Whirlpool WPC45 AM, Gold WPC4524AM41, Gold WPC4530AM41, Gold WPC4536AM41, Gold WPC4542AM41 Installation Instructions Manual

...

INSTALLATION INSTRUCTIONS FOR

a

PACKAGE HEAT PUMP OR PACKAGE COOLING UNIT

Table of Contents

HEAT PUMP/ELECTRIC COOLING SAFETY............................... 1

INSTALLATION REQUIREMENTS ................................................2

Tools and Parts ............................................................................2

Location Requirements................................................................2

Ductwork Requirements ..............................................................4

Electrical Requirements ............................................................... 4

INSTALLATION INSTRUCTIONS ..................................................4

Inspect Shipment ......................................................................... 4

Place Heat Pump or Air Conditioning Unit in Final Location.......5

Connect Condensate Drain ......................................................... 5

Install Ductwork............................................................................5

Filters ............................................................................................ 5

Electric Heat Installation and Adjustment.................................... 6

Make Electrical Connections .......................................................6

Complete Installation ...................................................................7

HEAT PUMP/ELECTRIC COOLING SAFETY

Recognize this symbol as a safety precaution.

Please adhere to the following warnings and cautions when installing, adjusting, altering, servicing or operating this unit.

SEQUENCE OF OPERATION ........................................................7

Start-up Procedure—Cooling Cycle ............................................7

Start-up Procedure—Heat Pump ................................................8

Final System Checks....................................................................8

Explanation and Guidance—Heat Pump.....................................8

Defrost Cycle................................................................................9

System Troubleshooting ............................................................10

Circulating Air Blower.................................................................11

Blower Performance Data ..........................................................12

CHARGE VERIFICATION .............................................................14

SYSTEM MAINTENANCE ............................................................16

TROUBLESHOOTING ..................................................................17

ASSISTANCE OR SERVICE .........................................................20

Accessories ................................................................................20

ATTENTION INSTALLATION PERSONNEL

Prior to installation, thoroughly familiarize yourself with this installation manual. Observe all safety warnings.

During installation or repair, caution is to be observed.

It is your responsibility to install the product safely and to educate the customer on its safe use.

Recognize Safety Symbols, Words and Labels

The following symbols and labels are used throughout this manual to

indicate immediate or potential hazards.It is the owner’s

responsibility to read and comply with all safety information and

instructions accompanying these symbols. Failure to heed safety

information increases the risk of serious personal injury or death,

property damage and/or product damage.

Placeho

for B

Code

Whirlpool Gold® Models

WGPH45**AM, WPC45**AM

WPIO-362

Hazards or unsafe practices could result in property

damage, product damage, severe personal injury or death.

Hazards or unsafe practices may result in property

damage, product damage, personal injury or death.

Hazards or unsafe practices may result in property

or product damage.

Tradewinds Distributing Company, LLC

WARNING

Goodman 1

CAUTION

CAUTION

Goodman 9

14610 Breakers Drive

Jacksonville, FL 32258

WARNING

Installation and repair of this unit should

be performed ONLY by individuals meeting

the requirements of an “Entry Level Technician”

as specified by the Air-Conditioning, Heating and

Refrigeration Institute (AHRI). Attempting to

install or repair this unit without such background may

result in product damage, personal injury or death.

Goodman 7

WARNING

HIGH VOLTAGE!

Goodman 6

Disconnect ALL power before servicing.

Multiple power sources may be present.

Failure to do so may cause property damage,

personal injury or death.

WARNING

Do not connect to or use any device that is not designcertified for use with this unit. Serious property damage,

personal injury, reduced unit performance and/or hazardous

conditions may result from the use of such non-approved

devices.

Goodman 36

WARNING

Connecting unit ductwork to unauthorized heat producing

devices such as a fireplace insert, stove, etc., may result

in property damage, fire, carbon monoxide poisoning,

explosion, personal injury or death.

Goodman 98

WARNING

This product contains or produces a chemical or

chemicals which may cause serious illness or death and

which are known to the State of California to cause

cancer, birth defects or other reproductive harm.

Goodman 45

WARNING

This unit must not be used as a “construction heater”

during the finishing phases of construction on a new

structure. This type of use may result in premature failure

of the unit due to extremely low return air temperatures

and exposure to corrosive or very dirty atmospheres.

Goodman 79

WARNING

Goodman 37

To prevent the risk of property damage, personal injury, or

death, do not store combustible materials or use gasoline

or other flammable liquids or vapors in the vicinity of this

unit.

IMPORTANT: The United States Environmental Protection

Agency (EPA) has issued various regulations regarding the

introduction and disposal of refrigerants in this unit. Failure to

follow these regulations may harm the environment and can lead

to the imposition of substantial fines. These regulations may vary

by jurisdiction. A certified technician must perform the installation

and service of this product. Should questions arise, contact your

local EPA office.

This product is designed and manufactured to permit installation

in accordance with national codes. It is the installer’s

responsibility to install this unit in accordance with national codes

and/or prevailing local codes and regulations.

INSTALLATION REQUIREMENTS

These instructions are intended as a general guide only for use by

qualified persons and do not supersede any national or local

codes in any way. Compliance with all local, state, or national

codes pertaining to this type of equipment should be determined

prior to installation.

Read this entire instruction manual, as well as the instructions

supplied in separate equipment, before starting the installation.

The installation of the heat pump or air conditioning unit, wiring,

warm air ducts, venting, etc., must conform to the requirements

of the National Fire Protection Association; the National Electrical

Code, ANSI/NFPA No. 70 (latest edition) in the United States, and

any state laws, local ordinances (including plumbing or

wastewater codes). Local authorities having jurisdiction should

be consulted before installation is made. Such applicable

regulations or requirements take precedence over the general

instructions in this manual.

Tool s and Parts

Gather the required tools before starting installation. Read and

follow the instructions provided with any tools listed here.

2

Tools needed

■ ⁵⁄₁₆" nut driver

■ Screwdriver

Parts needed

Check local codes and existing electrical supply. Read “Electrical

Requirements” and “Ductwork Requirements” before purchasing

parts.

■ Tap e mea s ure

Location Requirements

Consider the effect of the outdoor fan noise on conditioned

space and any adjacent occupied space. It is recommended that

the unit be placed so that the condenser air discharge does not

blow toward windows less than 25 ft (7.6 m) away.

Heat pumps require special location consideration in areas of

heavy snow accumulation and/or areas with prolonged

continuous subfreezing temperatures. Heat pump unit bases

have holes under the outdoor coil to permit drainage of defrost

water accumulation. The unit must be situated to allow free

unobstructed drainage of the defrost water and ice. A minimum

2" (5.1 cm) clearance under the outdoor coil is required in milder

climates.

Ground Level Preinstallation Details

The unit should be set on a solid, level foundation, preferably a

concrete slab at least 4" (10.2 cm) thick. The slab should be

above ground level and surrounded by a graveled area for good

drainage. Any slab used as a unit’s foundation should not adjoin

the building, since it is possible that sound and vibration may be

transmitted to the structure.

Rooftop Preinstallation Details

Check that the roof is weathertight and allows proper drainage of

condensation. Use steel or treated wood beams as unit support

for load distribution.

NOTE: To ensure proper condensate drainage, the unit must be

installed in a level position.

■ To avoid possible property damage or personal injury, the

roof must have sufficient structural strength to carry the

weight of the unit(s) and snow or water loads as required by

local codes. Consult a structural engineer to determine the

weight capabilities of the roof.

■ The unit may be installed directly on wood floors or on Class

A, Class B, or Class C roof covering material.

■ To avoid possible personal injury, a safe, flat surface for

service personnel should be provided.

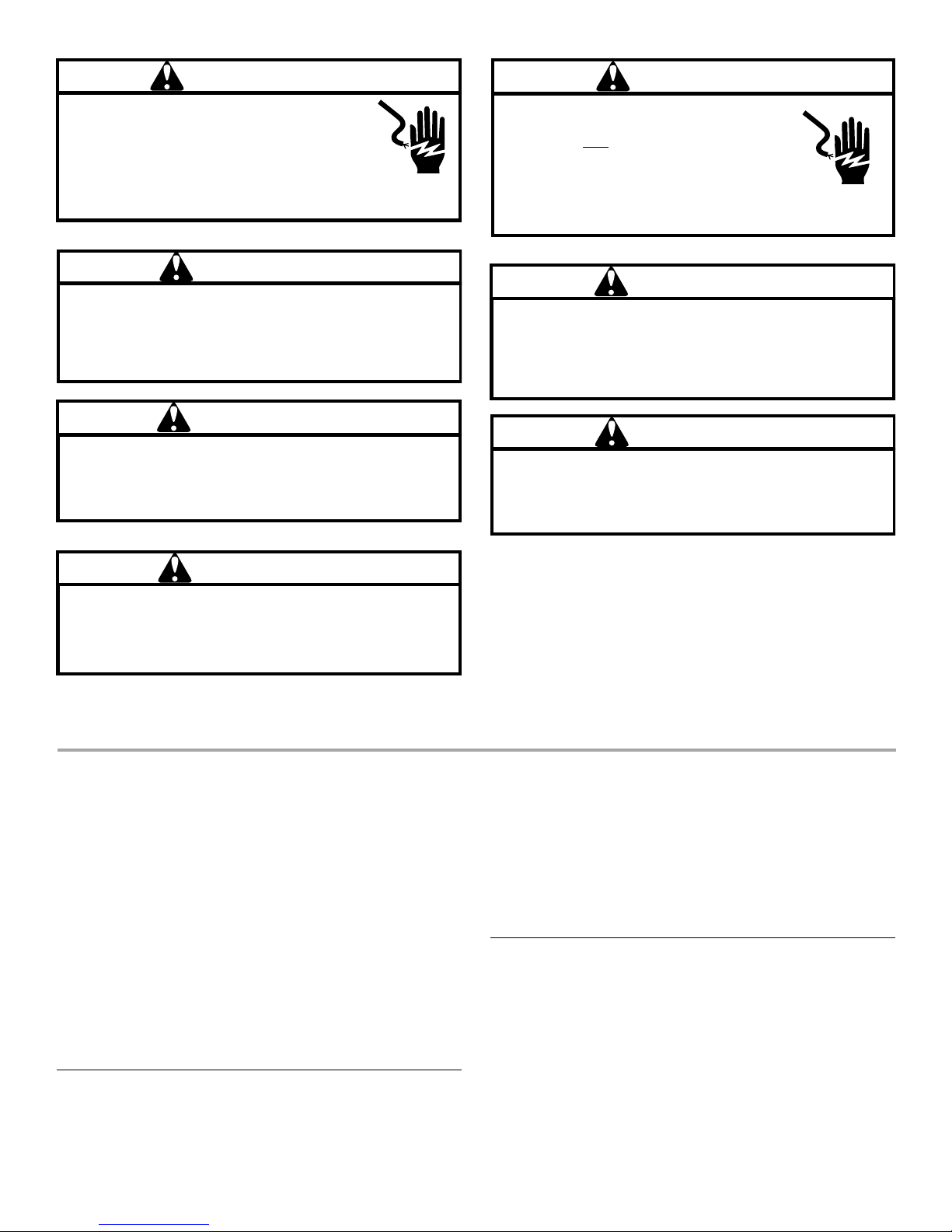

Rooftop Installation

■ The ductwork must be placed into the roof curb before

mounting the package unit.

Roof Curb G 2009 ENV3

Roof Curb Installations Only

NOTES:

■ Sufficient structural support must be determined prior to

locating and mounting the curb and package unit.

■ Curb insulation, cant strips, flashing and general roofing

material are furnished by the contractor.

■ Curbing must be installed in compliance with the National

Roofing Contractors Association Manual.

■ Construct ductwork using current industry guidelines.

Minimum Clearances

The unit is designed to be located outside the building with an

unobstructed condenser air inlet and discharge. Additionally, the

unit must be situated to permit access for service and

installation.

Condenser air enters from 3 sides. Air discharges upward from

the top of the unit. Refrigerant gauge connections are made on

the right-hand side of the unit as you face the compressor

compartment.

Electrical connections can be made on the right-hand side of the

unit. The best and most common application is for the unit to be

located 10" (25.4 cm) from the wall (4" [10.2 cm] minimum) with

the connection side facing the wall. This close-to-the-wall

application minimizes exposed wiring. Close-to-the-wall

application assures free, unobstructed air to the other 2 sides. In

more confined application spaces, such as corners, provide a

minimum 10" (25.4 cm) clearance on all air inlet sides.

Allow 18" (45.7 cm) minimum for service access to the

compressor compartment and controls. The top of the unit

should be completely unobstructed.

If the unit is to be located under an overhang, there should be a

minimum of 36" (91.4 cm) clearance and provisions made to

deflect the warm discharge air out from under the overhang.

3

Minimum Clearances

36"

(91.4 cm)

36"

(91.4 cm)

B

10"

(25.4 cm)

A

C

36"

(91.4 cm)

Down Discharge Applications

Cut insulation around bottom openings and remove panels from

the bottom of the unit, saving the screws holding the panels in

place.

NOTE: Single phase models require installation of horizontal duct

kit #20464501PDGK (medium chassis) and #20464502PDGK

(large chassis).

Panel Removal

A. Wall

B. Unit

C. Curb

Ductwork Requirements

■ Install all conditioned air plenums, ducts and air filters in

accordance with NFPA 90B Standard for the Installation of

Warm Air Heating and Air-Conditioning Systems (latest

edition).

■ The heat pump or air conditioning unit is provided with

flanges for the connection of the plenum and ducts.

■ All air filters must be listed as Class 2 air filters.

■ All ductwork must be made of materials and insulated to

meet local, state and national codes. Ductwork installed

outdoors must be sealed, weatherproof and sheltered against

physical damage. Caulking, flashing or other means of

adequately providing a permanent weather seal should be

used where duct penetrates a building or structure opening.

Airflow Conversion

Units can easily be converted from horizontal to downflow airflow

delivery. In downflow or high static installations, the installer

should measure the total external static and review the blower

performance charts before performing the installation. In some

installations it will be necessary to change the blower speed to

provide proper airflow.

Horizontal Airflow

Single phase models are shipped without horizontal duct covers.

If needed, these kits may be ordered through your local supplier.

B

A

A. Supply air panel

B. Return air panel

Electrical Requirements

WARNING

HIGH VOLTAGE!

Disconnect ALL power before servicing.

Multiple power sources may be present.

Failure to do so may cause property damage,

personal injury or death.

NOTE: All outdoor wiring must be suitable for outdoor use. Use

copper conductors only.

■ All field wiring must be done in accordance with National

Electrical Code requirements, applicable requirements of UL,

or local codes, where applicable.

■ Electrical wiring, disconnect means and over-current

protection are to be supplied by the installer. Refer to the

rating plate for the maximum over-current protection,

minimum service ampacity, and operating voltage. See the

wiring connection diagrams in “Troubleshooting.”

■

This heat pump or air conditioning unit must be electrically

grounded in accordance with National Electric Code (ANSI/

NFPA 70) requirements, applicable requirements of UL, or local

codes, where applicable.

Goodman 6

INSTALLATION INSTRUCTIONS

Inspect Shipment

This heat pump or air conditioning unit is shipped in one

package, completely assembled and wired. The indoor

thermostat and accessories are shipped in a separate carton

when ordered.

■ Check the heat pump or air conditioning unit rating plate to

confirm specifications are as ordered.

■ Upon receipt of heat pump or air conditioning unit, inspect it

for possible shipping damage.

4

Be sure to examine the heat pump or air conditioning unit

inside the carton if the carton is damaged.

■ If damage is found, it should be noted on the carrier’s freight

bill. Damage claims should be filed with the carrier

immediately. Claims of shortages should be filed with the

seller within 5 days.

NOTE: If any damages are discovered and reported to the carrier,

do not install the heat pump or air conditioning unit, since your

claim may be denied.

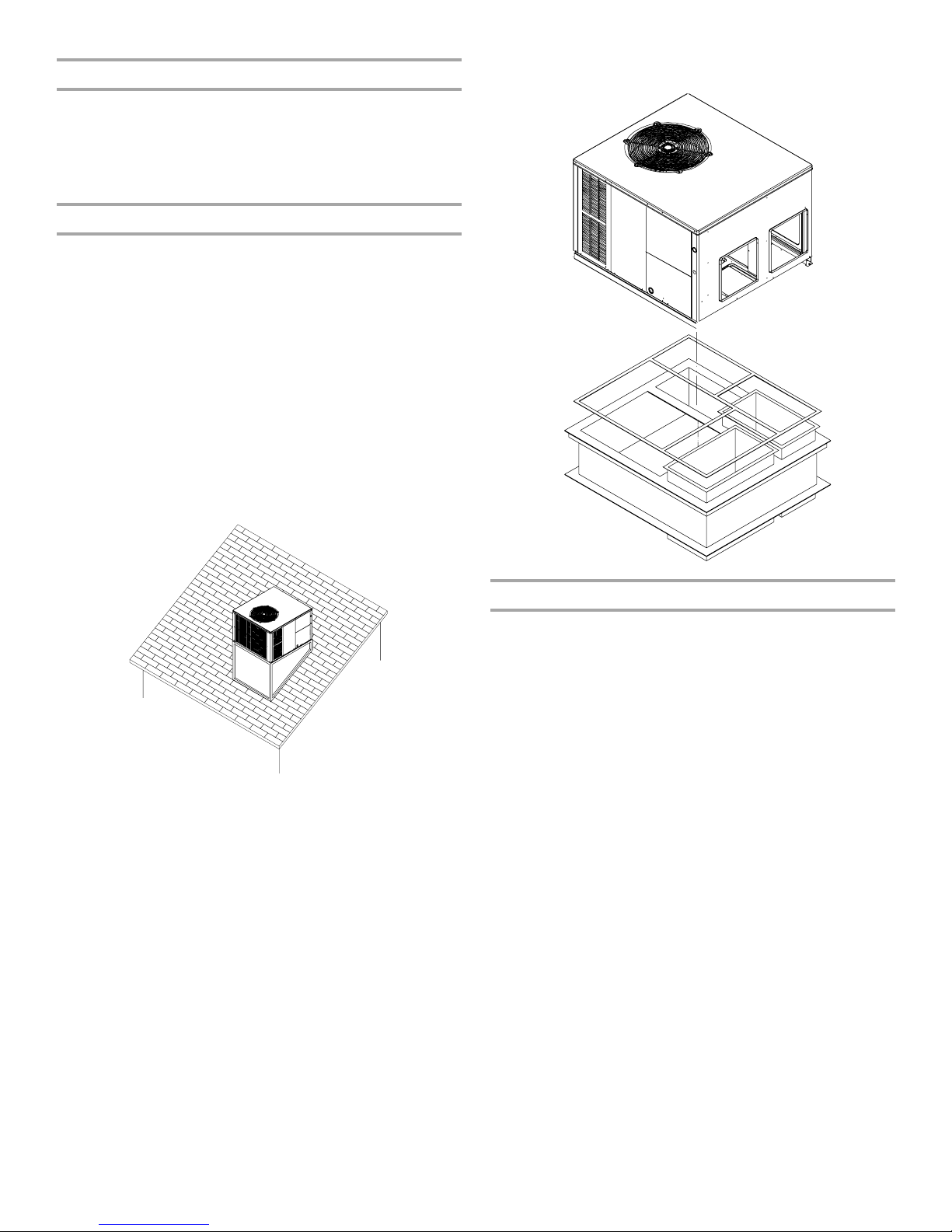

Place Heat Pump or Air Conditioning Unit in

Final Location

A

F

WARNING

To prevent property damage, the unit should remain in

an upright position during all rigging and moving

operations. To facilitate lifting and moving when a crane

is used, place the unit in an adequate cable sling.

Goodman 109

WARNING

To prevent property damage, personal injury or death,

ensure the roof has sufficient structural strength to carry

the weight of the unit(s), roof curb, snow loads and water

loads as required by local codes. Consult a structural

engineer to determine the weight capabilities of the roof.

Goodman 110

CAUTION

To avoid possible personal injury, a safe, flat surface for

service personnel should be provided.

IMPORTANT: If you are using a bottom discharge with the roof

curb, the ductwork should be attached to the curb prior to the

installation of the unit.

Lower the unit carefully onto the roof mounting curb. While you

are rigging the unit, the center of gravity will cause the condenser

end of the unit to be lower than the supply air end.

Rigging

The condensate drain connection of the evaporator is a half

coupling of ³⁄₄" N.P.T. A ³⁄₄" drain line with trap must be installed

on all applications to avoid accumulation of condensate.

Condensate Drain Connection

■ Install the condensate drain trap as shown. Use a ³⁄₄" (1.9 cm)

NPT drain connection size or larger.

■ An external trap must be installed for proper condensate

drainage.

■ Unit must be level or slightly inclined toward drain.

Goodman 111

Placeholder for Rigging art

Connect Condensate Drain

E

D

A. Drain connection

B. 2" (5.1 cm) minimum

C. 3" (7.6 cm) minimum

B

C

D. Positive liquid seal (required)

E. Flexible tubing, hose or pipe

F. U n it

Install Ductwork

IMPORTANT:

■ Install ductwork in accordance with NFPA 90B and any local

codes.

■ When the unit is installed so that the supply ducts carry air

circulated by the unit to areas outside the space containing

the unit, the return air shall be handled by a duct or ducts

sealed to the unit casing and terminated outsides the space

containing the unit.

■ If there is no complete return air duct system, the return air

connection must be sealed to the unit casing and run full size

to a location outside the utility room or space housing the unit

to avoid a negative pressure on the venting system.

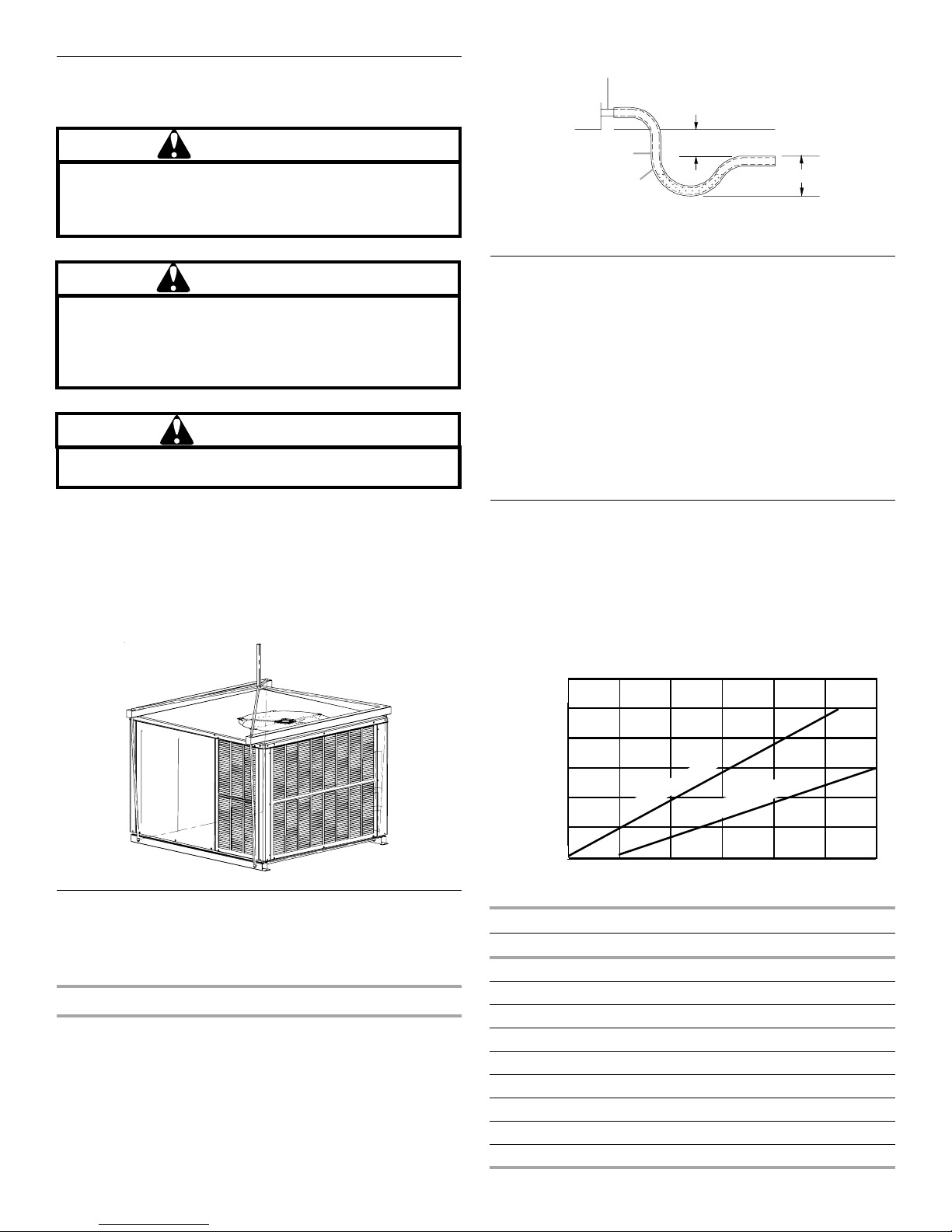

Filters

Filters are not provided with unit, and must be supplied and

installed in the return duct system by the installer. A field installed

filter grille is recommended for easy and convenient access to

the filters for periodic inspection and cleaning. Filters must have

adequate face area for the rated quantity of the unit. See the Air

Delivery Table for the recommended filter size.

Air Delivery Table

Nominal Filter Area

Minimum Filter Size

Nominal Size—in. (cm) Nominal Area—sq ft (cm

10 x 20 (25.4 x 50.8) 1.4 (1,301)

14 x 20 (35.6 x 50.8) 1.9 (1,765)

14 x 25 (35.6 x 63.5) 2.4 (2,230)

15 x 20 (38.1 x 50.8) 2.1 (1,951)

16 x 20 (40.6 x 50.8) 2.2 (2,044)

16 x 25 (40.6 x 63.5) 2.8 (2,601)

20 x 20 (50.8 x 50.8) 2.8 (2,601)

20 x 25 (50.8 x 63.5) 3.5 (3,252)

25 x 25 (63.5 x 63.5) 4.3 (3,995)

2

sq ft (cm

)

7

(6,503)

6

(5,574)

5

(4,645)

4

(3,716)

3

(2,787)

2

(1,858)

Disposable Filter

Permanent Filter

500 1,000 1,500 2,000 2,500 3,000 3,500

Airflow - SCFM

2

)

5

Electric Heat Installation and Adjustment

Make Electrical Connections

WARNING

Goodman 6

Disconnect ALL power before servicing.

Multiple power sources may be present.

Failure to do so may cause property damage,

personal injury or death.

This series of electric cooling and heat pump package equipment

is designed to accept a field installed electric heat kit. The unit is

equipped to easily install the HKR Series Electric Heat Kit. Full

installation instructions are included in this kit. Please use this

document for guidance in field equipping the package unit with

electric heat.

Choose the heat kit that fits the application for the specific

installation. Permanently mark the unit’s nameplate with the

model being installed. High and low voltage connections are

detailed in the heat kit instructions.

Indoor blower motor speed tap selection may need to be

modified to accommodate normal continuous operation to

prevent a nuisance trip. See the following charts.

WPC45(24-48) Models

Unit Model Number 5 8 10 15 20

WPC4524AM41 3 3 3 x x

WPC4530AM41 3333x

WPC4536AM41 3333x

WPC4542AM41 3333x

WPC4548AM41 33333

All models are factory-shipped at T3 speed.

WGPH45(24-60) Models

Unit Model Number 5 8 10 15 20

WGPH4524AM41 x x x

WGPH4530AM41 x x x x

WGPH4536AM41 x x x x

WGPH4543AM41 x x x x

WGPH4549AM41 x x x x x

WGPH4560AM41 x x x x x

HIGH VOLTAGE!

Electric Heat KW

Electric Heat KW

Wiring

WARNING

Goodman 6

Disconnect ALL power before servicing.

Multiple power sources may be present.

Failure to do so may cause property damage,

personal injury or death.

All wiring should be made in accordance with the National

Electrical Code (N.E.C). The local power company should be

consulted to determine the availability of sufficient power to

operate the unit. The voltage, frequency and phase at the power

supply should be checked to make sure it corresponds to the

unit’s rated voltage requirement.

Install a branch circuit fused disconnect near the unit, in

accordance with the N.E.C. or local codes. Wire sizes and overcurrent protection should be determined from the unit nameplate

ampacity and in accordance with Branch Circuit Ampacity chart

or the N.E.C. Under no circumstances should wiring be sized

smaller than is recommended by either of these 2 sources.

Branch Circuit

Ampacity

Supply Wire

Length—ft (m) 15 20 25 30 35 40 45 50

200 (61) 64443322

150 (45.7) 86644433

100 (30.5) 108866644

50 (15.2) 14 12 10 10 8 8 6 6

Fuses smaller than that recommended on the wiring diagrams

could result in unnecessary fuse failure or service calls. The use

of protective devices of larger size than indicated could result in

extensive damage to the equipment. The manufacturer bears no

responsibility for damage caused to equipment as result of the

use of larger than is recommended size protective devices.

All units have undergone a run test prior to packaging for

shipment. This equipment has been started at minimum rated

voltage and checked for satisfactory operation. Do not attempt to

operate this unit if the voltage is not within the minimum and

maximum voltages shown on nameplate.

All exterior wiring must be within approved weatherproof conduit.

The unit must be permanently grounded in accordance with local

codes, or in absence of local codes, with N.E.C. ANSI/ NFPA No.

70-1984 or latest edition by using ground lug in the control box.

Fuses or HACR type circuit breakers may be used where codes

permit.

HIGH VOLTAGE!

6

High Voltage Wiring

Single Phase—Connect the 2 leads to terminals L1 and L2 in the

electrical control section, using wire sizes specified in the wiring

table.

Loading...

Loading...