INSTALLATION INSTRUCTIONS

2-w

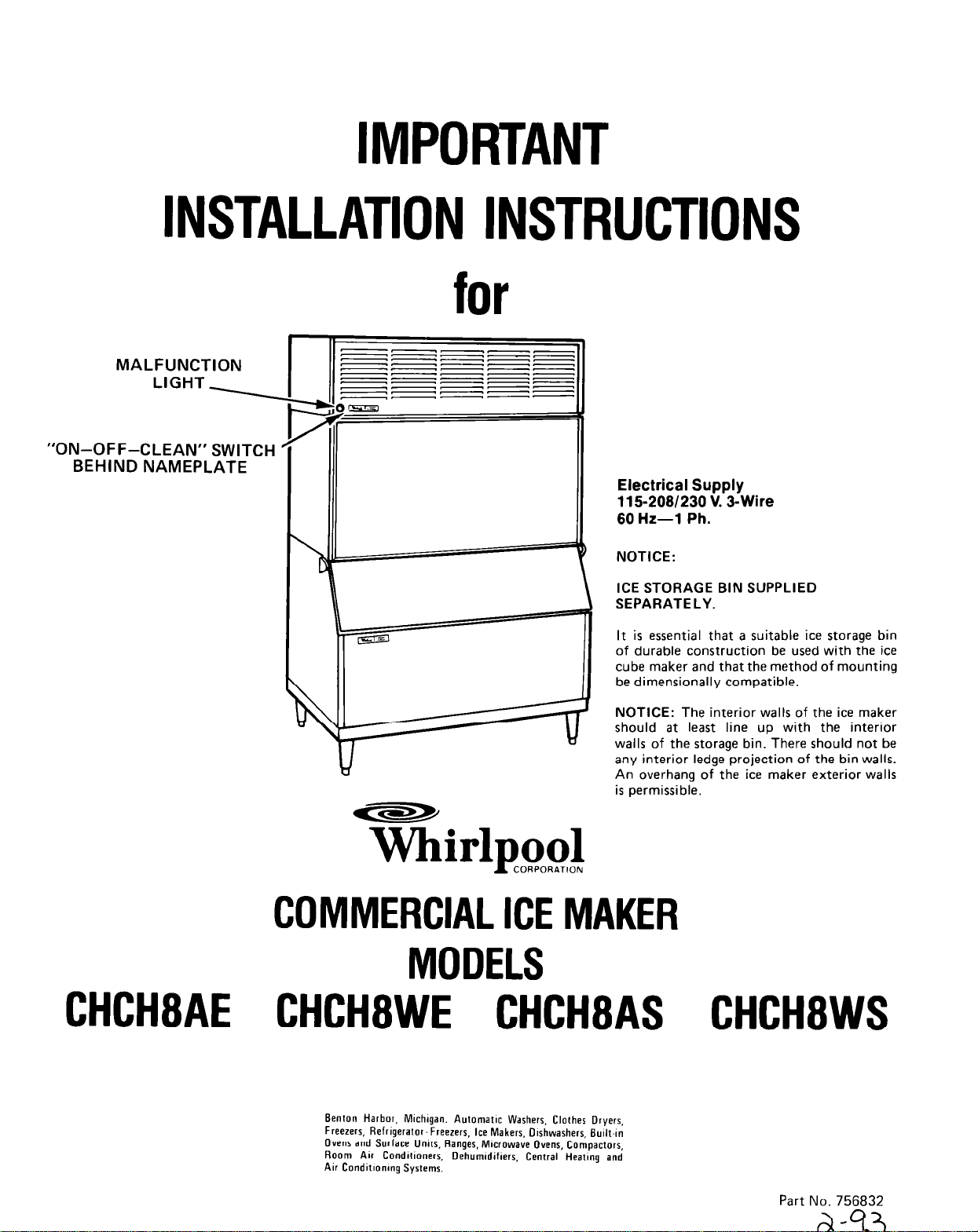

MALFUNCTION

LIGHT.

“ON-OFF-CLEAN” SWITCH

BEHIND NAMEPLATE

IMPORTANT

for

Electrical Supply

115208/230 V. 3-Wire

60

Hz-l Ph.

NOTICE:

ICE STORAGE BIN SUPPLIED

SEPARATELY.

It is essential that a suitable ice storage bin

of durable construction be used with the ice

cube maker and that the method of mounting

be dimensionally compatible.

NOTICE: The interior walls of the ice maker

should at least line up with the interior

walls of the storage bin. There should not be

any interior ledge projection of the bin walls.

An overhang of the ice maker exterior walls

is permissible.

Whirlpoo

CORPORATII

COMMERCIAL ICE MAKER

MODELS

CHCH8AE CHCH8WE CHCH8AS CHCH8WS

Benton Harbor, Mlchlgan. Auromatlc Washers, Clothes Dryers,

Freezers, Refrlgeralor-Freezers, Ice Makers. Dlshwasherr, Budt-ln

Ovens and Surface Umts, Ranges, Mwowave Ovens, Compactors,

Room AN Condltmners, Llehumldifwrs. Central Heatmg and

Air Conditmnmg Systems.

Part No. 756832

GENERAL INFORMATION

LOCATE

THIS UNIT MUST BE

INSTALLED IN AN

AREA PROTECTED FROM

THE ELEMENTS, SUCH

AS WIND, RAIN, WATER

SPRAY OR DRIP.

1. Unit must be at least 3” from back wall for air circulation. Adequate air circulation must be provided on top

and other sides for performance.

2. If air cooled ice maker is installed in a closed room, 1000

C.F.M. of air must be exchanged through the room to maintain the room air at 10’ F. warmer than the available

ambient air temperature.

3. The head may be installed on either a Whirlpool bin or

field-constructed bin. In either case, be sure the floor will

support the combined weight of the ice maker and the

stored ice cubes. (Approximately 300 Ibs. per leg, if using a

Whirlpool bin.)

4. Level bin before installing head. The ice maker head

must be level to insure proper water flow over the freezing

plates.

If height of ice maker exceeds 90” when installed on a

Whirlpool bin and bin expander a leg kit model CECK3

must be used for additional stability.

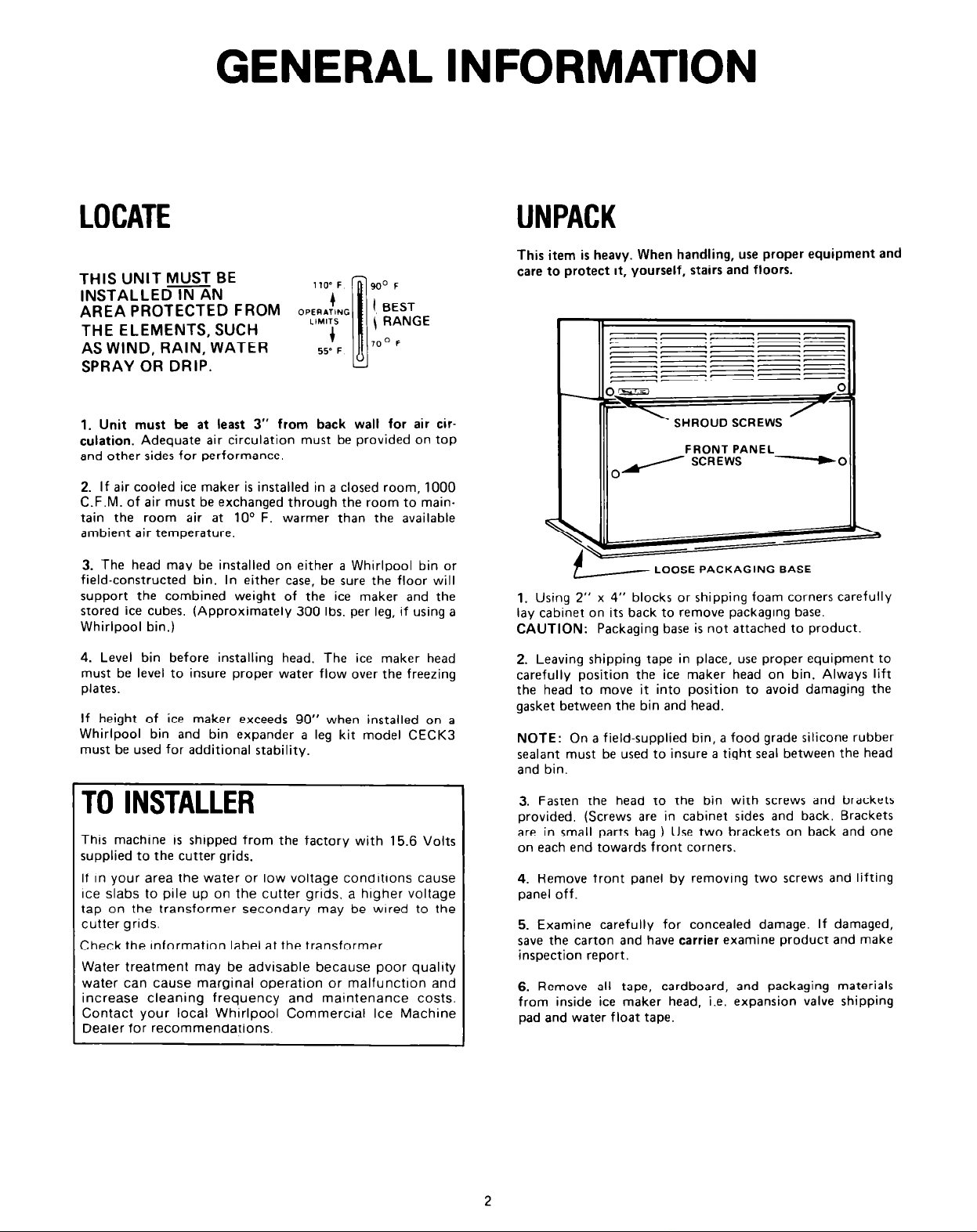

110” F

1

OPERATING

LIMITS

1

55” F

90’ F

1 BEST

\ RANGE

70’ F

UNPACK

This item is heavy. When handling, use proper equipment and

care to protect it, yourself, stairs and floors.

FRONT PANEL

OH SCREWS -O

r

1. Using 2” x 4” blocks or shipping foam corners carefully

lay cabinet on its back to remove packaging base.

CAUTION: Packaging base is not attached to product.

2. Leaving shipping tape in place, use proper equipment to

carefully position the ice maker head on bin. Always lift

the head to move it into position to avoid damaging the

gasket between the bin and head.

NOTE: On a field-supplied bin, a food grade silicone rubber

sealant must be used to insure a tight seal between the head

and bin.

LOOSE PACKAGING BASE

TO INSTALLER

This machine is shipped from the factory with 15.6 Volts

supplied to the cutter grids.

If In your area the water or low voltage conditions cause

Ice slabs to pile up on the cutter grids. a higher voltage

tap on the transformer secondary may be wired to the

cutter grids.

Check the Information label at the transformer.

Water treatment may be advisable because poor quality

water can cause marginal operation or malfunction and

increase cleaning frequency and maintenance costs.

Contact your local Whirlpool Commercial Ice Machine

Dealer for recommendations.

3. Fasten the head to the bin with screws and brackets

provided. (Screws are in cabinet sides and back. Brackets

are in small parts bag.) Use two brackets on back and one

on each end towards front corners.

4. Remove front panel by removing two screws and lifting

panel off.

5. Examine carefully for concealed damage. If damaged,

save the carton and have carrier examine product and make

inspection report.

6. Remove all tape, cardboard, and packaging materials

from inside ice maker head, i.e. expansion valve shipping

pad and water float tape.

2

FOR THE ELECTRICIAN

CONFORM TO ALL APPLICABLE CODES

It

IS

the personal responslbrlrty and oblrgatlon of the

cuslomer to contact a qualIfted installer to assure that the

electrtcal rnstallatron IS adequate and IS In conformance

with the National ElectrIcat Code and local codes and

ordrnances

NOTE:

time delay fuses.

REMOVE TOP SHROUD

1. Loosen screws on lower front corners of shroud.

A separate circuit must be used with 20 ampere

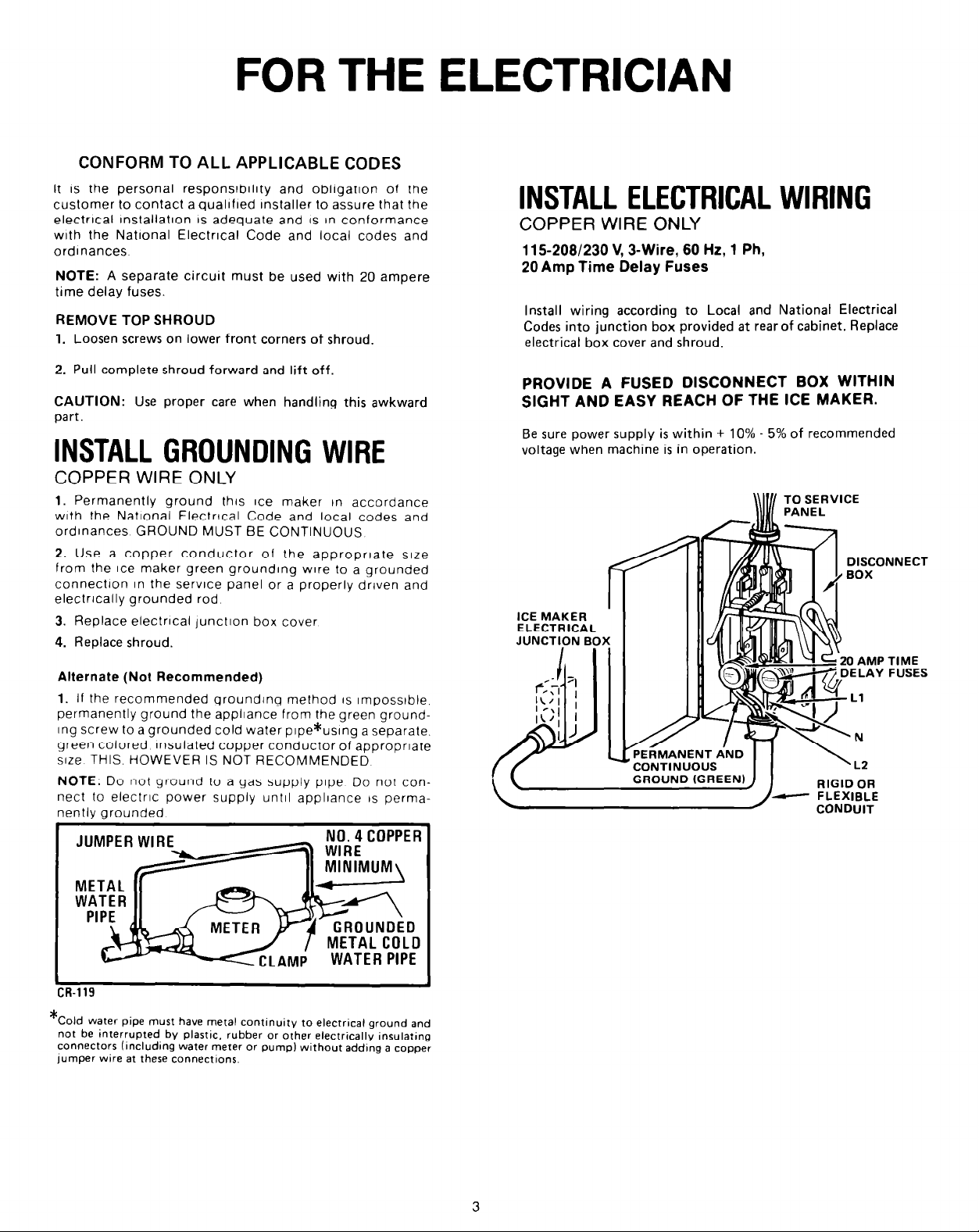

INSTALL ELECTRICAL WIRING

COPPER WIRE ONLY

115-2081230 V, 3-Wire, 60 Hz, 1 Ph,

20 Amp Time Delay Fuses

Install wiring according to Local and National Electrical

Codes into junction box provided at rear of cabinet. Replace

electrical box cover and shroud.

2. Pull complete shroud forward and lift off.

CAUTION: Use proper care when handling this awkward

part.

INSTALL GROUNDING WIRE

COPPER WIRE ONLY

1. Permanently ground this Ice maker In accordance

with the National ElectrIcal Code and local codes and

ordinances GROUND MUST BE CONTINUOUS

2. Use a copper conductor of the appropriate size

from the Ice maker green grounding wrre to a grounded

connectlon In the service panel or a properly driven and

electrlcally grounded rod

3. Replace electrical junction box cover

4. Replace shroud.

Alternate (Not Recommended)

1. If the recommended grounding method IS Impossible.

permanently ground the appliance from the green grounding screw to a grounded cold water plpe*usrng a separate.

green colored, insulated copper conductor of appropriate

size THIS. HOWEVER IS NOT RECOMMENDED

NOTE: Do not ground to a gas supply pipe Do not connect to electric power supply until applrance IS permanently grounded

PROVIDE A FUSED DISCONNECT BOX WITHIN

SIGHT AND EASY REACH OF THE ICE MAKER.

Be sure power supply is within + 10% - 5% of recommended

voltage when machine is in operation.

TO SERVICE

PANEL

DISCONNECT

ICE MAKER

ELECTRICAL

JUNCTION BOX

AMP TIME

LAY FUSES

:I

*

Cold water pipe

not be interrupted by plastic, rubber or other electrically insulating

connectors (including water merer or pump) without adding a copper

jumper wire at these connections.

must have

metal continuity to electrical ground and

Loading...

Loading...