Whirlpool GXU7130DXB0, GXU7130DXB1, GXU7130DXQ0, GXU7130DXQ1, GXU7130DXS0 Owner’s Manual

...

30" (76.2 CM) RANGE HOOD

Installation Instructions and Use & Care Guide

HOTTE D’ASPIRATION DE 30" (76,2 CM)

Instructions d’installation et Guide d’utilisation et d’entretien

Table of Contents/Table des matières..................................................................2

IMPORTANT: READ AND SAVE THESE INSTRUCTIONS.

FOR RESIDENTIAL USE ONLY.

IMPORTANT : LIRE ET CONSERVER CES INSTRUCTIONS.

POUR UTILISATION RÉSIDENTIELLE UNIQUEMENT.

LI3Y5B/W10320576B

TABLE OF CONTENTS TABLE OF CONTENTS

RANGE HOOD SAFETY ........................................................... 3

INSTALLATION REQUIREMENTS .......................................... 4

Tools and Parts .................................................................... 4

Location Requirements ....................................................... 4

Venting Requirements ......................................................... 5

Electrical Requirements ....................................................... 7

INSTALLATION INSTRUCTIONS ........................................... 7

Prepare Location ................................................................. 7

Install Range Hood ............................................................... 9

Make Electrical Connection ................................................ 10

Complete Installation ......................................................... 10

RANGE HOOD USE ............................................................. 11

Range Hood Controls ........................................................ 11

RANGE HOOD CARE ........................................................... 11

Cleaning ............................................................................ 11

WIRING DIAGRAM ............................................................... 12

ASSISTANCE OR SERVICE ................................................. 13

In the U.S.A. ...................................................................... 13

In Canada .......................................................................... 13

Accessories ....................................................................... 13

WARRANTY .......................................................................... 14

SÉCURITÉ DE LA HOTTE DE CUISINIÈRE ......................... 15

EXIGENCES D'INSTALLATION ............................................ 17

Outils et pièces .................................................................. 17

Exigences d'emplacement ................................................ 17

Exigences concernant l'évacuation ................................... 18

Spécifications électriques ................................................. 20

INSTRUCTIONS D'INSTALLATION ..................................... 20

Préparation de l'emplacement .......................................... 20

Installation de la hotte ........................................................ 22

Raccordement électrique ................................................... 24

Achever l’installation ......................................................... 24

UTILISATION DE LA HOTTE ............................................... 25

Commandes de la hotte de cuisinière ............................... 25

ENTRETIEN DE LA HOTTE ................................................. 25

Nettoyage .......................................................................... 25

SCHÉMA DE CÂBLAGE ....................................................... 26

ASSISTANCE OU SERVICE ................................................. 27

Accessoires ....................................................................... 27

GARANTIE ............................................................................ 27

2

RANGE HOOD SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

State of California Proposition 65 Warnings:

WARNING: This product contains one or more chemicals known to the State of California to cause cancer.

WARNING: This product contains one or more chemicals known to the State of California to cause birth defects or other

reproductive harm.

You can be killed or seriously injured if you don't immediately

follow instructions.

You

can be killed or seriously injured if you don't

instructions.

follow

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

3

INSTALLATION REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed

■ Drill

■ 1¼" (3.0 cm) drill bit

1

⁄8" (3.0 mm) drill bit for pilot holes

■

■ Pencil

■ Wire stripper or utility knife

■ Tape measure or ruler

■ Caulking gun and weatherproof caulking compound

■ Flat-blade screwdriver

■ Phillips screwdriver

■ Saber or keyhole saw

■ Vent clamps

■ Metal snips

■ Compass or 8" (20.3 cm) circle template

Parts supplied

Remove parts from package. Check that all parts are included.

■ 2 - Metal filters

■ 6 - 3.5 x 9.5 mm mounting screws

■ 3 - 4.5 x 13 mm damper screws

■ 3¼" x 10" (8.3 x 25.4 cm) damper/vent connector

■ T-20 Torx®† adapter

Location Requirements

IMPORTANT: Observe all governing codes and ordinances.

■ It is the installer’s responsibility to comply with installation

clearances specified on the model/serial rating plate. The

model/serial rating plate is located inside the range hood on

the left wall.

■ Range hood location should be away from strong draft areas,

such as windows, doors and strong heating vents.

■ Cabinet opening dimensions that are shown must be used.

Given dimensions provide minimum clearance. Consult the

cooktop/range manufacturer installation instructions before

making any cutouts.

■ Grounded electrical outlet is required. See “Electrical

Requirements” section.

■ The hood is factory-set for vented installations.

■ All openings in ceiling and wall where range hood will be

installed must be sealed.

For Mobile Home Installations

The installation of this range hood must conform to the

Manufactured Home Construction Safety Standards, Title

24 CFR, Part 328 (formerly the Federal Standard for Mobile

Home Construction and Safety, title 24, HUD, Part 280)

or when such standard is not applicable, the standard for

Manufactured Home Installation 1982 (Manufactured Home

Sites, Communities and Setups) ANSI A225.1/NFPA 501A*, or

latest edition, or with local codes.

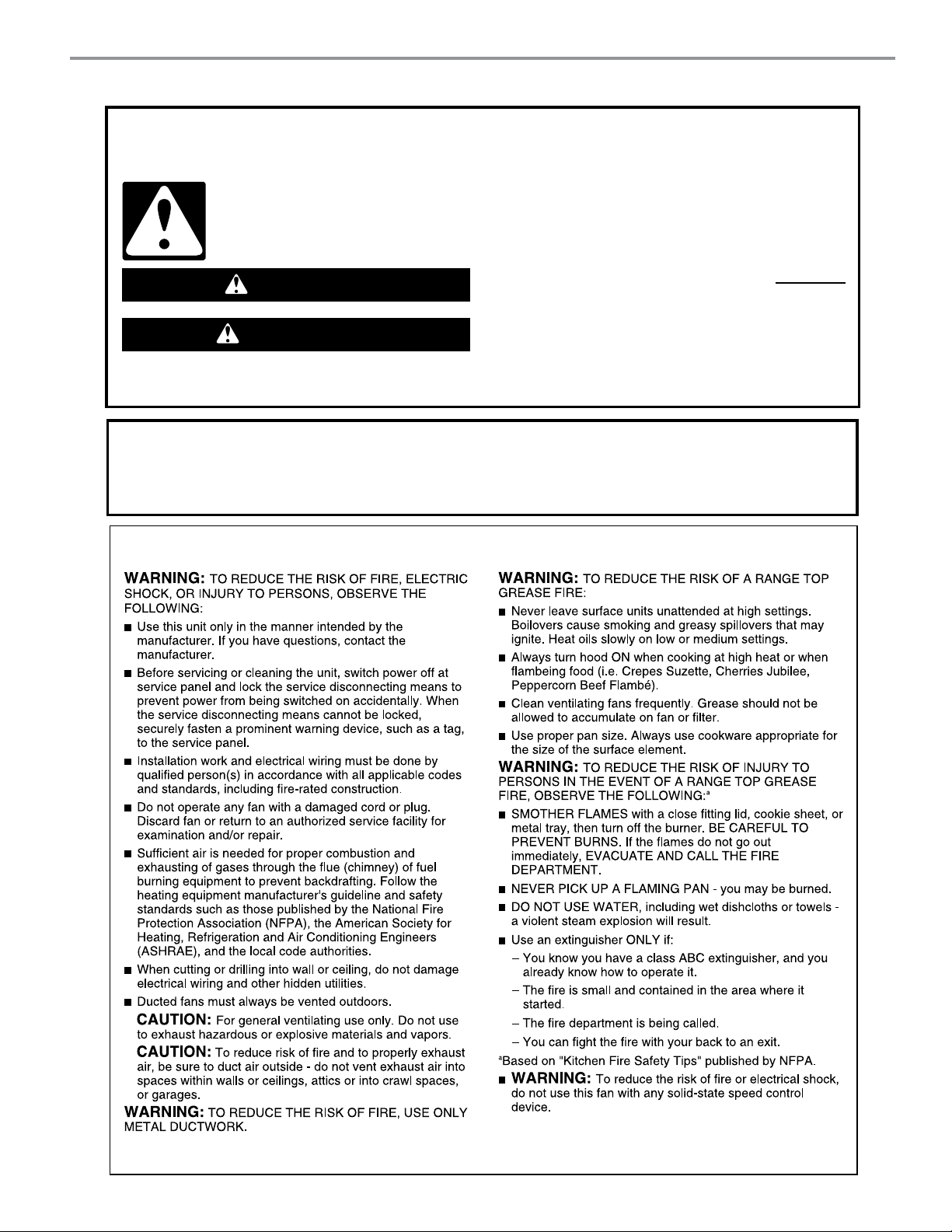

Product Dimensions

1³⁄₄"

(4.4 cm)

4¹⁄₁₆" (10.3 cm)

Parts needed

■ 3¼" x 10" (8.3 x 25.4 cm) or 6" (15.2 cm) or larger round metal

venting

■ 6" (15.2 cm) or larger round damper, if using 6" (15.2 cm) or

larger round vent system

■ 3¼" x 10" (8.3 x 25.4 cm) to 6" (15.2 cm) or larger diameter

transition piece if using 6" (15.2 cm) or larger diameter round

vent system.

■ 3 - UL listed wire connectors

For cabinets with recessed bottoms:

■ Two 2" (5.1 cm) wide filler strips. Length and thickness

determined by recess dimensions.

■ Four flat head wood screws or machine screws with washers

and nuts (to attach filler strips).

®†TORX is a registered trademark of Acument Intellectual Properties, LLC

4³⁄₄"

(12.1 cm)

³⁄₄"

(2.0 cm)

29¹⁵⁄₁₆" (76.0 cm)

1¹⁄₂"

(3.8 cm)

9"

(22.9 cm)

20"

(50.8 cm)

1"

(2.5 cm)

4

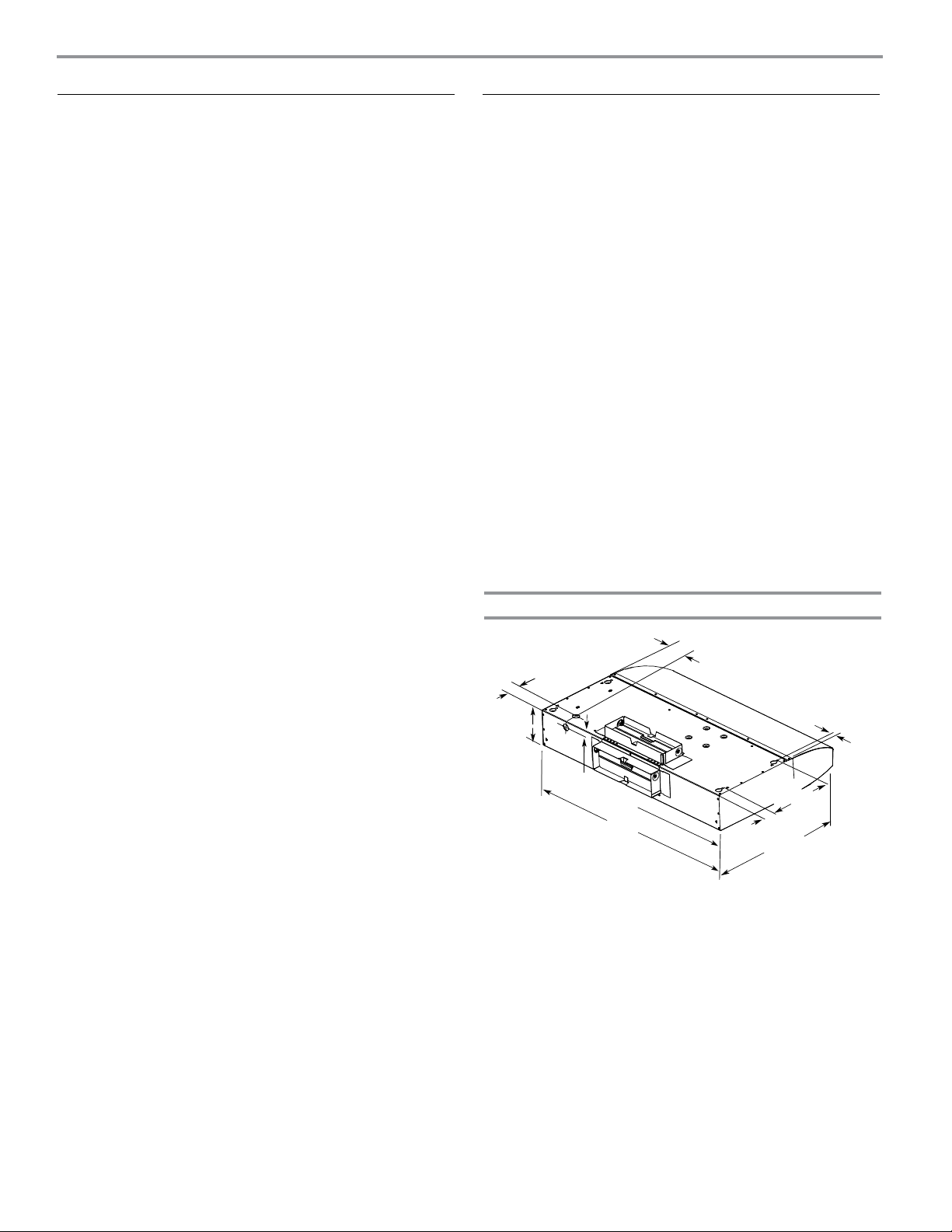

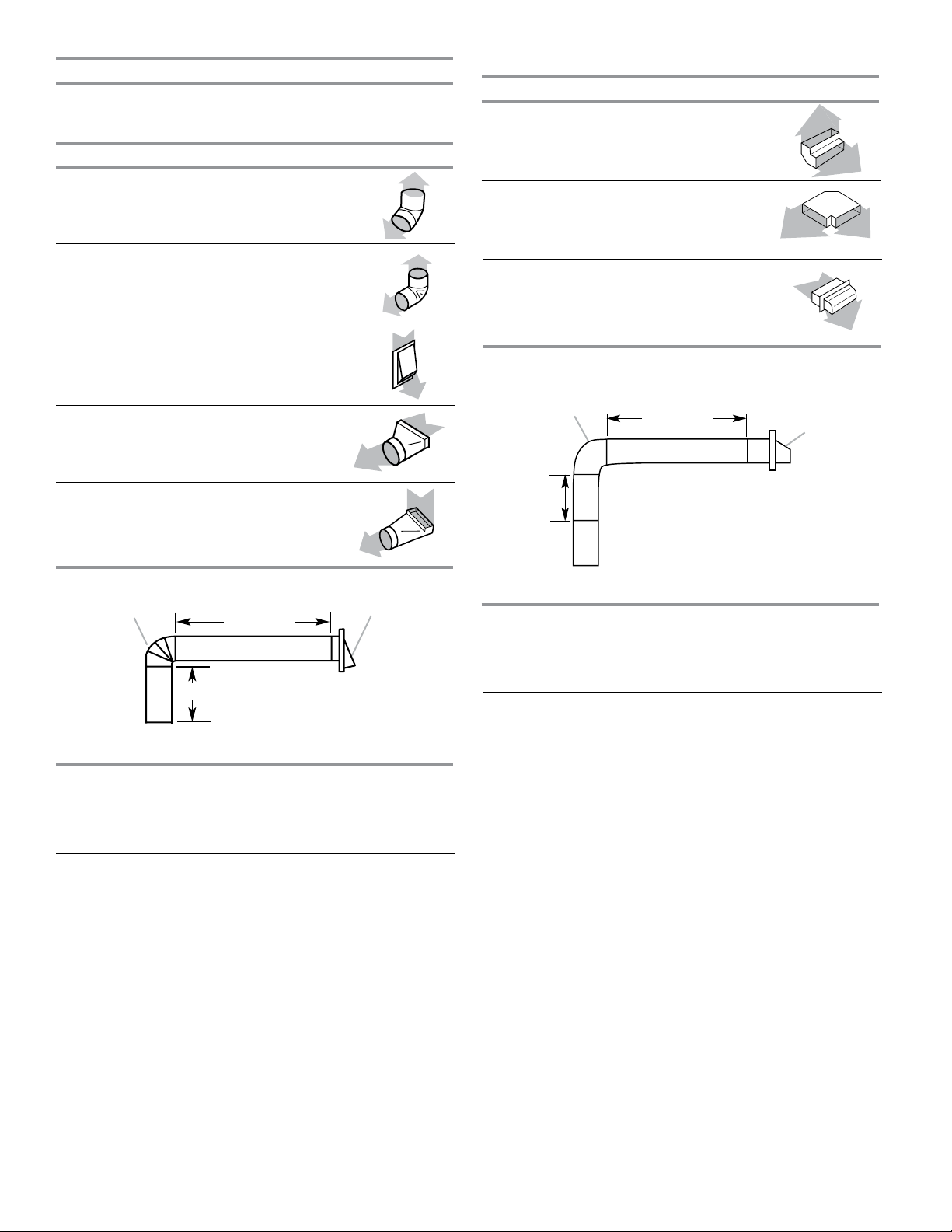

Installation Clearances

B

A

E

Cold Weather Installations

An additional back draft damper should be installed to minimize

backward cold air flow and a thermal break should be installed

to minimize conduction of outside temperatures as part of the

vent system. The damper should be on the cold air side of the

thermal break.

The break should be as close as possible to where the vent

C

system enters the heated portion of the house.

Makeup Air

Local building codes may require the use of make up air

systems when using ventilation systems greater than specified

CFM of air movement. The specified CFM varies from

locale to locale. Consult your HVAC professional for specific

requirements in your area.

D

Venting Methods

Vent system can terminate either through the roof or wall. Use

3¼" x 10" (8.3 x 25.4 cm) with a maximum vent length of 35 ft

(10.7 m) or 6" (15.2 cm) or larger round vent with a maximum

length of 50 ft (15.2 m) for vent system.

NOTE: Flexible vent is not recommended. Flexible vent

creates back pressure and air turbulence that gently reduces

performance.

The ducting from this fan to the outside of the building has a

strong effect on the air flow, noise and energy use of the fan.

Use the shortest, straightest duct routing possible for best

performance, and avoid installing the fan with smaller ducts

than recommended. Insulation around the ducts can reduce

energy loss and inhibit mold growth. Fans installed with existing

ducts may not achieve their rated airflow.

A. 18" (45.7 cm) min. clearance - upper cabinet to countertop

B. 24" (61.0 cm) min. for electric cooking surfaces

27" (68.6 cm) min. for gas cooking surfaces

30" (76.2 cm) suggested max. - bottom of range hood to cooking

surface

C. 30" (76.2 cm) min. cabinet opening width

D. 13" (33.0 cm) cabinet depth

E. 36" (91.4 cm) base cabinet height

Venting Requirements

■ Vent system must terminate to the outdoors.

■ Do not terminate the vent system in an attic or other enclosed

area.

■ Do not use a 4" (10.2 cm) laundry-type wall cap.

■ Use a 6" (15.2 cm) or larger round metal vent or a 3¼" x 10"

(8.3 x 25.4 cm) rectangular metal vent. Rigid metal vent is

recommended. Plastic or metal foil vent is not recommended.

■ The length of vent system and number of elbows should be

kept to a minimum to provide efficient performance.

For the most efficient and quiet operation:

■ Use no more than three 90° elbows.

■ Make sure there is a minimum of 24" (61 cm) of straight vent

between the elbows if more than 1 elbow is used.

■ Do not install 2 elbows together.

■ Use clamps to seal all joints in the vent system.

■ The vent system must have a damper. If roof or wall cap has a

damper, do not use damper supplied with the range hood.

■ Use caulking to seal exterior wall or roof opening around the

cap.

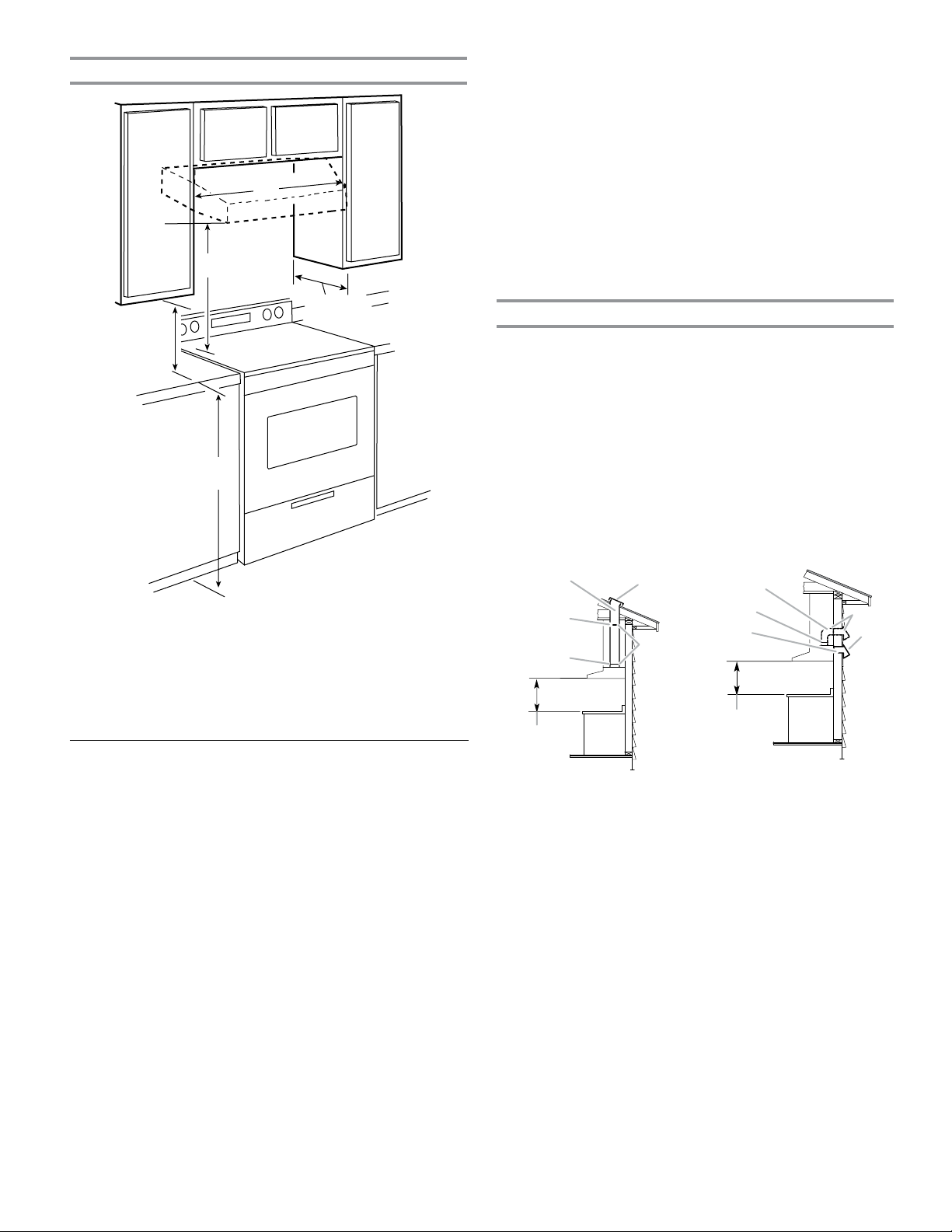

A

B

E

F

A

B

C

F

E

C

D

D

A. 6" (15.2 cm) or larger round

vent or a 3¼" x 10" (8.3 x

25.4 cm) rectangular vent

through roof

B. Round vent: use 6" (15.2 cm)

or larger round damper

(purchased separately)

C. Round vent: use 3¼" x 10"

(8.3 x 25.4 cm) to 6" (15.2 cm)

or larger diameter transition

piece

(purchased separately)

D. 27" (68.6 cm) - 30" (76.2 cm)

above gas cooking surface

24" (61.0 cm) - 30" (76.2 cm)

above electric cooking

surface

E. Roof cap

F. Seal duct joints with duct

tape/caulk

Ensure duct joints and exterior penetrations are sealed with

caulk or other similar material to create an air-tight path and to

minimize building heat loss and gain and reduce the potential

for condensation.

Place/wrap insulation around duct and/or fan in order to

minimize possible condensation buildup within the duct,

building heat loss and gain.

A. 6" (15.2 cm) or larger round

vent or a 3¼" x 10" (8.3 x

25.4 cm) rectangular vent

through the wall

B. Round vent: use 3¼" x 10" (8.3

x 25.4 cm) to 6" (15.2 cm) or

larger diameter transition piece

(purchased separately)

C. 3¼" x 10" (8.3 x 25.4 cm)

through the wall

D. 27" (68.6 cm) - 30" (76.2 cm)

above gas cooking surface

24" (61.0 cm) - 30" (76.2 cm)

above electric cooking surface

E. Wall cap

F. Seal duct joints with duct

tape/caulk

5

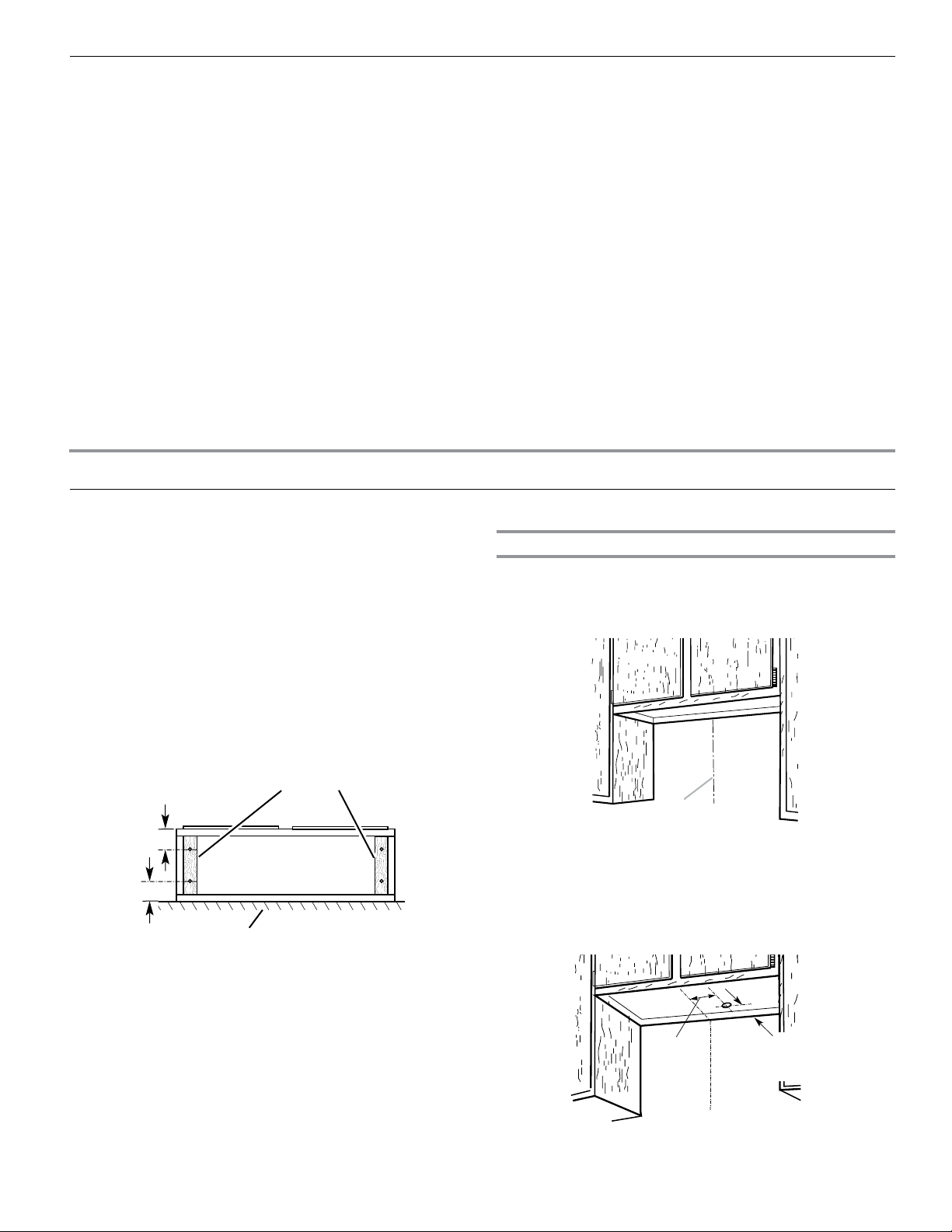

Calculating Vent System Length

To calculate the length of the system you need, add the

equivalent feet (meters) for each vent piece used in the system.

6" (15.2 cm) or Larger Round Vent System

Vent Piece Round

45° elbow 2.5 ft

(0.8 m)

3¼" x 10" (8.3 cm x 25.4 cm) Vent System

Vent Piece

3¼" x 10" (8.3 cm x 25.4 cm)

90° elbow

3¼" x 10" (8.3 cm x 25.4 cm)

flat elbow

5.0 ft

(1.5 m)

12.0 ft

(3.7 m)

90° elbow 5.0 ft

(1.5 m)

6" (15.2 cm) or larger

wall cap

3¹⁄₄" x 10" (8.3 cm x 25.4 cm)

to 6" (15.2 cm) or larger

3¹⁄₄" x 10" (8.3 cm x 25.4 cm)

to 6" (15.2 cm) or larger

0.0 ft

(0.0 m)

4.5 ft

(1.4 m)

5.0 ft

(1.5 m)

90° elbow

Example vent system

90˚ elbow

2 ft (0.6 m)

6 ft (1.8 m)

Wall cap

3¼" x 10" (8.3 cm x 25.4 cm)

wall cap

0.0 ft

(0.0 m)

Example vent system

3

¹⁄₄" x 10"

elbow

6 ft (1.8 m)

Wall cap

= 13.0 ft (3.9 m)

(8.3 x 25.4 cm)

2 ft

(0.6 m)

Maximum Recommended Length = 35 ft (10.7 m)

1 - 90° elbow = 5.0 ft (1.5 m)

8 ft (2.4 m) straight = 8.0 ft (2.4 m)

1 - wall cap = 0.0 ft (0.0 m)

Length of 3¼" x 10" (8.3 cm x 25.4 cm)

system

Maximum Recommended Length = 50 ft (15.2 m)

1 - 90° elbow = 5.0 ft (1.5 m)

1 - wall cap = 0.0 ft (0.0 m)

8 ft (2.4 m) straight = 8.0 ft (2.4 m)

Length of 7" (17.8 cm) system = 13.0 ft (3.9 m)

6

Electrical Requirements

Observe all governing codes and ordinances.

Ensure that the electrical installation is adequate and in

conformance with National Electrical Code, ANSI/NFPA 70

(latest edition), or CSA Standards C22.1-94, Canadian Electrical

Code, Part 1 and C22.2 No. 0-M91 (latest edition) and all local

codes and ordinances.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

■ A 120 Volt, 60 Hz., AC only, 15-amp, fused electrical circuit

is required.

INSTALLATION INSTRUCTIONS

Prepare Location

NOTE: It is recommended that the vent system be installed

before hood is installed.

Before making cutouts, make sure there is proper clearance

within the ceiling or wall for exhaust vent.

1. Disconnect power.

2. Determine which venting method to use: roof or wall.

3. Select a flat surface for assembling the range hood. Place

covering over that surface.

4. Lift the range hood and set it upside down onto covered

surface.

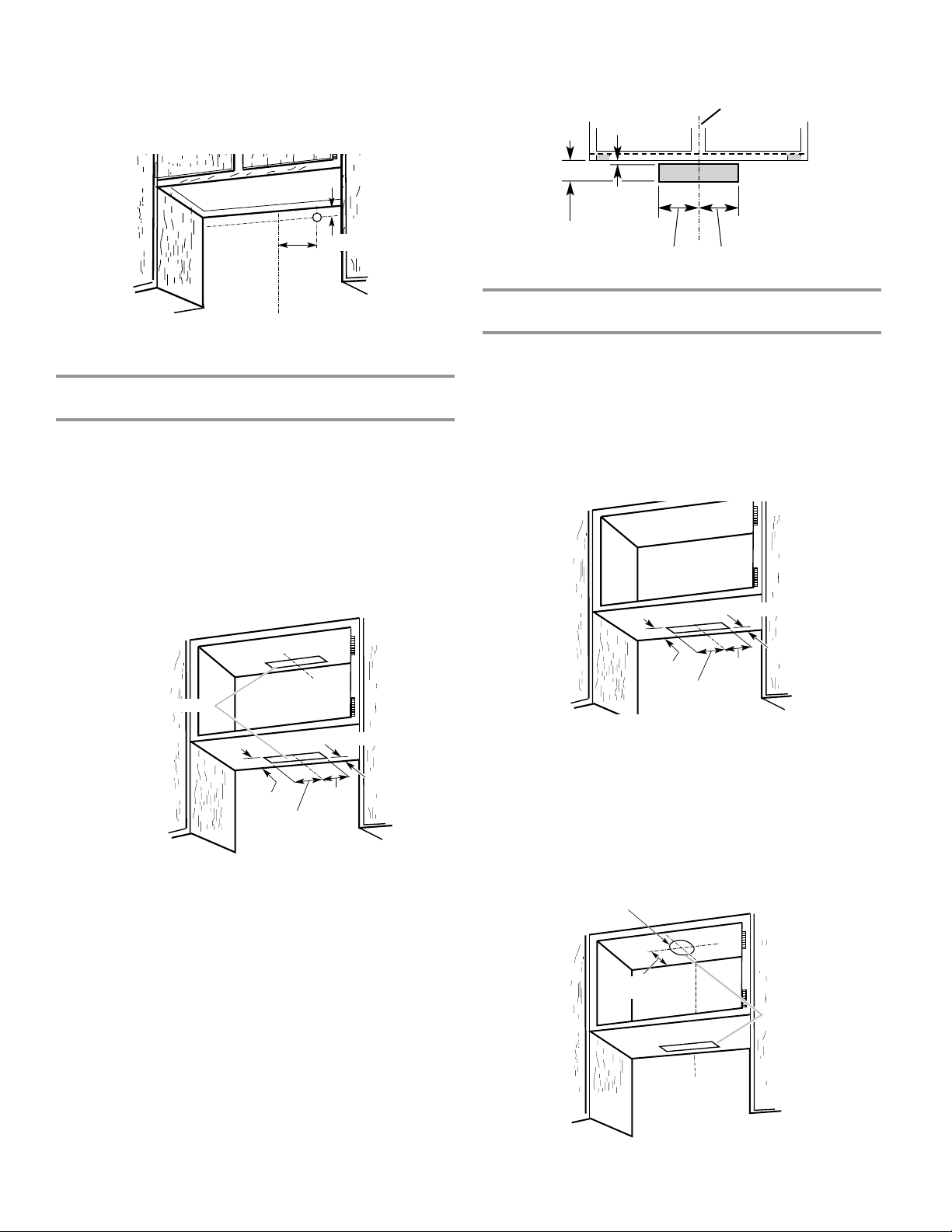

5. If cabinet has recessed bottom, add wood filler strips on

each side. Install screws to attach filler strips in locations

shown.

■ If the house has aluminum wiring, follow the procedure

below:

1. Connect a section of solid copper wire to the pigtail

leads.

2. Connect the aluminum wiring to the added section of

copper wire using special connectors and/or tools

designed and UL listed for joining copper to aluminum.

Follow the electrical connector manufacturer's

recommended procedure. Aluminum/copper connection

must conform with local codes and industry accepted

wiring practices.

■ Wire sizes and connections must conform with the rating of

the appliance as specified on the model/serial rating plate.

The model/serial plate is located behind the filter on the

rear wall of the range hood.

■ Wire sizes must conform to the requirements of the

National Electrical Code, ANSI/NFPA 70 (latest edition), or

CSA Standards C22. 1-94, Canadian Electrical Code, Part

1 and C22.2 No. 0-M91 (latest edition) and all local codes

and ordinances.

Determine Wiring Hole Location

Cut only one 11⁄4" (3.2 cm) diameter wiring access hole. See

Step 2 for wiring hole location instructions.

1. Determine and clearly mark a vertical centerline on the wall

and cabinet in the area the vent opening will be made.

3" (7.6 cm)

3" (7.6 cm)

Wood filler strips

(recessed cabinet

bottoms only)

Cabinet

bottom

Wall

A

A. Centerline

2. To wire through top:

Mark a line distance “A” from the right of the centerline on

the underside of the cabinet. Mark the point on this line that

3

is 1

⁄4" (4.4 cm) from back wall. Drill a 1¼" (3.2 cm) diameter

hole through the cabinet at this point.

A

A. 10

Centerline

7

⁄8" (27.6 cm)

1¹⁄₄" (4.3 cm)

from wall,

not cabinet

frame

7

3. To wire through wall:

Mark a line distance “A” from the right of the centerline on

the underside of the wall. Mark the point on this line that is

3

⁄4" (1.9 cm) from the underside of the cabinet. Drill a

11⁄4" (3.2 cm) diameter hole through the rear wall at this

point.

³⁄₄" (1.9 cm)

A

Centerline

7

A. 10

⁄8" (27.6 cm)

Style 1 - Cut Openings for 3¼" x 10" (8.3 cm x 25.4 cm)

Rectangular Vent System

Roof Venting

To make a 41⁄4" x 10½" (10.8 cm x 26.7 cm) rectangular

cutout on the underside of cabinet top and bottom:

1

1. Mark lines

on the centerline of the underside of cabinet.

2. Mark lines 5¼" (13.3 cm) to the right and left of the

centerline on the underside of cabinet.

3. Use saber or keyhole saw to cut a rectangular opening for

vent.

4. Repeat steps 1-3 for the underside of the top of the cabinet.

⁄2" (1.3 cm) and 43⁄4" (12.1 cm) from the back wall

3. Use saber or keyhole saw to cut a rectangular opening in the

wall for the vent.

Centerline

5¹⁄₄"

(13.3 cm)

3 ⁷⁄₈"

(9.8 cm)

³⁄₈"

(0.9 cm)

Cabinet

front

5¹⁄₄"

(13.3 cm)

Style 2 - Cut Openings for 3¼" x 10" (8.3 x 25.4 cm)

Rectangular Vent to Round Vent Transition

Roof Venting

To make a 41⁄4" x 10½" (10.8 cm x 26.7 cm) rectangular

cutout on the underside of cabinet bottom:

1

1. Mark lines

on the centerline of the underside of cabinet.

2. Mark lines 5¼" (13.3 cm) to the right and left of the

centerline on the underside of cabinet.

3. Use saber or keyhole saw to cut a rectangular opening for

vent.

⁄2" (1.3 cm) and 43⁄4" (12.1 cm) from the back wall

*¹⁄₂" (1.3 cm)

Cabinet cutouts

*¹⁄₂" (1.3 cm)

5¹/₄"

5¹/₄"

(13.3 cm)

*4³⁄₄"

(12.1 cm)

(13.3 cm)

*From wall, not cabinet frame

Wall Venting

To make a 3½" x 10½" (8.9 cm x 26.7 cm) rectangle in the

wall:

3

1. Make 2 lines by measuring

down from underside of cabinet and mark on the centerline

on the back wall.

2. Mark lines 5¼" (13.3 cm) to the right and left of the

centerline on the wall.

⁄8" (0.9 cm) and 37⁄8" (9.8 cm)

5¹/₄"

5¹/₄"

(13.3 cm)

*4³⁄₄"

(12.1 cm)

(13.3 cm)

*From wall, not cabinet frame

To make a circular vent opening on the underside of the

cabinet top:

1. Mark a centerline on the underside of the top of cabinet.

2. Mark a line 5" (12.7 cm) from the back wall on the underside

of the top of cabinet.

3. Use a compass or a circle template to draw a circle with a

diameter that is ¼" (0.64 cm) larger than the vent.

4. Use saber or keyhole saw to cut the circular vent opening.

Circular vent opening

*5"

(12.7 cm)

Cabinet

cutouts

*From wall, not

cabinet frame

8

Install Vent System

1. Install vent through the vent opening in upper cabinet or

wall. Complete venting system according to the selected

venting method. See “Venting Requirements” section.

2. Use caulking to seal exterior wall or roof opening around the

cap.

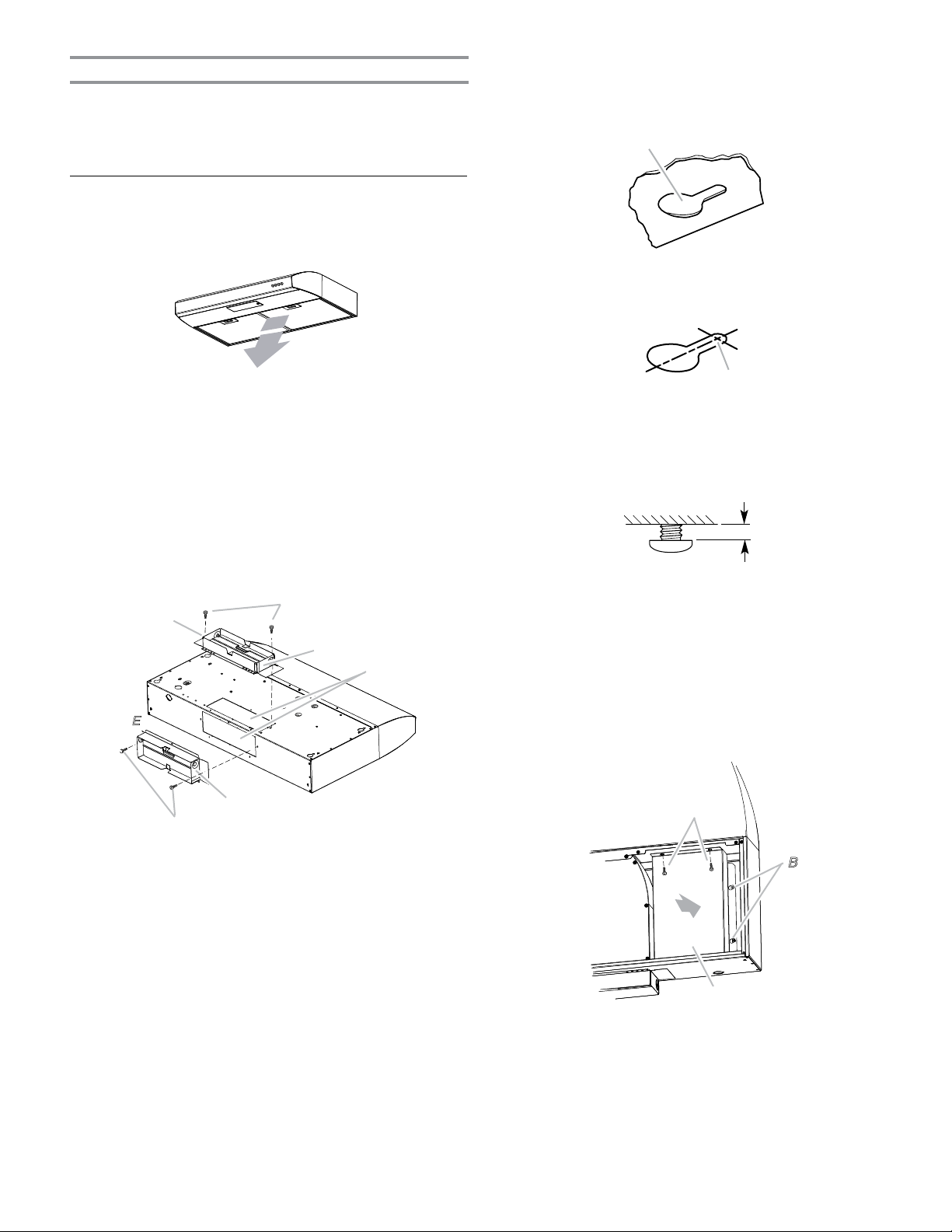

Install Range Hood

Complete Preparation

1. Remove the grease filters. See the “Range Hood Care”

section.

2. Lift the range hood up under cabinet and determine final

location by centering beneath cabinet. Mark on the

underside of cabinet the location of the 4 keyhole mounting

slots on the range hood. Set range hood aside on a covered

surface.

A

A. Keyhole slot

3. Use 1⁄8" (3 mm) drill bit and drill 4 pilot holes as shown.

■ Depending on your installation, remove either top or rear

rectangular vent knockout. If using round vent, remove

top rectangular knockout.

■ Make sure damper pivot is nearest to top/back edge of

range hood.

■ Remove tape from damper flap.

NOTE: The exhaust adaptor/damper can be installed up

to 1" (2.5 cm) on either side of the hood center to

accommodate off-center ductwork.

■ If using rectangular vent, attach rectangular damper/

vent connectors to the range hood using sheet metal

screws.

B

A

C

D

E

C

B

A. Vertical vent

B. Sheet metal screws

C. Hinge pin

D. Vent knockouts

E. Horizontal vent

A

A. Drill pilot hole.

4. Install the 4 - 4.5 mm x 13 mm mounting screws in pilot

holes. Leave about 1⁄4" (6.4 cm) space between screw heads

and cabinet to slide range hood into place.

¹⁄₄"

(6.4 mm)

5. Run the home power supply cable according to the National

Electric Code or CSA standards and local codes and

ordinances. There must be enough wiring from the fused

disconnect (or circuit breaker) box to make the connection in

the hood electrical terminal box.

NOTE: Do not reconnect power until the installation is

complete.

6. Remove the screws from the terminal box cover. Then slide

the cover toward the outside edge of range hood to position

the large end of the keyhole slots over the mounting tabs.

A

B

NOTE: If the wall cap is directly behind the vent

connector, the dampers in the connector and wall cap

must not interfere with each other. Remove the vent

connector damper if they interfere.

■ If using round vent, attach vent transition piece

(purchased separately) to range hood top using sheet

metal screws.

C

A. Screws

B. Mounting tabs

C. Terminal box cover

9

Loading...

Loading...