WHIRLPOOL EV209NBT User Manual

UPRIGHT FREEZER ICE MAKER KIT

INSTALLATION INSTRUCTIONS

MACHINE À GLAÇONS DU CONGÉLATEUR VERTICAL—

INSTRUCTIONS D’INSTALLATION

IMPORTANT: READ AND SAVE THESE INSTRUCTIONS. INSTALLATION REQUIRES 2 OR MORE PEOPLE.

IMPORTANT : LIRE ET CONSERVER CES INSTRUCTIONS. L’INSTALLATION NÉCESSITE

L’INTERVENTION DE 2 PERSONNES OU PLUS.

Table of Contents/Table des matières

FREEZER ICE MAKER SAFETY ...........................................................1

INSTALLATION REQUIREMENTS .......................................................2

INSTALLATION INSTRUCTIONS .........................................................4

TROUBLESHOOTING............................................................................7

SÉCURITÉ DE LA MACHINE À GLAÇONS DU CONGÉLATEUR...... 9

EXIGENCES D’INSTALLATION............................................................ 9

INSTRUCTIONS D’INSTALLATION ...................................................12

DÉPANNAGE........................................................................................ 15

FREEZER ICE MAKER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

can be killed or seriously injured if you don't

You

instructions.

follow

W10326826A

INSTALLATION REQUIREMENTS

B

Tools and Parts

Tools Needed

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

■ Cordless drill

■ ¹⁄₄" nut driver and drill bit

■ Flat-blade screwdriver

■ #2 Phillips screwdriver

■ ⁷⁄₁₆" and ¹⁄₂" open-end

wrenches or two adjustable

wrenches

■ Small ³⁄₄" round file

■ Tubing cutter

■ Scissors

■ Ruler

■ Level

■ Step stool (optional)

Parts Needed

■ Your freezer dealer has a kit available with a ¹⁄₄" (6.35 mm)

saddle-type shutoff valve, a union, and copper tubing.

■ Or you can purchase a ¹⁄₄" (6.35 mm) copper tubing with

shutoff valve and a ¹⁄₄" (6.35 mm) compression fitting

(coupling).

■ Depending on water line connections, you may also need a ¹⁄₄"

(6.35 mm) nut and ¹⁄₄" (6.35 mm) ferrule.

Parts Supplied with Freezer

Remove the parts from the Ice Maker Adapter kit that was

supplied with your freezer. Check to see that these parts are

included.

A

B

Parts Supplied with Ice Maker Kit

Remove the parts from the ice maker kit. Check to see that all

parts are included. Some of the included parts will not be used for

this freezer.

IMPORTANT: Do not remove the tubing from the water valve. It

has been factory installed and leak tested. Do not move the

compression nut that connects the tubing to the valve or the valve

may leak after you connect it to the water supply.

A

D

C

E

G

K

I

J

M

F

H

L

N

A. Ice maker

B. Ice bin*

C. Water valve with tubing

C

D. Fill tube (short)*

E. Gasket*

F. Short extension tube*

G. Metal water tube insert

H. Long extension tube*

I. Ice maker clips (2)*

J. Tubing clips (2)*

K. Water valve tubing clamp

L.

¹⁄₂

" hex-head sheet metal screws (4)

M.

³⁄₄

" hex-head sheet metal screws (2)

¹⁄₂

" hex-head machine screws (2)

N.

*Not used in two door freezer

A. Long shutoff arm

B. Ice maker cover

C. Flat wire shelf

2

Water Supply Requirements

Read all directions before you begin.

IMPORTANT:

■ If you turn the freezer on before the water line is connected,

turn the ice maker OFF.

■ All installations must meet local plumbing code requirements.

■ Use plastic tubing and check for leaks. Install plastic tubing

only in areas where temperatures will remain above freezing.

Tools Needed

■ Flat-blade screwdriver

■ ⁷⁄₁₆" and ¹⁄₂" open-end wrenches or two adjustable wrenches

■ ¹⁄₄" nut driver and drill bit

■ Cordless drill

NOTE: Your freezer dealer has a kit available with a ¹⁄₄" (6.35 mm)

saddle-type shutoff valve, a union, and plastic tubing. Before

purchasing, make sure a saddle-type valve complies with your

local plumbing codes. Do not use a piercing-type or ³⁄₁₆"

(4.76 mm) saddle valve which reduces water flow and clogs more

easily.

Water Supply Connection

Connect to Water Line

Water Pressure

A cold water supply with water pressure of between 30 and

120 psi (207 to 827 kPa) is required to operate the ice maker. If

you have questions about your water pressure, see the Use and

Care Guide or call a licensed, qualified plumber.

Reverse Osmosis Water Supply

If a reverse osmosis water filtration system is connected to your

cold water supply, the water pressure to the system needs to be a

minimum of 40 to 60 psi (276 to 414 kPa).

If the water pressure to the reverse osmosis system is less than 40

to 60 psi (276 to 414 kPa), a booster pump can be inserted into

the small tubing that goes from the cold water line to the reverse

osmosis system.

If you have questions about your water pressure, refer to the Use

and Care Guide or call a licensed, qualified plumber.

1. Unplug freezer or disconnect power.

2. Turn OFF main water supply. Turn ON nearest faucet long

enough to clear line of water.

3. Locate a ½" to 1¹⁄₄" (12.7 mm to 3.18 cm) vertical cold water

pipe near the freezer.

IMPORTANT:

■ Make sure it is a cold water pipe.

■ Horizontal pipe will work, but drill on the top side of the

pipe, not the bottom. This will help keep water away from

the drill and normal sediment from collecting in the valve.

4. To determine the length of plastic tubing you need, measure

from the connection on the lower left rear of freezer to the

water pipe. Add 7 ft (2.1 m) to allow for cleaning. Use ¹⁄₄"

(6.35 mm) O.D. (outside diameter) plastic tubing. Be sure both

ends of plastic tubing are cut square.

5. Using a cordless drill, drill a ¹⁄₄" (6.35 mm) hole in the cold

water pipe you have selected.

A

G

B

C

DEF

A. Cold water pipe

B. Pipe clamp

C. Copper tubing

D. Compression nut

E. Compression sleeve

F. Shutoff valve

G. Packing nut

6. Fasten the shutoff valve to the cold water pipe with the pipe

clamp. Be sure the outlet end is solidly in the ¹⁄₄" (6.35 mm)

drilled hole in the water pipe and that the washer is under the

pipe clamp.

7. Tighten the packing nut.

8. Tighten the pipe clamp screws evenly so washer makes a

watertight seal. Do not overtighten or you may crush the

plastic tubing.

9. Slip the compression sleeve and compression nut onto the

plastic tubing as shown.

10. Insert the end of the tubing into the outlet end squarely as far

as it will go. Screw compression nut onto outlet end with

adjustable wrench. Do not overtighten.

11. Place the free end of the tubing in a container or sink, and turn

ON the main water supply. Flush the tubing until water is clear.

12. Turn OFF the shutoff valve on the water pipe. Coil the plastic

tubing.

3

INSTALLATION INSTRUCTIONS

A

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

1. Unplug freezer or disconnect power.

WARNING

Excessive Weight Hazard

Use two or more people to move and install freezer.

Failure to do so can result in back or other injury.

Prepare Freezer

5. To remove the lower storage bin, pull the bin forward, lift up

and pull forward again to fully extend the sliders. Lift the

storage bin off the sliders. Push the sliders back into the

freezer.

6. Remove the ice maker cover mounting screws from the left-

hand interior freezer wall.

7. Install the ice maker cover behind the mullion using the

mounting screws.

2. Pull the freezer away from the wall so that you can access the

rear.

When Moving Your Freezer:

Your freezer is heavy. When moving the freezer for

cleaning or service, be sure to cover the floor with cardboard

or hardboard to avoid floor damage. Always pull the freezer

straight out when moving it. Do not wiggle or “walk” the

freezer when trying to move it, as floor damage could occur.

3. Open the freezer door and remove the mullion basket clamp.

4. Lift out the small mullion basket.

A. Ice maker cover

8. Remove the tape from the fill tube located on the back of the

freezer. Make sure the fill tube is clear of all tape.

9. Remove the ice maker connection cover.

10. Pull the 4-wire harness out from behind the freezer’s back

cover as far as possible without forcing. Hang it over the edge

of the cutout.

11. Reinstall the ice maker connection cover.

A

A. Connection cover

4

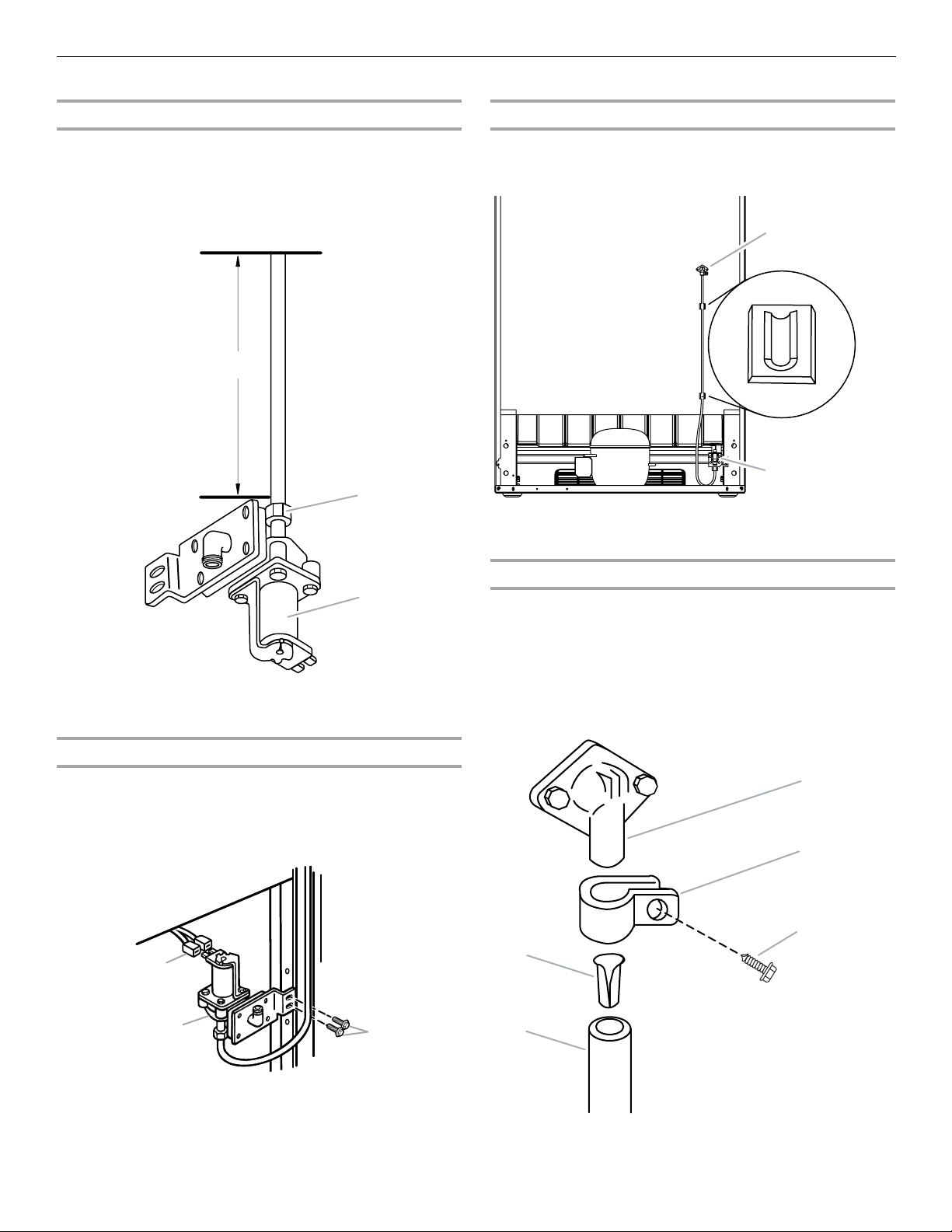

Install the Tubing and Water Valve

A

B

C

Prepare the Water Valve Tubing

1. Untape the coiled flexible tubing coming from the water valve

and straighten it.

2. Starting at the top of the compression nut on the water valve,

measure 32" (81.28 cm) and mark the location on the tubing.

3. Using a pair of scissors, make an even cut across the tubing

at the mark. Discard the excess tubing.

32"

(81.28 cm)

Install the Tubing Clips

1. Peel the backing from the adhesive strips on the tubing clips.

2. Press the clips against the back of the freezer in the locations

shown below.

A

B

A. Fill tube

B. Water valve

A. Compression nut

B. Water valve

Install the Water Valve

1. Insert the 2-pin connector over the water valve solenoid

terminals as far as possible. You can position the connector

with the wires at either terminal.

2. Mount the water valve to the mounting holes in the cabinet

frame with ¹⁄₂" hex-head machine screws.

A

Connect the Water Valve Tubing

1. Position the water valve tubing clamp with the round hole

facing toward you and slide it over the end of the fill tube

spout.

NOTE: One of the flanges on the water valve tubing clamp is

made for a threaded screw and one side has a round hole.

2. Thread a ¹⁄₂" hex-head sheet metal screw into the water valve

tubing clamp and finger tighten.

3. Place the metal water tube insert into the water valve tubing.

C

D

E

A

B

A. 2-pin connector

B. Water valve

C.

¹⁄₂

" hex-head machine screws

B

A. Water tube insert

B. Water valve tubing

C. Fill tube spout

D. Water valve tubing clamp

E.

¹⁄₂

" hex-head sheet

metal screw

5

Loading...

Loading...