Whirlpool KSFS20QEAL0, KSBS20QEBL0, KSFS20QEBL0, ED20DBXEW00, ED20DBXEN00 User Manual

...

CONSUMER SER VICES TECHNICAL

EDUCATION GROUP PRESENTS

26" DEEP26" DEEP

26" DEEP

26" DEEP26" DEEP

SIDE - BY SIDESIDE - BY SIDE

SIDE - BY SIDE

SIDE - BY SIDESIDE - BY SIDE

REFRIGERAREFRIGERA

REFRIGERA

REFRIGERAREFRIGERA

KSBS20QEWH0KSBS20QEWH0

KSBS20QEWH0

KSBS20QEWH0KSBS20QEWH0

KSBS20QEAL0KSBS20QEAL0

KSBS20QEAL0

KSBS20QEAL0KSBS20QEAL0

TT

OR/ FREEZERSOR/ FREEZERS

T

OR/ FREEZERS

TT

OR/ FREEZERSOR/ FREEZERS

MODELSMODELS

MODELS

MODELSMODELS

ED20DBXEW00ED20DBXEW00

ED20DBXEW00

ED20DBXEW00ED20DBXEW00

ED20DBXEN00ED20DBXEN00

ED20DBXEN00

ED20DBXEN00ED20DBXEN00

R-84

KSBS20QEBL0KSBS20QEBL0

KSBS20QEBL0

KSBS20QEBL0KSBS20QEBL0

KSFS20QEWH0KSFS20QEWH0

KSFS20QEWH0

KSFS20QEWH0KSFS20QEWH0

KSFS20QEAL0KSFS20QEAL0

KSFS20QEAL0

KSFS20QEAL0KSFS20QEAL0

KSFS20QEBL0KSFS20QEBL0

KSFS20QEBL0

KSFS20QEBL0KSFS20QEBL0

ED20DBXEB00ED20DBXEB00

ED20DBXEB00

ED20DBXEB00ED20DBXEB00

ED20DFXEW00ED20DFXEW00

ED20DFXEW00

ED20DFXEW00ED20DFXEW00

ED20DFXEN00ED20DFXEN00

ED20DFXEN00

ED20DFXEN00ED20DFXEN00

ED20DFXEB00ED20DFXEB00

ED20DFXEB00

ED20DFXEB00ED20DFXEB00

JOB AID

Part No. 4321940

i

INTRODUCTION

This Job Aid,

companion video tape,

provides specific information on for the installation, service and repair of 20 cu. ft. side-by-side

refrigerator/freezers with 26" deep cabinets.

26" DEEP SIDE-BY-SIDE REFRIGERATOR/FREEZERS

recent information on design, features, troubleshooting, service and repair procedures. Whir lpool

required sweep charge procedures are to be strictly adhered to when repairing the sealed system.

For a complete explanation of those procedures, refer to the Job Aid,

PROCEDURES FOR THE 90's

26" DEEP SIDE-BY-SIDE REFRIGERATOR/FREEZERS

26" DEEP SIDE-BY-SIDE REFRIGERAT OR/FREEZERS,

has been compiled to provide the most

, (Part No. 4321717) and its companion video (Part No. 4321718.)

, (Part No. 4321940), and the

(Part No. 4321970),

SWEEP CHARGE

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair 22 cu. ft. side-by-side refrigerator/freezers with 26" deep

cabinets.

The objectives of the Job Aid are:

The service technician will -

• Understand proper safety precautions.

• Follow proper refrigerant recover y procedures.

• Successfully troubleshoot and diagnose malfunction.

• Successfully perform necessary repairs.

• Successfully return the refrigerator/freezer to proper operational status.

TO THE INSTRUCTOR/INDEPENDENT STUDENT

At the end of certain sections of this Job Aid you will find a "Confirmation of Lear ning Exercise." A

symbol that looks like this ( ✎) indicates that a pencil and two "Hi-Light" mar kers may be necessary

to complete the exercise. Certain exercises may require that service procedures be performed if an

appropriate appliance is available.

WHIRLPOOL CORPORATION ASSUMES NO RESPONSIBILITY

FOR ANY REPAIRS MADE ON OUR PRODUCTS BY ANYONE

OTHER THAN AUTHORIZED SERVICE TECHNICIANS.

© 1996 Whirlpool Corporation, Benton Harbor, MI 49022

ii

TABLE OF CONTENTS

INTRODUCTION.................................................................................................................. ii

TABLE OF CONTENTS ...................................................................................................... iii

SECTION ONE

FEATURES AND DESIGNFEATURES AND DESIGN

FEATURES AND DESIGN

FEATURES AND DESIGNFEATURES AND DESIGN

Safety.............................................................................................................................. 1

R134a Service Information ............................................................................................. 2

............................................................................................

..............................................

............................................................................................

SECTION TWO

Installation Considerations ...................................... 3

SECTION THREE

THEORY OF OPERATIONTHEORY OF OPERATION

THEORY OF OPERATION

THEORY OF OPERATIONTHEORY OF OPERATION

Temperature Controlled Meat Locker .......................................................................................... 5

Ice and Water Dispensers............................................................................................................ 5

Temperature Control Operation ...................................................................................................9

Adaptive Defrost Function ......................................................................................................... 10

............................................................................................

..............................................

............................................................................................

SECTION FOUR

COMPONENT ACCESSCOMPONENT ACCESS

COMPONENT ACCESS

COMPONENT ACCESSCOMPONENT ACCESS

................................................................................................

................................................

................................................................................................

1313

13

1313

SECTION FIVE

11

1

11

55

5

55

DIAGNOSIS AND TROUBLESHOOTINGDIAGNOSIS AND TROUBLESHOOTING

DIAGNOSIS AND TROUBLESHOOTING

DIAGNOSIS AND TROUBLESHOOTINGDIAGNOSIS AND TROUBLESHOOTING

Troubleshooting Guide ............................................................................................................... 21

Dignostic Tests ........................................................................................................................... 23

SECTION SIX

TECH TIPSTECH TIPS

TECH TIPS

TECH TIPSTECH TIPS

Condensation Patterns .............................................................................................................. 25

Wiring Diagram .......................................................................................................................... 26

Strip Circuits............................................................................................................................... 27

Model Number Designation ....................................................................................................... 29

Product Specification and Warranty Information Sources......................................................... 29

..............................................................................................................

....................................................... 25

..............................................................................................................

......................................................................

...................................

......................................................................

iii

2121

21

2121

iv

>>

View Section 1 of the Video Tape

SECTION 1

GENERAL INFORMATIONGENERAL INFORMATION

GENERAL INFORMATION

GENERAL INFORMATIONGENERAL INFORMATION

SAFETY

! WARNING

▲

To avoid the risk of electrical shock,

property damage, personal injury or death:

• The power cord must be plugged into a 3-prong grounding-type wall receptacle, g rounded

in accordance with the National Electrical Code, ANSI/NFPA 70 - latest edition and local

codes and ordinances.

• It is the personal responsibility of the consumer to have a proper 3-prong wall receptacle

installed by a qualified electrician.

• DO NOT, UNDER ANY CIRCUMSTANCES, REMOVE

THE POWER CORD GROUNDING PRONG.

• A separate adequately fused and grounded circuit

should be available for this appliance.

• Do not remove any grounding wires from individual

components while servicing, unless the component

is to be removed and replaced.

important to replace all grounding wires when

components are replaced.

It is extremely

! CAUTION

▲

To avoid the risk of

property damage OR personal injury:

• Tape doors closed when adjusting hinges or doors.

• do not dispense ice into thin glass, fine china or delicate crystal. Cracks or chips may

result from ice dropping into container and from combined pressure of hands and

dispenser bar.

• When servicing the ice dispenser system, unplug the refrigerator and remove the ice

storage bin.

1

R134a REFRIGERANT

SERVICE INFORMATION

This product uses R134a refrigerant. This refrigerant requires synthetic Ester Oil in the compressor.

This cooling system does not tolerate contamination from any of the following:

• Other Refrigerants

• Moisture

• Petroleum-based Lubricants

• Silicone Lubricants

• Cleaning Compounds

• Rust Inhibitors

• Leak Detection Dyes

• Any Other Type of Additive

As a result the following precautions should be observed:

• Use equipment dedicated to R134a sealed system service only.

• Do not leave a replacement compressor open to the atmosphere for more than 10 minutes.

• Always replace the filter-drier when performing any repairs on the sealed system.

• USE ONLY R134a REFRIGERANT FOR BACKFLUSHING AND SWEEP PROCEDURES.

• If the rubber plugs on the service replacement compressor appear to have been tampered

with or removed, DO NOT USE THE COMPRESSOR. Get another one.

• The filter-drier MUST be cut from the sealed system. Never unbraze the filter-drier from

system tubing. Applying heat will drive moisture back into the sealed system.

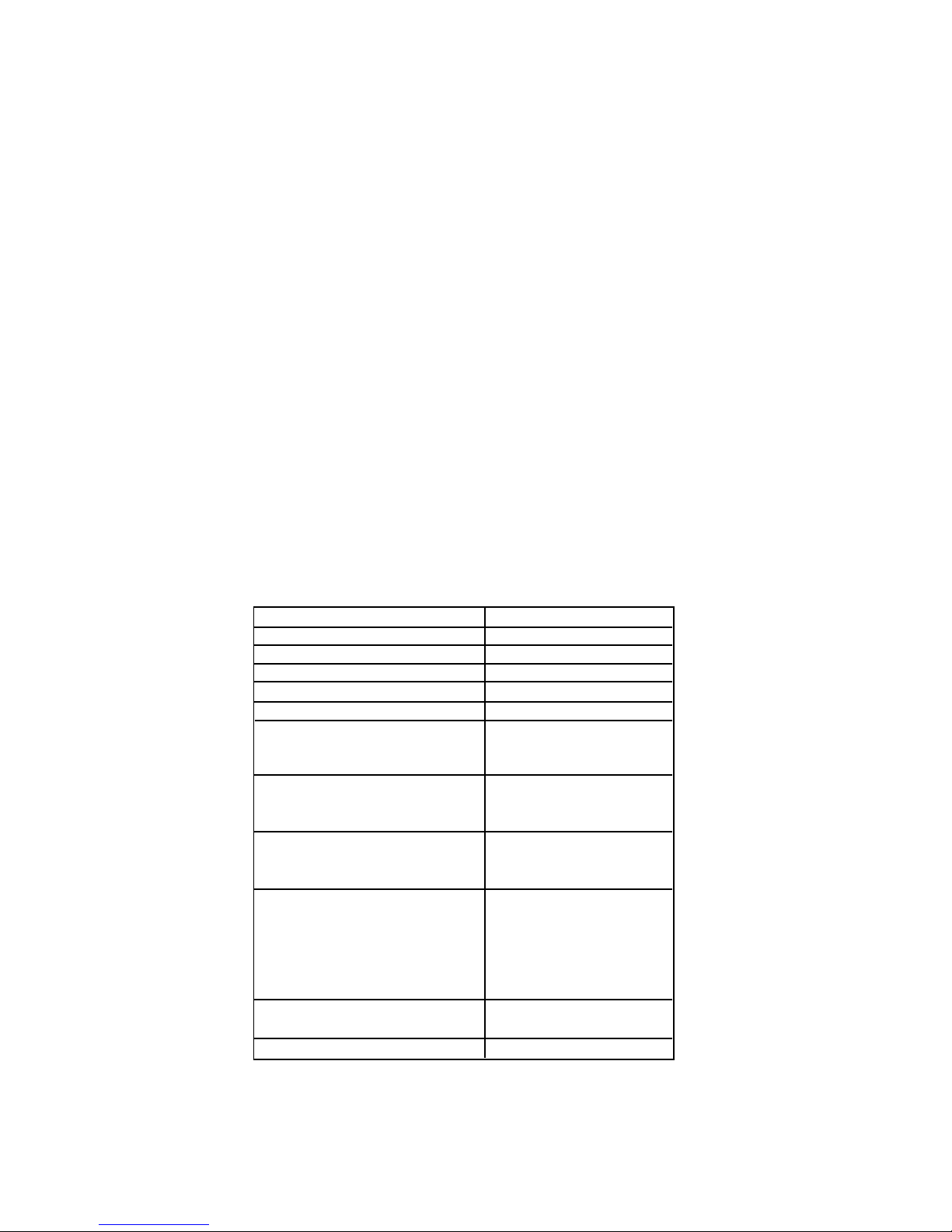

HEAL TH AND SAFETY HANDLING

Allowable Over all Exposure Limit

Vapor Exposure to Skin

Liquid Exposure to Skin

Vapor Exposure to Eyes

Liquid Exposure to Eyes

Above Minimum Exposure Limit

Safety and Handling

Spill Management

Fire and Explosion Hazards

Storage Conditions

Disposal Procedure

R134a

1,000 ppm

No Effect

Can Cause Frostbite

Very Slight Irritation

Can Cause Frostbite

Can Cause Asphyxiation,

T ach ycardia and Cardiac

Arrhythmias.

Wear appropriate Skin and

Eye protection. Use adequate

Ventilation.

Remove or Extinguish Ignition

or Combustible Sources.

Evacuate or Ventilate Area.

May Decompose if contact with

Flames and Heating

elements. Container Ma y

Explode IF Heated Due to

Pressure Rise. Comb ustion

Products are Toxic.

The Procedures/Rules for R12

also Apply to R134a.

Reclaim

SEE

SWEEP CHARGE PROCEDURES FOR THE 90's

Part No. 4321717 FOR COMPLETE INSTRUCTION ON

SERVICING THE SEALED SYSTEM.

,

2

>

>

View Section 2 of the Video Tape

SECTION 2

GENERAL INFORMATIONGENERAL INFORMATION

GENERAL INFORMATION

GENERAL INFORMATIONGENERAL INFORMATION

INSTALLATION CONSIDERATIONS

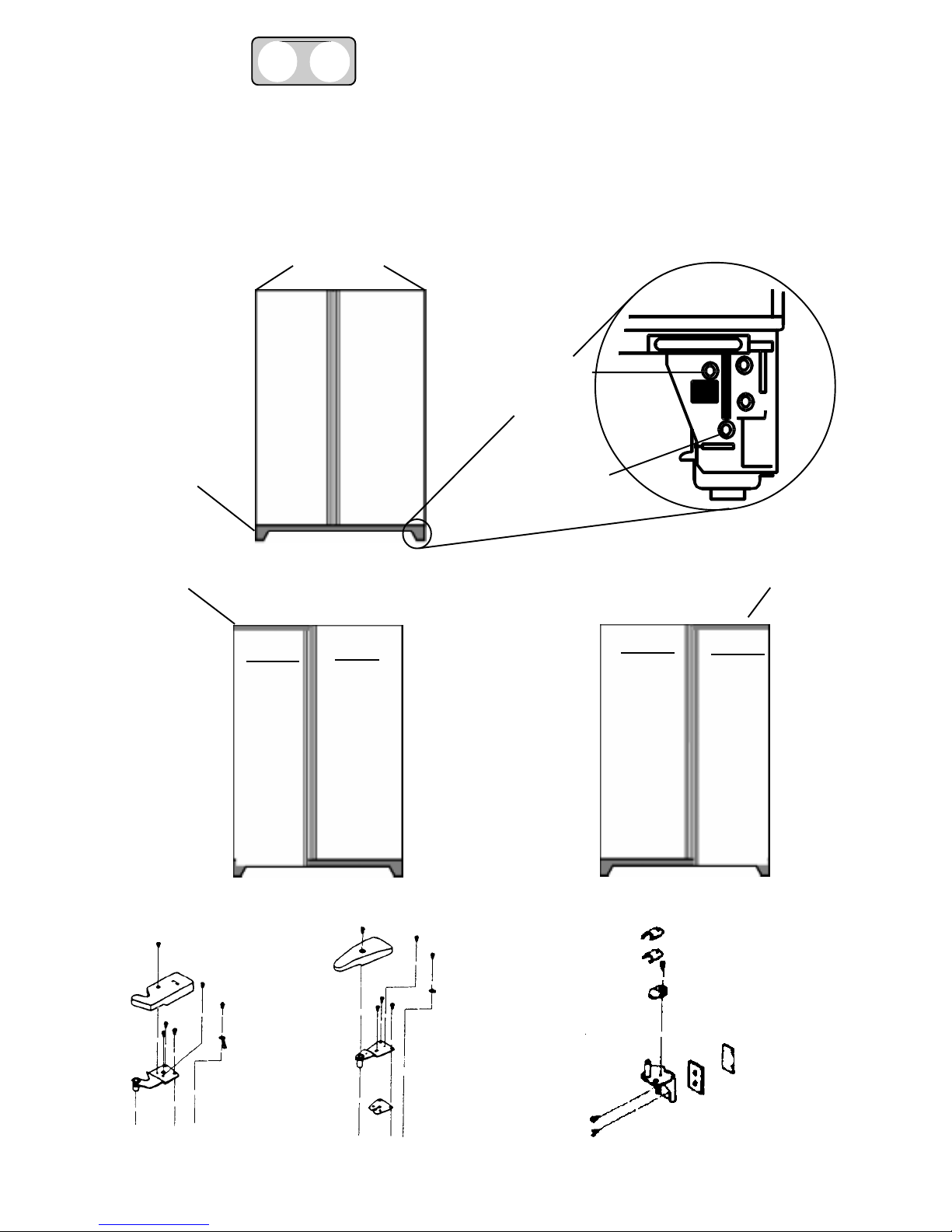

LEVELING THE UNIT AND ALIGNING THE DOORS

Top Hinge

Locations

▲

▲

Fig. 1

Toe Grille

Location

Door T oo

Low

Fig. 2

▲

▲

▲

▲

Rear Roller

Adjustment

Screw

Front Roller

Adjustment

Screw

Fig. 3

▲

▲

▲

▲

Door T oo

▲

Low

Hinge

Cover

Top

Hinge

Fig. 4

Shim

Shim

Shim

Door Closer

Bottom

Hinge

3

Shim

Shim

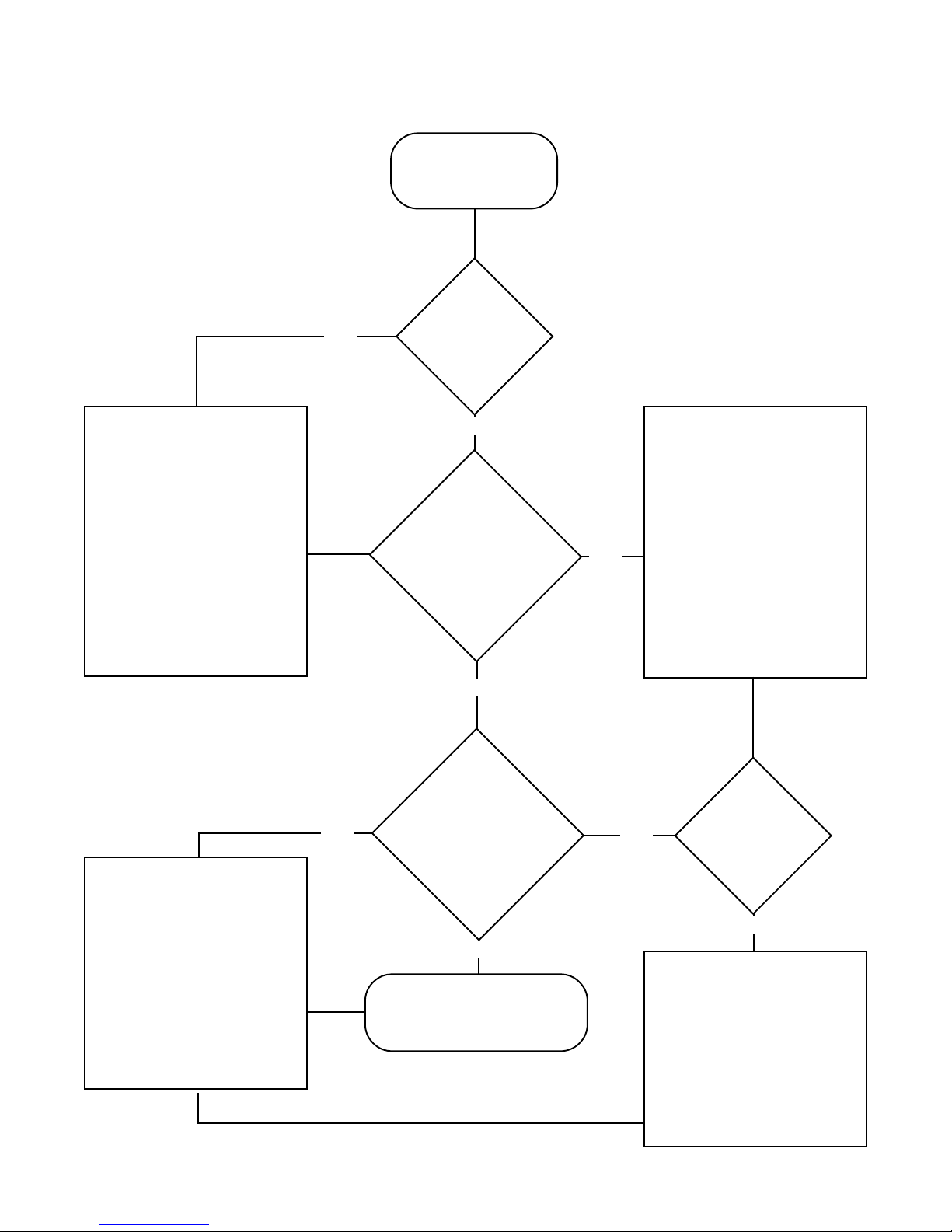

ALIGNMENT AND LEVELING PROCEDURES FLOW CHART

Slide Unit

into

Final Location.

▲

Is

NO

Unit

Stable?

▲

1. Remove toe grille by

pulling forward at

each end.

2. Turn roller adjustment screw(s) clockwise until unit is

firmly on all

roller(s). (

3. If unit is not stable

due to uneven flooring, use shims under

rear roller(s).

Fig. 6

)

▲

1. Remove top hinge

cover. Loosen top

hinge screws. (

2. Adjust both doors so

tops are aligned and

gap is consistent

from top to bottom.

3. Tighten top hinge

screws and replace

the covers.

Fig. 9

▲

▲

YES

▲

Are Tops of Doors

Aligned with Each

Other?

(Fig. 7)

YES

NO

1. Remove toe grille by

pulling forward at

each end.

2. Turn roller adjustment screw for the

▲

door that is lower

clockwise.

3. Open and close both

doors to confirm

doors are aligned.

4. Repeat until doors

are aligned.

▲

▲

Is Center Gap

NO

)

▲

Consistent from

Top to

Bottom?

(

Fig. 8

)

YES

▲

Replace T oe Grille.

▲

YES

1. Turn roller adjustment screw(s) counterclockwise until

unit is firmly on all

rollers.

2. If unit is not stable

due to uneven flooring, use shims under

rear rollers.

Is

Unit

Stable?

NO

▲

4

>

>

View Section 3 of the Video Tape

SECTION 3

THEORY OF OPERATIONTHEORY OF OPERATION

THEORY OF OPERATION

THEORY OF OPERATIONTHEORY OF OPERATION

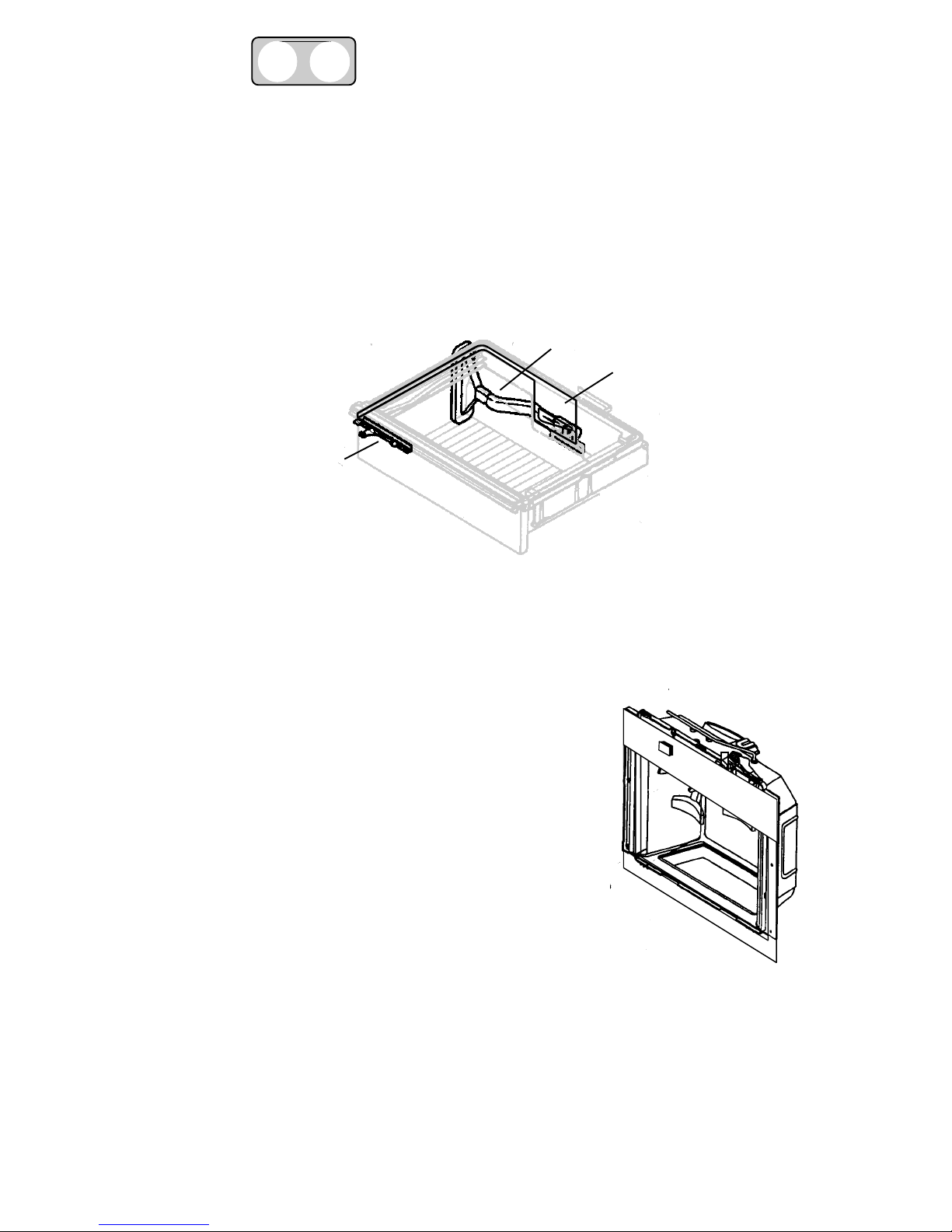

TEMPERATURE CONTROLLED MEAT LOCKER

The 26" deep side-by-side refrigerator/freezer is equipped with a chilled meat locker which will keep

the contents of the drawer approximately 5°F colder than the rest of the refrigerator section.

A slide on the front of the drawer operates a damper which directly controls the amount of freezer air

drawn into the drawer through an air duct.

AIR

DUCT

(Fig. 5)

▲

DAMPER

▲

▲

Fig. 5

SLIDE

CONTROL

ICE AND WATER DISPENSER

For ice and water dispensing, a plumbing connection must be made between the household water

supply and the dual solenoid valve mounted on the rear cabinet rail.

Ice dispensing operates as follows:

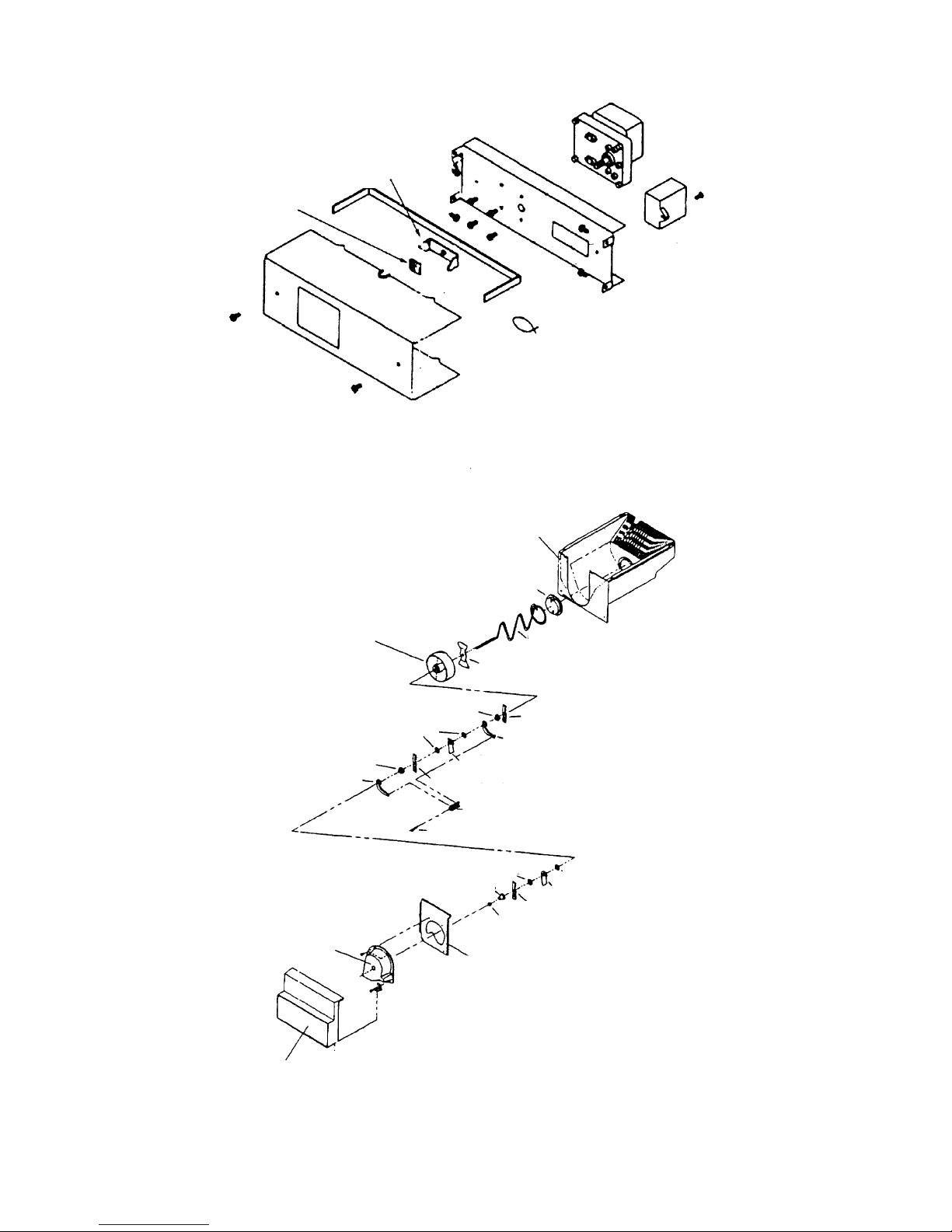

1. The automatic ice maker is mounted on the

back wall of the freezer liner. Water automatically

fills the mold, freezes into ice and dumps ice into the

the storage bin.

2. When the storage bin is full, a shut-off arm prevents

additional ice production until ice has been removed,

which lowers the shut-off arm. The storage bin will hold

approximately 8 pounds of ice. A motor driven helix is

mounted near the bottom of the storage bin.

When energized, the helix moves the ice to the front of

the storage bin where ice is directed into a lift wheel

mechanism.

3. In cube mode, the helix turns ice lift wheel counter-clockwise.

Ice bypasses the crusher blades and is dispensed into a glass.

4. In crushed mode, the helix turns clockwise forcing the ice into the crusher blades. Crushed ice

pieces will vary in size and shape.

5. Keep bits of ice from being sprayed beyond glass by placing a glass with a large opening close to

the ice chute.

(Fig. 8)

(Fig. 7)

Fig. 6

5

A UGER MOTOR

ASSEMBLY

LOCKING NUT

AUGER MOTOR

COVER

AUGER MOTOR

DRIVER

CAPACITOR

AUGER MOTOR

SUPPORT

Fig. 7

ICE BUCKET

ASSEMBLY

STEPPED WASHER

STATIC BLADE

BLADE COVER

CRUSHED ICE LIFT

WHEEL

STEPPED WASHER

WAVED WASHERS

WAVED WASHER

STEPPED WASHER

ICE BUCKET

HELIX CAP

ICE AGITATOR

CRUSHED ICE BAR

ROTATING BLADE

STATIC BLADE

ICE DAMPER

ROTATING BLADE

BLADE ANCHOR

ROLL PIN

WAVED WASHER

ICE DAMPER

ROTATING BLADE

LOCKING NUT

ICE CRUSHER FRONT

CRUSHED ICE BUCKET

FRONT

Fig. 8

6

6. Dispense ice by holding glass against ice lever ar m. The mechanically operated ice chute door

opens, and the motor driven helix is energized and ice is automatically dispensed into glass.

When glass is withdrawn, a delay mechanism slowly closes the ice chute door.

! WARNING

▲

To avoid risk of personal Injury or property damage, refrig erator must be

unplugged and ice storage bin must be removed before attempting to service

dispenser system. Never put fing ers, hands, or foreign objects Into Ice dispenser

opening while attempting to manually clear stalls or jams. Never use sharp

objects to break Ice. In case of stall or jam in cube or crushed mode, dispense in

opposite mode several times. There may be a delay when switching between

cube and crushed ice. This is normal. It takes a few seconds for cubes to be

moved from storage bin.

7. Sometimes a mound of “snow” will form on the door and/or ice chute. This condition is normal and

usually occurs with the repeated dispensing of crushed ice. “Snow” will eventually evaporate or

moisture can be wiped dry.

8. If the dispenser bar is held for long periods, the dispenser motor shuts off automatically after 2 to

3 minutes to prev ent ov erload. The motor resets automatically after 3 minutes and ice dispensing

can continue.

9. Use only ice from internal automatic ice maker. Do not add purchased ice cubes or cubes made

in any other manner. Dispenser operates only with cubes of proper size and shape.

10. Allow 12 hours after installation before first harvest of ice. Time required depends on freezer

temperature and amounts of food in freezer and refrigerator compartments.

11. The storage bin fills in three to four days depending on frequency of use. Two to 4 pounds of ice

will be made in a 24-hour period with a 0°F to 2°F freezer food temperature.

12. To temporarily meet demands for increased ice production, turn freezer control to colder setting.

Return freezer control to normal setting as soon as possible.

Water dispenser operates as f ollows:

1. The reservoir is located in the refrigerator section directly behind the crisper drawers. The reservoir

inlet tube comes from a solenoid valve mounted on the rear cabinet rail.

2. The reservoir holds approximately 40 ounces of water.

3. The outlet tube exits through the refrigerator floor and travels through a conduit foamed into the

cabinet bottom to a location just short of the freezer door bottom hinge. 5/16 inch tube is reduced

to 1/4 inch by means of a coupling. The tube enters the freezer door through the center of the

hinge pin and runs up the left flange of the door and crosses over the top of the cavity behind the

water dispensing lever.

following glasses, since the water tube leading to the dispenser from the water reser voir is not

refrigerated.

(Fig. 9)

NOTE: The first glass of water will be somewhat warmer than

4. The reservoir is filled by holding a glass against water the lever arm until water flo ws into a glass .

5. If household plumbing has been disturbed, thoroughly flush the water system. This will help

remove foreign materials in the water and also flush plumbing in refrigerator.

7

Loading...

Loading...