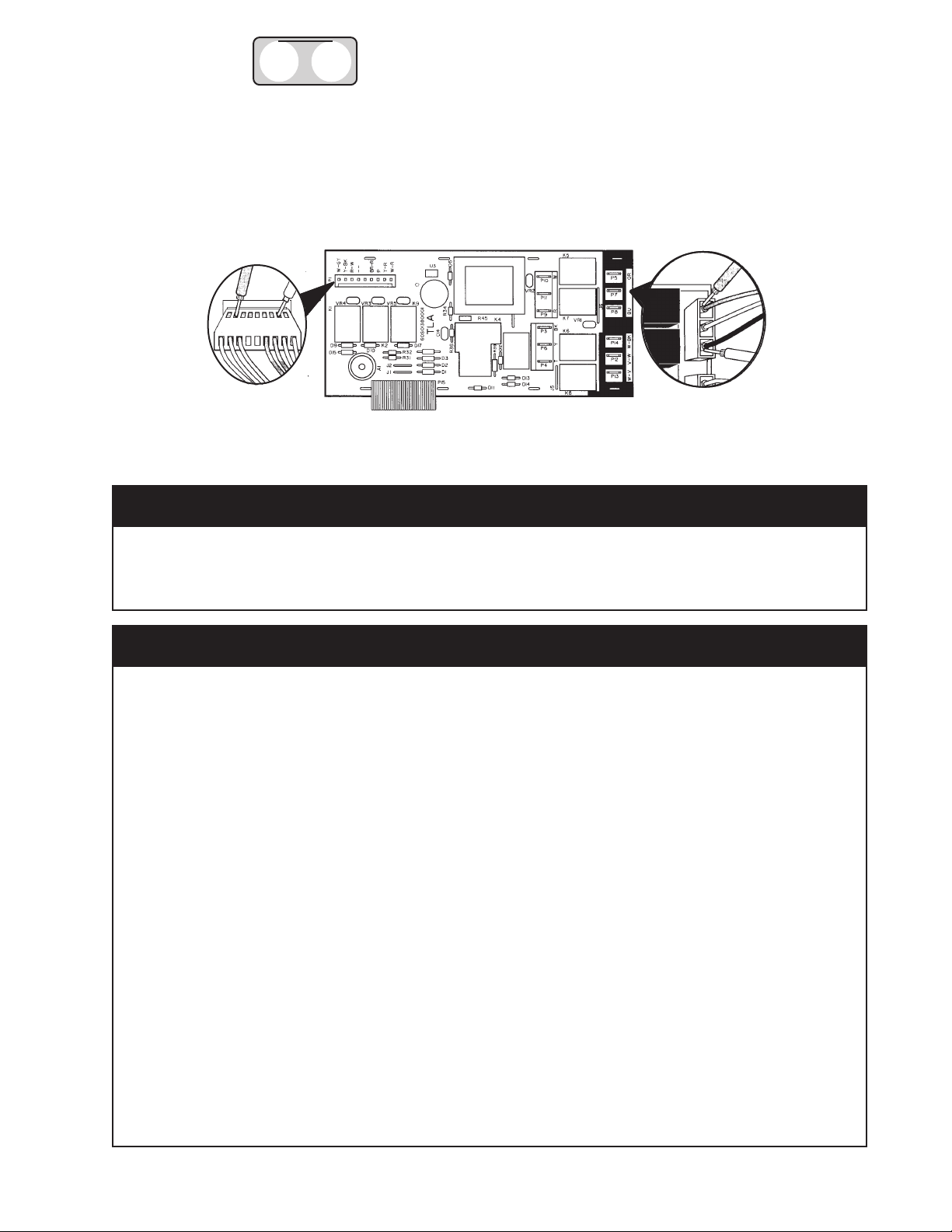

All tests/checks should be made with a VOM or DVM having a sensativity of 20,000 ohms per volt

DC or greater. Voltage check should be made with wires connected.

Fig. 1

SAFETY

(Figure 1)

! WARNING

ss

s

ss

ELECTRICAL SHOCK HAZARD

Disconnect the unit from household electric supply before servicing.

Failure to do so could result in serious injury or death.

! CAUTION

ss

s

ss

ELECTROST A TIC DISCHARGE (ESD) SENSITIVE ELECTRONICS

Do not open the package containing the service replacement control assembly unitl it is time to

install it. ESD problems are present everywhere. ESD may damage or weaken the electronic

control assembly. The new control assembly may appear to work well after repair is finished,

but failure may occur at a later date due to ESD stress.

Use an anti-static wrist strap.

Connect wrist strap to green ground connection point or

unpainted metal in the appliance.

-OR-

Touch your finger repeatedly

to a green ground connection point

or unpainted metal in the appliance.

Before moving the part from its package,

touch the anit-static bag to a green ground connection

point or unpainted metal in the appliance.

Avoid touching electronic parts or terminal contacts;

handle electronic control assembly by edges only.

When repackaging a failed electronic control assembly in the anit-static bag,

observe above precautions.

1

-- NO-- NO

-- NO

-- NO-- NO

TES --TES --

TES --

TES --TES --

2

>>

View Section 2 of the Video Tape

Section 2

INSTALLATION CONSIDERATIONS

The most common cause of electronic control failure are the result of issues related to proper installation. Before servicing the appliance, perform the following checks:

· Is the power cord firmly plugged into a live circuit with proper voltage?

· Has a household fuse blown or circuit breaker tripped? Is the circuit on a time delay fuse?

· Is the washer or dryer in Lockout? Push and hold LOCKOUT select pad under OPTIONS for 5

seconds to release.

· Are both hot and cold water faucets open and water supply hoses unobstructed?

· Check all connections before replacing components. Broken or loose wires and defective termi

nals can cause the same failure symptoms as a defective component.

1. Connectors: Look at the top of the connector for broken or loose wires. Check for wires not

pressed into the connector far enough to engage metal barbs.

(Figure 2)

2. Voltage: All voltage checks must be made with all connectors ATTACHED to the board(s).

3. Resistance: All resistance checks must be made with wiring harness or connectors

DISCONNECTED.

If the appliance appears to be properly installed and a problem still exists, further diagnosis is required.

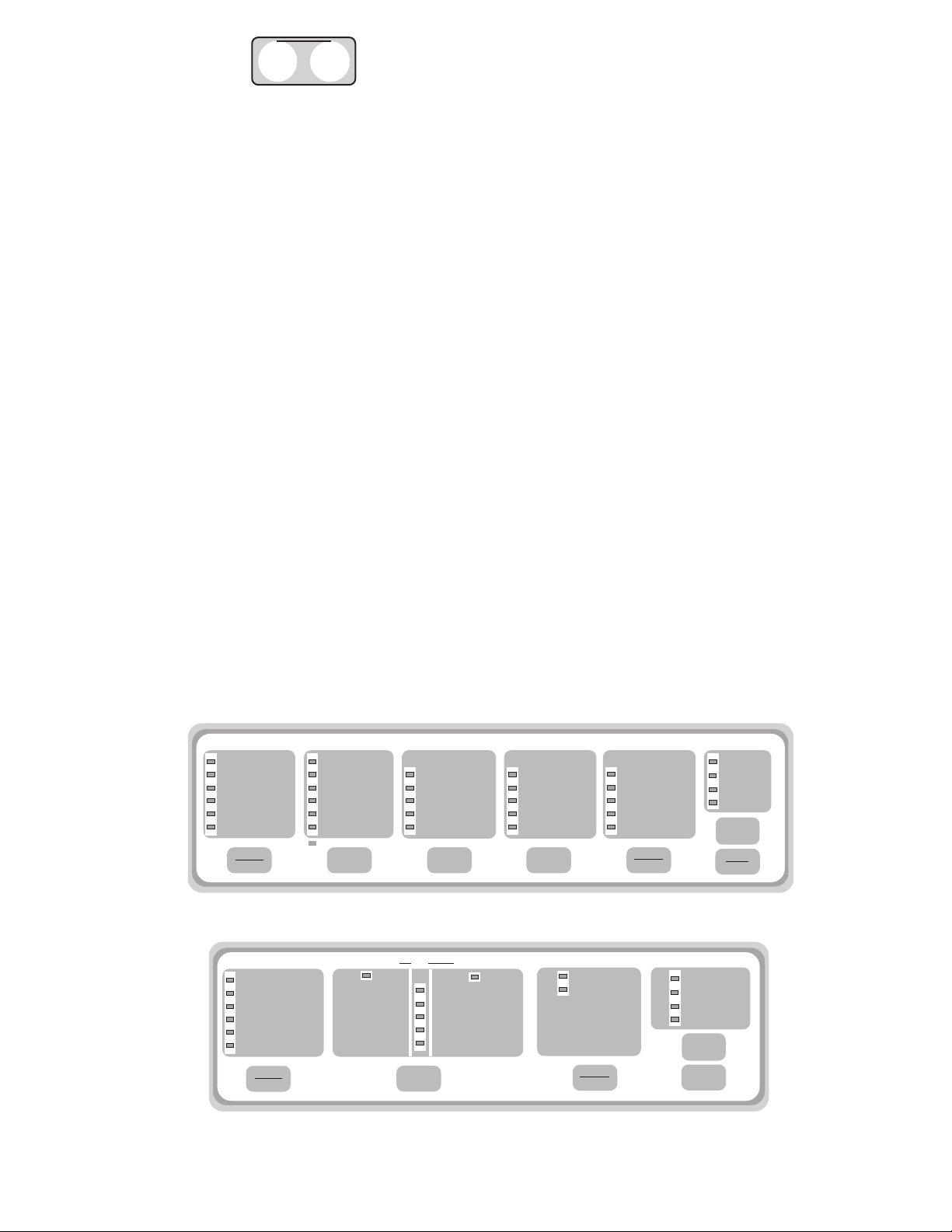

Washer

Fabric/Cycles Time Load Size Tem peratu re Options Status

Heavy

Regular

Perm Press

Delicate

Hand Wash

Soak

On

Select

14

Heavy

12

10

Normal

8

6

Light

4

Delay Hours

Extra Large

Medium

Small

Wash/Rinse

Hot/Warm

Hot/Cold

Warm/Warm

Warm/Cold

Cold/Cold

SelectSelectSelect

Super Wash

Extra Rinse

Rinse & Spin-High

Rinse & Spin-Low

Spin Only - High

Select

LockOut

Fill/Wash

Rinse

Final Spin

LockOut

Cancel

Start

Delay

Ü

Dryer

Status

Drying

Cool Down

Finish Guard

LockOut

Cancel

Start

Reg/Heavy-High

Perm Press-Med

Delicate-Low

Fluff Air-No Heat

Tumble Press-Med

Damp Dry-High

On

Select

AutomaticCycles/Temps

Very Dry

More Dry

*Reg Dry

Less Dry

Least Dry

or

Select

Timed

90 Min

70 Min

50 Min

30 Min

10 Min

Options

Cycle Signal

Finish Guard

Select

LockOut

Fig. 2

3

Ü

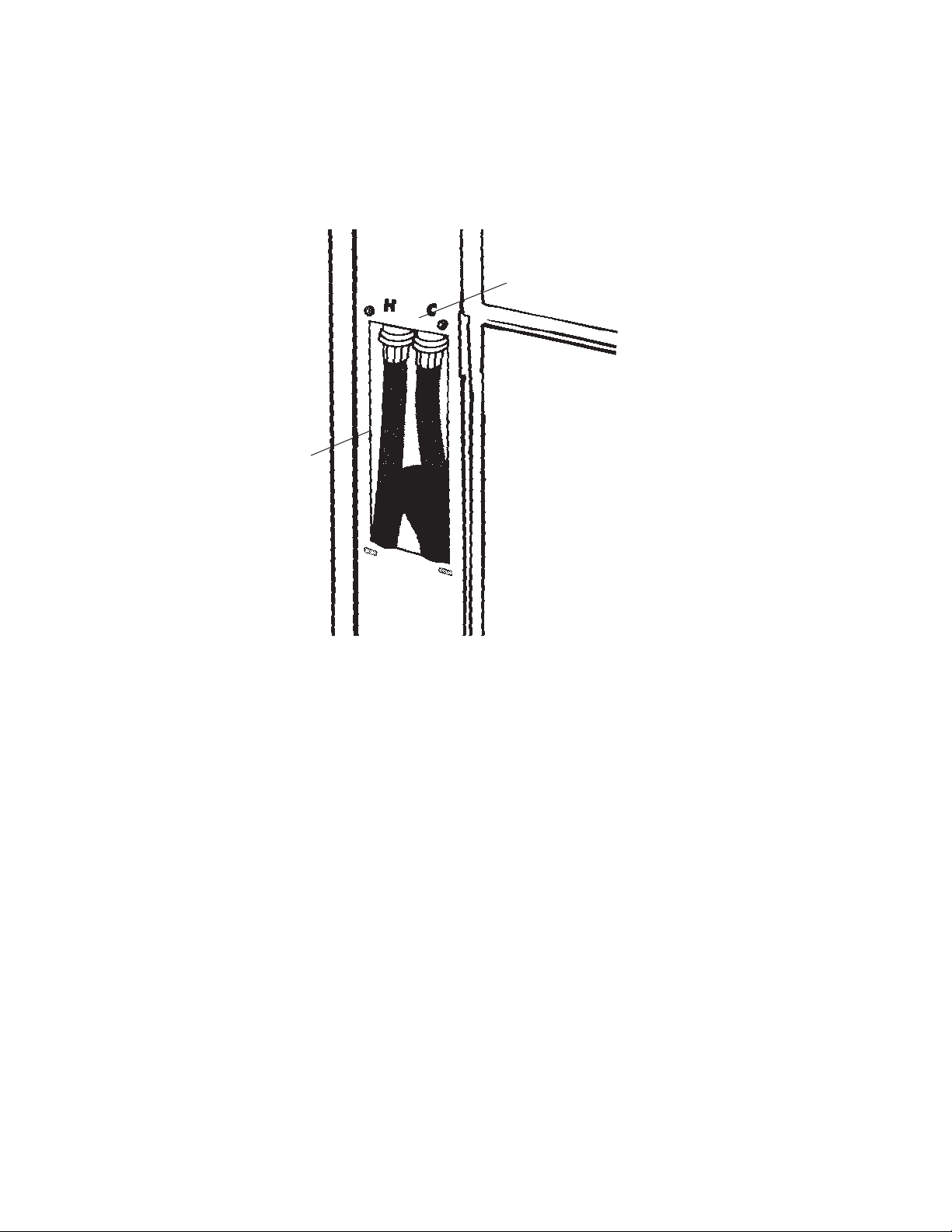

INLET HOSES

The rubber washers and inlet hoses on washers with 5th Generation Electronic Controls have been

installed in the factory . They will be found tucked into a cavity immediately below the inlet valve at the

back of the washer.

the plastic retainer inside the washer.

Figure 3

RUBBER WASHERS

ARE INST ALLED A T

(Fig. 3)

AND INLET HOSES

F AC TOR Y

Some effort will be required to separate the free ends of the hoses from

WATER INLET

VALVE

ss

ss

s

s

ss

ss

4

Section 2Section 2

Section 2

Section 2Section 2

( (

..

) )

(

.

( (

..

1. If a washer or dryer equipped with 5th Generation Electronic Controls fails to operate properly,

what should be the first step in servicing the appliance?

o a. Replace the Electronic Control Assembly

o b. Make sure the appliance is plugged into a live receptacle.

o c. Check the individual components on the printed circuit board.

o d. Call for technical assistance.

2. If the washer or dryer is in LOCKOUT:

o a. Press and hold the LOCKOUT button down for 5 seconds.

o b. Unplug the appliance and wait 30 seconds before plugging it back in.

o c. Press and hold the CANCEL button down for 5 seconds.

o d. Replace the Electronic Control Assembly.

3. All voltage checks must be made:

CONFIRMATION OF UNDERSTANDINGCONFIRMATION OF UNDERSTANDING

)

CONFIRMATION OF UNDERSTANDING

) )

CONFIRMATION OF UNDERSTANDINGCONFIRMATION OF UNDERSTANDING

EXERCISESEXERCISES

EXERCISES

EXERCISESEXERCISES

o a. With the appliance unplugged.

o b. With the connectors attached to the printed circuit board.

o c. W ith the connector disconnected from the printed circuit board.

o d. While the appliance is running.

4. All resistance checks must be made:

o a. With the connectors disconnected from the printed circuit board.

o b. With the connectors connected to the printed circuit board.

o c. With the appliance unplugged.

o d. With the appliance running.

5. The factory installed inlet hoses:

o a. Should be disconnected before removing the free ends from the washer.

o b. Will require some effort to separate the free ends from their plastic retainer.

o c. Should not be removed from the cavity until the washer is ready for operation.

o d. Require that the rubber washers be installed on the inlet end.

5

-- NO-- NO

-- NO

-- NO-- NO

TES --TES --

TES --

TES --TES --

6