Whirlpool EDP-EDN User Manual

Installation, Operation and Maintenance Instructions

P.O. Box 310

Lynnfield, MA 01940

Phone: 781-961-1660

Fax: 781-334-2541

For sales, parts and service, call 781-961-1660

Installation,

Operation and

Maintenance

Instructions for

Endurance

EBP Series Modulating Combination Boiler

(natural or propane gas)

EDP Series Modulating Hydronic Boiler

(natural or propane gas)

EDN Series Modulating Boiler, non ferrous

(natural or propane gas)

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualified in hot water boiler installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in flue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty.

If the information in this manual is not

W ARNING

followed exactly , a fire or explosion may

result causing property damage, personal

injury or loss of life.

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

WHA T TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call

the fire department.

Installation and service must be performed by a

qualified installer , service agency, or gas

supplier .

Assurez-vous de bien suivres les instructions

données dans cette notice pour réduire au

minimum le risque d’incendie ou d’explosion ou

pour éviter tout dommage matériel, toute

blessure ou la mort.

Ne pas entreposer ni utiliser d’essence ni

d’autres vapeurs ou liquides inflammables dans

le voisinage de cet appareil ou de tout autre

appareil.

QUE F AIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas vous

servir des téléphones dansle bâtiment où vous

vous trouvez.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions

du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le sservice des incendies.

L’installation et l’entretien doivent être assurés p a r

un installateur ou un service d’entretien qualifié ou

par le fournisseur de gaz.

AVERTISSEMENT

30-418D

Page 2

LAARS HEATING SYSTEMS

TABLE OF CONTENTS

SECTION 1.

General Information

1A. Introduction................................................... 3

1B. Codes and Standards ................................... 3

1C. Unpacking the Appliance.............................. 4

1D. Locating the Appliance.................................. 4

1E. Clearances ................................................... 4

SECTION 2.

Venting Options

2A. Direct Vent Kits............................................. 4

2B. Installing Direct Vent Kits.............................. 4

2C. Locating the Vent on an Outside Wall...........4

2D. Stainless Steel Single Pipe Horizontal

and Vertical Vents.........................................7

2E. Air Source for Combustion

(when not direct vented) ............................... 7

2F. Connecting Special Gas Vent

to the Appliance ............................................ 8

2G. Securing Special Gas Vent...........................8

SECTION 3.

Gas Piping

3A. Gas Piping .................................................... 8

3B. Domestic Water Piping (EBP only) ............... 9

SECTION 7.

Maintenance and Component Description

7A. Unit Pump................................................... 19

7B. Gas Valve ...................................................19

7C. Safety Limit Switch ..................................... 19

7D. Operating Control Printed Circuit

Board (PCB) ............................................... 19

7E. Igniter / Flame Sensor Assembly ................ 20

7F. Transformer ................................................ 20

7G. Blower ........................................................ 20

7H. Transfer Tank (EBP only) ........................... 20

7I. Thermostatic Union (EDP/EDN only) .......... 20

7J Cleaning the Boiler Coil ..............................20

SECTION 8.

Servicing

8A. Sequence of Operation ...............................21

8B. Trouble Shooting - Fault Codes .................. 22

8B-1. Fault Code Identification.................... 22

8B-2. Fault Correction................................. 22

8B-3. Resolving Lockouts ...........................22

Fault Trees ................................................. 23

SECTION 9.

Gas Valve Calibration

9A. Gas Valve Calibration ................................. 31

SECTION 4.

Hydronic Heat Piping

4A. Hydronic Piping........................................... 10

4B. Using in a Combined Hot Water

Heating and Chilled Water

Cooling System........................................... 12

4C. Water Quality and Treatment...................... 13

SECTION 5.

Electrical Connections

5A. Electrical Connections ................................ 13

SECTION 6.

Boiler Start-UpP

6A. Common Vent Test..................................... 17

6B. Filling the System ....................................... 18

6C. Firing Burner............................................... 18

6D. Mode and On/Off Buttons Operation .......... 19

SECTION 10.

Symptom Evaluations

10A. Delayed Ignition .......................................... 31

10B. Short Cycling .............................................. 32

10C. Noisy Operation ..........................................32

10D. Insufficient Hot Water (EBP only) ............... 32

10E. High Gas Consumption............................... 33

SECTION 11.

Parts Identification.......................................... 34

Endurance

Page 3

SECTION 1.

General Information

1A. Introduction

EBP - This appliance is a low pressure, direct

vent, hot water boiler that provides priority domestic

hot water on demand as well as hydronic space heating

system. The unit has a twenty gallon tank which holds

boiler water (and is not domestic water storage).

The boiler water is kept hot at all times to

provide immediate response to call for heat or

domestic water. Domestic water is heated by the boiler

water through a stainless steel plate heat exchanger.

EDP/EDN - This appliance is a low pressure,

direct vent, cold start hot water boiler that provides

heat for hydronic space heating.

Both appliances incorporate a circulating pump

and a bypass loop, and provide circulation for the

heating system and adequate flow for its own needs.

It may be necessary to install a system circulator to

achieve the required flow rate through the system.

Both appliances feature a forced draft, premixed

combustion system. All air for combustion is supplied

with the gas to the burner (flame holder). Both the

intake air and the gas are metered through separate

orifices before entering the combustion air blower.

The blower forces the air/fuel mixture through the

flame holder and into the combustion chamber. The

mixture is ignited from the hot surface ignitor and

burns. Hot gases are forced out between the passes of

the heat exchanger into the flue collector. Flue gases

are discharged into the outside atmosphere through the

vent terminal.

The appliance can operate with a concentric vent

system that will provide outside air for combustion.

Other venting arrangements can be provided for the

appliance to include an alternative 50 equivalent feet

maximum horizontal or condensate trapped vertical

vent.

1B. Codes and Standards

The Endurance may be a direct vent or Category

IV Boiler. All installations must be made in

accordance with:

1. The National Fuel Gas Code, ANSI Z223.1 latest

edition, or.

2. CAN/CGA B149 “Installation Codes for Gas

Burning appliances and Equipment” and with the

requirements of the local utility or other

authorities having jurisdiction. Such application

requirements take precedence over the general

instructions contained herein.

All electrical wiring is to be done in accordance with:.

1. The National Electrical Code ANSI / NFPA70

latest edition or

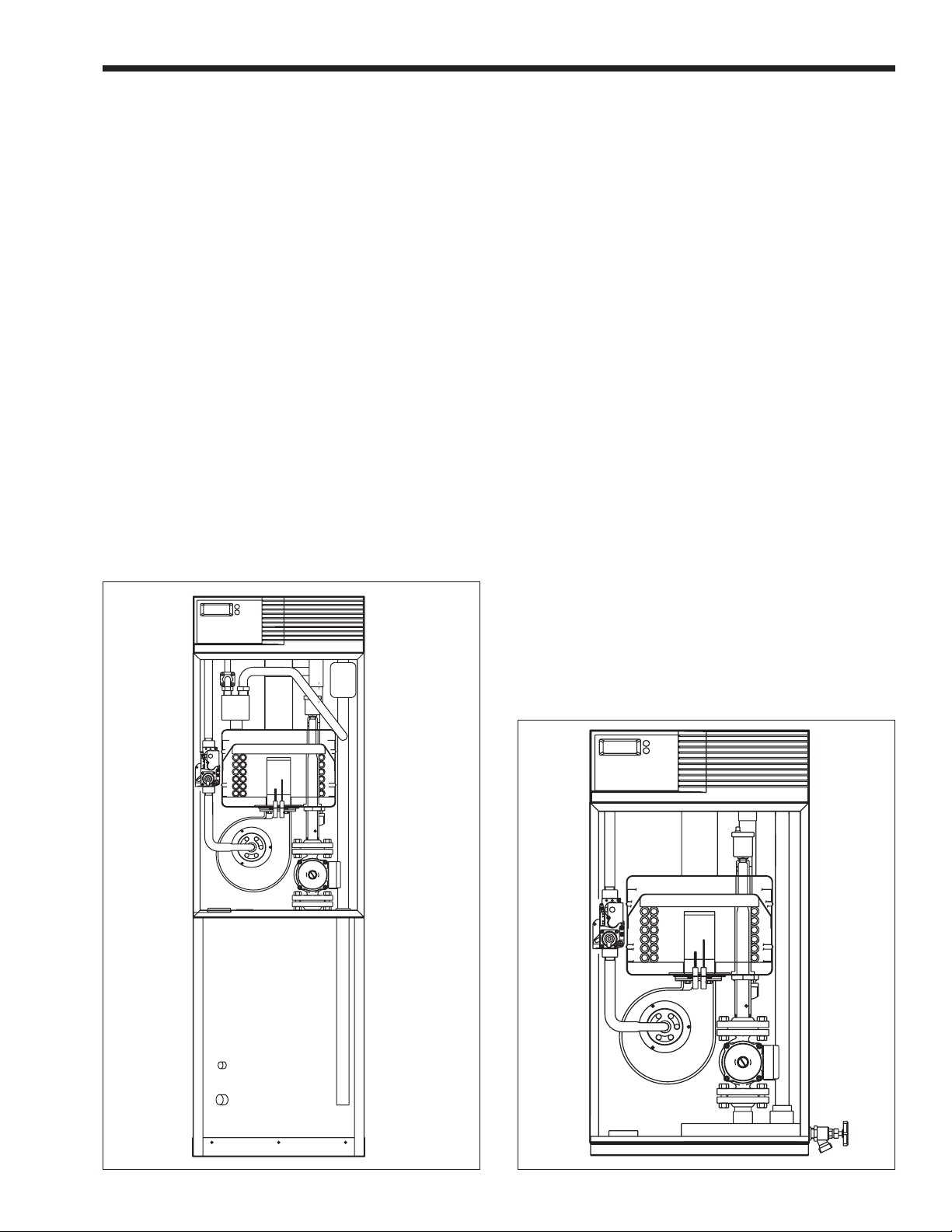

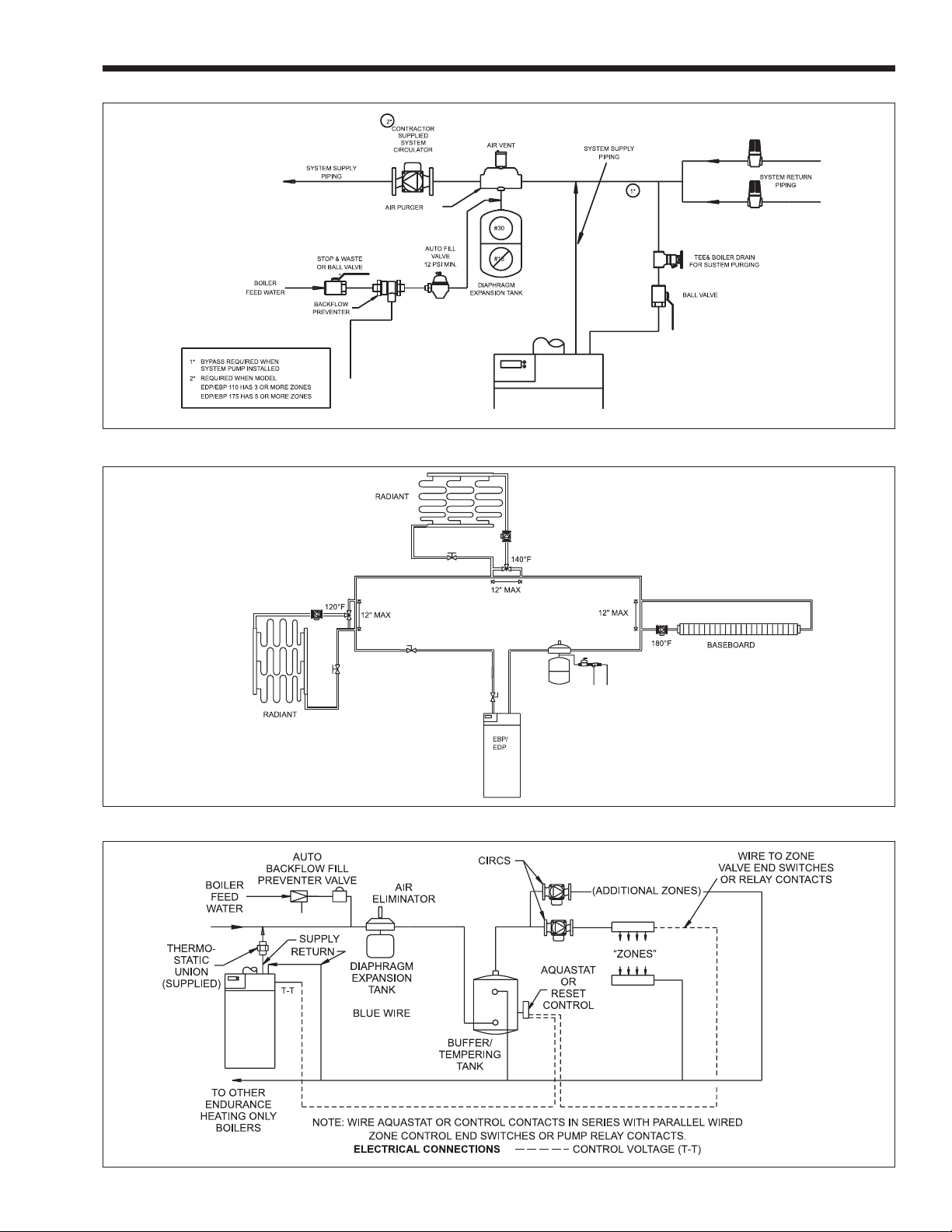

Figure 1. Combo Heating/Domestic Water (Model EBP).

Figure 2. Heating Unit (Model EDP/EDN).

Page 4

LAARS HEATING SYSTEMS

2. The CSA standard C22.1 “Canadian Electrical

Code - Part 1” and local codes.

All vent installations must be made in accordance with:

1. Part 7, Venting of Equipment of the National Fuel

Gas Code, ANSI 223.1 latest edition, or applicable

provisions of the local building codes or

2. CAN/CGA B149.

When required by the jurisdiction authority, the

installations must conform to the American Society of

Mechanical Engineers' Safety Code for Controls and

Safety Devices for Automatically Fired Boilers, No.

CSD-1.

1C. Unpacking the Appliance

Remove all packing and tie down materials.

Make immediate claims (to the carrier) if the

appliance and its packaging are damaged.

1D. Locating the Appliance

The appliance is designed for installation on

combustible flooring, in alcoves, basements, closets,

or utility rooms. It must not be installed on carpeting.

IF INSTALLED IN A FINISHED AREA,

PROVISION SHOULD BE MADE FOR DRAINAGE

OF ANY ACCIDENTAL SPILLAGE OR LEAKAGE.

The location for the unit should be chosen with

regard to venting dimensions, convenient access to

piping, and accessibility for service and cleaning.

The boiler shall be installed so that the gas

ignition system components are protected from water

(dripping, spraying, rain, etc.) during appliance

operation or service (circulator replacement, control

replacement, etc.).

SECTION 2.

Venting Options

2A. Direct Vent Kits

When using a direct vent kit, the appliance is a

sealed combustion unit. All of its air is drawn in from

the outside through the 5" outer pipe. Flue gases are

vented through the 3" vent pipe positioned inside the

5" intake pipe. The hot flue gases are surrounded by

the intake flow of cooler outdoor air. This vent system

may be installed through, and be in contact with,

combustible materials. Except for roof vent kit (max 7'

vertical) all venting should pitch away (down) from

unit.

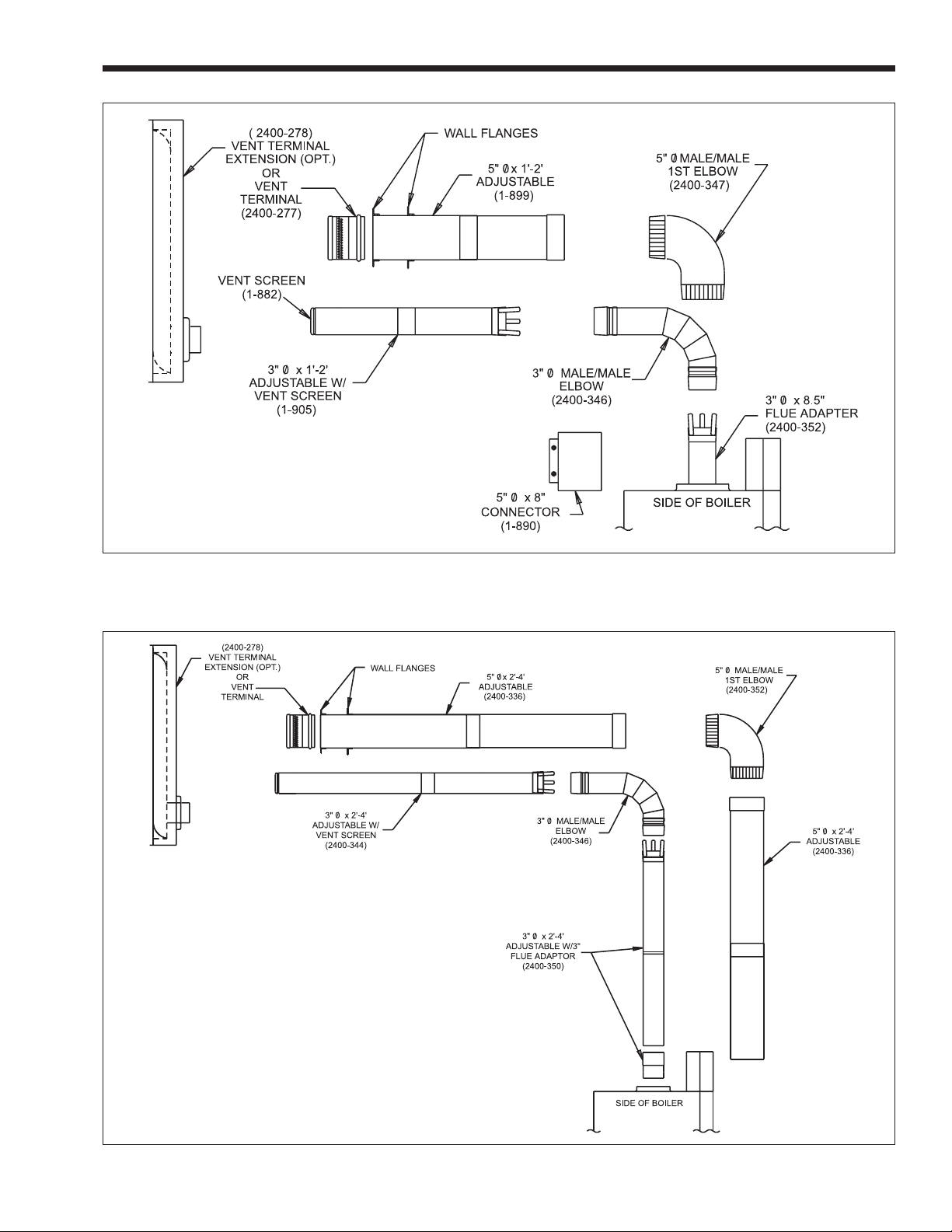

2B. Installing Direct Vent Kits

The direct vent appliance is certified with a

maximum of 15 linear feet (4.6m) of vent pipe and

three sets of elbows. There are two basic vent kits

available, together with various additional elbow and

extension kits if required (see Figures 3 and 4).

Detailed installation instructions are provided in the kits.

For additional length and/or fittings, the

following components are available:

3" and 5" elbow set Part Number 2400-330

5" x 1' extensions Part Number 2400-332

5" x 2' extensions Part Number 2400-334

5" x 2' to 4' adjustable

extensions Part Number 2400-336

3" x 1' extensions Part Number 2400-338

3" x 2' extensions Part Number 2400-340

3" x 2' to 4' adjustable

extensions Part Number 2400-342

1E. Clearances

The dimension and criteria in Table 1 should be

followed when choosing the location for the unit.

2C. Locating the Vent on an Outside Wall

The center line of the vent opening must be at

least 16½" (419mm) above grade, outside, and at least

13½" (343mm) from any other building opening, such

as doors, windows, etc. Vent opening should be well

away from shrubbery or other obstructions that would

A B

AGA/CGA AGA CGA

in.

Left Side 1 25 6 152 24 610

Right Side 1 25 12 305 24 610

Top Side 1 25 14 356 24 406

Back 1 25 9 229 12 305

Front 1 25 24 610 24 610

mm

in.

mm

in.

mm

prevent free air flow to and from vent terminal. Do not

terminate vent under decks, stairways, or car ports.

NOTE: Should it be impossible to locate

opening center line 16½" (419mm) above grade, use

optional vent terminal extension (p/n 2400-278).

Vent terminals must also be at least 3' (0.9m)

above any forced air inlet located within 10' (3.0m),

and at least 7' (2.1m) above grade when located

adjacent to a public walkway, and cannot terminate in

Vent: Direct Vent 0 0 0 0

Vent: Category IV 3 76 3 76

A. Minimum clearance from combustible construction to

meet AGA/CGA requirements.

B. Recommended clearance for accessibility and venting.

Table 1. Clearances

a location where condensate or vapor may be a

nuisance, hazard, or could be a detriment to other

equipment. Vent terminals must have a minimum

clearance of 4' (1.2m) (6' (1.8m) in Canada)

horizontally from, and in no case above or below

electrical meters, gas meters, regulators, and relief

equipment unless a 4' (1.2m) horizontal distance is

maintained.

Endurance

Page 5

Figure 3. Part number 2400-500 provides all of the required venting materials for appliance installations adjacent to an

outside wall and for installation of wall mounted units. Requires minimum above unit clearance of 13" (330mm) and

provides maximum horizontal length of 24" from unit center line to outside wall face.

Figure 4. Part number 2400-326 for vent installations which require adjustable height and horizontal run. This kit

provides vertical and horizontal lengths of pipe from 2' to 3½' (0.6 to 1.1m). To adapt 2400-278 (vent terminal

extension) remove 3" screen section of telescoping piece. Companion section will directly fit extension.

Page 6

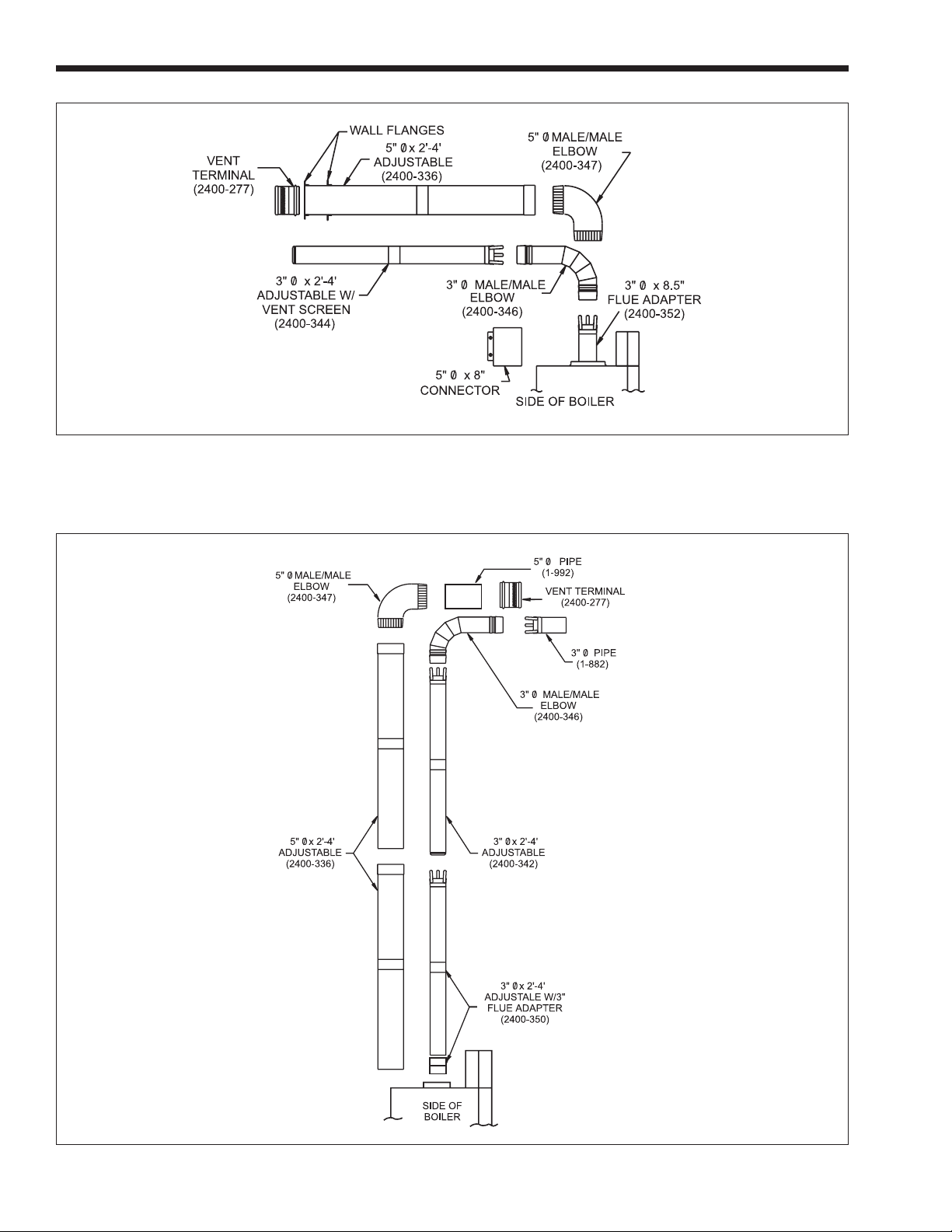

Figure 5. Part number 2400-328 provides all of the required venting materials for appliance installations that require

adjustable horizontal run, but a short vertical run. It requires minimum above unit clearance of 13" (330mm) and

provides for an adjustable horizontal run of 2' to 3-1/2' (0.6 to 1.1m).

LAARS HEATING SYSTEMS

Figure 6. Part number 2400-360 provides the required venting materials for concentric through-the-roof vents. It allows

for a vertical vent, straight off the top of the unit, from 2 to 7 feet (0.6 to 2.1m).

Endurance

Figure 7. For Appliances Certified as Direct Vent.

Figure 8. Typical vent installation with 18" or less

overhead clearance to outside.

Page 7

2D. Stainless Steel Single Pipe Horizontal

and Vertical Vents - Category IV

Stainless steel special gas Vent listed to U.L.

Standard 1738 and U.L.C. Standard 636 may be used

Minimum clearance from

combustibles (vent) 3" 76mm

Max. flue gas temp. 325°F 163°C

Max. vent pressure 1.5" WC 0.4kPa

Max. equivalent ft. of venting 3" 76mm

(any combination of horizontal diameter diameter

or vertical) 50 equiv. ft. 15.2m

Max. equivalent ft. of venting 100 equiv. ft. 30.5m

(any combination of horizontal

or vertical) 4" diameter 102mm dia.

Table 2. Appliance Venting Design Data.

to vent all models. Vent pipe and fittings are

manufactured to these standards by HeatFab, Inc.

under the trade name of Saf-T Vent

under the trade name of Z-Vent. Follow the Special

Gas Vent manufacturer's instructions regarding design,

location and assembly of the vent system.

The appliance may be vented with any number of

elbows or fittings provided that the maximum

equivalent feet of venting is not exceeded. Elbows

(90°) in the vent system shall be considered to be 5

equivalent feet (1.5m). When vented with special gas

vent, the appliance must not be common vented with

any other appliance.

For applications requiring vertical venting

through a roof, the above limitations apply. Vertical

vents greater than 7' (2.1m) in length must offset a

condensate trap tee p/n 2400-358 adjacent to the

appliance. Utilize vent cap p/n 2400-370 to terminate

vertical venting.

®

and by Z-Flex

™

Figure 9. Multiple Concentric Vent Clearances.

When appliances are used, the concentric vent

terminals must be at least 12" apart, edge-to-edge (see

Figure "term").

Do not locate the vent terminal where blockage

by snow is a possibility, or where flue products could

strike against building materials and cause

degradation. If the vent terminal location chosen is

less than 18" below an overhang, the 3" vent pipe

must extend to the outside edge of the overhang (see

Figure 6).

2E. Air Source For Combustion

(when not direct vented)

When using Category IV venting methods the

appliance draws all combustion air through its top and

from the adjacent space. When locating the appliance

in unconfined spaces in buildings, infiltration may be

adequate to provide air for combustion and ventilation.

However, in buildings of unusually tight construction,

or when locating the appliance in a confined space,

additional air should be provided and the following

guidelines must be followed.

1. If the space is in a building of unusually tight

construction, air should be obtained from

outdoors, or from spaces which freely connect

with outdoors.

2. For boilers in confined rooms, two permanent

openings shall be provided - one within 12"

(305mm) of the ceiling, and one within 12"

(305mm) of the floor of each room. Each

opening shall be at least one square inch

Page 8

Figure 10. Special Gas Vent Connection.

Figure 11. Non-Concentric Combustion Air Source.

(6.5 sq. cm) per 1,000 BTU/hr (293W) boiler

input, but not be less than 100 square inches

(645.2 sq. cm). These openings shall freely

connect with areas having adequate infiltration

from outside.

3. When all air is provided from outdoors, the

confined space shall be provided with one

opening within 12" of the ceiling. This opening

shall connect directly, or by ducts, with outdoors

or spaces (crawl or attic) that freely connect

with the outdoors, and shall have a minimum free

area of:

a. 1 sq. in. per 3000 BTU/hr (7 cm

2

/kw) of the

total input rating of all equipment located

in the enclosure, and

b. Not less than the sum of the areas of all

vent connectors in the confined space.

2F. Connecting Special Gas Vent

to the Appliance

Part number 2400-372 is used with a vent

terminal (p/n 2400-277) to secure the 3 inch special

LAARS HEATING SYSTEMS

gas vent to the flue outlet of the appliance. Heat-Fab

pipe or fittings (p/n 2400-350 or 2400-352) or the male

end of Z-Vent pipe (Z-Vent # 02 SVEPXX030) may

be installed over the flue outlet of the Appliance (see

Figure 10).

2G. Securing Special Gas Vent

Attach p/n 2400-277 with sheet metal screws to

the 5" collar on the appliance with a short piece of 5"

pipe or to the end of the 5" combustion air duct.

Attach p/n 2400-372 bracket and tighten clamp. Form

the tabs on the bracket onto the special gas vent pipe

and secure the tabs with the 3" clamp. After the clamp

has been tightened, fold the end of the tabs down over

the clamp (see Figure 10).

DO NOT use screws in any portion of the 3"

special gas vent.

When providing combustion air from another

location, the connection of the 5" duct to the appliance

must be secured with sheet metal screws.

Each 5" joint in the 5" duct must be secured with

sheet metal screws.

In this type of installation, p/n 2400-372 must be

used to secure the special gas vent at the point where it

exits the duct. The combustion air supply should be

protected from debris entering the duct with an

appliance vent terminal, p/n 2400-277, as shown in

Figure 8 or with a large mesh screen.

Follow the special gas vent manufacturer's

instructions for cleaning and sealing all parts before

assembling.

Apply ¼" bead of silicone sealer (GE108 or

Novagard 400) to the 3" flue outlet of the appliance

approximately 1" from the end.

Slide 3" inner vent pipe or 1-880 adapter, when

using outer 3" telescoping section, over the appliance

flue outlet and push down to stop (do not force pipe

beyond stop).

Apply another bead of silicone around this joint

and smooth out.

Apply ¼" bead of silicone to subsequent 3" joints.

An alternate, nonconcentric combustion air

source may be installed (as shown in Figure 11),

provided that the minimum 4" diameter combustion air

duct does not exceed 15' (4.6m). Termination should

include an air screen and be located in a qualified air

space (see Section 2E) or outside.

SECTION 3.

3A. Gas Piping

The appliance requires an inlet gas pressure of at

least 4" w.c. (1.0kPa) and no greater than 13" WC

(3.2kPa). Check with your local gas utility or supplier

for availability of this pressure range.

Refer to Table 3 to size the supply piping to

minimize pressure drop between meter or regulator

and unit.

Endurance

Page 9

Length

ft.

10

20

30

40

50

75

100

150

of Pipe

m

3

6.1

9.1

12.2

15.2

22.9

30.5

45.7

MBTU/h

1/2" 3/4" 1" 1-1/4"

MBTU/h

278

190

152

130

115

93

79

64

Additional length to be added for each tee or bend

ft

1.7

132

92

73

63

ft

1.3

kW

38.7

27

21.4

18.5

m

0.4

1. Run gas supply line in accordance with all

applicable codes.

2. Locate and install manual shutoff valves in

accordance with state and local requirements.

3. Install drip leg, ground joint union and drip cap

to trap sediment and for test gauge access.

4. Support all piping with proper hangers.

5. All threaded joints should be coated with piping

compound resistant to the action of liquefied

petroleum gas.

6. The boiler and its individual shutoff valve must

be disconnected from the gas supply piping

system during any pressure testing of that system

at test pressures in excess of ½ psig (3.5kPa).

7. The boiler must be isolated from the gas supply

piping system by closing its individual manual

shutoff valve during any pressure testing of the

gas supply piping system at test pressures equal

to or less than ½ psig (3.5kPa)

8. The boiler and its gas connection must be leak

tested before placing the boiler in operation.

9. Purge all air from gas lines.

Capacity of Pipe

Table 3.

kW

81.5

55.7

44.5

38.1

33.7

27.2

23.1

18.8

m

0.5

MBTU/h

520

350

285

245

215

175

150

120

ft

2.2

kW

152.4

102.6

83.5

71.8

63

51.3

44

35.2

m

0.7

MBTU/h

1050

730

590

500

440

360

305

250

ft

2.7

be no higher than 120°F mixed delivery

temperature or as local codes dictate.

RECOMMENDS ANTI-SCALD TEMPERING

(MIXING) VALVES (see Figure 12).

2. Connect gate or shutoff valve 13 to tempering

(mixing) valve 12 “MIX” port, and cold

water inlet.

3. Install supplied flow restrictor 14 ahead of

tempering (mixing) valve tee.

4. Connect pressure relief valve 1 (if required by

codes), maximum 150 PSI as close to the unit as

possible. No other valves or restrictions may be

installed between the Endurance and the relief

valve.

DO NOT USE A TEMPERATURE/PRESSURE

RELIEF VALVE AS THIS IS NOT A STORAGE

HOT WATER HEATER.

Note: Installations with water containing 10

or more grains of hardness, must be installed with

appropriate water treatment.

kW

307.7

213.9

172.9

146.5

128.9

105.5

89.4

73.3

m

0.8

LAARS

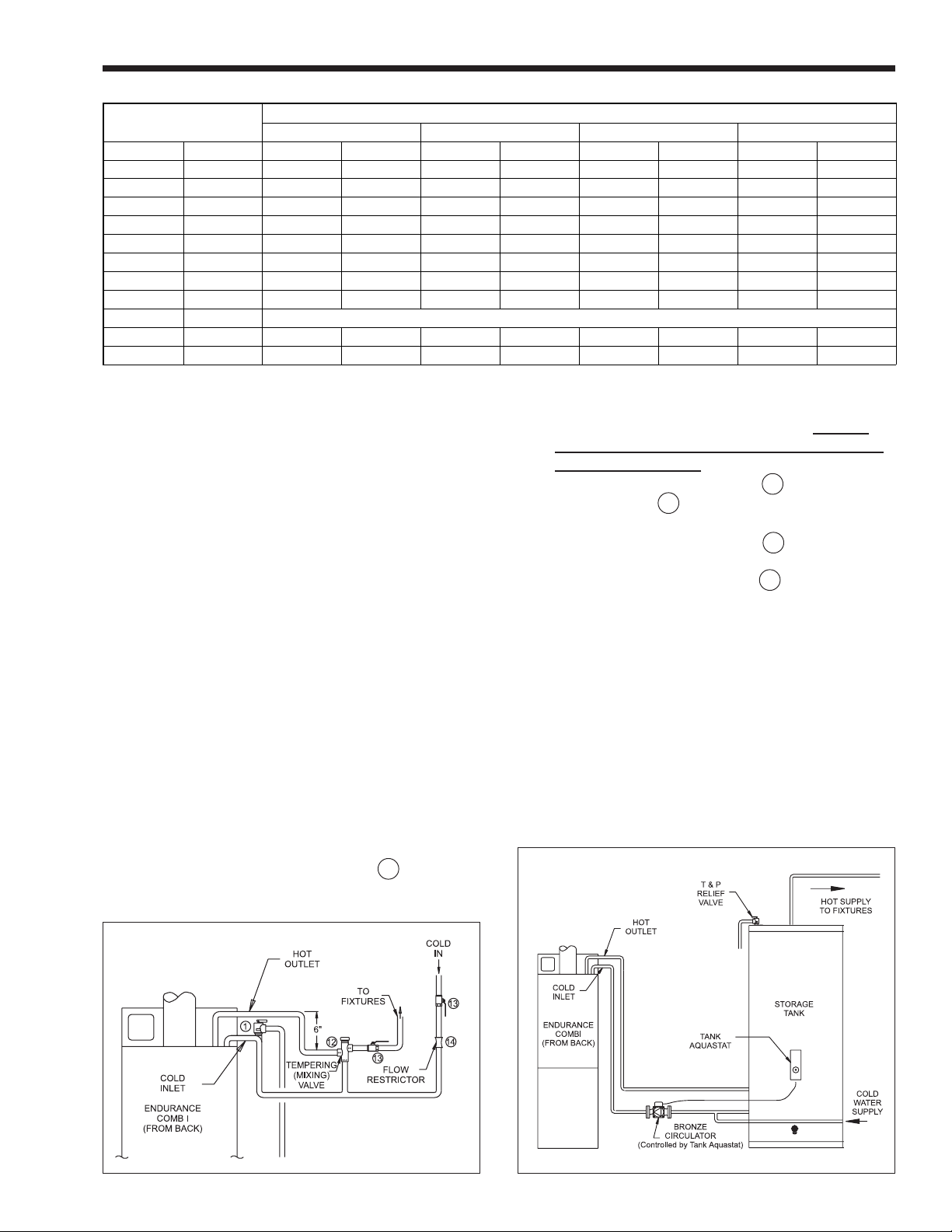

3B. Domestic Water Piping (EBP only)

1. Connect tempering (mixing) valve 12 “Hot” port

to hot water outlet from unit. This valve should

Figure 12. Domestic Water Piping. Figure 13. Domestic Water Piping With Storage Tank.

Page 10

Figure 14. EBP Domestic Water Piping with Recirculating Loop.

LAARS HEATING SYSTEMS

WARNING

Failure to install a hot water tempering (mixing)

valve (12) creates a scalding hazard with potential for

serious bodily injury. Some brands of tempering

(mixing) valves are not designed as anti-scald valves.

Where domestic water is supplying multiple

apartments or large whirlpool tubs, additional storage

tank may be connected as shown in Figure 13. The

bronze circulator shown must be connected to tank

aquastat and must not run continuously. If the

circulator is wired to run continuously, unit's domestic

water flow switch will keep the unit in domestic water

priority, and no water will be allowed to be sent to the

heating system.

SECTION 4.

Hydronic Heat Piping

4A. Hydronic Piping

The appliance incorporates its own circulating

pump and bypass loop and is capable of providing

flow through heating zones, in addition to what it

needs for itself. Model size 110 is capable of

providing flow for two heating zones (up to 67 feet of

¾" baseboard each), and model 175 is capable of

providing flow for four heating zones (up to 67 feet of

¾" baseboard, each).

EDP/EDN boilers installed in radiant (in floor)

systems and other low mass boilers should be provided

with a buffer/blender tank to assure a controlled

supply temperature, and to prevent short cycling. In

radiant systems utilizing 3-way tempering valves, a

bypass pipe must be installed between supply and

return piping.

1. EBP ONLY: Connect system supply to 1¼"

supply connection marked “SUPPLY”.

2. EDP/EDN ONLY: Connect 1¼" thermostatic

union to system supply connection in direction

designated with union.

3. Pipe the discharge of the relief valve, full size, to

a drain or in a manner to prevent injury in the

event of pressure relief.

4. Install an air purger in flow supply line as shown

in Figures 15, 16 or 17.

5. Install automatic float type air vent on air scoops.

6. Install a diaphragm expansion tank in boiler

outlet piping. To ensure sufficient expansion

volume for the hydronic system water, due to

heat-up and cool-down during normal operation,

a #30 or larger expansion tank must be used on

EBP combo units.

NOTE: Never install expansion tank and auto

fill valve on return.

7. If necessary, install a properly sized circulator

with optional isolation valves in supply beyond

expansion tank.

Caution

All hot water pipes must be installed with a minimum

1" (25mm) clearance from combustible materials.

8. Connect boiler feed water supply with shut off

valve to inlet connection of automatic fill valve.

Locate in boiler outlet piping.

9. If codes require, install suitable back flow

preventer between automatic fill valve and city

main.

10. The appliance may be installed in single and

multiple zone systems (using either zone valves

Endurance

Figure 15. Hydronic Piping EDP/EBP with Zone Valves.

Page 11

Figure 16. Piping, Single EDP/EBP Boiler for Multiple Temperature Systems.

Figure 17. Piping, Model “EDP/EDN” for Radiant Floor.

Loading...

Loading...