Whirlpool CHW9900VQ1, CHW9900VQ0 Installation Guide

WASHERINSTALLATIONINSTRUCTIONS

Commercial Automatic Washer

Laveuse Automatique

Table of Contents

WASHER SAFETY .............................................................. 1

INSTALLATION REOUIREMENTS ..................................... 2

Tools and Parts ................................................................ 2

Options ............................................................................ 3

Location Requirements ................................................... 3

Drain System ................................................................... 4

Electrical Requirements ................................................... 4

INSTALLATION INSTRUCTIONS ....................................... 5

Remove Transport System .............................................. 5

Connect the Inlet Hoses .................................................. 5

Route the Drain Hose ...................................................... 6

Secure the Drain Hose .................................................... 7

Level the Washer ............................................................. 7

Complete Installation ....................................................... 7

SETUP INSTRUCTIONS .................................................... 8

General User Information ................................................ 8

Control Setup Procedures ............................................... 8

Start Operating Setup ..................................................... 9

Washer Diagnostic Mode .............................................. 12

CLEANING YOUR WASHER ............................................ 13

Water Inlet Hoses .......................................................... 13

ASSISTANCE OR SERVICE ............................................. 14

Accessories ................................................................... 14

WARRANTY ...................................................................... 15

Table des Mati@es

SECURITE DE LA LAVEUSE ........................................... 16

EXIGENCES D'INSTALLATION ....................................... 17

Outillage et pi_ces ......................................................... 17

Options .......................................................................... 17

Exigences d' emplacement ............................................ 17

Syst_me de vidange ...................................................... 18

Sp6cifications 61ectriques ............................................. 19

INSTRUCTIONS D'INSTALLATION ................................. 19

D6pose du syst_me de transport .................................. 19

Raccordement des tuyaux d'alimentation ..................... 20

Acheminement du tuyau de vidange ............................. 21

Immobilisation du tuyau de vidange ............................. 21

R6glage de I'aplomb de la laveuse ............................... 21

Achever I'installation ..................................................... 22

INSTRUCTIONS DE CONFIGURATION .......................... 22

Information g6n6rale pour I'utilisateur ........................... 22

Proc6dures de r6glage des syst_mes de commande...23

Param6trage pour mise en marche ............................... 24

Mode de diagnostic de la laveuse ................................. 26

NETTOYAGE DE LA LAVEUSE ........................................ 27

Tuyaux d'arriv6e d'eau .................................................. 28

ASSISTANCE OU SERVICE ............................................. 29

Accessoires ................................................................... 29

GARANTIE ........................................................................ 30

WASHERSAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

W10179179A

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using the washer, follow basic

precautions, including the following:

[] Read all instructions before using the washer.

[] Do not wash articles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry-cleaning solvents, other flammable,

or explosive substances as they give off vapors

that could ignite or explode.

[] Do not add gasoline, dry-cleaning solvents, or

other flammable, or explosive substances to the

wash water. These substances give off vapors

that could ignite or explode.

[] Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for 2 weeks or more. HYDROGEN GAS IS

EXPLOSIVE. If the hot water system has not

been used for such a period, before using the

washing machine, turn on all hot water faucets

and let the water flow from each for several

minutes. This will release any accumulated

hydrogen gas. As the gas is flammable, do not

smoke or use an open flame during this time.

SAVE THESE INSTRUCTIONS

Do not allow children to play on or in the washer. Close

supervision of children is necessary when the washer is

used near children.

Before the washer is removed from service or discarded,

remove the door or lid.

[] Do not reach into the washer if the drum, tub or agitator

is moving.

[] Do not install or store the washer where it will be

exposed to the weather.

[] Do not tamper with controls.

[] Do not repair or replace any part of the washer or

attempt any servicing unless specifically recommended

in this manual or in published user-repair instructions

that you understand and have the skills to carry out.

[] See "Electrical Requirements" for grounding instructions.

INSTALLATIONREQUIREMENTS

Parts supplied for PD Models:

[] Service door lock cam

Gather the required tools and parts before starting installation.

The parts supplied are in the washer drum.

Tools needed for connecting the water inlet hoses

[] Pliers (that open to [] Flashlight (optional) [] Screws (2)

19A6"[39.5 mm]) Alternate Parts

Tools needed for installation

[] Open end wrenches

14 mm and 13 mm

[] Level

Parts supplied

A B

E

[] Wood block

[] Ruler or measuring tape

c D

A. U-shaped hose form

B. Water inlet hoses (2)

C. Inlet hose washers (4)

D. Transit bolt hole plug (4)

E. Beaded tie strap

Parts supplied for PR Models:

[] Card reader bezel

[] Card reader wire harness

Your installation may require additional parts. If you are

interested in purchasing one of the items listed here, call the toll-

free number in the "Assistance or Service" section.

If you have You will need to buy

Laundry tub or standpipe Sump pump system (if not already

taller than 96" (2.4 m) available)

Overhead sewer

Floor drain Siphon break,Part Number

Drainhose too short 4 ft (1.2 m) drain hose extension

Water faucets beyond 2 longer water fill hoses:

reachof fill hoses 6 ft (1.8 m) Part Number 76314

Standard 20 gal. (76 L),

30" (76.2 cm) tall drain tub or utility

sink and sump pump (available

from local plumbing suppliers)

285834; additional drain hose,

Part Number 8318155; and

connector kit, Part Number 285835

kit, Part Number285863

10 ft (3.0 m) Part Number 350008

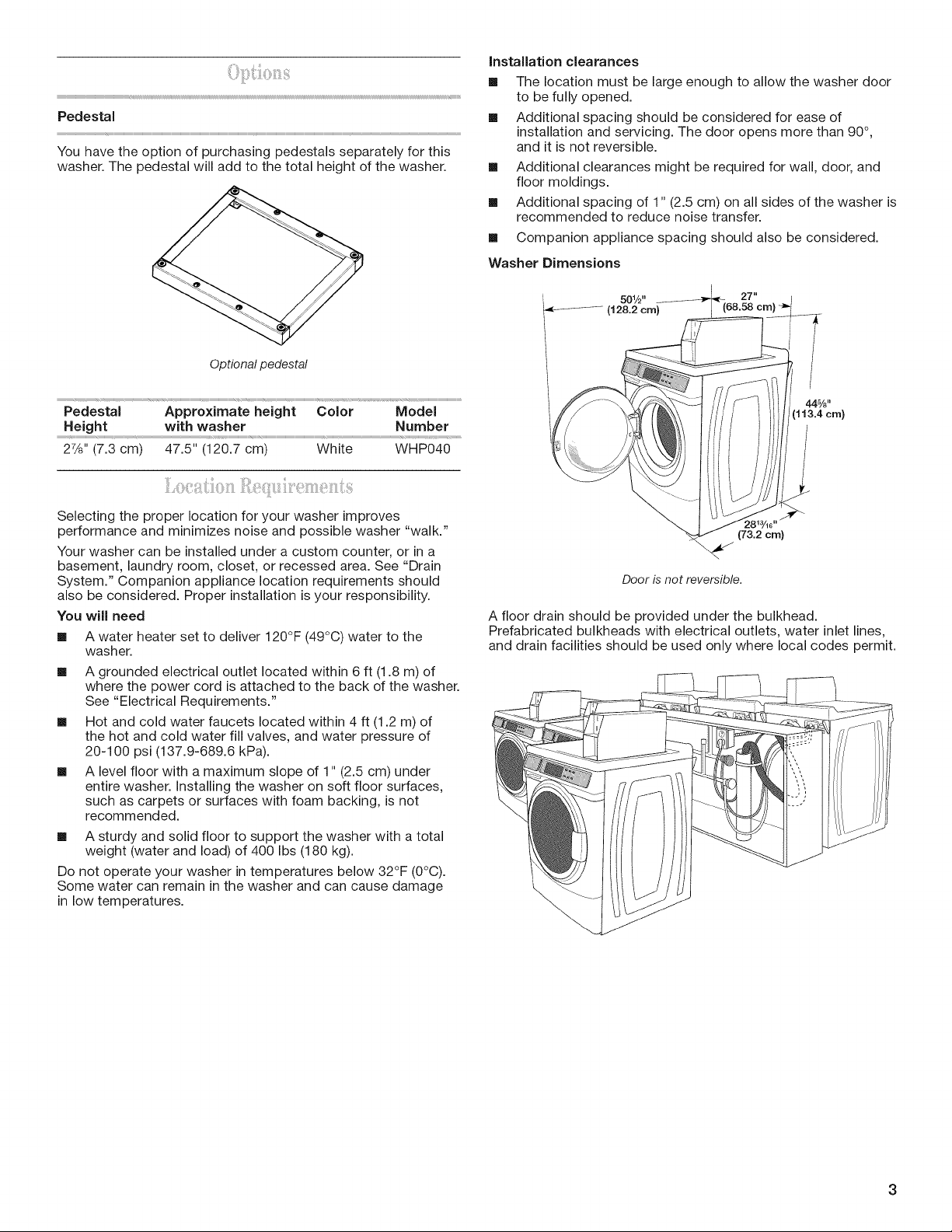

Pedestal

You have the option of purchasing pedestals separately for this

washer. The pedestal will add to the total height of the washer.

Installation clearances

[] The location must be large enough to allow the washer door

to be fully opened.

[] Additional spacing should be considered for ease of

installation and servicing. The door opens more than 90°,

and it is not reversible.

[] Additional clearances might be required for wall, door, and

floor moldings.

[] Additional spacing of 1" (2.5 cm) on all sides of the washer is

recommended to reduce noise transfer.

[]

Companion appliance spacing should also be considered.

Washer Dimensions

501/2" 27"

Optional pedestal

Pedestal Approximate height Color Model

Height with washer Number

22/8'' (7.3 cm) 47.5" (120.7 cm) White WHP040

Selecting the proper location for your washer improves

performance and minimizes noise and possible washer "walk."

Your washer can be installed under a custom counter, or in a

basement, laundry room, closet, or recessed area. See "Drain

System." Companion appliance location requirements should

also be considered. Proper installation is your responsibility.

You will need

[] A water heater set to deliver 120°F (49°C) water to the

washer.

[] A grounded electrical outlet located within 6 ft (1.8 m) of

where the power cord is attached to the back of the washer.

See "Electrical Requirements."

[] Hot and cold water faucets located within 4 ft (1.2 m) of

the hot and cold water fill valves, and water pressure of

20-100 psi (137.9-689.6 kPa).

[] A level floor with a maximum slope of 1" (2.5 cm) under

entire washer. Installing the washer on soft floor surfaces,

such as carpets or surfaces with foam backing, is not

recommended.

[] A sturdy and solid floor to support the washer with a total

weight (water and load) of 400 Ibs (180 kg).

Do not operate your washer in temperatures below 32°F (0°C).

Some water can remain in the washer and can cause damage

in low temperatures.

/

44%"

1113.4 cm}

(73.2 cm)

Door is not reversible.

A floor drain should be provided under the bulkhead.

Prefabricated bulkheads with electrical outlets, water inlet lines,

and drain facilities should be used only where local codes permit.

3

The washer can be installed using the standpipe drain system

(floor or wall), the laundry tub drain system, or the floor drain

system. Select the drain hose installation method you need.

See "Tools and Parts."

Standpipe drain system - wall or floor (views A & B)

The standpipe drain requires a minimum diameter standpipe of

2" (5.0 cm). The minimum carry-away capacity can be no less

than 17 gal. (64 L) per minute.

The top of the standpipe must be at least 30" (76.2 cm) high and

no higher than 96" (2.4 m) from the bottom of the washer.

A B

Laundry tub drain system (view C}

The laundry tub needs a minimum 20 gal. (76 L) capacity.

The top of the laundry tub must be at least 30" (76.2 cm)

above the floor.

Floor drain system (view D}

The floor drain system requires a siphon break that may be

purchased separately. See "Tools and Parts."

The siphon break must be a minimum of 28" (71.0 cm) from

the bottom of the washer. Additional hoses might be needed.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter,

Do not use an extension cord,

Failure to follow these instructions can result in death,

fire, or electrical shock.

[] A 120 volt, 60 Hz., AC only, 15- or 20-amp, fused electrical

supply is required. A time-delay fuse or circuit breaker is

recommended. It is recommended that a separate circuit

serving only this appliance be provided.

[] This washer is equipped with a power supply cord having a

3 prong grounding plug.

[] To minimize possible shock hazard, the cord must be

plugged into a mating, 3 prong, grounding-type outlet,

grounded in accordance with local codes and ordinances.

If a mating outlet is not available, it is the personal

responsibility and obligation of the customer to have the

properly grounded outlet installed by a qualified electrician.

[] If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

[] Do not ground to a gas pipe.

[] Check with a qualified electrician if you are not sure the

washer is properly grounded.

[] Do not have a fuse in the neutral or ground circuit.

C D

GROUNDING INSTRUCTIONS

For a grounded, cord-connected washer:

This washer must be grounded. In the event of a malfunction

or breakdown, grounding will reduce the risk of electrical

shock by providing a path of least resistance for electric

current. This washer is equipped with a cord having an

equipment-grounding conductor and a grounding plug. The

plug must be plugged into an appropriate outlet that is

properly installed and grounded in accordance with all local

codes and ordinances.

3=

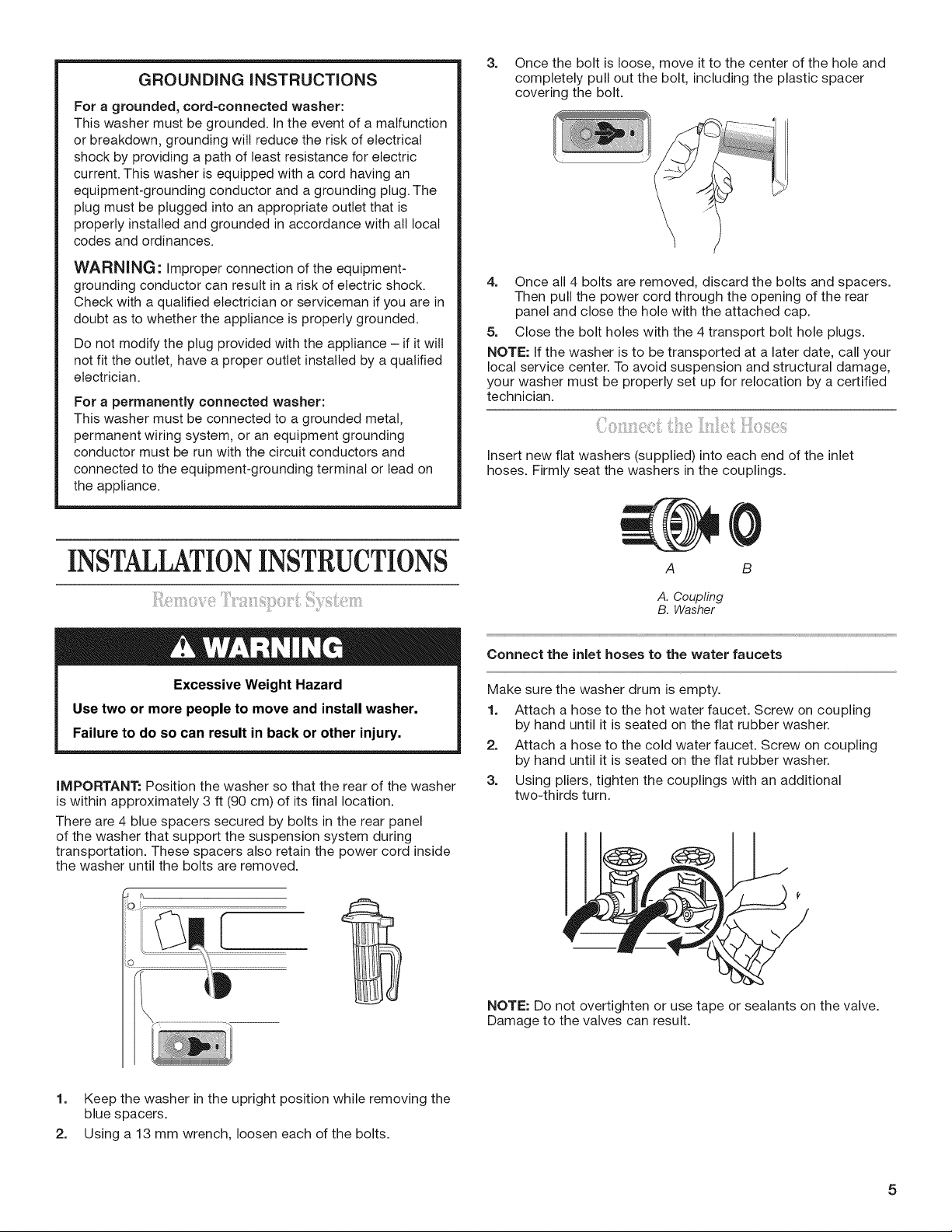

Once the bolt is loose, move it to the center of the hole and

completely pull out the bolt, including the plastic spacer

covering the bolt.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or serviceman if you are in

doubt as to whether the appliance is properly grounded.

Do not modify the plug provided with the appliance - if it wilt

not fit the outlet, have a proper outlet installed by a qualified

electrician.

For a permanently connected washer:

This washer must be connected to a grounded metal,

permanent wiring system, or an equipment grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead on

the appliance.

INSTALLATIONINSTRUCTIONS

Excessive Weight Hazard

Use two or more people to move and install washer.

Failure to do so can result in back or other injury.

IMPORTANT: Position the washer so that the rear of the washer

is within approximately 3 ft (90 cm) of its final location.

There are 4 blue spacers secured by bolts in the rear panel

of the washer that support the suspension system during

transportation. These spacers also retain the power cord inside

the washer until the bolts are removed.

4. Once all 4 bolts are removed, discard the bolts and spacers.

Then pull the power cord through the opening of the rear

panel and close the hole with the attached cap.

5. Close the bolt holes with the 4 transport bolt hole plugs.

NOTE: If the washer is to be transported at a later date, call your

local service center. To avoid suspension and structural damage,

your washer must be properly set up for relocation by a certified

technician.

Insert new flat washers (supplied) into each end of the inlet

hoses. Firmly seat the washers in the couplings.

A B

A. Coupling

B. Washer

Connect the inlet hoses to the water faucets

Make sure the washer drum is empty.

1. Attach a hose to the hot water faucet. Screw on coupling

by hand until it is seated on the flat rubber washer.

2. Attach a hose to the cold water faucet. Screw on coupling

by hand until it is seated on the flat rubber washer.

3. Using pliers, tighten the couplings with an additional

two-thirds turn.

1. Keep the washer in the upright position while removing the

blue spacers.

2. Using a 13 mm wrench, loosen each of the bolts.

NOTE: Do not overtighten or use tape or sealants on the valve.

Damage to the valves can result.

5

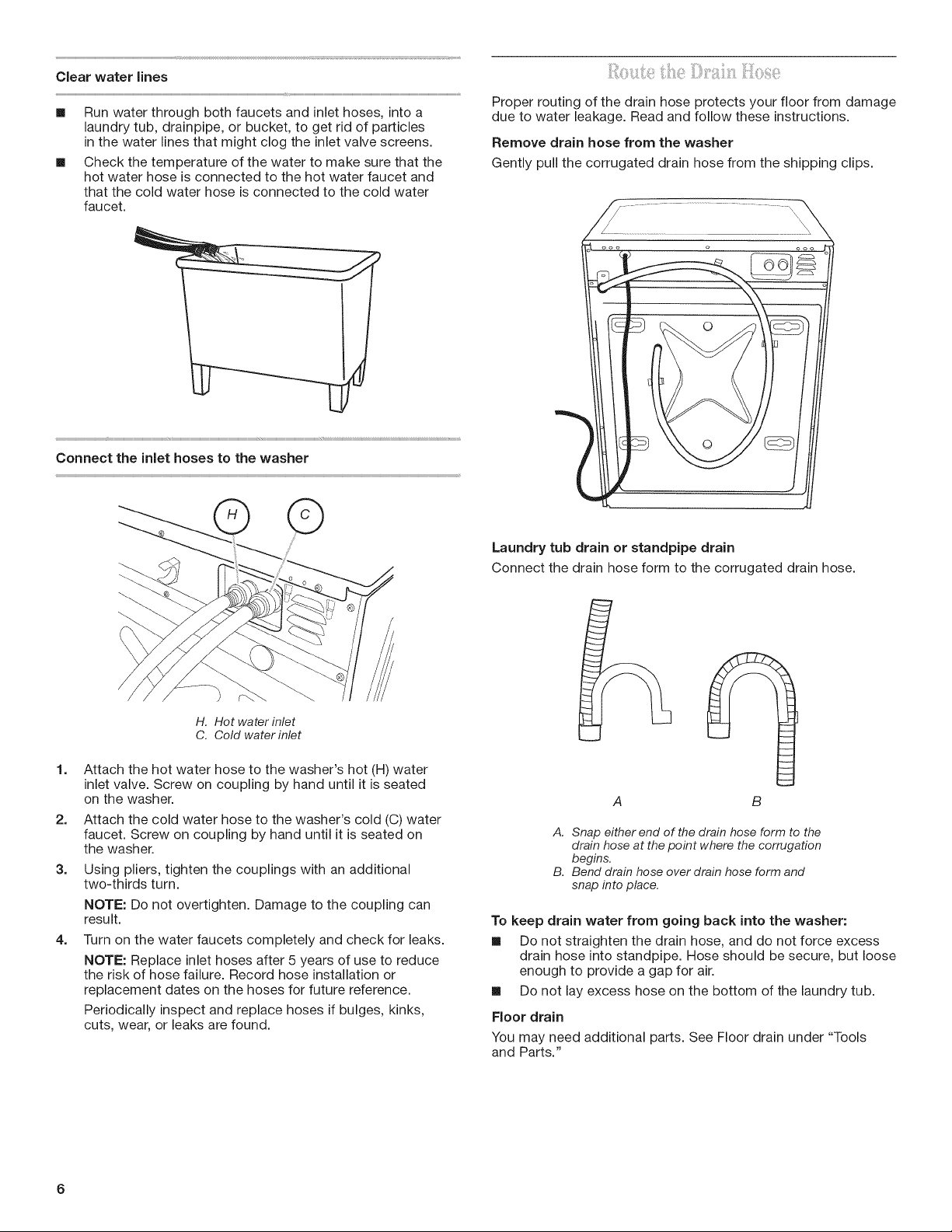

Clear water lines

[] Run water through both faucets and inlet hoses, into a

laundry tub, drainpipe, or bucket, to get rid of particles

in the water lines that might clog the inlet valve screens.

[] Check the temperature of the water to make sure that the

hot water hose is connected to the hot water faucet and

that the cold water hose is connected to the cold water

faucet.

Proper routing of the drain hose protects your floor from damage

due to water leakage. Read and follow these instructions.

Remove drain hose from the washer

Gently pull the corrugated drain hose from the shipping clips.

Laundry tub drain or standpipe drain

Connect the drain hose form to the corrugated drain hose.

H. Hot water inlet

C. Cold water inlet

1=

Attach the hot water hose to the washer's hot (H) water

inlet valve. Screw on coupling by hand until it is seated

on the washer.

2=

Attach the cold water hose to the washer's cold (C) water

faucet. Screw on coupling by hand until it is seated on

the washer.

3=

Using pliers, tighten the couplings with an additional

two-thirds turn.

NOTE: Do not overtighten. Damage to the coupling can

result.

4=

Turn on the water faucets completely and check for leaks.

NOTE: Replace inlet hoses after 5 years of use to reduce

the risk of hose failure. Record hose installation or

replacement dates on the hoses for future reference.

Periodically inspect and replace hoses if bulges, kinks,

cuts, wear, or leaks are found.

B

A. Snap either end of the drain hose form to the

drain hose at the point where the corrugation

begins.

B. Bend drain hose over drain hose form and

snap into place.

To keep drain water from going back into the washer:

[] Do not straighten the drain hose, and do not force excess

drain hose into standpipe. Hose should be secure, but loose

enough to provide a gap for air.

[] Do not lay excess hose on the bottom of the laundry tub.

Floor drain

You may need additional parts. See Floor drain under "Tools

and Parts."

1.

Drape the power cord over the washer top.

2.

Move the washer to its final location.

3.

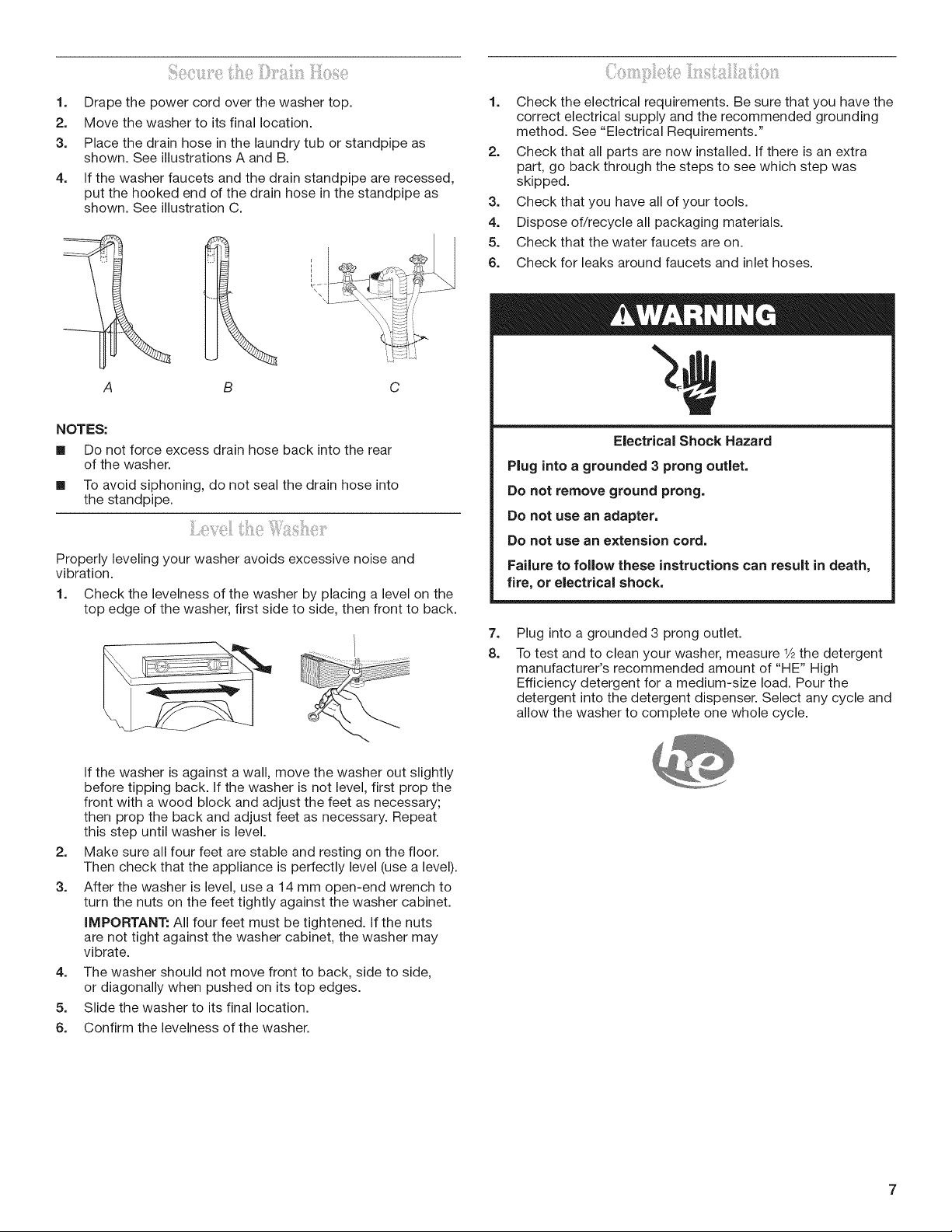

Place the drain hose in the laundry tub or standpipe as

shown. See illustrations A and B.

4.

If the washer faucets and the drain standpipe are recessed,

put the hooked end of the drain hose in the standpipe as

shown. See illustration C.

!:I

A B C

1.

Check the electrical requirements. Be sure that you have the

correct electrical supply and the recommended grounding

method. See "Electrical Requirements."

2.

Check that all parts are now installed, if there is an extra

part, go back through the steps to see which step was

skipped.

3.

Check that you have all of your tools.

4.

Dispose of/recycle all packaging materials.

5.

Check that the water faucets are on.

6.

Check for leaks around faucets and inlet hoses.

NOTES:

[] Do not force excess drain hose back into the rear

of the washer.

[] To avoid siphoning, do not seal the drain hose into

the standpipe.

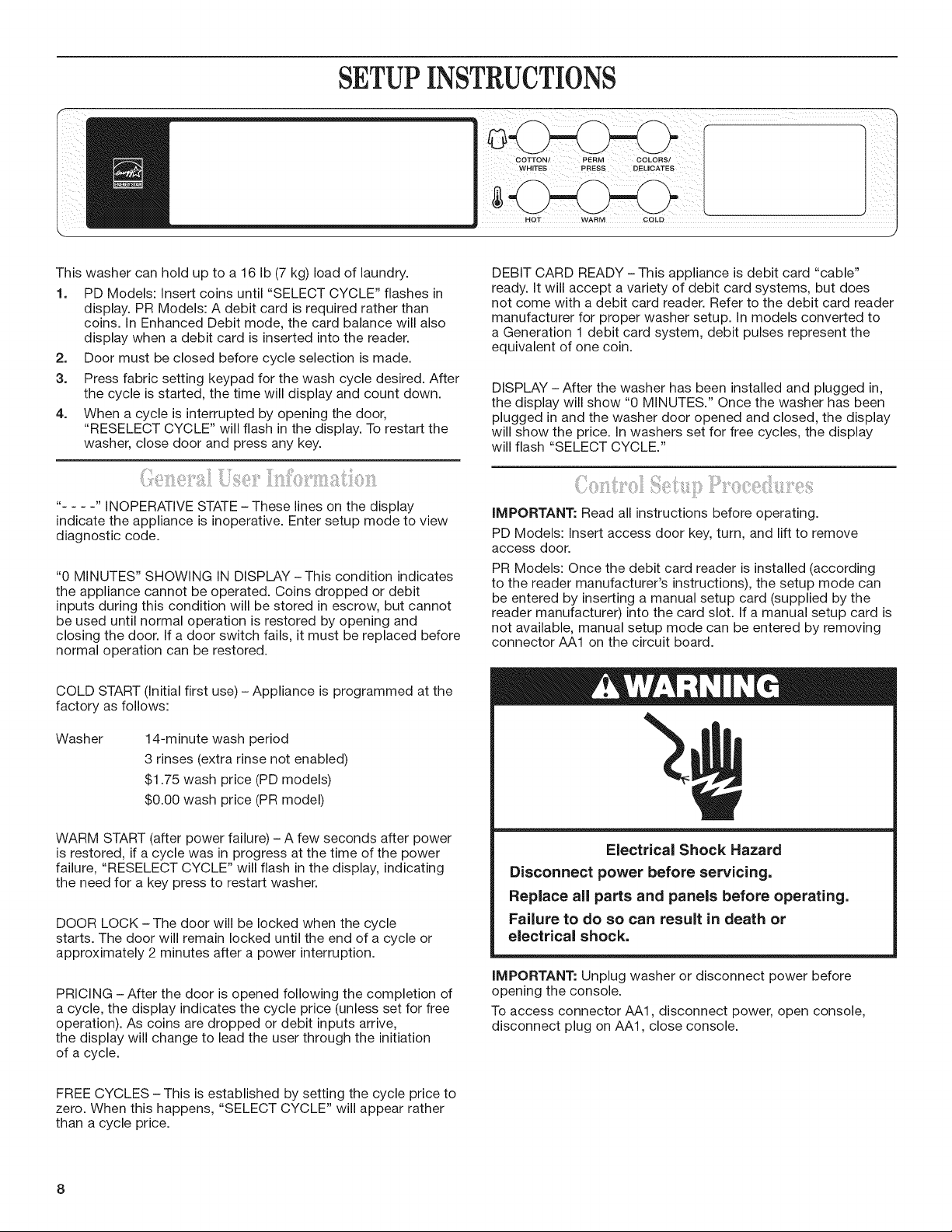

Properly leveling your washer avoids excessive noise and

vibration.

1. Check the levelness of the washer by placing a level on the

top edge of the washer, first side to side, then front to back.

If the washer is against a wall, move the washer out slightly

before tipping back. If the washer is not level, first prop the

front with a wood block and adjust the feet as necessary;

then prop the back and adjust feet as necessary. Repeat

this step until washer is level.

2.

Make sure all four feet are stable and resting on the floor.

Then check that the appliance is perfectly level (use a level).

3.

After the washer is level, use a 14 mm open-end wrench to

turn the nuts on the feet tightly against the washer cabinet.

IMPORTANT: All four feet must be tightened. If the nuts

are not tight against the washer cabinet, the washer may

vibrate.

4.

The washer should not move front to back, side to side,

or diagonally when pushed on its top edges.

5.

Slide the washer to its final location.

6.

Confirm the levelness of the washer.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

7.

Plug into a grounded 3 prong outlet.

8.

To test and to clean your washer, measure 1/2the detergent

manufacturer's recommended amount of "HE" High

Efficiency detergent for a medium-size load. Pour the

detergent into the detergent dispenser. Select any cycle and

allow the washer to complete one whole cycle.

7

SETUPINSTRUCTIONS

This washer can hold up to a 16 Ib (7 kg) load of laundry.

1. PD Models: insert coins until "SELECT CYCLE" flashes in

display. PR Models: A debit card is required rather than

coins. In Enhanced Debit mode, the card balance will also

display when a debit card is inserted into the reader.

2. Door must be closed before cycle selection is made.

3. Press fabric setting keypad for the wash cycle desired. After

the cycle is started, the time will display and count down.

4. When a cycle is interrupted by opening the door,

"RESELECT CYCLE" will flash in the display. To restart the

washer, close door and press any key.

.... iNOPERATIVE STATE -These lines on the display

indicate the appliance is inoperative. Enter setup mode to view

diagnostic code.

"0 MINUTES" SHOWING IN DISPLAY- This condition indicates

the appliance cannot be operated. Coins dropped or debit

inputs during this condition will be stored in escrow, but cannot

be used until normal operation is restored by opening and

closing the door. If a door switch fails, it must be replaced before

normal operation can be restored.

COLD START (initial first use) - Appliance is programmed at the

factory as follows:

DEBIT CARD READY - This appliance is debit card "cable"

ready. It will accept a variety of debit card systems, but does

not come with a debit card reader. Refer to the debit card reader

manufacturer for proper washer setup. In models converted to

a Generation 1 debit card system, debit pulses represent the

equivalent of one coin.

DISPLAY - After the washer has been installed and plugged in,

the display will show "0 MINUTES." Once the washer has been

plugged in and the washer door opened and closed, the display

will show the price. In washers set for free cycles, the display

will flash "SELECT CYCLE."

IMPORTANT: Read all instructions before operating.

PD Models: Insert access door key, turn, and lift to remove

access door.

PR Models: Once the debit card reader is installed (according

to the reader manufacturer's instructions), the setup mode can

be entered by inserting a manual setup card (supplied by the

reader manufacturer) into the card slot. If a manual setup card is

not available, manual setup mode can be entered by removing

connector AA1 on the circuit board.

Washer

WARM START (after power failure) - A few seconds after power

is restored, if a cycle was in progress at the time of the power

failure, "RESELECT CYCLE" will flash in the display, indicating

the need for a key press to restart washer.

DOOR LOCK - The door will be locked when the cycle

starts. The door will remain locked until the end of a cycle or

approximately 2 minutes after a power interruption.

PRiCiNG -After the door is opened following the completion of

a cycle, the display indicates the cycle price (unless set for free

operation). As coins are dropped or debit inputs arrive,

the display will change to lead the user through the initiation

of a cycle.

FREE CYCLES - This is established by setting the cycle price to

zero. When this happens, "SELECT CYCLE" will appear rather

than a cycle price.

14-minute wash period

3 rinses (extra rinse not enabled)

$1.75 wash price (PD models)

$0.00 wash price (PR model)

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

FaUure to do so can result in death or

electrical shock.

iMPORTANT: Unplug washer or disconnect power before

opening the console.

To access connector AA1, disconnect power, open console,

disconnect plug on AA1, close console.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to fo{iow these instructions can result in death,

fire, or electrica{ shock.

Plug in washer or reconnect power. The washer is now in the

setup mode.

The temperature keypads and the digital display are used to set

up the controls.

The display can contain 4 numbers and/or letters and a decimal

point. These are used to indicate the setup codes and related

code values available for use in programming the appliance.

HOW TO USE THE KEYPADS TO PROGRAM

THE CONTROLS

1. The HOT keypad is used to adjust the values associated

with setup codes. Pressing the keypad will change the value

by increments. Rapid adjustment is possible by holding the

keypad down.

2. The WARM keypad will advance you through the setup

codes. Pressing the keypad will advance you to the

next available setup code. Holding the keypad down will

automatically advance through the setup codes at a rate

of one per second.

3. The COLD keypad is used to select or deselect options.

Before proceeding, it is worth noting that, despite all of the

options available, an owner can simply choose to un-crate a

new commercial washer, hook it up, plug it in, and have a unit

that operates.

Units are preset at the factory for a 14-minute wash period and

3 rinses (no extra rinse).

SETUP CODES

The WARM keypad will advance you from code to code. The

HOT keypad will change the code value. The COLD keypad will

select or deselect options.

FOR PR MODELS: The setup codes are the same as for the

"PD" model except where noted.

The setup code is indicated by the one or two left-hand

characters. The setup code value is indicated by the two or

three right-hand characters.

CODE EXPLANATION

607 6 REGULAR CYCLE PRICE

07 Represents the number of quarters (coin 1);

may adjust from 0-39. (See VALUE OF COIN 1.)

Advance from 0-39 by pressing HOT.

Currently set for 7 quarters = $1.75.

PR MODEL ONLY: Currently set for 0 quarters.

PS MODEL ONLY: Represents the number of

push-in actuations of the coin slide to start the

washer.

601 setting would represent one coin slide

actuation.

Press WARM keypad once to advance

to next code.

800 8 ADDITIONAL RINSE OPTION

This option is either SELECTED "ON" or NOT

SELECTED "OFR"

00 Not Selected "OFR"

Ar Selected "ON."

Press COLD keypad once for this selection.

Press WARM keypad once to advance

to next code.

900 9 CYCLE COUNTER OPTION

This option is either SELECTED "ON" or NOT

SELECTED "OFR"

00 Not Selected "OFR"

0C Selected "ON" and not able to be deselected.

Press COLD keypad 3 consecutive times to

select "ON." Once selected "ON" it cannot be

deselected.

Press WARM keypad once to advance

to next code.

This option is either SELECTED "ON" or NOT

SELECTED "OFR"

00 Not Selected "OFR"

0C Selected "ON."

Press COLD keypad 3 consecutive times to select

"ON" and 3 consecutive times to remove (Not

Selected "OFF"). Counter resets by going from

"OFF" to "ON."

Press WARM keypad once to advance

to next code.

CO Selected "ON" and not able to be deselected.

To select "ON" and not able to be deselected, first

select "ON," then within 2 seconds, press COLD

twice, HOT once, and exit setup mode.

2.00 2. SPECIAL PRICING OPTIONS

This option is either SELECTED "ON" or NOT

SELECTED "OFF."

00 Not Selected "OFR"

SP Selected "ON."

Press COLD keypad once for this selection.

If SPECIAL PRICING OPTION is selected, you have access

to codes 3.XX through 9.XX.

Press WARM keypad once to advance to next code.

9

Options to use if SPECIAL PRiCiNG is selected.

When exiting setup code "9.", it must show current day

of week.

3.07 3. SPECIAL CYCLE PRICE

07 Represents the number of quarters (coin 1);

may adjust from 0-39. (See VALUE OF COiN 1.)

Advance from 0-39 by pressing HOT.

Currently set for 7 quarters = $1.75

PR MODEL ONLY: Currently set for 0 quarters.

Press WARM keypad once to advance

to next code.

5.00 5. TIME-OF-DAY CLOCK, MINUTES

00 This is the TIME-OF-DAY CLOCK, minute setting;

select 0-59 minutes by pressing HOT keypad.

Press WARM keypad once to advance

Days of the week SPECIAL PRICE DAY

If selected, would show

10 Day 1 Sunday 1S

20 Day 2 Monday 2S

30 Day 3 Tuesday 3S

40 Day 4 Wednesday 4S

50 Day 5 Thursday 5S

60 Day 6 Friday 6S

70 Day 7 Saturday 7S

Press WARM keypad once to advance to next code.

to next code.

6.00 6. TIME-OF-DAY CLOCK, HOURS

(NOTE: Uses military time or 24 hr. clock)

00 This is the TIME-OF-DAY CLOCK, hour setting;

select 0-23 hours by pressing HOT keypad.

Press WARM keypad once to advance

:::::::::::::::::::::::::: _',_HHHH_HHHHHHHHHHHHHHHHHH_r_,_HHHHHHHHH_r,,,__HHHH_HHHHHHHHHHH_HHHHHHHHHHHHHH_r_HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH_

to next code.

7.00 7. SPECIAL PRICE START HOUR

(NOTE: Uses military time or 24 hr. clock)

........................................................................................................ r

00 This is the start hour; 0-23 hours. Select START

HOUR by pressing HOT keypad.

Press WARM keypad once to advance

r i r r r r r r r r r r_ ........................................................................................................................................................................

to next code.

8.00 8. SPECIAL PRICE STOP HOUR

(NOTE: Uses military time or 24 hr. clock)

00 This is the stop hour; 0-23 hours. Select STOP

HOUR by pressing HOT keypad.

Press WARM keypad once to advance

to next code.

9.10 9. SPECIAL PRICE DAY

10 This represents the day of the week and whether

special pricing is selected for that day. A number

followed by "0" indicates no selection that

particular day (9.10). A number followed by an "S"

indicates selected for that day (9.1S). To change

the value of "0" and "S," use the "COLD" key.

Days of the week (1-7) are selected by pressing

A.00 A. VAULT VIEWING OPTION

This option is either SELECTED "ON" or NOT

SELECTED "OFR"

O0 Not Selected "OFR"

SC SC Selected "ON."

Press COLD keypad once for this selection.

When selected, the money and/or cycle counts

will be viewable (if counting is selected), when

the coin box is removed. Press WARM keypad

once to advance to next code.

b.05 b. VALUE OF COIN 1

05 This represents the value of coin 1 in number of

nickels. 05 = $0.25.

By pressing HOT keypad you have the option of

1-199 nickels. PS MODEL ONLY: Represents the

total vend price in nickels.

Example: b.30 is equal to $1.50.

Press WARM keypad once to advance

to next code.

C.20 C. VALUE OF COIN 2

20 This represents the value of coin 2 in number of

nickels; 20 = $1.00.

PR MODEL ONLY: Currently set for $0.25.

By pressing HOT keypad you have the option of

1-199 nickels.

HOT keypad.

10

O0 Not Selected "OFR"

CS CS Selected "ON."

Press COLD keypad 3 consecutive times for

this selection. When coin slide mode is selected,

set b. equal to value of slide in nickels. Set

Step 6 (regular cycle price) and Step 3 (special

cycle price) to number of slide operations, if the

installer sets up "CS" on a coin drop model, it

will not register coins.

Press WARM keypad once to advance

to next code.

Loading...

Loading...