CONSUMER SER VICES TECHNICAL

EDUCATION GROUP PRESENTS

26" DEEP26" DEEP

26" DEEP

26" DEEP26" DEEP

SIDE - BY SIDESIDE - BY SIDE

SIDE - BY SIDE

SIDE - BY SIDESIDE - BY SIDE

REFRIGERAREFRIGERA

REFRIGERA

REFRIGERAREFRIGERA

KSBS20QEWH0KSBS20QEWH0

KSBS20QEWH0

KSBS20QEWH0KSBS20QEWH0

KSBS20QEAL0KSBS20QEAL0

KSBS20QEAL0

KSBS20QEAL0KSBS20QEAL0

TT

OR/ FREEZERSOR/ FREEZERS

T

OR/ FREEZERS

TT

OR/ FREEZERSOR/ FREEZERS

MODELSMODELS

MODELS

MODELSMODELS

ED20DBXEW00ED20DBXEW00

ED20DBXEW00

ED20DBXEW00ED20DBXEW00

ED20DBXEN00ED20DBXEN00

ED20DBXEN00

ED20DBXEN00ED20DBXEN00

R-84

KSBS20QEBL0KSBS20QEBL0

KSBS20QEBL0

KSBS20QEBL0KSBS20QEBL0

KSFS20QEWH0KSFS20QEWH0

KSFS20QEWH0

KSFS20QEWH0KSFS20QEWH0

KSFS20QEAL0KSFS20QEAL0

KSFS20QEAL0

KSFS20QEAL0KSFS20QEAL0

KSFS20QEBL0KSFS20QEBL0

KSFS20QEBL0

KSFS20QEBL0KSFS20QEBL0

ED20DBXEB00ED20DBXEB00

ED20DBXEB00

ED20DBXEB00ED20DBXEB00

ED20DFXEW00ED20DFXEW00

ED20DFXEW00

ED20DFXEW00ED20DFXEW00

ED20DFXEN00ED20DFXEN00

ED20DFXEN00

ED20DFXEN00ED20DFXEN00

ED20DFXEB00ED20DFXEB00

ED20DFXEB00

ED20DFXEB00ED20DFXEB00

JOB AID

Part No. 4321940

i

INTRODUCTION

This Job Aid,

companion video tape,

provides specific information on for the installation, service and repair of 20 cu. ft. side-by-side

refrigerator/freezers with 26" deep cabinets.

26" DEEP SIDE-BY-SIDE REFRIGERATOR/FREEZERS

recent information on design, features, troubleshooting, service and repair procedures. Whir lpool

required sweep charge procedures are to be strictly adhered to when repairing the sealed system.

For a complete explanation of those procedures, refer to the Job Aid,

PROCEDURES FOR THE 90's

26" DEEP SIDE-BY-SIDE REFRIGERATOR/FREEZERS

26" DEEP SIDE-BY-SIDE REFRIGERAT OR/FREEZERS,

has been compiled to provide the most

, (Part No. 4321717) and its companion video (Part No. 4321718.)

, (Part No. 4321940), and the

(Part No. 4321970),

SWEEP CHARGE

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair 22 cu. ft. side-by-side refrigerator/freezers with 26" deep

cabinets.

The objectives of the Job Aid are:

The service technician will -

• Understand proper safety precautions.

• Follow proper refrigerant recover y procedures.

• Successfully troubleshoot and diagnose malfunction.

• Successfully perform necessary repairs.

• Successfully return the refrigerator/freezer to proper operational status.

TO THE INSTRUCTOR/INDEPENDENT STUDENT

At the end of certain sections of this Job Aid you will find a "Confirmation of Lear ning Exercise." A

symbol that looks like this ( ✎) indicates that a pencil and two "Hi-Light" mar kers may be necessary

to complete the exercise. Certain exercises may require that service procedures be performed if an

appropriate appliance is available.

WHIRLPOOL CORPORATION ASSUMES NO RESPONSIBILITY

FOR ANY REPAIRS MADE ON OUR PRODUCTS BY ANYONE

OTHER THAN AUTHORIZED SERVICE TECHNICIANS.

© 1996 Whirlpool Corporation, Benton Harbor, MI 49022

ii

TABLE OF CONTENTS

INTRODUCTION.................................................................................................................. ii

TABLE OF CONTENTS ...................................................................................................... iii

SECTION ONE

FEATURES AND DESIGNFEATURES AND DESIGN

FEATURES AND DESIGN

FEATURES AND DESIGNFEATURES AND DESIGN

Safety.............................................................................................................................. 1

R134a Service Information ............................................................................................. 2

............................................................................................

..............................................

............................................................................................

SECTION TWO

Installation Considerations ...................................... 3

SECTION THREE

THEORY OF OPERATIONTHEORY OF OPERATION

THEORY OF OPERATION

THEORY OF OPERATIONTHEORY OF OPERATION

Temperature Controlled Meat Locker .......................................................................................... 5

Ice and Water Dispensers............................................................................................................ 5

Temperature Control Operation ...................................................................................................9

Adaptive Defrost Function ......................................................................................................... 10

............................................................................................

..............................................

............................................................................................

SECTION FOUR

COMPONENT ACCESSCOMPONENT ACCESS

COMPONENT ACCESS

COMPONENT ACCESSCOMPONENT ACCESS

................................................................................................

................................................

................................................................................................

1313

13

1313

SECTION FIVE

11

1

11

55

5

55

DIAGNOSIS AND TROUBLESHOOTINGDIAGNOSIS AND TROUBLESHOOTING

DIAGNOSIS AND TROUBLESHOOTING

DIAGNOSIS AND TROUBLESHOOTINGDIAGNOSIS AND TROUBLESHOOTING

Troubleshooting Guide ............................................................................................................... 21

Dignostic Tests ........................................................................................................................... 23

SECTION SIX

TECH TIPSTECH TIPS

TECH TIPS

TECH TIPSTECH TIPS

Condensation Patterns .............................................................................................................. 25

Wiring Diagram .......................................................................................................................... 26

Strip Circuits............................................................................................................................... 27

Model Number Designation ....................................................................................................... 29

Product Specification and Warranty Information Sources......................................................... 29

..............................................................................................................

....................................................... 25

..............................................................................................................

......................................................................

...................................

......................................................................

iii

2121

21

2121

iv

>>

View Section 1 of the Video Tape

SECTION 1

GENERAL INFORMATIONGENERAL INFORMATION

GENERAL INFORMATION

GENERAL INFORMATIONGENERAL INFORMATION

SAFETY

! WARNING

▲

To avoid the risk of electrical shock,

property damage, personal injury or death:

• The power cord must be plugged into a 3-prong grounding-type wall receptacle, g rounded

in accordance with the National Electrical Code, ANSI/NFPA 70 - latest edition and local

codes and ordinances.

• It is the personal responsibility of the consumer to have a proper 3-prong wall receptacle

installed by a qualified electrician.

• DO NOT, UNDER ANY CIRCUMSTANCES, REMOVE

THE POWER CORD GROUNDING PRONG.

• A separate adequately fused and grounded circuit

should be available for this appliance.

• Do not remove any grounding wires from individual

components while servicing, unless the component

is to be removed and replaced.

important to replace all grounding wires when

components are replaced.

It is extremely

! CAUTION

▲

To avoid the risk of

property damage OR personal injury:

• Tape doors closed when adjusting hinges or doors.

• do not dispense ice into thin glass, fine china or delicate crystal. Cracks or chips may

result from ice dropping into container and from combined pressure of hands and

dispenser bar.

• When servicing the ice dispenser system, unplug the refrigerator and remove the ice

storage bin.

1

R134a REFRIGERANT

SERVICE INFORMATION

This product uses R134a refrigerant. This refrigerant requires synthetic Ester Oil in the compressor.

This cooling system does not tolerate contamination from any of the following:

• Other Refrigerants

• Moisture

• Petroleum-based Lubricants

• Silicone Lubricants

• Cleaning Compounds

• Rust Inhibitors

• Leak Detection Dyes

• Any Other Type of Additive

As a result the following precautions should be observed:

• Use equipment dedicated to R134a sealed system service only.

• Do not leave a replacement compressor open to the atmosphere for more than 10 minutes.

• Always replace the filter-drier when performing any repairs on the sealed system.

• USE ONLY R134a REFRIGERANT FOR BACKFLUSHING AND SWEEP PROCEDURES.

• If the rubber plugs on the service replacement compressor appear to have been tampered

with or removed, DO NOT USE THE COMPRESSOR. Get another one.

• The filter-drier MUST be cut from the sealed system. Never unbraze the filter-drier from

system tubing. Applying heat will drive moisture back into the sealed system.

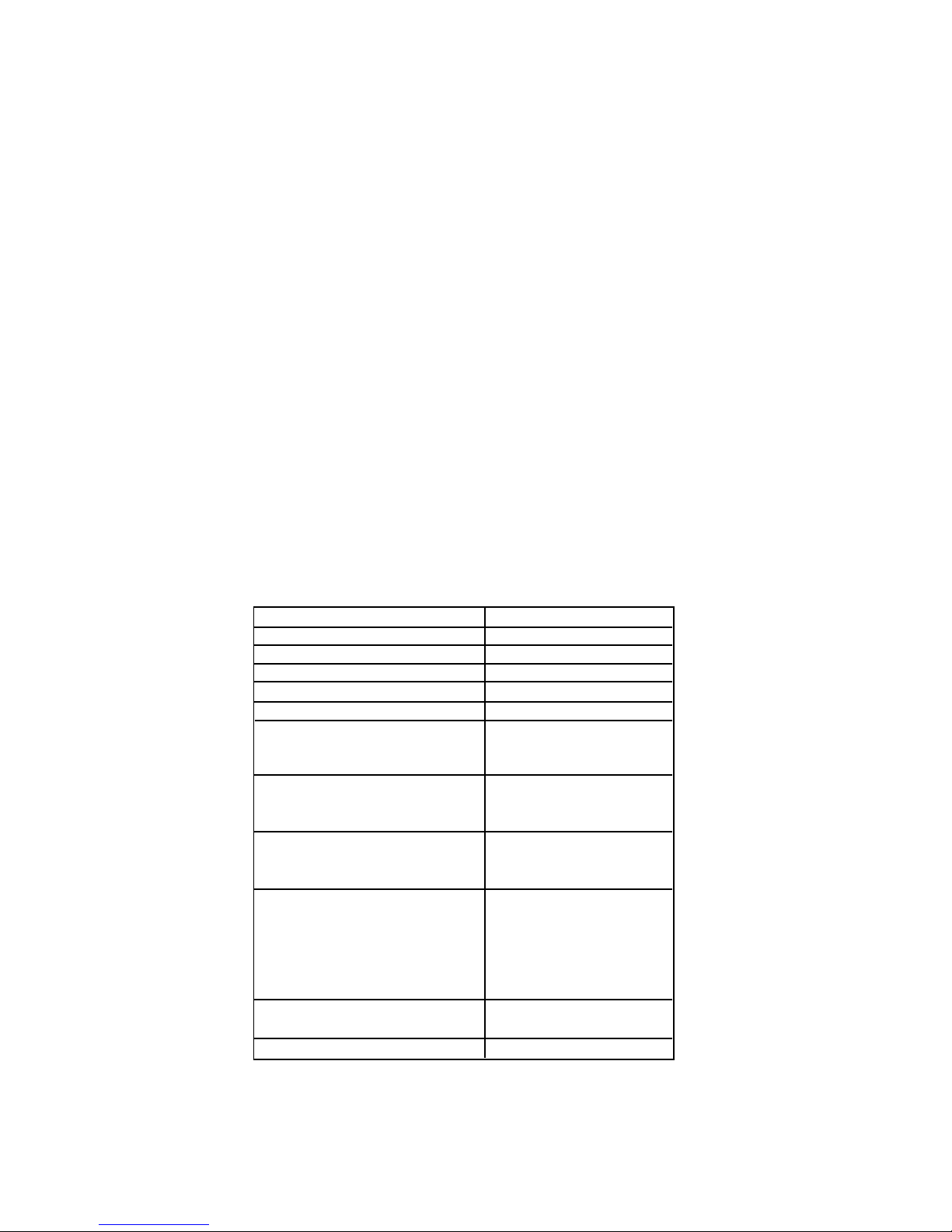

HEAL TH AND SAFETY HANDLING

Allowable Over all Exposure Limit

Vapor Exposure to Skin

Liquid Exposure to Skin

Vapor Exposure to Eyes

Liquid Exposure to Eyes

Above Minimum Exposure Limit

Safety and Handling

Spill Management

Fire and Explosion Hazards

Storage Conditions

Disposal Procedure

R134a

1,000 ppm

No Effect

Can Cause Frostbite

Very Slight Irritation

Can Cause Frostbite

Can Cause Asphyxiation,

T ach ycardia and Cardiac

Arrhythmias.

Wear appropriate Skin and

Eye protection. Use adequate

Ventilation.

Remove or Extinguish Ignition

or Combustible Sources.

Evacuate or Ventilate Area.

May Decompose if contact with

Flames and Heating

elements. Container Ma y

Explode IF Heated Due to

Pressure Rise. Comb ustion

Products are Toxic.

The Procedures/Rules for R12

also Apply to R134a.

Reclaim

SEE

SWEEP CHARGE PROCEDURES FOR THE 90's

Part No. 4321717 FOR COMPLETE INSTRUCTION ON

SERVICING THE SEALED SYSTEM.

,

2

>

>

View Section 2 of the Video Tape

SECTION 2

GENERAL INFORMATIONGENERAL INFORMATION

GENERAL INFORMATION

GENERAL INFORMATIONGENERAL INFORMATION

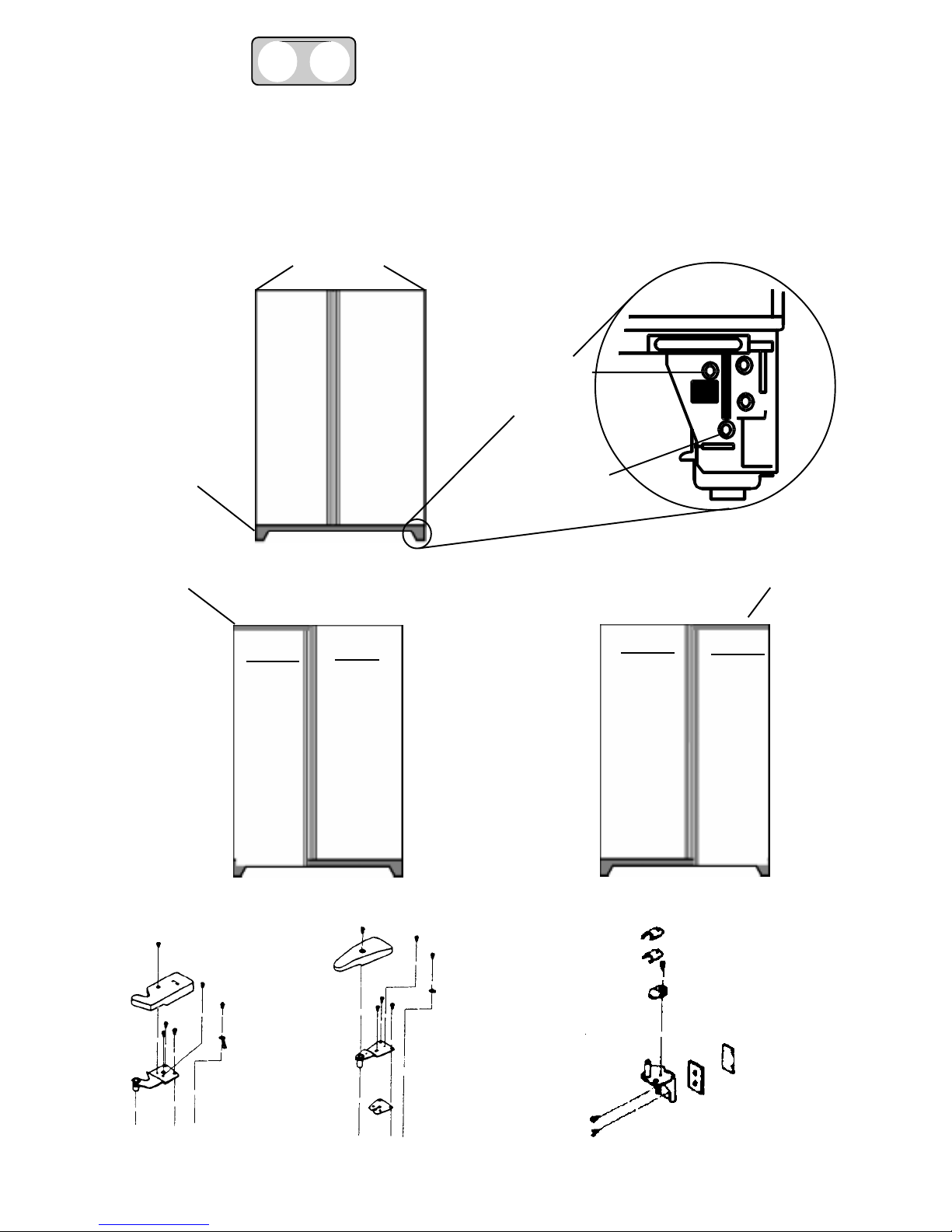

INSTALLATION CONSIDERATIONS

LEVELING THE UNIT AND ALIGNING THE DOORS

Top Hinge

Locations

▲

▲

Fig. 1

Toe Grille

Location

Door T oo

Low

Fig. 2

▲

▲

▲

▲

Rear Roller

Adjustment

Screw

Front Roller

Adjustment

Screw

Fig. 3

▲

▲

▲

▲

Door T oo

▲

Low

Hinge

Cover

Top

Hinge

Fig. 4

Shim

Shim

Shim

Door Closer

Bottom

Hinge

3

Shim

Shim

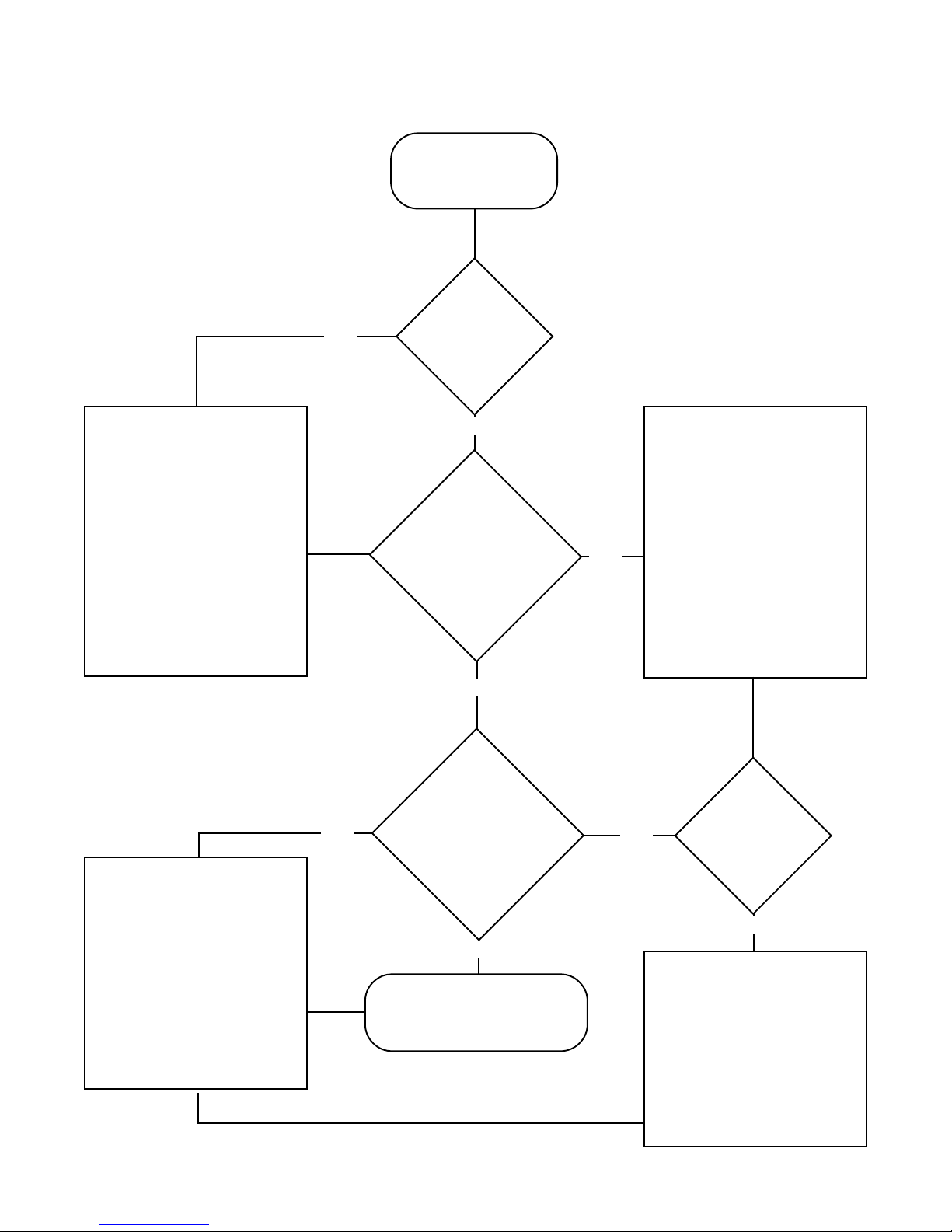

ALIGNMENT AND LEVELING PROCEDURES FLOW CHART

Slide Unit

into

Final Location.

▲

Is

NO

Unit

Stable?

▲

1. Remove toe grille by

pulling forward at

each end.

2. Turn roller adjustment screw(s) clockwise until unit is

firmly on all

roller(s). (

3. If unit is not stable

due to uneven flooring, use shims under

rear roller(s).

Fig. 6

)

▲

1. Remove top hinge

cover. Loosen top

hinge screws. (

2. Adjust both doors so

tops are aligned and

gap is consistent

from top to bottom.

3. Tighten top hinge

screws and replace

the covers.

Fig. 9

▲

▲

YES

▲

Are Tops of Doors

Aligned with Each

Other?

(Fig. 7)

YES

NO

1. Remove toe grille by

pulling forward at

each end.

2. Turn roller adjustment screw for the

▲

door that is lower

clockwise.

3. Open and close both

doors to confirm

doors are aligned.

4. Repeat until doors

are aligned.

▲

▲

Is Center Gap

NO

)

▲

Consistent from

Top to

Bottom?

(

Fig. 8

)

YES

▲

Replace T oe Grille.

▲

YES

1. Turn roller adjustment screw(s) counterclockwise until

unit is firmly on all

rollers.

2. If unit is not stable

due to uneven flooring, use shims under

rear rollers.

Is

Unit

Stable?

NO

▲

4

>

>

View Section 3 of the Video Tape

SECTION 3

THEORY OF OPERATIONTHEORY OF OPERATION

THEORY OF OPERATION

THEORY OF OPERATIONTHEORY OF OPERATION

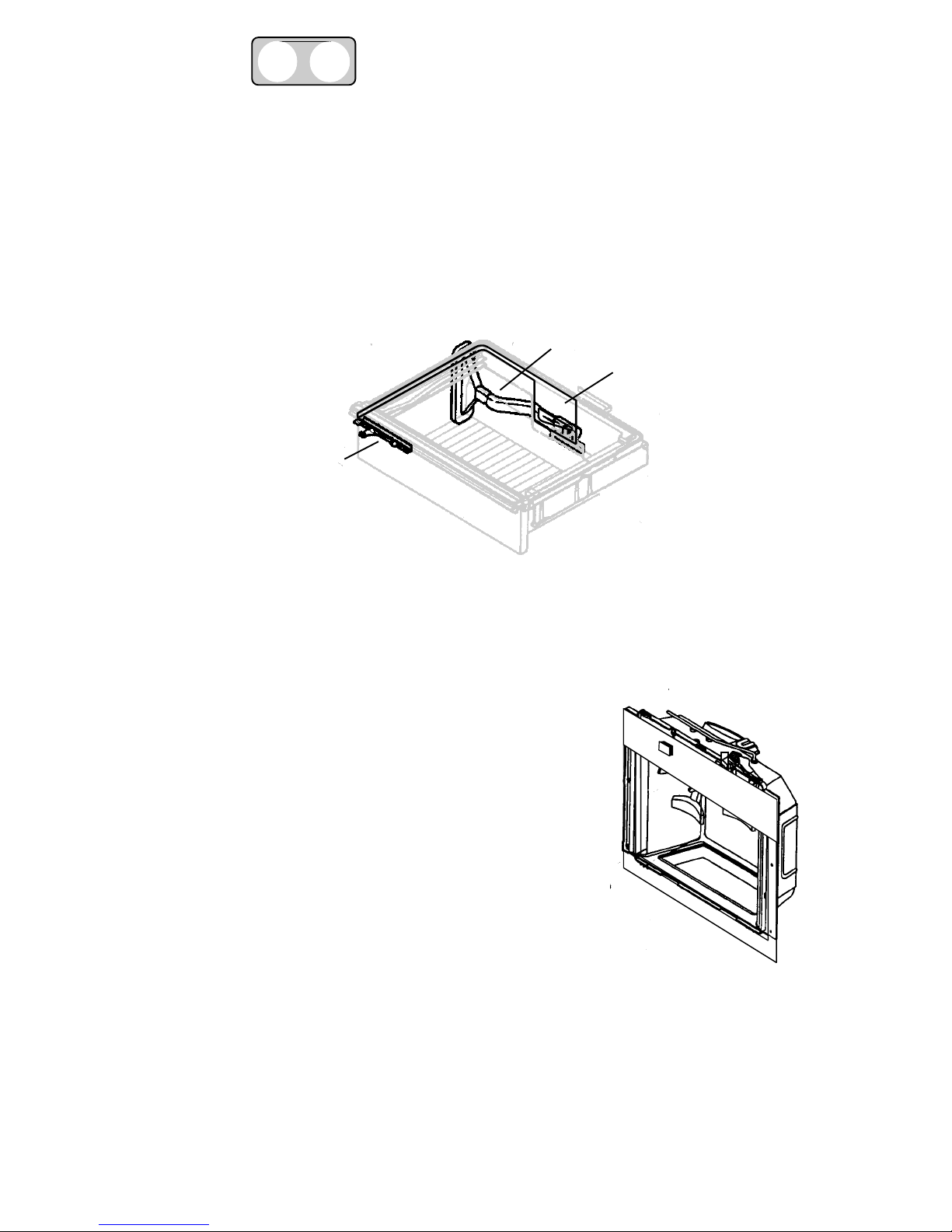

TEMPERATURE CONTROLLED MEAT LOCKER

The 26" deep side-by-side refrigerator/freezer is equipped with a chilled meat locker which will keep

the contents of the drawer approximately 5°F colder than the rest of the refrigerator section.

A slide on the front of the drawer operates a damper which directly controls the amount of freezer air

drawn into the drawer through an air duct.

AIR

DUCT

(Fig. 5)

▲

DAMPER

▲

▲

Fig. 5

SLIDE

CONTROL

ICE AND WATER DISPENSER

For ice and water dispensing, a plumbing connection must be made between the household water

supply and the dual solenoid valve mounted on the rear cabinet rail.

Ice dispensing operates as follows:

1. The automatic ice maker is mounted on the

back wall of the freezer liner. Water automatically

fills the mold, freezes into ice and dumps ice into the

the storage bin.

2. When the storage bin is full, a shut-off arm prevents

additional ice production until ice has been removed,

which lowers the shut-off arm. The storage bin will hold

approximately 8 pounds of ice. A motor driven helix is

mounted near the bottom of the storage bin.

When energized, the helix moves the ice to the front of

the storage bin where ice is directed into a lift wheel

mechanism.

3. In cube mode, the helix turns ice lift wheel counter-clockwise.

Ice bypasses the crusher blades and is dispensed into a glass.

4. In crushed mode, the helix turns clockwise forcing the ice into the crusher blades. Crushed ice

pieces will vary in size and shape.

5. Keep bits of ice from being sprayed beyond glass by placing a glass with a large opening close to

the ice chute.

(Fig. 8)

(Fig. 7)

Fig. 6

5

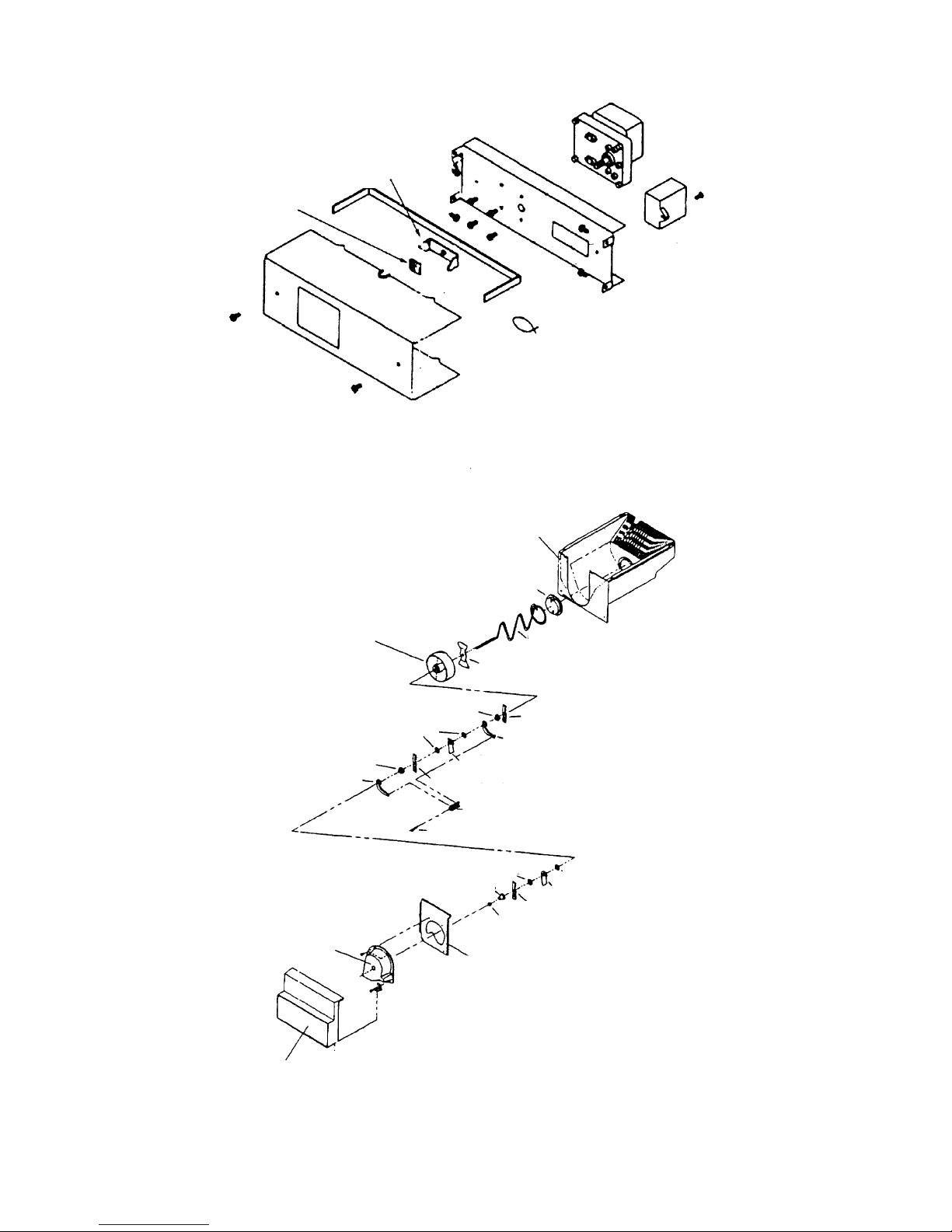

A UGER MOTOR

ASSEMBLY

LOCKING NUT

AUGER MOTOR

COVER

AUGER MOTOR

DRIVER

CAPACITOR

AUGER MOTOR

SUPPORT

Fig. 7

ICE BUCKET

ASSEMBLY

STEPPED WASHER

STATIC BLADE

BLADE COVER

CRUSHED ICE LIFT

WHEEL

STEPPED WASHER

WAVED WASHERS

WAVED WASHER

STEPPED WASHER

ICE BUCKET

HELIX CAP

ICE AGITATOR

CRUSHED ICE BAR

ROTATING BLADE

STATIC BLADE

ICE DAMPER

ROTATING BLADE

BLADE ANCHOR

ROLL PIN

WAVED WASHER

ICE DAMPER

ROTATING BLADE

LOCKING NUT

ICE CRUSHER FRONT

CRUSHED ICE BUCKET

FRONT

Fig. 8

6

6. Dispense ice by holding glass against ice lever ar m. The mechanically operated ice chute door

opens, and the motor driven helix is energized and ice is automatically dispensed into glass.

When glass is withdrawn, a delay mechanism slowly closes the ice chute door.

! WARNING

▲

To avoid risk of personal Injury or property damage, refrig erator must be

unplugged and ice storage bin must be removed before attempting to service

dispenser system. Never put fing ers, hands, or foreign objects Into Ice dispenser

opening while attempting to manually clear stalls or jams. Never use sharp

objects to break Ice. In case of stall or jam in cube or crushed mode, dispense in

opposite mode several times. There may be a delay when switching between

cube and crushed ice. This is normal. It takes a few seconds for cubes to be

moved from storage bin.

7. Sometimes a mound of “snow” will form on the door and/or ice chute. This condition is normal and

usually occurs with the repeated dispensing of crushed ice. “Snow” will eventually evaporate or

moisture can be wiped dry.

8. If the dispenser bar is held for long periods, the dispenser motor shuts off automatically after 2 to

3 minutes to prev ent ov erload. The motor resets automatically after 3 minutes and ice dispensing

can continue.

9. Use only ice from internal automatic ice maker. Do not add purchased ice cubes or cubes made

in any other manner. Dispenser operates only with cubes of proper size and shape.

10. Allow 12 hours after installation before first harvest of ice. Time required depends on freezer

temperature and amounts of food in freezer and refrigerator compartments.

11. The storage bin fills in three to four days depending on frequency of use. Two to 4 pounds of ice

will be made in a 24-hour period with a 0°F to 2°F freezer food temperature.

12. To temporarily meet demands for increased ice production, turn freezer control to colder setting.

Return freezer control to normal setting as soon as possible.

Water dispenser operates as f ollows:

1. The reservoir is located in the refrigerator section directly behind the crisper drawers. The reservoir

inlet tube comes from a solenoid valve mounted on the rear cabinet rail.

2. The reservoir holds approximately 40 ounces of water.

3. The outlet tube exits through the refrigerator floor and travels through a conduit foamed into the

cabinet bottom to a location just short of the freezer door bottom hinge. 5/16 inch tube is reduced

to 1/4 inch by means of a coupling. The tube enters the freezer door through the center of the

hinge pin and runs up the left flange of the door and crosses over the top of the cavity behind the

water dispensing lever.

following glasses, since the water tube leading to the dispenser from the water reser voir is not

refrigerated.

(Fig. 9)

NOTE: The first glass of water will be somewhat warmer than

4. The reservoir is filled by holding a glass against water the lever arm until water flo ws into a glass .

5. If household plumbing has been disturbed, thoroughly flush the water system. This will help

remove foreign materials in the water and also flush plumbing in refrigerator.

7

6. If odor, taste and sediment are a problem, a granulated activated carbon filter should be installed

on the household plumbing line.

7. Underneath the ice and water dispenser is a small sump to catch any spillage that may occur.

This is not a drain. However the sump is heated to speed up water evaporation. A removable

grille isprovided as a sump cover.

8. A six watt lamp is activated each time the water or ice dispensing lever ar ms are depressed.

Turning cavity night light switch off does not affect lamp being activated by ice or water levers.

9. The night light is activated by a photoelectric cell mounted in the dispenser front cover plaque.

Depending on ambient light, the night light may not always be on at full br ightness. This is

normal. The night light can be tur ned off manually.

W ATER FLOW

DIAGRAM

Fig. 9

Night Light

Automatic

Switch

Automatic Ice Maker

¼" O.D.

Plastic Tubing

Photoelectric

Cell

Ice & Water

Dispenser

¼" O.D.

Plastic Tubing

Water Inlet Valve

▲

▲

¼" O.D. x 5/16" O.D.

Plastic Compression

Union

Plastic Conduit

(foamed in Place)

Incoming Water

Line Connection

(Hose Coupling

x ¼" O.D.

Copper T ube

Fitting)

Water Reservoir

5/16" O.D.

Plastic Tubing

½" O.D.

¼" O.D.

Plastic

Tubing

8

TEMPERATURE CONTROL OPERATION

1. Freezer temperature is regulated by an air sensing thermostat located at the top rear of the

refrigerator compartment. A sensing tube goes into a well which routes the tube into the freezer

section. This thermostat actuates the compressor to circulate refr igerant through the sealed

system.

(Fig. 10)

The thermostat should be set to maintain 0°F to 2°F freezer food temperature.

REFRIGERANT

FLOW

Fig. 10

Freezer

Temperature

Sensor

Thermostat

Capillary/Suction Line

Heat Exchanger

Evaporator Inlet

Flange

Loop

Center

Mullion Loop

Evaporator

Outlet

Evaporator

Condenser

Compressor

Discharge Line

Capillary T ube

Compressor

Suction Line

Process Stub

High-Side

Filter/Drier

Condenser Fan

Compressor

Process Stub

Condenser

Outlet

Center Mullion

Loop

9

2. Refrigerator temperature is regulated by an air damper control. This control governs the amount

of refrigerated air entering the refrigerator compartment.

(Fig. 11)

The control should be set to

maintain 28°F to 40°F fresh food temperature.

Evaporator Fan

Freezer Back

(Air Baffle)

Air Supply to

Refrigerator

Compartment

Cold Air

Damper

Meat locker

Air

Air

Return

Condenser

Fan

Evaporator

Condenser

Compressor

AIR

FLOW

Fig. 11

10

ADAPTIVE DEFROST OPERATION

1. This unit is equipped with Adaptive Defrost Control (ADC).

a predetermined length of compressor run time. The length of accumulated compressor run time

is determined by a microprocessor that monitors the length of a defrost cycle (the time) interval

between energizing the defrost heater and the defrost thermostat opening). The microprocessor

then adapts or changes the amount of accumulated compressor run time between defrost cycles.

Fig. 12

(Fig. 12)

A defrost cycle occurs after

2. The accumulated Compressor Run Time between Defrost (CRTD) will be one of the five values

under normal operation:

CRTD (0) = 4 hours (Start Up)

CRTD (1) = 8 hours

CRTD (2) = 12 hours

CRTD (3) = 16 hours

CRTD (4) = 72 hours (Vacation)

• If the defrost cycle length is low, (19 minutes or less), indicating a small frost load, the CRTD

for the next defrost cycle is advanced to the next level.

• If the defrost cycle length is 19 to 24 minutes, indicating a normal frost load, the CRTD for the

next defrost cycle is not changed.

• If the defrost cycle length is 24 minutes or more, the CRTD for the next defrost cycle is lowered

one level.

• When the product is first installed or after a power interruption, the first CRTD will be 4 hours.

3. Vacation Mode: A CRTD of 72 hours will be initiated when the following three conditions exist:

• The defrost interval must have advanced to CRTD (3) = 16 hours.

• Both the refrigerator and freezers doors must have remained closed since the last defrost

cycle.

• The defrost thermostat must have opened in less than 19 minutes during the last defrost cycle.

11

4. Vacation Mode Defrost Interval Interruption: The Vacation Mode Defrost Interval will be

interrupted when either the freezer or refrigerator door is opened.

• The next defrost cycle will occur 8 hours after the door is opened and the ADC will rever t to

CRTD (1) = 8 hours.

• If the defrost thermostat remains closed for 19 minutes or more, the ADC will revert the CRTD

back one level.

5. A six minute dwell time occurs after the defrost thermostat opens before the compressor and

condenser fan motor operate.

6. If the defrost thermostat does not open within 29 minutes from the start of a defrost cycle, the

ADC will terminate the defrost cycle automatically.

7. Forced Defrost: To force a defrost cycle to occur, open and close the refr igerator or freezer

door light switch four times in eight seconds allowing ½ second between each action.

IMPORTANT:

• The compressor must be running when forcing defrost.

• The evaporator fan motor is delayed through the defrost ther mostat and will not operate until

the defrost thermostat closes.

• To by-bass the 6 minute dwell time after a defrost cycle or to terminate a forced defrost, disconnect power to the unit for 30 seconds.

8. When Defrost Mode terminates (the defrost bi-metal opens) the evaporator fan motor will not

operate until the defrost bi-metal resets. This could take approximately five minutes.

Section Three

CONFIRMATION OF LEARNINGCONFIRMATION OF LEARNING

CONFIRMATION OF LEARNING

CONFIRMATION OF LEARNINGCONFIRMATION OF LEARNING

EXERCISESEXERCISES

EXERCISES

EXERCISESEXERCISES

12

>

>

View Section 4 of the Video Tape

SECTION 4

COMPONENT ACCESSCOMPONENT ACCESS

COMPONENT ACCESS

COMPONENT ACCESSCOMPONENT ACCESS

Accessing the components in the 26" Deep Side-by-Side Refrigerator/Freezer is gener ally quite similar

to other typical Whirlpool units.

COMPONENT COMPARTMENT

Components located in the component compartment are assembled on a slide out tray at the bottom

of the unit. The compressor, condenser, condenser fan and water valves are located in this area.

Accessing the Component Compartment

To gain access to these components the compartment cover must be removed and the tray slid out.

(Fig. 13)

1. Remove the seven (7) hex-head screws secur ing the compar tment cover to the cabinet.

2. Remove the eight (8) screws securing the heat exchanger cover to the back of the unit.

3. Remove the double water valve from its mounting bracket by releasing the retainer clip and

sliding the valve assembly out of the bracket.

4. Remove the hex-head screw securing the filter-drier bracket to the right side of the cabinet

and push the filter-drier gently out of the way of the slide out tray mounting screw.

5. Remove the two (2) hex-head screws securing the slide out tray to the lower cabinet frame

rail.

6. Carefully slide the tray out from the unit.

NOTE: Be sure none of the tubing is excessively bent or kinked while pulling the tray out.

Fig. 13

13

Accessing the Heat Exchanger and Wiring Harness

The heat exchanger, water supply tube to the automatic ice maker and wiring har ness are located

under two (2) metal heat exchanger covers on the back of the cabinet.

1. Remove the seven (7) hex-head screws secur ing the component compar tment cover to the

cabinet.

2. Remove the eight (8) hex-head screws securing the long metal cover to the back of the

cabinet.

3. Remove the six (6) hex-head screws securing the L-shaped cover to the back of the cabinet.

FREEZER SECTION

The evapor ator , automatic ice maker , ice crusher and other associated components are all accessible

inside the freezer section.

Removing the Automatic Ice Maker

1. Remove the extension from the water inlet tube.

2. Remove the hex-head screw securing the bottom

bracket to the back of the freezer section.

LOOSEN

THESE SCREWS

3. Loosen the two (2) screws in the slotted brack ets at

the top of the automatic ice maker three or four turns.

(These screws must be removed if the rear cover is

to be removed.)

4. Slide the automatic ice maker up and off the screws.

5. Disconnect the automatic ice maker wiring harness

connector and remove the automatic ice maker from

the unit.

(Fig. 14)

Fig. 14

REMOVE

THIS SCREW

Servicing the Ice Dispenser Motor

The ice dispenser motor box contains the motor and start capacitor that turns the helix in the ice

container to deliver ice to the "Through The Door" ice dispenser.

Removal:

NOTE: It may be necessary to remove the freezer

compartment light and shelving brackets before the

ice dispenser motor box is to be removed.

(Fig. 15)

1. Remove the four (4) hex-head screws

securing the motor box to the sides

of the freezer compartment.

2. Disconnect the wiring harness connectors from the motor and capacitor

terminals.

Fig. 15

LOCATOR

TABS

WIRING

HARNESS

PATH

3. Carefully slide the motor box straight forward and out of the freezer compartment.

14

NOTE: When replacing the motor box be sure the wiring harness routes through the box correctly.

Portions of the harness are covered with a plastic sheath that allows the wiring to pass into and out

of the box at the top (down from the automatic ice maker) and right side (to the light fixture.)

Replacement:

1. Reconnect the wiring harness connectors to the motor and star t capacitor.

2. Align the four (4) locator tabs at the back of the motor box with the four slots in the rear cover

of the freezer section.

3. Replace the four (4) hex-head screws to secure the box to the sides of the freezer section.

Accessing the Freezer Compartment Temperature Sensing Tube

The freezer compartment temperature sensing tube can be accessed by removing the rear freezer

compartment cover.

1. Remove the automatic ice

maker.

2. Remove the ice dispenser motor box.

3. Remove the hex-head screw securing the

air supply cover to the right side of the

freezer compartment.

4. Remove the nine (9) screws securing the

rear cover from the back wall of the freezer

compartment.

(Fig. 16)

Fig. 16

NOTE: It may be necessary to remove the shelving

brackets before the rear cover is removed.

5. Carefully pull one side of the rear cover

forward and remove the cover from the

freezer.

6. The temperature sensing tube is located at

the top of the compartment encased in a

plastic sensor well.

Servicing the Evaporator and Other Related Components

The evaporator, evaporator fan, defrost bi-metal and defrost

heater are located behind the evaporator cover.

1. Remove the rear cover. (See procedure above.)

2. Remove the eight (8) screws securing the evaporator cover

in the freezer section.

3. Pull the evaporator cover up and out of the unit.

(Fig. 17)

Fig. 17

15

Removing the Evaporator Fan Motor

The evaporator fan motor is mounted on a bracket that is

attached to a shroud mounted to the back wall of the

freezer section.

1. Removing the two (2) hex-head scre ws that secure

the fan motor bracket to the shroud.

2. Disconnect the wiring harness connectors from the

evaporator fan motor terminals.

(Fig. 18)

Fig. 18

EV APORATOR

FAN SHROUD

FAN

MOTOR

BRACKET

Servicing the Evaporator, Defrost Bi-Metal and Defrost Heater

The evaporator, defrost bi-metal

units.

(Fig. 19)

and defrost heater

(Fig. 20)

are servicable parts on these

Removing the Defrost Bi-Metal

1. Disconnect the wiring harness connectors from the defrost bi-metal leads.

2. Slide the bi-metal mounting clip from the inlet tubing of the evaporator.

Removing the Defrost Heater Element

1. Disconnect the wiring harness connectors from the defrost heater element leads.

2. Carefully unsnap the evapor ator tubing from the four (4) plastic clips that secure the ev aporator

to the heat shield at the back of the freezer compartment and remove the styrofoam b loc ks on

both sides of the evaporator. Do not break these blocks. They will need to be reinstalled

when replacing the evaporator in the freezer section.

3. Tip the bottom of the ev aporator up and, with a pair of needlenose pliers, remo ve the clips that

secure the heater element to the bottom of the evaporator. This will free the heater element

from the evaporator.

Fig. 19

STYROFOAM

BLOCKS

Fig. 20

HEATER

ELEMENT

HEATER

ELEMENT

CLIPS

16

Refrigerator Section

The thermostat, air ducts and drinking water reservoir are all accessible from inside the refrigerator

section.

Removing the Drinking Water Reservoir

The drinking water reservoir

bottom shelf and vegetable crispers must be removed.

1. Depress the top tabs on the drinking water

reservoir cover.

2. Pull the top of the cover forward and

dislodge the bottom tabs.

3. Pull the cover up and out of the unit.

4. Remove the hex-head screw securing the

reservoir to the back wall of the refrigerator

section.

5. Pull the water supply and feed tubes from

their foamed in conduits and remove the

reservoir from the unit.

(Fig. 21)

is located at the bottom of the refrigerator section. NOTE: The

RESERVOIR

COVER

DRINKING

WATER

RESERVOIR

Fig. 21

Accessing the Thermostat and Cold Air Control Damper

The thermostat and cold air control damper are located behind the control cover at the top of the

refrigerator section.

1. Remove the thermostat and control damper

knobs.

(Fig. 22)

2. Remove the hex-head screw securing the

control cover bracket to the left side of the

refrigerator section.

3. Dislodge the four (4) tabs securing the

control cover to the top and back of the

refrigerator section.

Removing the Thermostat

1. Remove the two screws securing the

thermostat to the ther mostat bracket.

(Fig. 23)

2. Remove the sealer material from the end

of the sensor well.

3. Carefully pull the temperature sensing tube

from the sensor well.

4. Remove the thermostat from the unit.

KNOBS

BRACKET

Fig. 22

THERMOSTAT

BRACKET

SENSOR

WELL

Fig. 23

THERMOSTAT

17

Removing Cold Air Damper

1. Remove the control cover.

2. Remove the two (2) phillips-head screws securing

the cold air damper to the duct work.

(Fig. 24)

COLD AIR

DUCT

3. Remove the cold air damper from the unit.

ICE AND WATER DISPENSING UNIT

The freezer door contains the drinking water and cubed

and crushed ice dispensing unit. A description of the

cubed and crushed ice delivery process can be found in

Section Two, "Theory of Operation", in this Job Aid.

Drinking water is delivered to the dispenser through a

plastic tube that enters the door through the bottom

hinge. A coupling in the supply tube is located near the

hinge.

cavity to the right hand lever in the dispenser.

The wiring harness enters the freezer door through

the top hinge.

(Fig. 25)

Servicing the Dispenser Assembly

The supply tube tr avels inside the door

(Fig. 26)

Fig. 24

DAMPER

ASSEMBLY

Fig. 25

Fig. 26

NOTE: Flush Look (Built-In) Models - Remove the two trim-panel channels at the top and bottom of

the front cover before attempting to remove the dispenser assembly.

1. Remove the switch cap and unsnap the two (2) tabs at the bottom of the front cover from the

housing first. Pull the bottom out and lift and the front cover from the housing.

2. Remove the two (2) hex-head screws securing the metal control panel cover to the dispenser

housing. This will also free the control brac ket from the housing although it will remain tethered

to the freezer door by the wiring harness.

3. Disconnect the wiring harness connectors from the ter minals

on the switches and light fixture in the control bracket.

(Fig. 28)

(Fig. 27)

Fig. 27

Removing the Dispenser Assembly

1. Do the previous three procedures.

2. Remove the eight (8) hex-head screws securing

the dispenser housing to the freezer door.

3. Carefully pull the housing from the door.

4. Pull the water supply tube from the top of the dispenser housing.

5. Pull the wiring harness leads from the dispenser housing.

6. Disconnect the wiring harness connectors to the electric

foil heater.

(Fig. 29)

18

Fig. 28

Fig. 29

FLUSH LOOK MODELS

Factory Installed Flush Look Trim Package

A FLUSH LOOK (BUILT-IN) model can be purchased with factory

installed perimeter molding around the doors. This molding extends

beyond the top of the door to hide the top hinges and is designed to

accommodate custom panels for both the refrigerator and freezer

doors.

These models have a modified top hinge to allow the door to open

fully with the perimeter molding in place.

A perimeter kit

attached to the front edge of the refrigerator cabinet to fill any possible gaps up to 3/4" on

the sides and top of the unit.

PERIMETER

MOLDING

(Fig. 31)

SIDE

is supplied with these models that can be

TOP

PERIMETER

MOLDING

CUT OUT FOR

DOOR

TRIM

Fig. 30

HINGE

HINGE

COVER

Fig. 31

Adapting Free Standing Models

Free Standing models can be adapted to have a similar appearance to factory-built Flush Look

models. The custom panel molding kit for the refrigerator and freezer doors can be ordered separately

and installed on the unit. These moldings do not extend beyond the top of the door. Therefore the

hinges will be visible.

19

Section Four

CONFIRMATION OF LEARNINGCONFIRMATION OF LEARNING

CONFIRMATION OF LEARNING

CONFIRMATION OF LEARNINGCONFIRMATION OF LEARNING

EXERCISESEXERCISES

EXERCISES

EXERCISESEXERCISES

20

>>

View Section 5 of the Video Tape

SECTION 5

TROUBLESHOOTING AND DIAGNOSTICSTROUBLESHOOTING AND DIAGNOSTICS

TROUBLESHOOTING AND DIAGNOSTICS

TROUBLESHOOTING AND DIAGNOSTICSTROUBLESHOOTING AND DIAGNOSTICS

TROUBLESHOO TING GUIDE

PROBLEM

1. Operating Sound Level A. See Owners manual for explanation of normal operating sounds.

2. Freezer Warm - Compressor Off A. Temperature Control defective or setting too warm.

B. Defrost control stalled in defrost mode (defective).

C. Compressor defective.

D. Overload and/or relay defective.

3. Too Cold in Refrigerator A. Refrigerator damper control knob set too cold.

B. Refrigerator damper control not closing.

C. Deli control set too cold. Also check for misalignment - causing

air bypass of meatkeeper.

D. Freezer temperature control knob set too cold.

E. Restricted condenser air.

F. Refrigerant shortage or restriction.

G. Overcharge

4. Freezer Warm - Compressor Cuts A Heavy usage and/or high ambient

Off on Overload B. Restricted condenser air

C. Compressor machine compartment back cover missing.

D. Cabinet elevated off floor.

E Condenser fan motor inoperative.

F. Condenser fan blade loose or missing.

G. Improper voltage.

H. Relay or overload faulty.

I. Compressor motor winding open.

J. Non-condensables in system

K. Overcharge

POSSIBLE CAUSE

5. Freezer Too Warm - Compressor A. Control knob set too warm.

Operating B. Control out of calibration

C. Restricted condenser air

D Inoperative condenser fan motor

E. Door left open.

F. Heavy usage

G. Freezer fan motor inoperative.

H. Defrost thermostat open.

I. Defrost heater open

J. Freezer or condenser fan blade loose or off.

K. Evaporator heavily frosted (See D,F,G,H,I,J, OR L).

L. Defrost control stuck in compressor nun mode.

M. Drain plugged.

N. Loss of refrigerant or restriction.

O. Inefficient compressor

6. Too Warm in Refrigerator A. Refrigerator setting too warm

B. Damper doesn’t open.

C Freezer control set too warm.

D. Supply air duct blocked.

E. Return air duct blocked.

F Forced air deli control set too warm or air supply tube blocked.

G. Heavy usage or high ambient temperature

7. Freezer Too Cold A. Freezer temperature control knob set too cold.

B. Freezer temperature control out of calibration.

21

TROUBLESHOOTING

PROBLEM

8. Long off Cycle - Too Warm at Start A. Low ambient temperature

B. Freezer temperature control knob set too warm.

C. Freezer temperature control out of calibration

9. Short off Cycle A. High ambient and/or heavy usage

B. Freezer control knob set too cold.

C. Freezer control out of calibration.

D. Light on constantly

E. Poor door seal

10. Long or Continuous Operation A. High ambient and/or heavy usage

B. Inadequate condenser air flow

C. Freezer temperature set too cold.

D. Freezer temperature control out of calibration.

E. Freezer temperature control relay frozen closed.

F. Loss of refrigerant or restriction

11. Short Run Cycle A. Low ambient and/or light usage

B. Freezer temperature control setting too warm or control out of

calibration

12. Condensation on Cabinet Exterior A. High humidity installation (design accepts bead of water on

exterior of cabinet after 4 hours with a 0° to 2°F. (-18° to -17°C.)

freezer food temperature and 38° to 40°F. (3°C to 4°C) refrigerator food temperature in 84% R.H. conditions (See example

of typical sweat pattern under above conditions.

B. Freezer control set too cold.

C. Freezer control out of calibration

D. Poor door gasket seal.

E. Insulation void.

POSSIBLE CAUSE

Fig. 13

)

13. Unit will not Deliver Ice Cubes A . No power to auger drive motor. Check circuitry through ice actuator switch and upper freezer breaker auger motor switch.

B. Drive Motor open

C. Run Capacitor inoperative.

D. Drive motor tripped out on overload after 90 seconds of con-

tinuous use. Allow three minutes to reset.

E. Nonelectrical malfunctions. Power off for a period of time lets

the cubes refreeze together. No use for a period of time lets the

cubes freeze together. Improperly sealing chute door (check with

flash light). Malfunction in drive train components of bucket

assembly.

14. Unit will not Deliver Water A. No power to water dispensing solenoid vase. Check circuitry

through water dispensing switch.

B. Water dispensing solenoid valve coil open

C. Water dispensing switch open

D. Water dispensing arm does not close water dispensing switch.

E. Water line or tank frozen.

F. Freezer door interlock switch is open.

15. Water Delivery Slow A. A kink in the tubing may restrict the water flow. Replace the

water line. Flow rate should be 1.7 to 3.5 liter per minute with

inlet pressure from 20 to 120 PSI (1.38 to 8.2 BAR).

16. Water Accumulating in the A Leak in the water tank or connection

Refrigerator Bottom Area

22

DIA GNOSTIC TESTS

See the Tech Sheet for test procedures on electrical and mechanical components not listed here.

SOLUTIONTESTCOMPONENT

Adaptive Defrost Control

Input Voltage Readings

and Checks

L1 to L2 - Line voltage should

be present whenever the unit

is powered.

K to L2 - Line voltage chould

be present with cold control

closed.

T to L2 - Line voltage should

be present when cold control

is closed, defrost thermostat

is closed and ADC is in defrost

mode.

R to L2 - Line voltage should

be present with refrigerator

door open. (Door light switch

closed)

F to L2 - Line voltage should

be present with freezer door

open. (Door light switch

closed)

Defrost Bi-Metal

Photosensative

Switch

Output Voltage Readings

and Checks

C to L2 - Line voltage should

be present when unit is

cooling. (Cold control closed)

D to L2 - Line voltage should

be present when unit is

defrosting. (Cold control

closed)

Check resistance across

terminals.

1. To check light sensor with

cavity light switch "on", cover

light sensor eye and the lamp

should light up at

approximately 50% of full

illumination.

2. Activate the water or ice

dispenser switch. Lamp

should light at full illumination.

1. With power off and the evaporator coil below

freezing, the bi-metal should show 0 ohms when

check with an ohmmeter.

Cut out temperature approximately 48°F

Cut in temperature approximately 13°F

1. If light fails to light up, go to step 2.

2.a) If lamp lights up replace light sensor

b) If lamp does not light up check cavity lamp

and socket. Either the lamp is burned out or the

socket is malfunctioning.

23

CONFIRMATION OF LEARNING EXERCISESCONFIRMATION OF LEARNING EXERCISES

CONFIRMATION OF LEARNING EXERCISES

CONFIRMATION OF LEARNING EXERCISESCONFIRMATION OF LEARNING EXERCISES

24

>

>

View Section 6 of the Video Tape

SECTION 6

TECH TIPSTECH TIPS

TECH TIPS

TECH TIPSTECH TIPS

TYPICAL EXTERNAL SWEAT PATTERNS

FRONTLEFT

BACK

RIGHT

TOP

CLASSIFICATION OF

CONDENSATION

1 = Haze or Fog

2 = Beading

3 = Beads or Small

Drops

4 = Drops Running

Together

BOTTOM

LOWER MULLION

Fig. 13

25

WIRING DIAGRAM

26

STRIP CIRCUITS

A UTOMATIC DEFROST CONTROL ENERGIZING CIRCUIT

COMPRESSOR RUN CIRCUIT

EVAPORATOR FAN CIRCUIT

DEFROST CIRCUIT

27

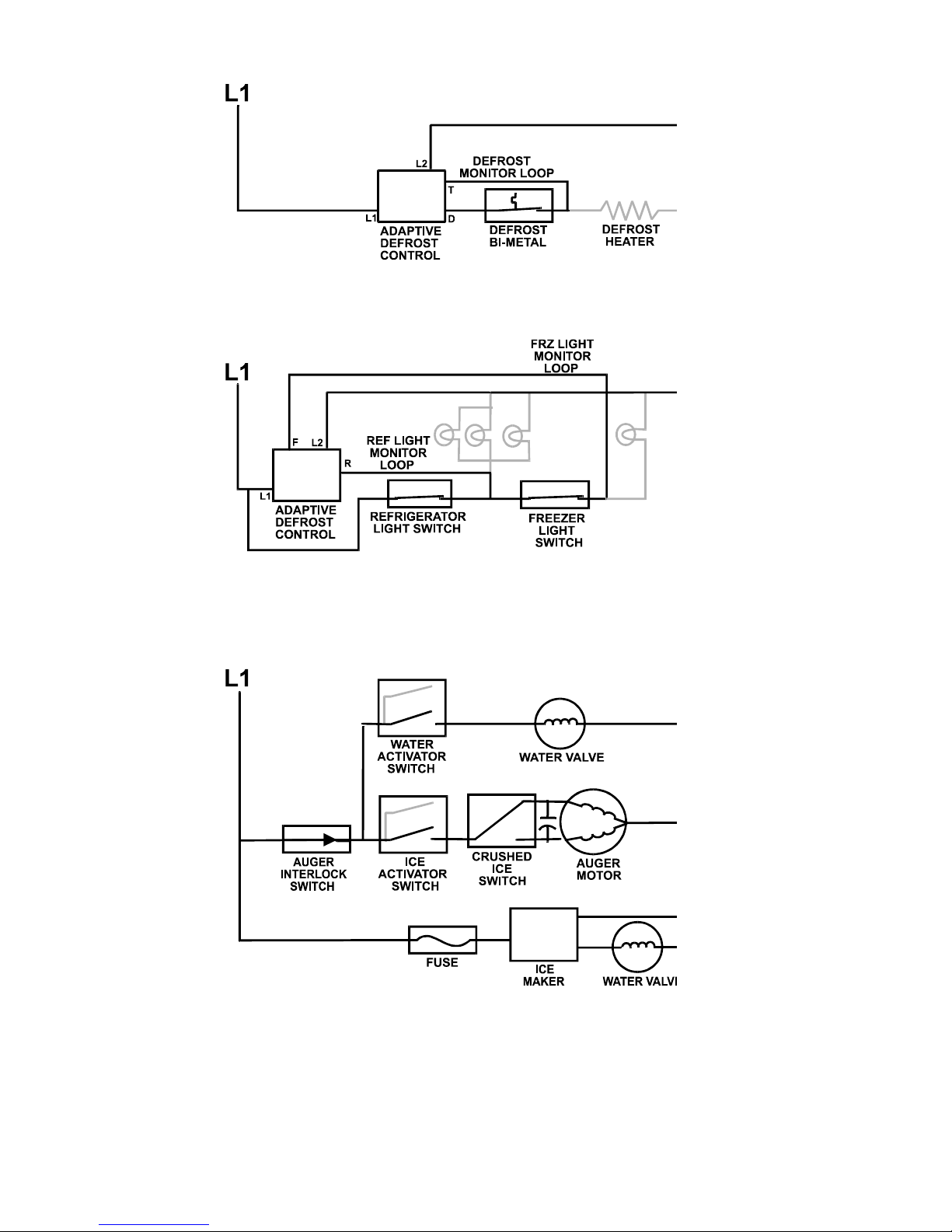

DEFROST RUN TIME MONITOR CIRCUIT

REFRIGERATOR AND FREEZER LIGHT MONITOR CIRCUIT

ICE & WATER DISPENSER AND AUTOMATIC ICE MAKER CIRCUIT

28

SERIAL AND MODEL NUMBER DESIGNATORS

The serial number for all Whirlpool and KitchenAid brand refrigerator/freezers contain the following

designations:

Manufacturer Site/Source

Calendar Y ear

Calendar Week

Sequential Serial Number

The model number for the KitchenAid brand 26" deep freestanding and flush look side-by-side refrigerator/freezers contain the following designations:

Model Number

Marketing Channel

(if present)

KitchenAid Brand = K

Product Identification

SB = Side-by-Side/Flush Look

SF = Side-by-Side/Freestanding

KSBS20 Q E WH 0

EC E 39 40174

Merchandise Scheme/Series

S = Superba

Capacity

Features

Year of

Introduction

Color

WH = White

AL = Almond

BL = Black

Engineering Changes (Numeric)

FOR PRODUCT SPECIFICATIONS AND WARRANTY INFORMATION

ON KITCHENAID BRAND CALL:

1-800-422-1230

29

The model number for the Whirlpool brand 26" deep freestanding and flush look side-by-side refrigerator/freezers contain the following designations:

Model Number

Marketing Channel

(if present)

Product Group

E = Refrigeration

Product Identification

Capacity

Model Series

D = DesignerStyle

Feature Code

B = Built-In

F = Freestanding

Door Swing

Year of Introduction

ED20DBXEW0

0

Color

W = White

N = Almond

B = Black

Energy/Power Designator

Engineering Changes (Numeric)

FOR PRODUCT SPECIFICATIONS AND W ARRANTY INFORMATION

ON WHIRLPOOL BRAND CALL:

800-253-1301

FOR TECHNICAL ASSISTANCE

ON WHIRLPOOL AND KITCHENAID BRANDS

WHILE AT THE CUSTOMER'S HOME CALL;

THE TECHNICAL ASSISTANCE LINE: 800-253-2870

Have your store number ready to identify you as an Authorized Servicer

30

ANSWER SHEET

CONFIRMATION OF LEARNINGCONFIRMATION OF LEARNING

CONFIRMATION OF LEARNING

CONFIRMATION OF LEARNINGCONFIRMATION OF LEARNING

EXERCISESEXERCISES

EXERCISES

EXERCISESEXERCISES

31

v

Loading...

Loading...