Whirlpool CGD8990XW2, CGD9050AW0, CGD9060AW0, CEW9100VQ0, CEW9100WQ0 Installation Guide

...Page 1

INSTALLATION

INSTRUCTIONS

Commercial Dryer

Gas or Electric

INSTRUCTIONS

D'INSTALLATION

S6cheuse _ usage

commercial

/_gaz ou 61ectrique

TABLE OF CONTENTS

Page

Dryer Safety ......................................................................... 2

Tools & Parts ........................................................................ 5

Dimensions/Clearances ...................................................... 6

Gas Dryer Installation Requirements ................................... 7

Electric Dryer installation Requirements ........................... 10

Dryer Venting Requirements ............................................. 23

Gas Supply Connection ..................................................... 25

Installing Leveling Legs, Coin Slide, and Coin Box ............... 27

Electric Dryer EEectrical Connections ................................. 28

Leveting ............................................................................. 22

Comptete Installation ........................................................ 23

Reversing Dryer Door Swing ............................................... 24

Maintenance Instructions .................................................. 26

If You Need Assistance ....................................................... 26

Etectronic Control Setup Instructions ................................ 27

Warranty .......................................................................... 33

TABLE DES MATIERES

Page

S6curit6 de la s6cheuse ...................................................... 34

Outils et pi_ces .................................................................. 37

Dimensions/Distances de d6gagement .............................. 38

Exigences d'installation pour la s6cheuse _ gaz ................... 39

Exigences d'instaliafion pour la s6cheuse 61ectrique ......... 43

Exigences concernant V6vacuation de la s6cheuse ............. 44

Sp6cifications de Valimentafion en gaz de la s6cheuse ....... 47

Installation des pieds de niveHement, de la glissi_re

monnaie et de la caisse _ monnaie .................................. 48

NiveHement ........................................................................ 49

Achever VinstaHafion ......................................................... 50

Inversion du sens d'ouverture de la porte de la s6cheuse .... 5:1

Instructions d'entretien ...................................................... 53

Si vous avez besoin d'assistance .......................................... 53

Instructions de r6gtage du tableau

de commande 6Jectronique ............................................... 54

Garanfie ............................................................................ 64

WI0184516D

WI0184517D - SP

www.whirlpoolcommerciallaundry.com

Page 2

DRYERSAFETY

Your safety and the safety of others are very important,

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

This is the safety alert symbol.

__ These words mean:

You can be killed or seriously injured if you don't immediatel v

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is,tell you how to reduce the chance of injury, and tell you what can

happen if the instructionsare not followed.

N|I lG - ...i.kofFi,o..

= Clothes dryer installation must be performed by a qualified installer.

- Install the clothes dryer according to the manufacturer's instructions and local codes.

= Do not install a clothes dryer with flexible plastic venting materials or flexible metal

(foil type) duct. if flexible metal duct is installed, it must be of a specific type identified

by the appliance manufacturer as suitable for use with clothes dryers. Flexible venting

materials are known to collapse, be easily crushed, and trap lint. These conditions will

obstruct clothes dryer airflow and increase the risk of fire.

= To reduce the risk of severe injury or death, follow all installation instructions.

= Save these instructions.

[] It is recommended that the owner post, in a prominent location, instructions for the customer's use in the event the customer

smells gas. This information should be obtained from your gas supplier.

[] Post the following warning in a prominent location.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

FOR YOUR SAFETY

i

Page 3

DRYERSAFETY

WARNING: For your safety, the information in this manual must be followed to minimize I

the risk of fire or explosion, or to prevent property damage, personal injury, or death, j

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

- WHAT TO DO iF YOU SMELL GAS:

= Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Clear the room, building, or area of all occupants.

o Immediately carl your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

• if you cannot reach your gas supplier, carl the fire department.

- Installation and service must be performed by a qualified installer, service agency, or

the gas supplier.

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the "What to do if you smell gas" instructions.

in the State of Massachusetts, the following installation instructions apply:

[] Installationsand repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

[] if using a ball valve, it shall be a T-handle type.

[] A flexible gas connector, when used, must not exceed 3 feet.

IMPORTANT: The gas installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 or the Canadian Natural Gas and Propane Installation Code, CSA B149.1.

The dryer must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National

Electrical Code, ANSIiNFPA 70 or Canadian Electrical Code, CSA C22.1.

I IMPORTANT: When discarding or storing your old clothes dryer, remove the door.

Page 4

DRYERSAFETY

iMPORTANT SAFETYiNSTRUCTiONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using the dryer, follow basic precautions,

including the following:

[] Read all instructions before using the dryer.

[] This dryer is intended only for drying clothes and textiles

that have been washed in water. Do not use for any

other purpose.

[] WARNING: If you smell gas, do not use the dryer or any

electrical equipment nearby. Warn other people to clear

the area. Contact the dryer owner immediately.

[] Do not place items exposed to cooking oils in your dryer.

Items contaminated with cooking oils may contribute to

a chemical reaction that could cause a load to catch fire.

[] Do not dry articles that have been previously cleaned

in, washed in, soaked in, or spotted with gasoline,

dry-cleaning solvents, other flammable, or explosive

substances as they give off vapors that could ignite

or explode.

[] Do not dry unwashed items in the dryer.

[] Do not allow children to play on or in the dryer. Close

supervision of children is necessary when the dryer is

used near children.

[] Before the dryer is removed from service or discarded,

remove the doors to the dryer compartment.

[] Do not reach into the dryer if the drum is moving.

[] Do not open door while dryer is in operation. It will stop.

[] Do not install or store the dryer where it will be exposed

to the weather.

[] Do not tamper with controls.

[] Clean dryer lint screen before or after each load.

[] Do not use this dryer without the lint screen in place.

[] Do not repair or replace any part of the dryer or attempt

any servicing unless specifically recommended in this

Installation Instructions or in published user-repair

instructions that you understand and have the skills

to carry out.

[] Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product.

[] Do not use heat to dry articles containing foam rubber or

similarly textured rubber-like materials.

[] The final part of a tumble dryer cycle occurs without heat

(cool-down cycle) to ensure that the articles are left at

a temperature that ensures that the items will not be

damaged.

[] WARNING: Never stop a tumble dryer before the end of

the drying cycle unless all items are quickly removed and

spread out so that the heat is dissipated. (Avoids risk of

spontaneous combustion).

[] Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of lint,

dust, and dirt.

[] The interior of the dryer and dryer exhaust vent should

be cleaned periodically by qualified service personnel.

[] See "Electrical Requirements" section for grounding

instructions.

SAVETHESE INSTRUCTIONS

4

Page 5

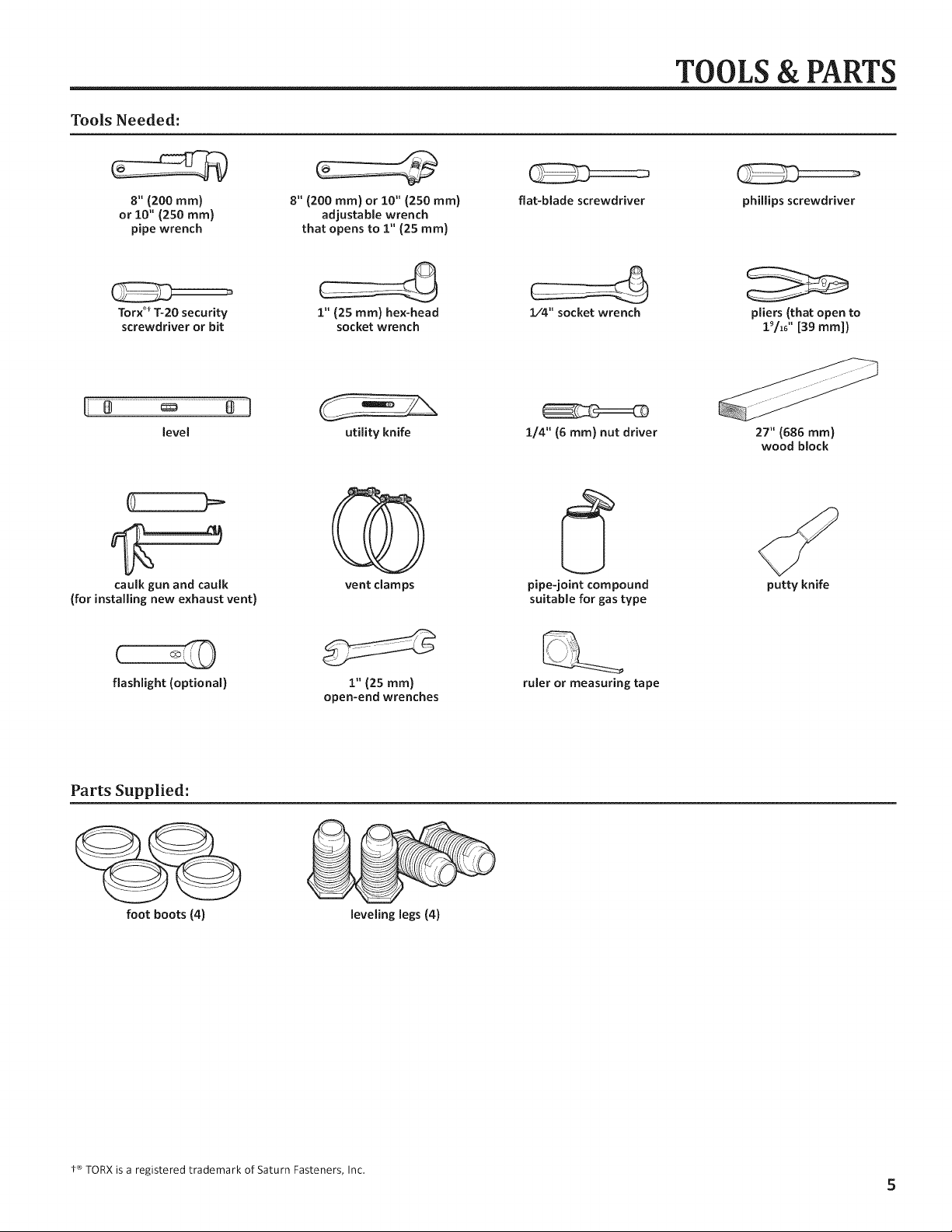

Tools Needed:

TOOLS & PARTS

8"(200 ram)

or 10" (250 ram)

pipe wrench

Torx _'*1"-20 security

screwdriver or bit

level

caulk gun and caulk vent clamps pipe-joint compound putty knife

(for installing new exhaust vent) suitable for gas type

8" (200 ram) or 10" (250 mm)

adjustable wrench

that opens to 1" (25 mm}

1" (25 mm) hex-head

socket wrench

utility knife i/4" (6 mm) nut driver 27" (686 mm)

flat-blade screwdriver

:L/4" socket wrench

phillips screwdriver

pliers (that open to

19/i_'' [39 mm]}

wood block

flashlight (optional) i" (25 ram)

Parts Supplied:

foot boots (4)

open-end wrenches

ruler or measuring tape

leveling legs (4)

t <_TORXis a registered trademark of Saturn Fasteners,Inc.

5

Page 6

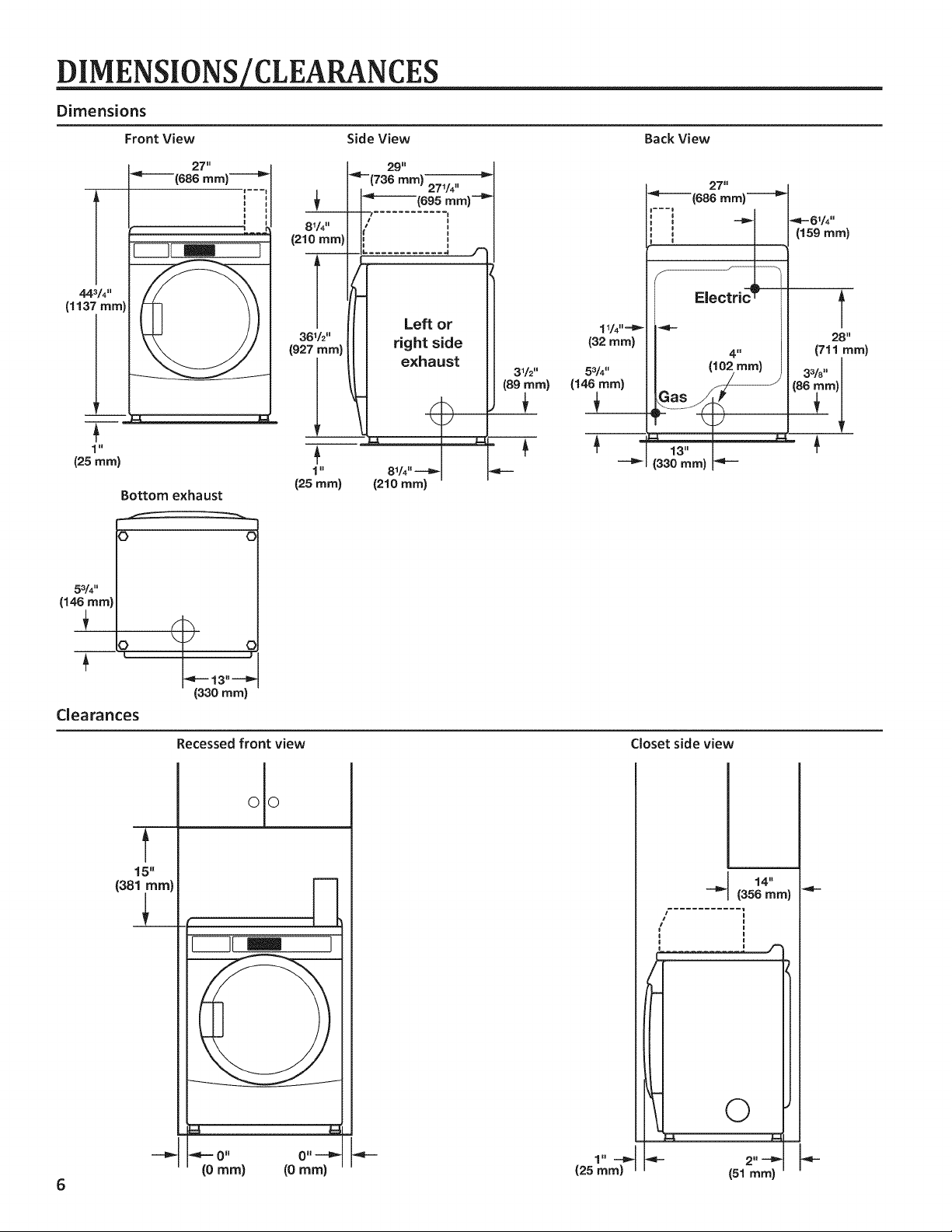

CLEARANCES

Dimensions

Front View SideView Back View

27 _n

_-'-'-'--(686 ram) --'-'-'--_

" L__

29"

"_-- (736 mm)_

l

l

81/4''

(210 ram)

___[ ............J r

"_----- (695 ram) --_

i ............ i

27/4

-,I-----(686 mm)-------_

27"

443/4''

(1137 ram)

"1"

(25 ram)

53]4"

(146 ram)

Clearances

Bottom exhaust

(330 ram)

13,,---_

/ Electri

Left or

361/2"

(927 ram)

(25 ram)

right side

exhaust

81/4"

(210 ram)

@:__

31/2"

(89 ram)

53/4"

(146 mm)

4 t_

(102 ram) ,/

13"

(330 ram) _-

28"

(711 ram)

33/8"

,°°7,1

o

J

Recessed front view

°1°

(0 mm) (0 ram)

O"

(25 ram)

Closet side view

0............

i

0

I o

14"

(356 mm}

(51 ram)

Page 7

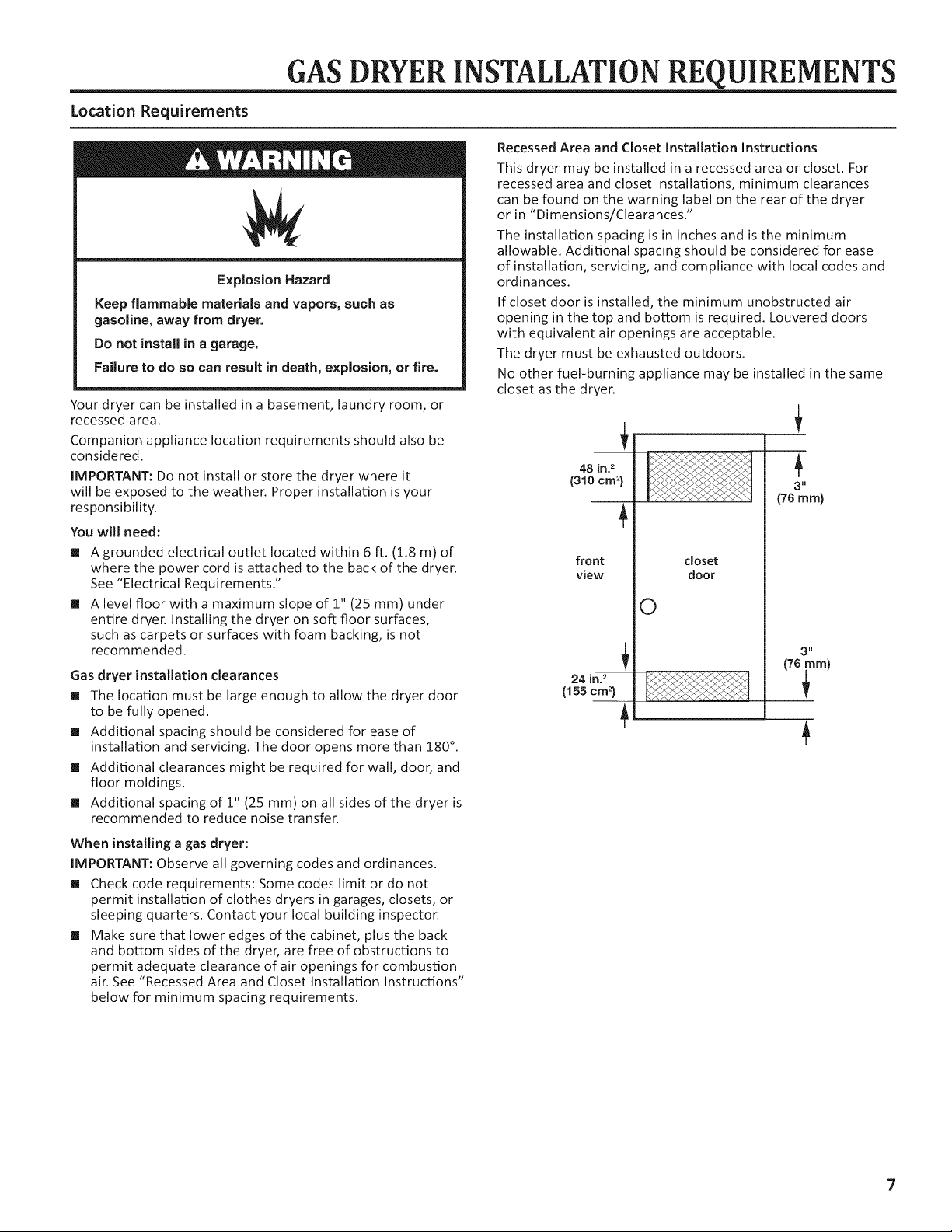

GASDRYERINSTALLATION REQUIREMENTS

Location Requirements

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Do not install in a garage.

Failure to do so can result in death, explosion, or fire.

Your dryer can be installed in a basement, laundry room, or

recessed area.

Companion appliance location requirements should also be

considered.

iMPORTANT: Do not install or store the dryer where it

will be exposed to the weather. Proper installation is your

responsibility.

You will need:

[] A grounded electrical outlet located within 6 ft. (1.8 m) of

where the power cord is attached to the back of the dryer.

See "Electrical Requirements."

[] A level floor with a maximum slope of 1" (25 mm) under

entire dryer. Installing the dryer on soft floor surfaces,

such as carpets or surfaces with foam backing, is not

recommended.

Gas dryer installation clearances

[] The location must be large enough to allow the dryer door

to be fully opened.

[] Additional spacing should be considered for ease of

installation and servicing. The door opens more than 180 °.

[] Additional clearances might be required for wall, door, and

floor moldings.

[] Additional spacing of 1" (25 mm) on all sides of the dryer is

recommended to reduce noise transfer.

When installing a gas dryer:

iMPORTANT: Observe all governing codes and ordinances.

[] Check code requirements: Some codes limit or do not

permit installation of clothes dryers in garages, closets, or

sleeping quarters. Contact your local building inspector.

[] Make sure that lower edges of the cabinet, plus the back

and bottom sides of the dryer, are free of obstructions to

permit adequate clearance of air openings for combustion

air. See "Recessed Area and Closet Installation Instructions"

below for minimum spacing requirements.

Recessed Area and Closet installation instructions

This dryer may be installed in a recessed area or closet. For

recessed area and closet installations, minimum clearances

can be found on the warning label on the rear of the dryer

or in "Dimensions/Clearances."

The installation spacing is in inches and is the minimum

allowable. Additional spacing should be considered for ease

of installation, servicing, and compliance with local codes and

ordinances.

If closet door is installed, the minimum unobstructed air

opening in the top and bottom is required. Louvered doors

with equivalent air openings are acceptable.

The dryer must be exhausted outdoors.

No other fuel-burning appliance may be installed in the same

closet as the dryer.

48 in.2

(310 cm2)

3"

(76 ram}

front

view

closet

door

0

3"

24 in.2

(155 cm 2)

(76_nm}

Page 8

GAS DRYERINSTALLATION RE UIREMENTS

Electrical Requirements

Gas Dryer Grounding

GROUNDING INSTRUCTIONS

[] For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord,

Failure to follow these instructions can result in death,

fire, or electrical shock.

iMPORTANT: The dryer must be electrically grounded in

accordance with local codes and ordinances or, in the absence

of local codes, with the National Electrical Code, ANSI/NFPA 70,

latest edition, or Canadian Electrical Code, CSAC22.1. If codes

permit and a separate ground wire is used, it isrecommended

that a qualified electrical installer determine that the ground

path isadequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park, Quincy, MA 02269

CSAInternational

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

[] Do not ground to a gas pipe.

[] Do not have a fuse in the neutral or ground circuit.

[] A 120 volt, 60 Hz, AC only, 15- or 20-amp, fused electrical

circuit is required. A time-delay fuse or circuit breaker is

also recommended. It is recommended that a separate

circuit serving only this dryer be provided.

[] This dryer is equipped with a power supply cord having a

3-prong grounding plug.

[] To minimize the possibility of shock, the cord must be

plugged into a mating, 3 prong, grounding-type outlet,

grounded in accordance with local codes and ordinances.

If a mating outlet is not available, it is the personal

responsibility and obligation of the customer to have the

properly grounded outlet installed by a qualified electrician.

[] If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that

the ground path is adequate.

[] Check with a qualified electrician if you are not sure the

dryer is properly grounded.

This dryer uses a cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged

into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

[] For a permanently connected dryer:

This dryer must be connected to a grounded metal,

permanent wiring system, or an equipment-grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead on

the dryer.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug on the power

supply cord: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

Page 9

GASDRYERINSTALLATION

Gas Supply

Explosion Hazard

Use a new CSA international approved gas supply line.

|nstall a shut=off valve,

Securely tighten all gas connections.

if connected to LP, have a qualified person make sure

gas pressure does not exceed 13" (330 ram) water

column.

Examples of a qualified person include:

|icensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

IMPORTANT: Observe all governing codes and ordinances.

This installation must conform with all local codes and

ordinances. In the absence of local codes, installation must

conform with American National Standard, National Fuel Gas

Code ANSI Z223.1/NFPA 54 or CAN/CSA B149.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park, Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

The design of this dryer has been certified by CSA International

for use at altitudes up to 10,000 feet (3048 m) above sea level

at the B.T.U. rating indicated on the model/serial plate. Burner

input adjustments are not required when the dryer is operated

up to this elevation.

When installed above 10,000 feet (3048 m), a four percent

(4%) reduction of the burner B.T.U. rating shown on the model/

serial plate is required for each 1,000 foot (305 m) increase in

elevation. For assistance when converting to other gas types

and/or installing above 10,000 feet (3048 m) elevation, contact

your local service company.

Page 10

ELECTRIC DRYERINSTALLATION RE L!IREMENTS

Location Requirements

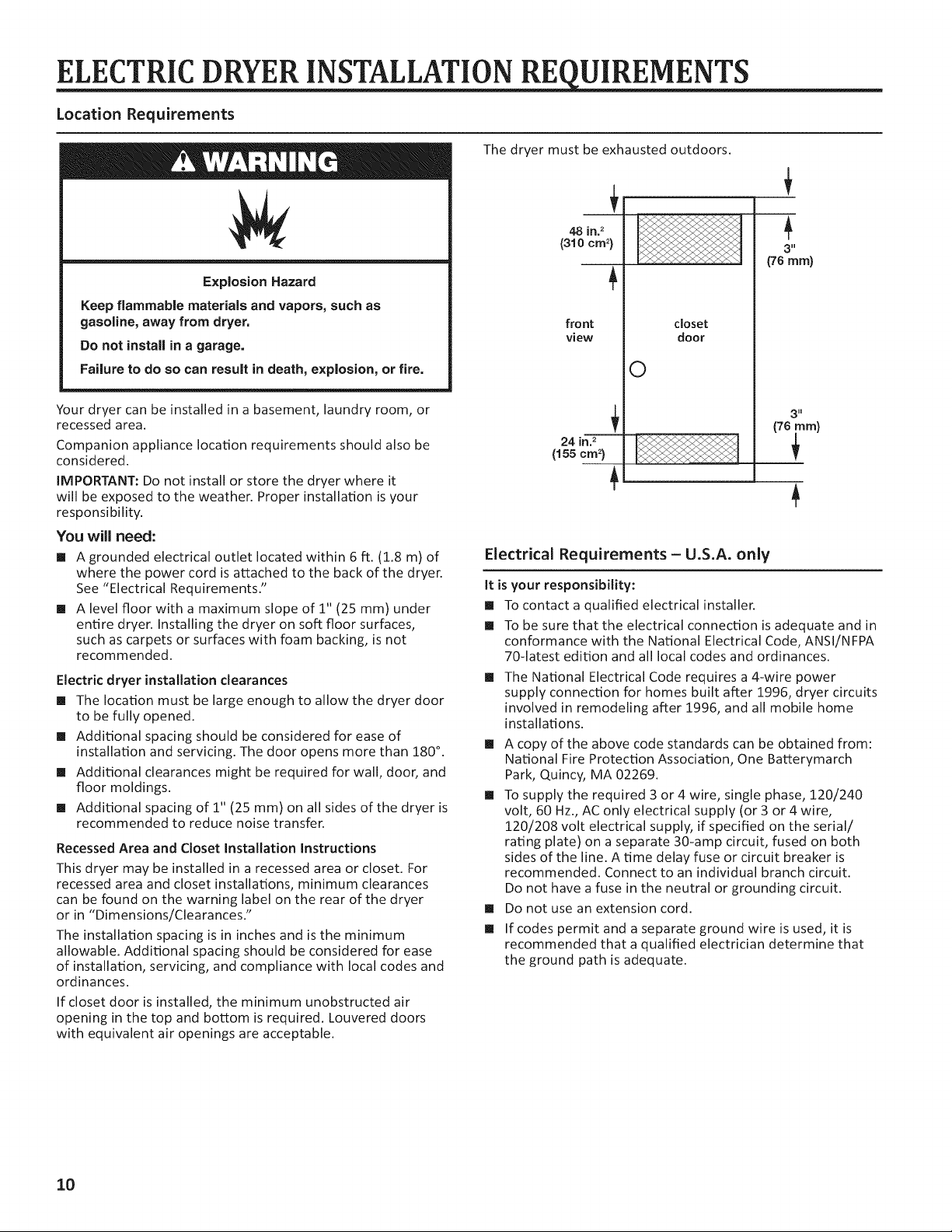

The dryer must be exhausted outdoors.

48 in.2

(310 cm2)

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Do not install in a garage.

Failure to do so can result in death, explosion, or fire.

Your dryer can be installed in a basement, laundry room, or

recessed area.

Companion appliance location requirements should also be

considered.

iMPORTANT: Do not install or store the dryer where it

will be exposed to the weather. Proper installation is your

responsibility.

You will need:

[] A grounded electrical outlet located within 6 ft. (1.8 m) of

where the power cord isattached to the back of the dryer.

See "Electrical Requirements."

[] A level floor with a maximum slope of 1" (25 mm) under

entire dryer. Installing the dryer on soft floor surfaces,

such as carpets or surfaces with foam backing, is not

recommended.

Electric dryer installation clearances

[] The location must be large enough to allow the dryer door

to be fully opened.

[] Additional spacing should be considered for ease of

installation and servicing. The door opens more than 180 °.

[] Additional clearances might be required for wall, door, and

floor moldings.

[] Additional spacing of 1" (25 mm) on all sides of the dryer is

recommended to reduce noise transfer.

Recessed Area and Closet Installation Instructions

This dryer may be installed in a recessed area or closet. For

recessed area and closet installations, minimum clearances

can be found on the warning label on the rear of the dryer

or in "Dimensions/Clearances."

The installation spacing is in inches and is the minimum

allowable. Additional spacing should be considered for ease

of installation, servicing, and compliance with local codes and

ordinances.

If closet door isinstalled, the minimum unobstructed air

opening in the top and bottom is required. Louvered doors

with equivalent air openings are acceptable.

Electrical Requirements - U.S.A. only

it is your responsibility:

[] To contact a qualified electrical installer.

[] To be sure that the electrical connection is adequate and in

conformance with the National Electrical Code, ANSI/NFPA

70-latest edition and all local codes and ordinances.

[]

The National Electrical Code requires a 4-wire power

supply connection for homes built after 1996, dryer circuits

involved in remodeling after 1996, and all mobile home

installations.

[]

A copy of the above code standards can be obtained from:

National Fire Protection Association, One Batterymarch

Park, Quincy, MA 02269.

[]

To supply the required 3 or 4 wire, single phase, 120/240

volt, 60 Hz., AC only electrical supply (or 3 or 4 wire,

120/208 volt electrical supply, if specified on the serial/

rating plate) on a separate 30-amp circuit, fused on both

sides of the line. A time delay fuse or circuit breaker is

recommended. Connect to an individual branch circuit.

Do not have a fuse in the neutral or grounding circuit.

[]

Do not use an extension cord.

[]

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that

the ground path is adequate.

front

view

24 in.2

(155cm_)

closet

door

0

3"

_6 ram}

10

Page 11

ELECTRICDRYERINSTALLATION

Electrical Requirements - U.S.A. only (cont.)

Electrical Connection

To properly install your dryer, you must determine the type

of electrical connection you will be using and follow the

instructions provided for it here.

[] This dryer is manufactured ready to install with a 3-wire

electrical supply connection. The neutral ground conductor

is permanently connected to the neutral conductor (white

wire) within the dryer. If the dryer is installed with a 4-wire

electrical supply connection, the neutral ground conductor

must be removed from the external ground connector

(green screw), and secured under the neutral terminal

(center or white wire) of the terminal block. When the

neutral ground conductor is secured under the neutral

terminal (center or white wire) of the terminal block, the

dryer cabinet is isolated from the neutral conductor.

[] If local codes do not permit the connection of a neutral

ground wire to the neutral wire, see "Optional 3-wire

connection" section.

[]

A 4-wire power supply connection must be used when the

appliance is installed in a location where grounding through

the neutral conductor is prohibited. Grounding through the

neutral is prohibited for (1) new branch-circuit installations

and (2) areas where local codes prohibit grounding through

the neutral conductor.

Electric Dryer Grounding

Electric Dryer Power Supply Cord

Fire Hazard

Use a new UL listed 30 amp power supply cord.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal,

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electrical shock.

GROUNDING INSTRUCTIONS

[] For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer uses a cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged

into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

[] For a permanently connected dryer:

This dryer must be connected to a grounded metal,

permanent wiring system, or an equipment-grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead on

the dryer.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug on the power

supply cord: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

If using a power supply cord:

Use a UL listed power supply cord kit marked for use with

clothes dryers. The kit should contain:

[] A UL listed 30-amp power supply cord, rated 120/240

volt minimum. The cord should be type SRD or SRDTand

be at least 4 ft. (1.22 m) long. The wires that connect to

the dryer must end in ring terminals or'U" shaped spade

terminals with upturned ends.

[] A UL listed strain relief.

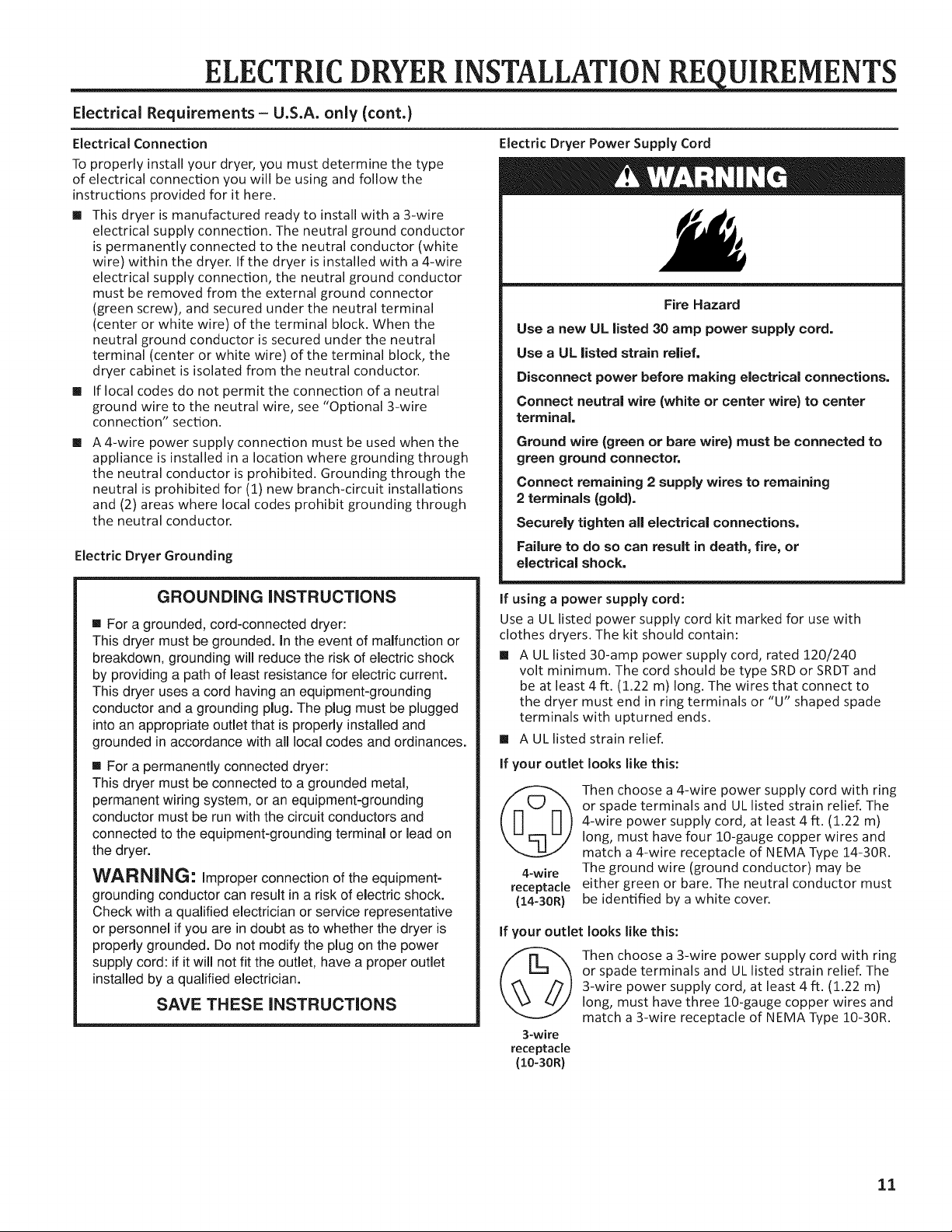

If your outlet looks like this:

Then choose a 4-wire power supply cord with ring

or spade terminals and UL listed strain relief. The

4-wire power supply cord, at least 4 ft. (1.22 m)

long, must have four lO-gauge copper wires and

match a4-wire receptacle of NEMA Type 14-30R.

4-wire

receptacle

(14-30R}

If your outlet looks like this:

3-wire

receptacle

(I0-30R}

The ground wire (ground conductor) may be

either green or bare. The neutral conductor must

be identified by awhite coven

Then choose a 3-wire power supply cord with ring

or spade terminals and UL listed strain relief. The

3-wire power supply cord, at least 4 ft. (1.22 m)

long, must have three lO-gauge copper wires and

match a 3-wire receptacle of NEMA Type 10-30R.

11

Page 12

ELECTRIC DRYERINSTALLATION RE UIREMENTS

Direct Wire

If connecting by direct wire:

Power supply cable must match power supply (4-wire or

3-wire) and be:

[] Flexible armored cable or nonmetallic sheathed copper

cable (with ground wire), covered with flexible metallic

conduit. All current-carrying wires must be insulated.

[] lO-gauge solid copper wire (do not use aluminum).

Fire Hazard

Use 10 gauge copper wire.

Use a UL listed strain relief,

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal.

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electrical shock.

[] At least 5 ft. (1.52 m) long.

Electrical Requirements - Canada only

Electrical Shock Hazard

Plug into a grounded 4 prong outlet,

Failure to do so can result in death or electrical shock.

it is your responsibility:

[] To contact a qualified electrical installer.

[] To be sure that the electrical connection is adequate

and in conformance with the Canadian Electrical Code,

C22.1 - latest edition and all local codes. A copy of the

above codes standard may be obtained from: Canadian

Standards Association, 178 Rexdale Blvd., Toronto, ON M9W

1R3 CANADA.

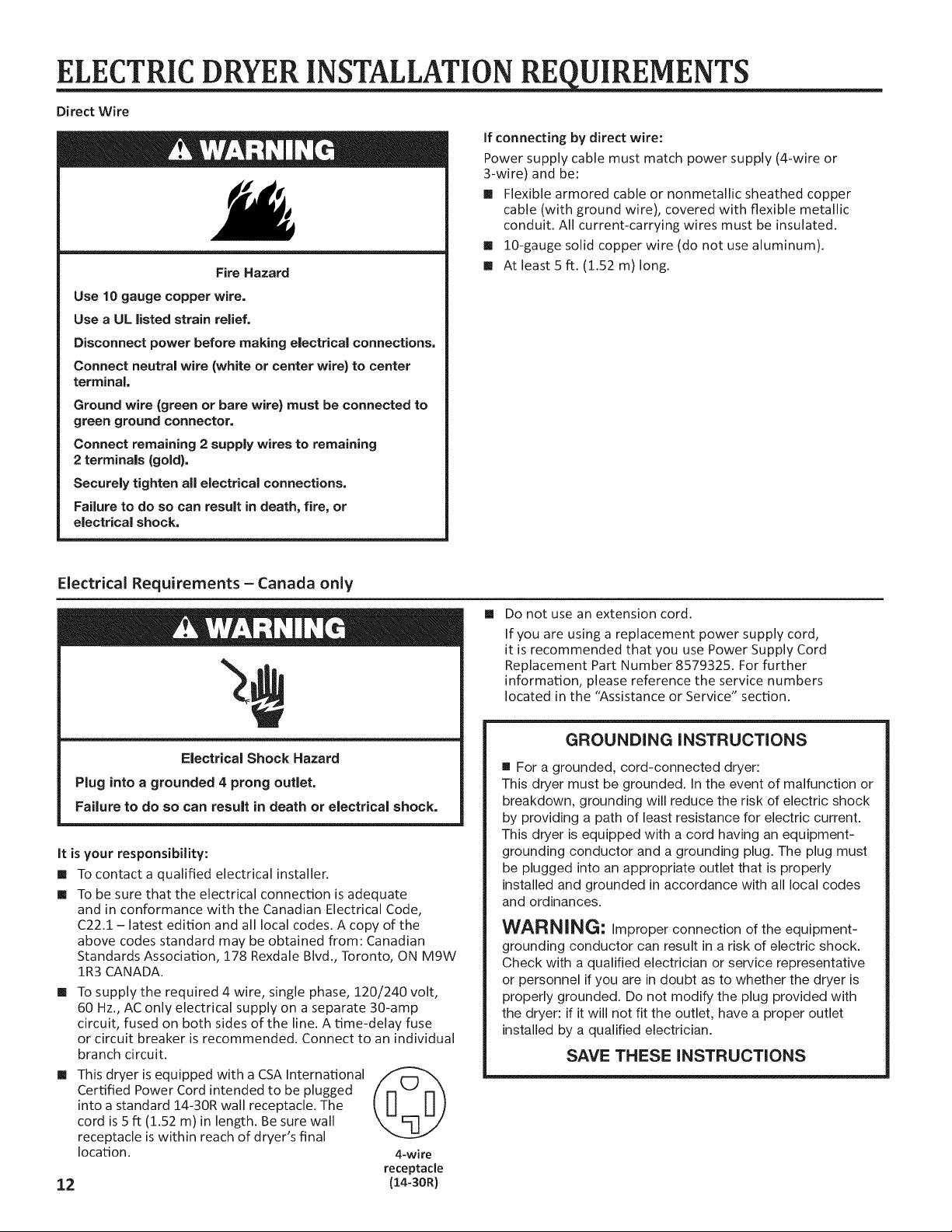

[] To supply the required 4 wire, single phase, 120/240 volt,

60 Hz., AC only electrical supply on a separate 30-amp

circuit, fused on both sides of the line. A time-delay fuse

or circuit breaker is recommended. Connect to an individual

branch circuit.

[] This dryer is equipped with a CSA International

Certified Power Cord intended to be plugged

into a standard 14-30R wall receptacle. The

cord is 5 ft (1.52 m) in length. Be sure wall

receptacle is within reach of dryer's final

location.

12

4-wire

receptacle

(14-30R}

[] Do not use an extension cord.

If you are using a replacement power supply cord,

it is recommended that you use Power Supply Cord

Replacement Part Number 8579325. For further

information, please reference the service numbers

located in the "Assistance or Service" section.

GROUNDING INSTRUCTIONS

m For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipment-

grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with

the dryer: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

Page 13

DRYERVENTING

Fire Hazard

Use a heavy metal vent,

Do not use a plastic vent,

Do not use a metal foil vent,

Failure to follow these instructions can result in death

or fire,

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

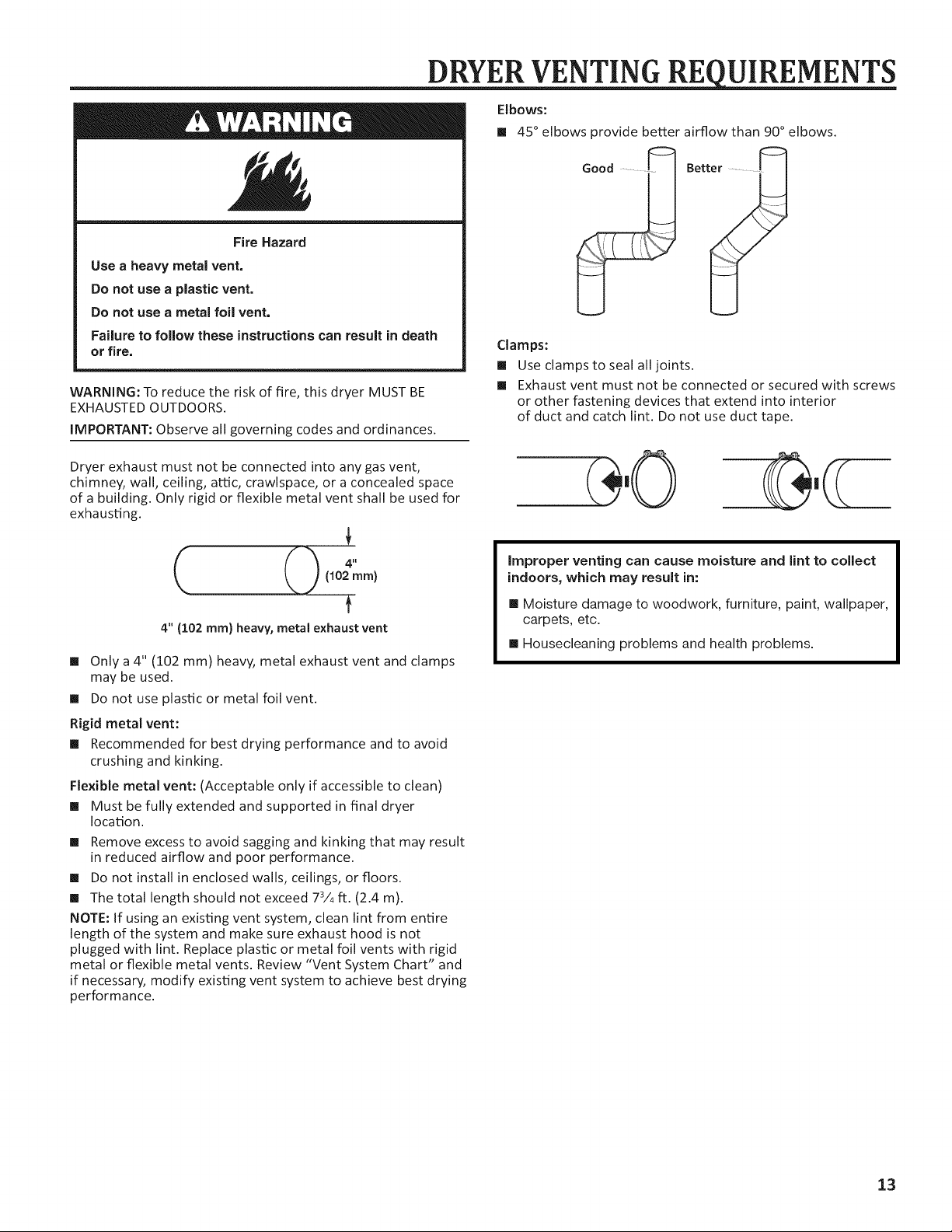

Dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, attic, crawlspace, or a concealed space

of a building. Only rigid or flexible metal vent shall be used for

exhausting.

!

_ 4"

4" (102 ram) heavy, metal exhaust vent

[] Only a4" (102 mm) heavy, metal exhaust vent and clamps

may be used.

[] Do not use plastic or metal foil vent.

Rigid metal vent:

[] Recommended for best drying performance and to avoid

crushing and kinking.

Flexible metal vent: (Acceptable only if accessible to clean)

[] Must be fully extended and supported in final dryer

location.

[] Remove excess to avoid sagging and kinking that may result

in reduced airflow and poor performance.

[] Do not install in enclosed walls, ceilings, or floors.

[] The total length should not exceed 73/4ft. (2.4 m).

NOTE: If using an existing vent system, clean lint from entire

length of the system and make sure exhaust hood is not

plugged with lint. Replace plastic or metal foil vents with rigid

metal or flexible metal vents. Review "Vent System Chart" and

if necessary, modify existing vent system to achieve best drying

performance.

(102 ram)

Elbows:

[] 45 ° elbows provide better airflow than 90° elbows.

............... Bet

Clamps:

[] Use clamps to seal all joints.

[] Exhaust vent must not be connected or secured with screws

or other fastening devices that extend into interior

of duct and catch lint. Do not use duct tape.

Improper venting can cause moisture and lint to collect

indoors, which may result in:

[] Moisture damage to woodwork, furniture, paint, wallpaper,

carpets, etc.

[] Housecleaning problems and health problems.

13

Page 14

DRYERVENTING RE UIREMENTS

Vent Hoods

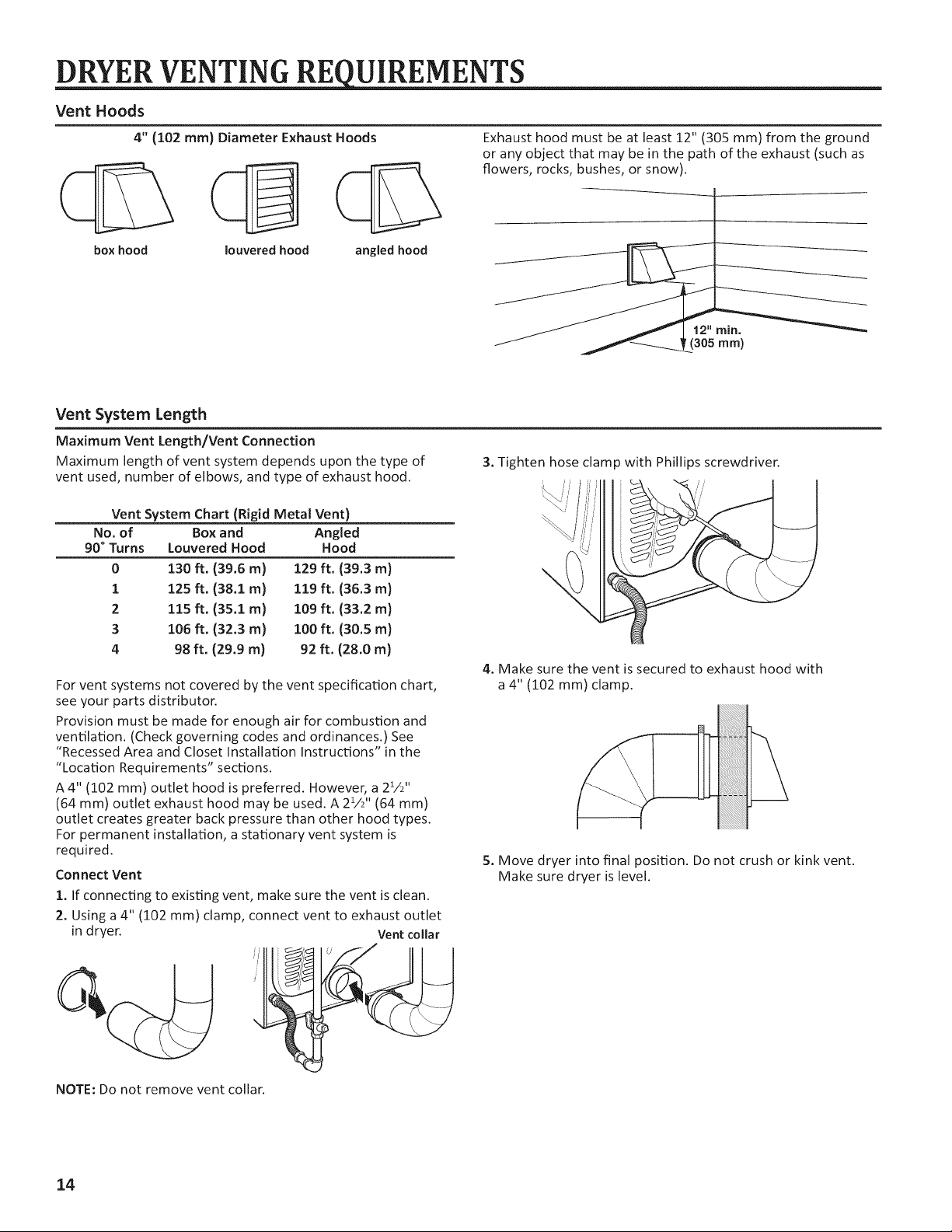

4" (102 mm) Diameter Exhaust Hoods

box hood louvered hood angled hood

Vent System Length

Maximum Vent Length/Vent Connection

Maximum length of vent system depends upon the type of

vent used, number of elbows, and type of exhaust hood.

Vent System Chart (Rigid Metal Vent}

No. of Box and Angled

90° Turns Louvered Hood Hood

0 130 ft. (39.6 m) 129 ft. (39.3 m)

I 125 ft. (38.1 m) 119 ft. (36.3 m)

2 115 ft. (35.1 m) 109 ft. (33.2 m)

3 106 ft. (32.3 m) 100 ft. (30.5 m)

4 98 ft. (29.9 m) 92 ft. (28.0 m)

For vent systems not covered by the vent specification chart,

see your parts distributor.

Provision must be made for enough air for combustion and

ventilation. (Check governing codes and ordinances.) See

"Recessed Area and Closet Installation Instructions" in the

"Location Requirements" sections.

A 4" (102 mm) outlet hood is preferred. However, a 21/2"

(64 mm) outlet exhaust hood may be used. A 21/2" (64 mm)

outlet creates greater back pressure than other hood types.

For permanent installation, a stationary vent system is

required.

Connect Vent

1. If connecting to existing vent, make sure the vent is clean.

2. Using a 4" (102 ram) clamp, connect vent to exhaust outlet

in dryer. Vent collar

Exhaust hood must be at least 12" (305 mm) from the ground

or any object that may be in the path of the exhaust (such as

flowers, rocks, bushes, or snow).

3. Tighten hose clamp with Phillips screwdriver.

\

4. Make sure the vent is secured to exhaust hood with

a 4" (102 mm) clamp.

5. Move dryer into final position. Do not crush or kink vent.

Make sure dryer is level.

NOTE: Do not remove vent collar.

14

Page 15

DRYERVENTING

If an Exhaust Hood Cannot be Used

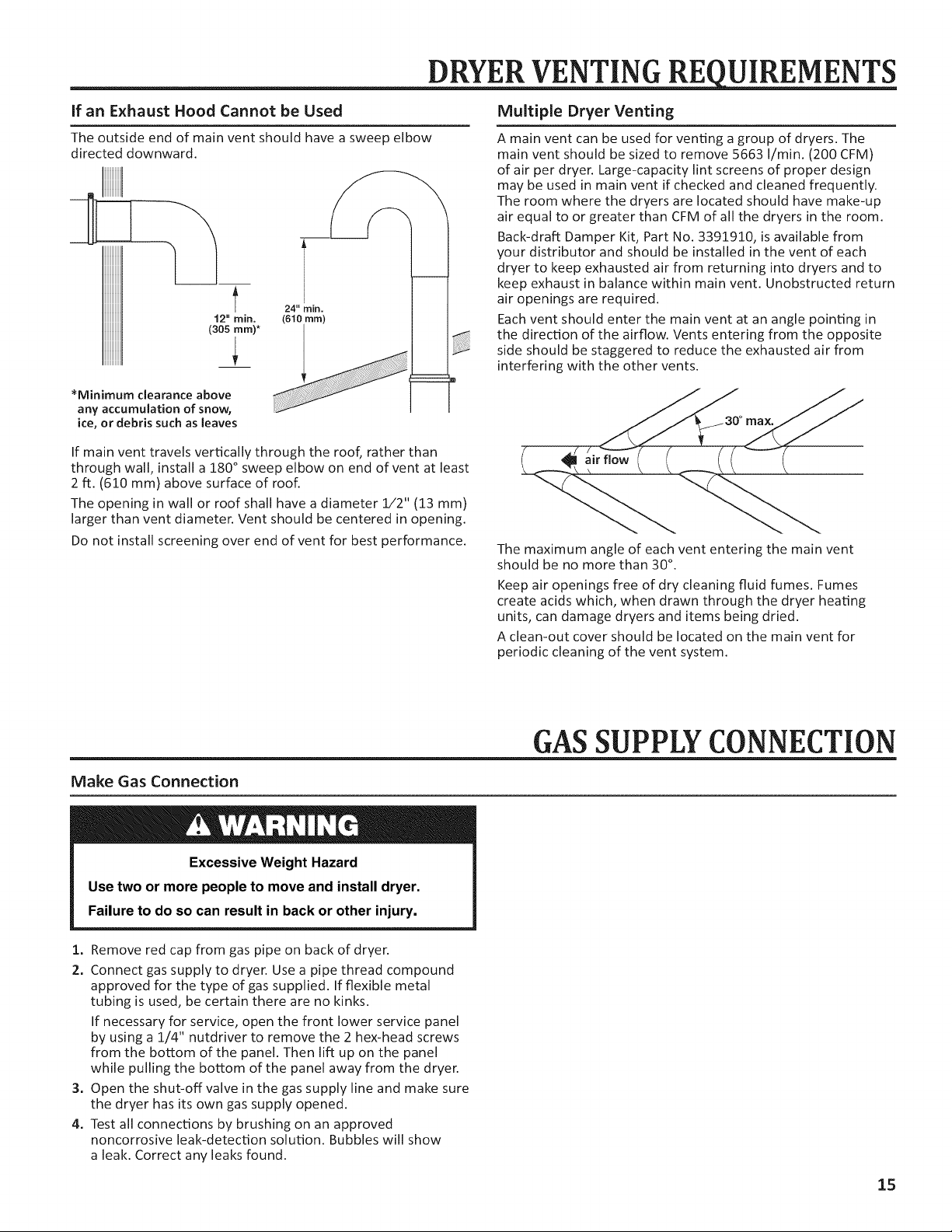

The outside end of main vent should have a sweep elbow

directed downward.

12" rain.

(305 ram)*

*Minimum clearance above

any accumulation of snow,

ice, or debris such as leaves

24" rain.

(610 ram)

If main vent travels vertically through the roof, rather than

through wall, install a 180 ° sweep elbow on end of vent at least

2 ft. (610 mm) above surface of roof.

The opening in wall or roof shall have a diameter 1/2" (13 mm)

larger than vent diameter. Vent should be centered in opening.

Do not install screening over end of vent for best performance.

Multiple Dryer Venting

A main vent can be used for venting a group of dryers. The

main vent should be sized to remove 5663 I/min. (200 CFM)

of air per dryer. Large-capacity lint screens of proper design

may be used in main vent if checked and cleaned frequently.

The room where the dryers are located should have make-up

air equal to or greater than CFM of all the dryers in the room.

Back-draft Damper Kit, Part No. 3391910, is available from

your distributor and should be installed in the vent of each

dryer to keep exhausted air from returning into dryers and to

keep exhaust in balance within main vent. Unobstructed return

air openings are required.

Each vent should enter the main vent at an angle pointing in

the direction of the airflow. Vents entering from the opposite

side should be staggered to reduce the exhausted air from

interfering with the other vents.

The maximum angle of each vent entering the main vent

should be no more than 30°.

Keep air openings free of dry cleaning fluid fumes. Fumes

create acids which, when drawn through the dryer heating

units, can damage dryers and items being dried.

A clean-out cover should be located on the main vent for

periodic cleaning of the vent system.

Make Gas Connection

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

1. Remove red cap from gas pipe on back of dryer.

2. Connect gas supply to dryer. Use a pipe thread compound

approved for the type of gas supplied. If flexible metal

tubing is used, be certain there are no kinks.

If necessary for service, open the front lower service panel

by using a 1/4" nutddver to remove the 2 hex-head screws

from the bottom of the panel. Then lift up on the panel

while pulling the bottom of the panel away from the dryer.

3. Open the shut-off valve in the gas supply line and make sure

the dryer has its own gas supply opened.

4. Test all connections by brushing on an approved

noncorrosive leak-detection solution. Bubbles will show

a leak. Correct any leaks found.

GASSUPPLY CONNECTION

15

Page 16

GAS SUPPLYCONNECTION

Type of Gas

This dryer is equipped for use with natural gas. It is design-

certified by CSA International for LP (propane and butane)

gases with appropriate conversion. No attempt shall be made

to convert dryer from gas specified on serial/rating plate for use

with a different gas without consulting the serving gas supplier.

Conversion must be done by a qualified service technician.

(5as conversion kit part numbers are listed on gas valve burner

base.

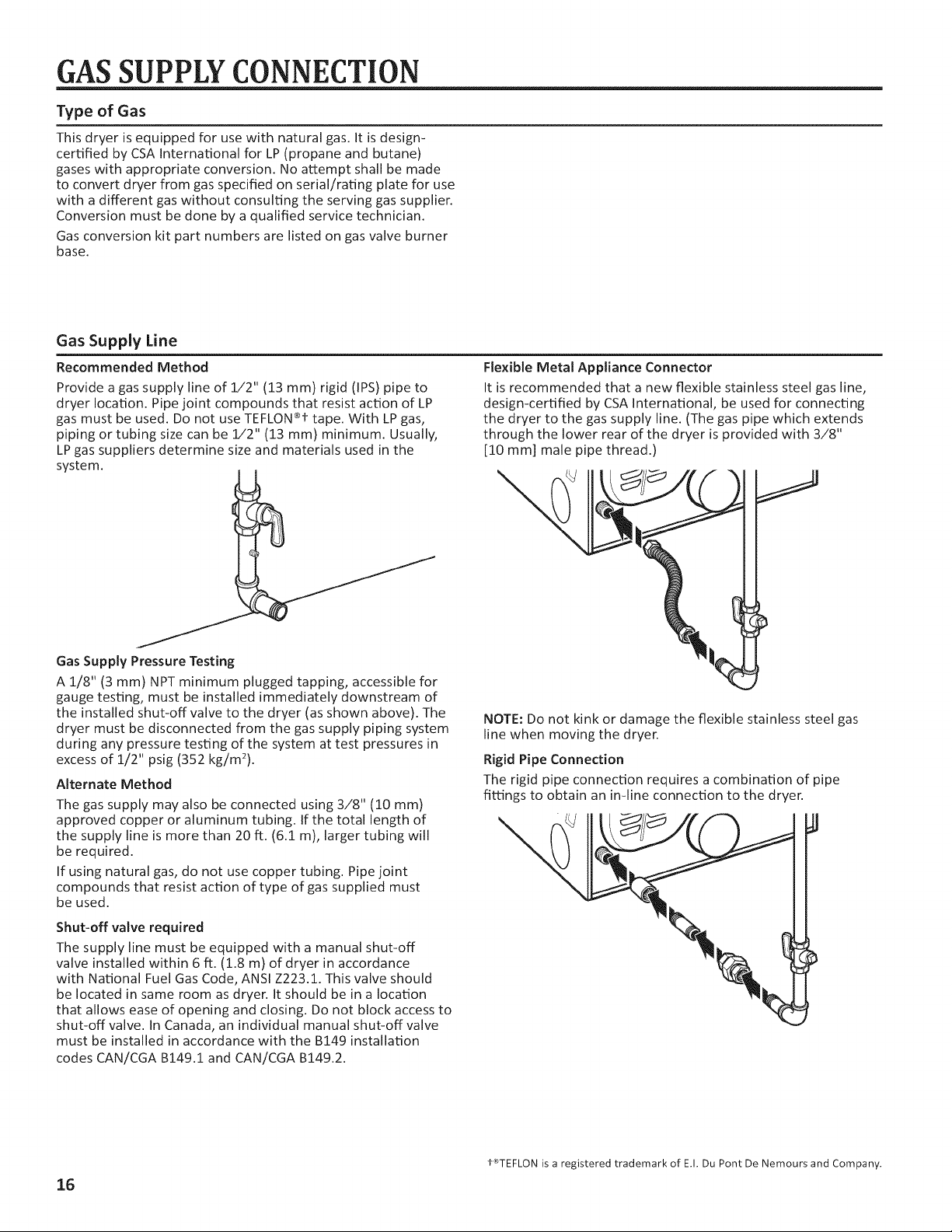

Gas Supply Line

Recommended Method

Provide a gas supply line of :1/2" (13 mm) rigid (IPS) pipe to

dryer location. Pipe joint compounds that resist action of LP

gas must be used. Do not useTEFLON®t tape. With LP gas,

piping or tubing size can be 1/2" (13 mm) minimum. Usually,

LPgas suppliers determine size and materials used in the

system.

Flexible Metal Appliance Connector

It is recommended that a new flexible stainless steel gas line,

design-certified by CSAInternational, be used for connecting

the dryer to the gas supply line. (The gas pipe which extends

through the lower rear of the dryer isprovided with 3/8"

[10 mm] male pipe thread.)

\

Gas Supply Pressure Testing

A 1/8" (3 mm) NPT minimum plugged tapping, accessible for

gauge testing, must be installed immediately downstream of

the installed shut-off valve to the dryer (as shown above). The

dryer must be disconnected from the gas supply piping system

during any pressure testing of the system at test pressures in

excess of 1/2" psig (352 kg/m=).

Alternate Method

The gas supply may also be connected using 3/8" (10 mm)

approved copper or aluminum tubing. If the total length of

the supply line is more than 20 ft. (6.1 m), larger tubing will

be required.

If using natural gas, do not use copper tubing. Pipe joint

compounds that resist action of type of gas supplied must

be used.

Shut-off valve required

The supply line must be equipped with a manual shut-off

valve installed within 6 ft. (1.8 m) of dryer in accordance

with National Fuel Gas Code, ANSI Z223.1. This valve should

be located in same room as dryer. It should be in a location

that allows ease of opening and closing. Do not block access to

shut-off valve. In Canada, an individual manual shut-off valve

must be installed in accordance with the B149 installation

codes CAN/CGA B149.1 and CAN/CGA B149.2.

NOTE: Do not kink or damage the flexible stainless steel gas

line when moving the dryer.

Rigid Pipe Connection

The rigid pipe connection requires a combination of pipe

fittings to obtain an in-line connection to the dryer.

16

t<"_TEFLONis a registered trademark of E.I. Du Pont De Nemours and Company.

Page 17

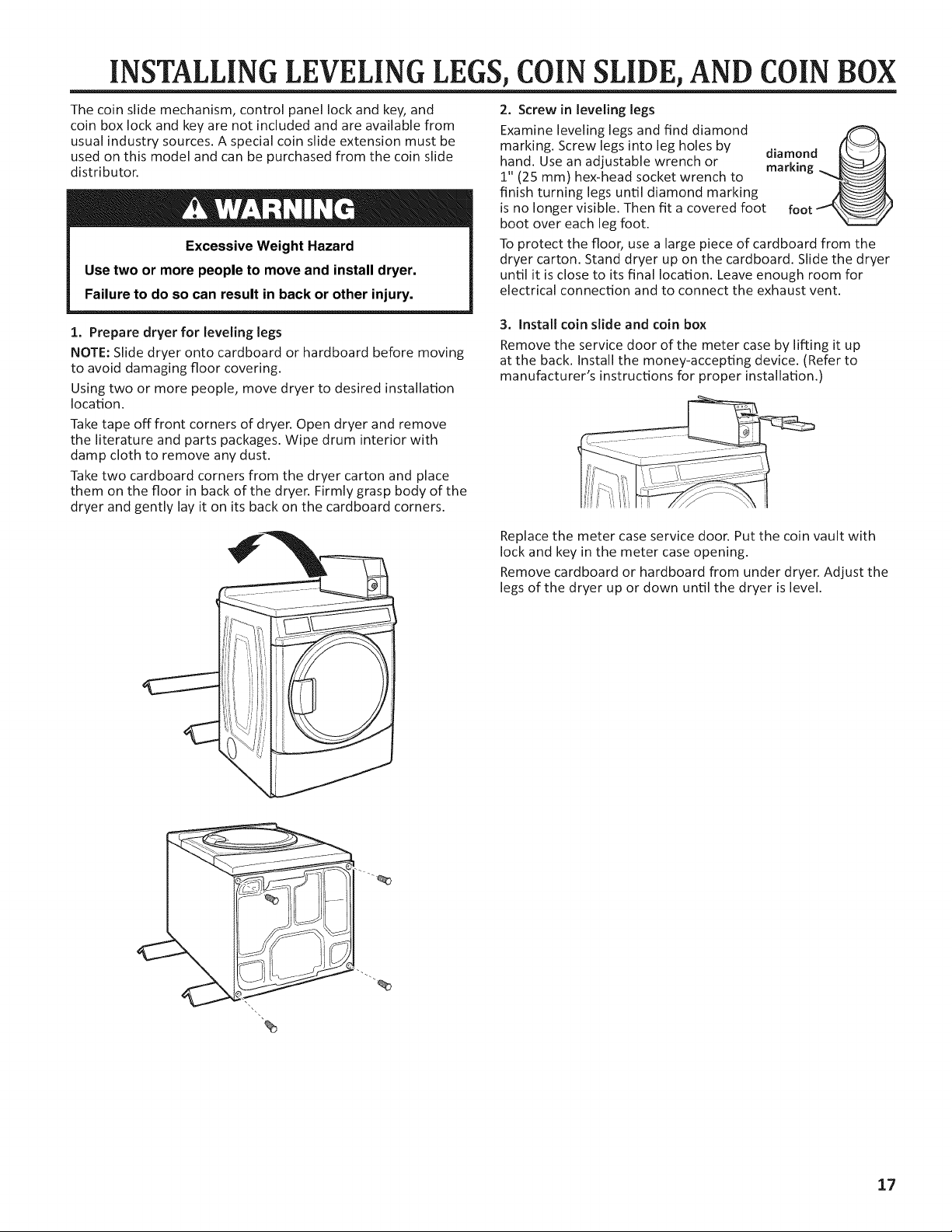

INSTALLINGLEVELING LEGS, COIN SLIDE, AND COIN BOX

The coin slide mechanism, control panel lock and key, and

coin box lock and key are not included and are available from

usual industry sources. A special coin slide extension must be

used on this model and can be purchased from the coin slide

distributor.

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

1. Prepare dryer for leveling legs

NOTE: Slide dryer onto cardboard or hardboard before moving

to avoid damaging floor covering.

Using two or more people, move dryer to desired installation

location.

Take tape off front corners of dryer. Open dryer and remove

the literature and parts packages. Wipe drum interior with

damp cloth to remove any dust.

Take two cardboard corners from the dryer carton and place

them on the floor in back of the dryer. Firmly grasp body of the

dryer and gently lay it on its back on the cardboard corners.

2. Screw in leveling legs

Examine leveling legs and find diamond

marking. Screw legs into leg holes by ,. , (1_

hand. Use an adjustable wrench or m=_i_o

1" (25 mm) hex-head socket wrench to ........ _

finish turning legs until diamond marking

is no longer visible. Then fit a covered foot foot

boot over each leg foot.

To protect the floor, use a large piece of cardboard from the

dryer carton. Stand dryer up on the cardboard. Slide the dryer

until it is close to its final location. Leave enough room for

electrical connection and to connect the exhaust vent.

3. Install coin slide and coin box

Remove the service door of the meter case by lifting it up

at the back. Install the money-accepting device. (Refer to

manufacturer's instructions for proper installation.)

Replace the meter case service door. Put the coin vault with

lock and key in the meter case opening.

Remove cardboard or hardboard from under dryer. Adjust the

legs of the dryer up or down until the dryer is level.

. QlamonQ

17

Page 18

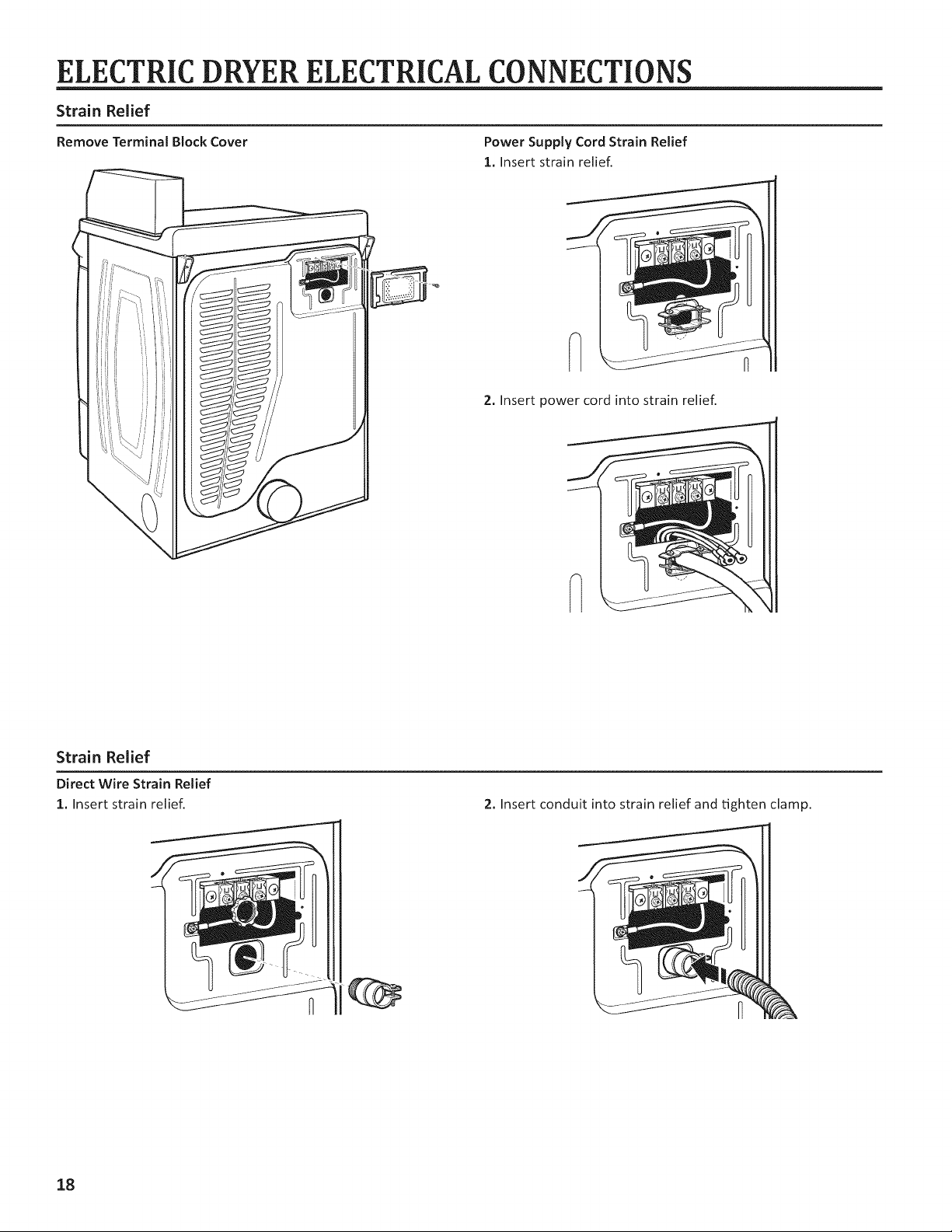

ELECTRIC DRYERELECTRICAL CONNECTIONS

Strain Relief

Remove Terminal Block Cover Power Supply Cord Strain Relief

1. Insert strain relief.

2. Insert power cord into strain relief.

Strain Relief

Direct Wire Strain Relief

1. Insert strain relief.

18

2, Insert conduit into strain relief and tighten clamp.

Page 19

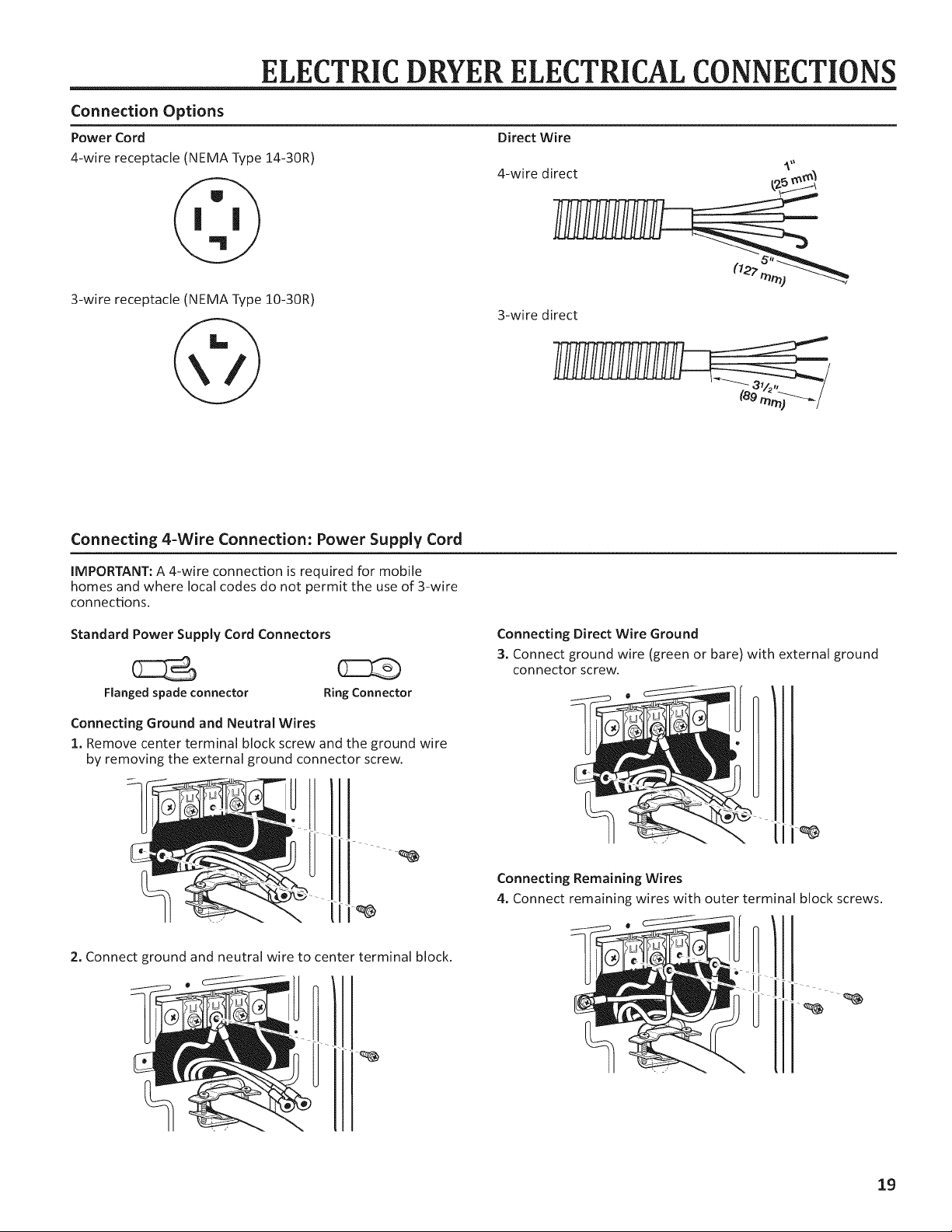

ELECTRIC DRYER ELECTRICAL CONNECTIONS

Connection Options

Power Cord

4-wire receptacle (NEMA Type 14-30R)

Direct Wire

4-wire direct

(127

3-wire receptacle (NEMA Type 10-30R)

Connecting 4-Wire Connection: Power Supply Cord

IMPORTANT: A 4-wire connection is required for mobile

homes and where local codes do not permit the use of 3-wire

connections.

Standard Power Supply Cord Connectors

Flangedspade connector Ring Connector

Connecting Ground and Neutral Wires

1. Remove center terminal block screw and the ground wire

by removing the external ground connector screw.

3-wire direct

Connecting Direct Wire Ground

3. Connect ground wire (green or bare) with external ground

connector screw.

2. Connect ground and neutral wire to center terminal block.

Connecting Remaining Wires

4. Connect remaining wires with outer terminal block screws.

19

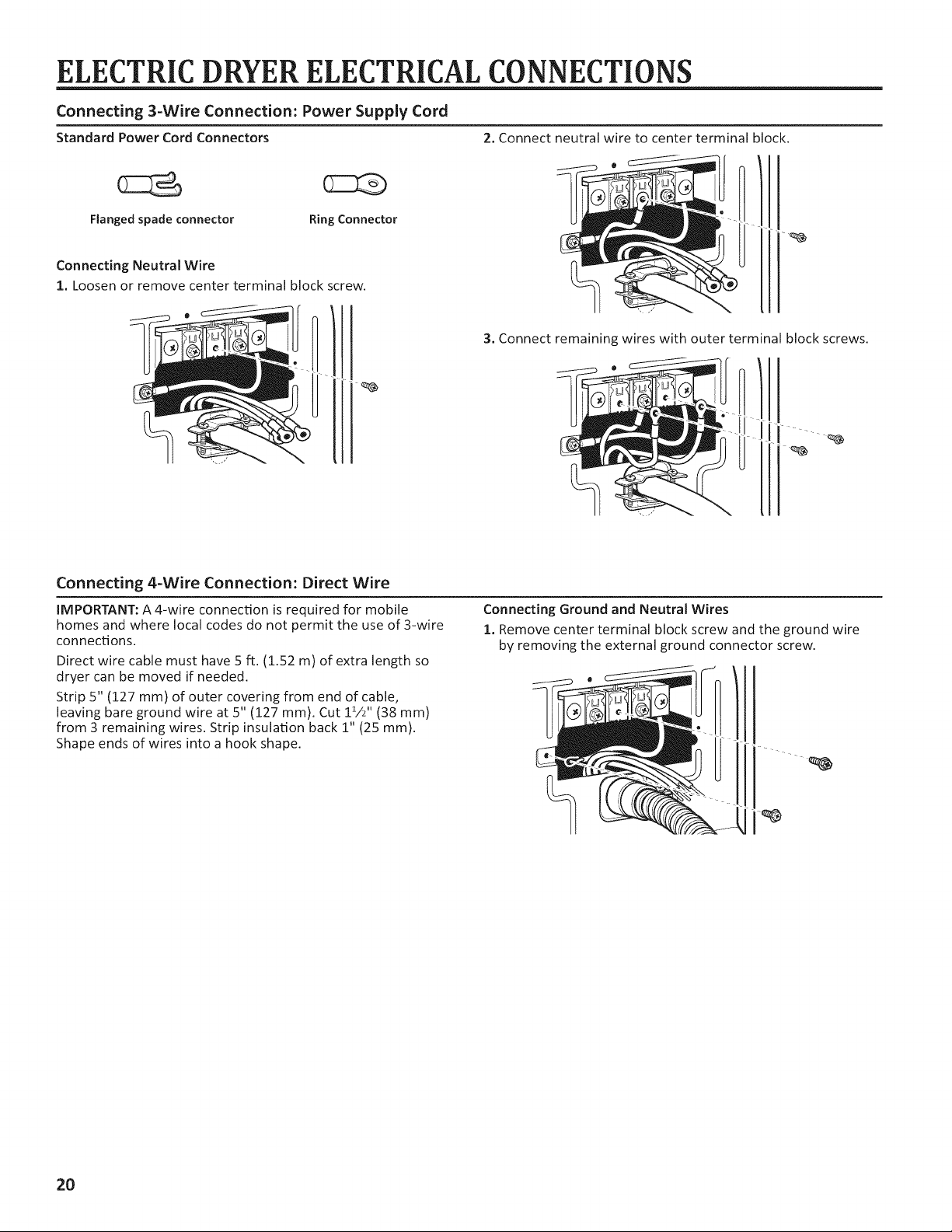

Page 20

ELECTRIC DRYERELECTRICAL CONNECTIONS

Connecting 3=Wire Connection: Power Supply Cord

Standard Power Cord Connectors 2. Connect neutral wire to center terminal block.

Connecting Neutral Wire

1. Loosen or remove center terminal block screw.

3. Connect remaining wires with outer terminal block screws.

I

Connecting 4-Wire Connection: Direct Wire

IMPORTANT: A 4-wire connection is required for mobile

homes and where local codes do not permit the use of 3-wire

connections.

Direct wire cable must have 5 ft. (1.52 m) of extra length so

dryer can be moved if needed.

Strip 5" (127 mm) of outer covering from end of cable,

leaving bare ground wire at 5" (127 mm). Cut 1t/2" (38 mm)

from 3 remaining wires. Strip insulation back 1" (25 mm).

Shape ends of wires into a hook shape.

Connecting Ground and Neutral Wires

1. Remove center terminal block screw and the ground wire

by removing the external ground connector screw.

20

Page 21

ELECTRIC DRYER ELECTRICAL CONNECTIONS

Connecting 4-Wire Connection: Direct Wire

Connecting Ground and Neutral Wires (cont.)

2. Connect ground and neutral wire to center terminal block.

Connecting Direct Wire Ground

3. Connect ground wire (green or bare) with external ground

connector screw.

Connecting Remaining Wires

4. Connect remaining wires to outer terminal block.

Connecting 3-Wire Connection: Direct Wire

Use where local codes permit connecting

cabinet-ground conductor to neutral wire.

Direct wire cable must have 5 ft. (1.52 m) of extra length so

dryer can be moved if needed.

Strip 3t/2 '' (89 mm) of outer covering from end of cable. Strip

insulation back 1" (25 mm). If using 3-wire cable with ground

wire, cut bare wire even with outer covering. Shape ends of

wires into a hook shape.

Connecting Neutral Wire

1. Loosen or remove center terminal block screw.

I

2. Connect neutral wire to center terminal block.

3. Connect remaining wires to outer terminal block.

21

Page 22

ELECTRIC DRYERELECTRICAL CONNECTIONS

Connecting 3-Wire Connection: Optional

Use for direct wire or power supply cord where local codes

do not permit connecting cabinet-ground conductor to

neutral were.

Connecting Neutral Wire

1. Remove center terminal block screw. Also remove neutral

ground wire by removing external ground conductor screw.

3. Connect remaining wires to outer terminal block.

2. Connect neutral wire and neutral wire of power supply cord/

cable to center terminal block.

LEVELING

Leveling your dryer properly reduces excess noise and vibration.

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury,

1. Remove cardboard from beneath dryer. Place a level on top

edges of dryer, checking each side and front. If not level, tip

dryer and adjust feet up or clown as shown in Steps 3 and 4,

repeating as necessary.

nt Jn

4. Connect a separate copper ground wire from the external

ground conductor to an adequate ground.

Not Level LEVEL Not Level

22

Page 23

LEVELING

2. Grip dryer from top and rock back and forth, making sure all

four feet are firmly on floor. Repeat, rocking dryer from side

to side. If dryer rocks, go to Step 3 and adjust leveling feet.

If all four feet are in firm contact with floor, go to Step 4.

3. If dryer is not level, use a 1" or 25 mm open-end or adjustable

wrench to turn jam nuts clockwise (as viewed from above)

on feet until they are about 1/2" (13 mm) from the dryer

cabinet. Then turn the leveling foot counterclockwise to lower

the dryer or clockwise to raise the dryer. Recheck levelness of

dryer and that all four feet are firmly in contact with the floor.

Repeat as needed.

HELPFULTIP: You may want to prop up front of dryer about 4"

(102 mm) with awood block or similar object that will support

weight of dryer.

\

4. When dryer is level and all four feet are firmly in contact with

the floor, use a 1" or 25 mm open-end or adjustable wrench

to turn jam nuts counterclockwise (as viewed from above)

on leveling feet tightly against dryer cabinet.

HELPFULTiP: You may want to prop dryer with wooden

block.

1. Check the electrical requirements. Be sure that you have the

correct electrical supply and the recommended grounding

method. See "Electrical Requirements."

2. Check that all parts are now installed. If there is an extra

part, go back through the steps.

3. Check that you have all of your tools.

4. Dispose of/recycle all packaging materials.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

COMPLETE INSTALLATION

6. Check dryer operation. Close dryer door. Insert coins in slide

and press slide in slowly. Select the Whites and Colors cycle

and let the dryer run for at least five minutes.

NOTE: Dryer door must be closed for dryer to operate.

7. Open the dryer door. Check that the inside of the dryer is

warm. If the burner does not ignite and you can feel no heat

inside the dryer, shut off dryer for five minutes. Check that

all supply valve controls are in "ON" position and that the

electrical cord is plugged in. Repeat five-minute test.

8. If drying time is too long, make sure that the lint screen is

clean and that there are no obstructions to airflow in the

dryer vent system.

9. Restart the dryer and allow it to complete a full cycle to

make sure it is working properly.

5. Plug into a grounded outlet, or connect power.

23

Page 24

REVERSING DRYERDOOR SWING

Remove the Door Assembly

1. Place a towel or soft cloth on top of dryer or work space to

avoid scratching of the surface.

2. Remove 3 of the 4 screws that hold the door hinge on the

front panel of the dryer. Partially loosen the remaining screw

with keyhole opening and lift the door offthe screw.

\

4. Lift the inner door assembly off outer door assembly.

5. Rotate outer door 180 °.

3. Lay the door assembly on a previously prepared fiat surface

with the inside (inner door assembly) facing up, and remove

6 phillips-head screws to release outer door assembly from

inner door assembly.

NOTE: It is important that you remove only 6 indicated screws.

Reverse Hinge

1. Use a small fiat-blade screwdriver to remove 2 plug strips

from the inner door. Slide the head of the screwdriver under

the plugs, without scratching inner door surface, and lift up

strip.

2. Remove the 4 screws that attach to inner door hinge.

24

Page 25

REVERSING DRYERDOOR SWING

3. Move hinge to other side. Reinstall 4 screws.

4. Reinstall plug strips on opposite side of the inner door.

Reverse the strike

1. Use a small fiat-blade screwdriver to remove plug strip from

the dryer door opening. Slide the head of the screwdriver

under the plugs, without scratching dryer surface, and lift

up strip.

2. Remove the strike using a Phillips screwdriver.

5. Check for fingerprints on the glass. Clean if necessary.

Replace the Door Assembly

1. Place the inner door assembly inside the outer door

assembly.

2. Reassemble the inner and outer door assemblies with the

6 screws.

3. Insert strike on the opposite side.

Reinstall the door

1. Partially insert the third screw from the top; then slide the

hinge onto this screw while hooking the hinge into the front

panel hole. Reattach door to dryer front panel with the

remaining three screws.

2. Check for fingerprints on the glass. Clean if necessary.

3. Close door and check that it latches securely.

25

Page 26

MAINTENANCEINSTRUCTIONS

[] Clean lint screen before and after each cycle.

[] Removing accumulated lint:

From inside the dryer cabinet:

Lint should be removed every 2 years or more often,

depending on dryer usage. Cleaning should be done

by a qualified person.

From the exhaust vent:

Lint should be removed every 2 years, or more often,

depending on dryer usage.

[] Keep area around dryer clear and free from combustible

materials, gasoline, and other flammable vapors and

liquids.

[] Keep dryer area clear and free from items that would

obstruct the flow of combustion and ventilation air.

If dryer does not operate, check the following:

[] Electrical supply is connected.

[] Circuit breaker is not tripped or house fuse is not blown.

[] Door is closed. Listen closely to hear the door switch

activate.

[] Control is set up properly and display shows cycle time.

[] Cycle selection button has been pushed firmly.

[] For gas dryers, check that gas supply shut-off valves are set

in open position.

IF YOU NEED ASSISTANCE

Contact your authorized Whirlpool ®Commercial Laundry distributor. To locate your authorized Whirlpool ®Commercial Laundry

distributor, or for web inquiries, visit www.WhirlpoolCommerdalLaundry.com.

If you cannot locate your distributor, the Commercial Laundry Support Center will answer any questions about operating or

maintaining your dryer not covered in the "Installation Instructions."

Just dial 1-800 NO BELTS(1-800-662-3587) -- the call is toll free.

When you call, you will need the dryer model number and serial number. Both numbers can be found on the serial-rating plate

located in the dryer door opening.

26

Page 27

ELECTRONICCONTROL SETUP INSTRUCTIONS

NOTE: After the dryer has been installed and plugged in,

the display will show "0 MINUTES." After the door has been

opened and closed, the display will show the vend price.

General User Information

SCROLLING"OUT OF ORDER" MESSAGE, FOLLOWEDBYA

FAILUREOR DIAGNOSTIC CODE,SHOWING IN DISPLAY-

This condition indicates the dryer is inoperative.

"0 MINUTES" SHOWING IN DISPLAY- This indicates the dryer

cannot be operated. Coins dropped or debit inputs during this

condition will be stored in escrow but cannot be used until

normal operation is restored by opening and closing the door.

If a door switch has failed, causing "0 MINUTES" to remain

in the display after the door is opened and closed, it must be

replaced before normal operation can be restored.

COLD START (Initial first use) - Dryer is programmed at the

factory as follows: $1.50 dry price (30 minutes)

WARM START(after power failure) - A few seconds after

power is restored, if a cycle was in progress at the time of

the power failure, "RESELECTCYCLE"will flash in the display,

indicating the need for a fabric setting button to be pressed

to restart dryer.

PRICING - After the door is opened and then closed following

the completion of a cycle, the display indicates the cycle price

(unless set for free operation, where the display will flash

"SELECT CYCLE"). As coins are dropped or debit inputs arrive,

the display will change to lead the user through the initiation

of a cycle.

There are four (4) types of dryer pricing:

Fixed "Vend" Pricing

A dryer setup for "Fixed Cycle" operation can only accept

additional time accumulated by increments equal to the length

of a complete dry cycle. A maximum of 99 minutes may be

purchased; no additional credit is given for coins dropped

with 99 minutes in the display.

Accumulator Pricing

If option d is set to d. 00, and the 6 code isset to one coin

1, then accumulator pricing is in effect. Cycle time can be

purchased one coin at a time up to the maximum time of

99 minutes.

Fixed Cycle With Top Off Pricing (available for use with coin

drops or card readers only)

A dryer set to offer "Top Off" capability will allow time to

be added to an existing dry cycle in increments equal to the

number of minutes of dry time per quarter (coin 1), up to 99

minutes, regardless of the cost required to start the dryer.

No credit isgiven for coins or debit inputs entered when the

control isdisplaying 99 minutes.

Penny increment offset is not applied to top off purchases.

FREECYCLES-This is established by setting the cycle price to

zero. When this happens, "SELECTCYCLE"will appear rather

than a cycle price. Any cycle started as a free cycle

will automatically terminate when the door is opened.

DEBIT CARD READY = This dryer is debit card ready.

It will accept a variety of debit card systems, but does NOT

come with a debit card reader. Refer to the debit card reader

manufacturer for proper dryer setup. When a Generation 2

card reader is installed, the dryer is placed in enhanced debit

mode.

In Enhanced Debit Mode, the top off price can be set

independently (see VALUE OF COIN 2), and the top off time is

calculated according to the following equation:

top off price top off time

full cycle price = full cycle length

In models converted to a Generation i debit card system, debit

pulses represent the equivalent of one coin (coin 1).

NOTE: Enhanced debit mode cannot be deselected.

Control Set-up Procedures

IMPORTANT: Read all instructions before operating.

The fabric setting buttons along with the digital display are

used to set up the dryer controls.

The display can contain 4 numbers and/or letters and a decimal

point. These are used to indicate the set-up codes and related

code values available for use in programming the dryer.

27

Page 28

ELECTRONICCONTROL SETUP INSTRUCTIONS

How to Use the Buttons to Program the Controls

1. The COTTON/WHITES button is used to adjust the values

associated with set-up codes. Pressing the button will

change the value by increments. Rapid adjustment is

possible by holding down the button.

2. The PERM PRESSbutton will advance through the set-up

codes. Pressing this button will advance to the next available

set-up code. Holding down the button will automatically

advance through the set-up codes at a rate faster than 1 per

second.

3. The COLORS/DELICATESbutton is used to select or deselect

options.

Start Operating Set-up

Insert service access door key, turn, and lift to remove service

access door.

Dryers with Card Reader Installed:

Once the debit card reader is installed (according to the

reader manufacturer's instructions), the set-up mode can be

entered by inserting a manual set-up card (supplied by the

reader manufacturer) into the card slot. If manual set-up card

is not available, only the diagnostic mode can be entered by

removing the service access door.

IMPORTANT: To access set-up mode or diagnostic mode, use

a service key to open the service access door. If a card reader

is installed, a service card is available for accessing diagnostics.

If a service key is not available, the AA1 connector must be

removed for access. The console must not be opened unless

power is first disconnected from the dryer. To access connector

AAI:

1. Unplug dryer or disconnect power.

2. Open console, remove plug on AA1, close console.

3. Plug in dryer or reconnect power.

The dryer is now in the set-up mode.

NOTE: It is not necessary to set up the dryer with the following

codes; the dryer is pre-set at the factory. These codes can be

used to change settings, if desired.

Set-Up Codes

[] The PERM PRESSbutton will advance from code to code.

[] The COTTON/WHITES button will change the code value.

[] The COLORS/DELICATESbutton will select or deselect

options.

The set-up code is indicated by the one or two left-hand

characters. The set-up code value is indicated by the two or

three right-hand characters.

NOTE: The first line of each code indicates the factory default.

Code Explanation

6 06 REGULAR CYCLEPRICE

6 06

When the d.xx is set to d.00, this 6 xx value represents

the number of quarters (coin 1) needed to start

the dryer; may adjust from 0-39. Change this value

by pressing the COTTON/WHITES button. 6 06 = 6

quarters = 51.50.

601

When the d.xx is set to d.CS, this 6 xx value represents

the number of push-in actuations of the coin slide

to start the dryer. 6 01 would equal one coin slide

activation.

• Press the PERM PRESSbutton once to advance to

next code.

7 05 REGULAR DRY TIME

7 05

When set to Coin Drop or Card Reader operation, the

dry time equals the Regular Dry Time value multiplied

by the Regular Cycle Price value. Example: 6 06 and

7 05 = (06 x 05 = 30 minutes).

7 30

For coinslide or OPL operation, the value is the amount

of minutes of dry time. Factory default of 30 minutes.

Pressing COTTON/WHITES adjusts the value from 1-99

minutes.

Press the PERM PRESSbutton once to advance to

next code.

8 00 TYPE OF DRYER PRICING

8 00

8 FC

9 00

Fixed Cycle with Top Off. Only available for use with

coin drops or card readers. For detailed description,

see General User Information.

Fixed Cycle. For detailed description, see General User

Information. Use COLORS/DELICATES button to make

this selection.

Press the PERM PRESS button once to advance to

next code.

CYCLECOUNTER OPTION

This option is either NOT SELECTED"OFF" or SELECTED

"ON."

9 O0

90C

Not Selected "OFF."

Selected "ON" and not able to be deselected.

Press the COLORS/DELICATES button

3 consecutive times to select "ON." Once

selected "ON" it cannot be deselected.

Press the PERM PRESS button once to advance to

next code.

28

Page 29

ELECTRONICCONTROL SETUP INSTRUCTIONS

Code

1.00

Explanation

MONEY COUNTER OPTION

This option iseither NOT SELECTED"OFF" or

SELECTED"ON."

1.00 Not Selected "OFF."

1.0C Selected "ON."

• Press the COLORS/DELICATES button

3 consecutive times to select "ON" and 3

consecutive times to deselect (Not Selected "OFF").

Counter resets by going from "OFF" to "ON."

1. CO Selected "ON" and not able to be deselected.

To select "ON" and not able to be deselected,

first select "ON," then within 2 seconds, press the

COLORS/DELICATES button twice, the COTTON/

WHITES button once, and exit set-up mode.

Press the PERM PRESS button once to advance to

next code.

2.00 SPECIAL PRICING OPTIONS

This option iseither NOT SELECTED"OFF" or

SELECTED"ON."

2.00

2. SP

Not Selected "OFF."

Selected "ON."

Press the COLORS/DELICATES button once to change

this selection.

If SPECIAL PRICING OPTION is selected, there is access to

codes "3.XX" through "9.×X."

e Press the PERM PRESSbutton once to advance to

next code.

OPTIONS 3.XX-9.XX TO USE IF SPECIAL PRICING

IS SELECTED

3.06 SPECIAL CYCLEPRICE

3.06

3.01

When the d.xx is set to d.00, this 3.xx value represents

the number of quarters (coin 1) needed to start

the dryer; may adjust from 0-39. Change this value

by pressing the COTTON/WHITES button. 3.06 = 6

quarters = S1.50.

When the d.xx is set to d.CS, this 3.xx value represents

the number of push-in actuations of the coin slide

to start the dryer. 3.01 would equal one coin slide

actuation.

Press the PERM PRESSbutton once to advance to

next code.

4.05 SPECIAL DRY TIME

4.05

When set to Coin Drop or Card Reader operation, the

dry time equals the Special Dry Time value multiplied

by the Special Cycle Price value. Example: 3 06 and

4 05 = (06 x 05 = 30 minutes).

4.30

For coinslide or OPL operation, this value represents

the number of minutes for full vend price. Factory

default of 30 minutes. By pressing the COTTON/

WHITES button, the value can be adjusted from 1-99

minutes.

Press the PERM PRESS button once to advance to

next code.

Code

5.00

5.00

Explanation

TIME-OF-DAY CLOCK, MINUTES

This is the TIME-OF-DAY CLOCK,minute setting;

select 0-59 minutes by pressing the COTTON/WHITES

button.

Press the PERM PRESSbutton once to advance to

next code.

6.00 TIME-OF-DAY CLOCK, HOURS

NOTE: Uses military time or 24 hr. clock.

6.00 This is the TIME-OF-DAY CLOCK, hour setting; select

0-23 hours by pressing the COTTON/WHITES button.

Press the PERM PRESSbutton once to advance to

next code.

7.00 SPECIAL PRICE START HOUR

NOTE: Uses military time or 24 hr. clock.

7.00 This is the start hour; 0-23 hours.

Select STARTHOUR by pressing the

COTTON/WHITES button.

Press the PERM PRESSbutton once to advance to

next code.

8.00 SPECIAL PRICE STOP HOUR

NOTE: Uses military time or 24 hr. clock.

8.00

This is the stop hour; 0-23 hours.

Select STOPHOUR by pressing the COTTON/WHITES

button.

Press the PERM PRESSbutton once to advance to

next code.

9. 10 SPECIAL PRICE DAY

9. 10

This represents the day of the week and whether

special pricing is selected for that day. A number

followed by "0" indicates no selection that particular

day (9.10). A number followed by an "S" indicates

selected for that day (9.1S). To change the value

of "0" and "S," use the COLORS/DELICATESbutton.

Days of the week (1-7) are selected by pressing the

COTTON/WHITES button.

When exiting set-up code "9/' the display must show the

current day of week:

DISPLAY DAY OF WEEK CODE (selected)

10 Day 1 = Sunday 1S

20 Day 2 = Monday 2S

30 Day 3 = Tuesday 3S

40 Day 4 = Wednesday 4S

50 Day 5 = Thursday 5S

60 Day 6 = Friday 6S

70 Day 7 = Saturday 7S

Press the PERM PRESS button once to advance to

next code.

29

Page 30

ELECTRONICCONTROL SETUP INSTRUCTIONS

Code Explanation Code

A. 00 VAULT VIEWING OPTION J. Cd

This option is either NOT SELECTED"OFF" or

SELECTED"ON." J. Cd

A. 00 Not Selected "OFF."

A. SC Selected "ON." J. C

• Press the COLORS/DELICATES button once to change

this selection. When selected, the money and/or

cycle counts will be viewable (if counter option(s) is

selected) when the coin box is removed.

Press the PERM PRESS button once to advance to

next code.

J. d

J. Ed

b. 05 VALUE OF COIN 1

b. 05

b. 30

C. 20 VALUE OF COIN 2

C. 20

This represents the value of coin 1 in number

of nickels: 05 = S0.25.

By pressing the COTTON/WHITES button, there is an

option of 1-199 nickels.

With coin slide activation, this represents the total

vend price in nickels. Example: b. 30 is equal to 51.50.

Press the PERM PRESS button once to advance to

next code.

This represents the value of coin 2 in number

L.00

L.00

L. PS

of nickels: 20 = 51.00.

By pressing the COTTON/WHITES button, there is an

option of 1-199 nickels.

C. 05

When a Gen 2 card reader is used, this code represents

n. CE

the value of top off in nickels. C. 05 = 50.25.

Pressthe PERM PRESSbutton once to advance to

next code.

d. 00

COIN SLIDE OPTION

This option is either Selected "ON" or Not Selected

"OFF." Coin slide use requires mounting of a coin slide

n. 00

n. CE

adapter plate into the metercase opening.

d. 00

d. CS

Not Selected "OFF."

Selected "ON." Pressthe COLORS/DELICATESbutton

3 consecutive times for this selection.

When coin slide mode is selected, set "b." equal to

value of vend price in nickels. Set set-up code 6 xx

(regular cycle price) and set-up code 3.xx (special

U. 00 PENNY INCREMENT OFFSET

U. 00

cycle price) to number of slide operations. If the

installer sets up "CS" on a coin drop operated model,

it will not register coins.

Pressthe PERM PRESSbutton once to advance to

next code.

E. 00

ADD COINS OPTION

NOTE: This option is only used with card reader or

coin drop. This option is either Selected "ON" or Not

Selected "OFF". This option causes the customer

display to show the number of coins (coin 1) to enter,

rather than the dollars-and-cents amount.

E. 00

E.AC

Not Selected "OFF."

Selected "ON."

Pressthe COLORS/DELICATESbutton

3 consecutive times to change this selection.

In enhanced debit mode, this option is not

selectable.

Pressthe PERM PRESSbutton once to advance to

30

next code.

Explanation

PAYMENT MODE (COIN/DEBIT OPTION}

Both coin and debit selected. Press the COLORS/

DELICATES button 3 consecutive times to change this

selection.

Coins selected, debit disabled. Press the COLORS/

DELICATES button 3 consecutive times to change this

selection.

Debit Card selected, coin disabled. This selection must

be used for free vend. Press the COLORS/DELICATES

button 3 consecutive times to change this selection.

Enhanced Debit is self-selected when a Generation 2

card reader is installed in the dryer. The "Ed" option

cannot be manually selected or deselected.

• Press the PERM PRESS button once to advance to

next code.

PRICESUPPRESSION OPTION

This option is either Selected "ON" or Not Selected

"OFF." This option causes the customer display to

show "ADD" or "AVAILABLE" rather than the amount

of money to add. (Used mainly in debit installations.)

Not Selected "OFF."

Selected "ON."

Press the COLORS/DELICATESbutton once to change

this selection.

Press the PERM PRESSbutton once to advance to

next code.

CLEARESCROW OPTION

This option is either Selected "ON" or Not Selected

"OFF." When selected, money held in escrow for 30

minutes without further escrow or cycle activity will

be cleared.

Not Selected "OFF."

Selected "ON."

Press the COLORS/DELICATESbutton once to change

this selection.

Press the PERM PRESSbutton once to advance to

next code.

This represents the penny increment price offset used

in Generation 2 (Enhanced Debit mode) card readers.

Choose from 0-4 pennies by pressing the COTTON/

WHITES button. This option does not apply to top off

feature.

Press the PERM PRESSbutton once to advance to

next code.

Page 31

ELECTRONICCONTROL SETUP INSTRUCTIONS

If cycle counter (90C) is selected, the following is true:

100 Cycles in HUNDREDS 10__22= 200

2 00 Cycles in ONES 2 2__5= 25

TOTAL CYCLES= 225

This is "VIEW ONLY" and cannot be cleared.

• Press the PERM PRESSbutton once to advance to next code.

If money counter (I.0C or I.C0) is selected, the following is

true:

300 Dollars in HUNDREDS 30:1 = _;100.00

400 Dollars in ONES 46__8_8= $ 68.00

500 Number of CENTS 57__55= ._ 00.75

TOTAL = ._168.75

END of SET-UP PROCEDURES

TO EXIT FROM SET-UP MODE

1. Close the service access door.

2. Disconnect dryer from power before reinstalling the AA1

connector, if it was removed.

3. Remove the manual set-up card.

Diagnostic Codes

If the set-up mode is entered and one of the following has

previously occurred, the appropriate diagnostic code will be

in the display.

d5

Blocked coin 1 or coin drop UI control

circuit failure (coin recognition and

customer display disabled while

blockage persists).

d 9 Voltage detected below 90 VACfor

8 seconds.

d 13 Blocked coin 2 or coin drop UI control

circuit failure (coin recognition and

customer display disabled while

blockage persists).

d 16 Not receiving communications

from installed debit card reader in

Enhanced (Generation 2) Debit mode.

F 01

F 22

Dryer motor control circuit error

(cycles and price display disabled until

diagnostic code is manually cleared).

The control doesn't know if the motor

relay is bad (stuck on), the motor relay

drive circuit is bad (shorted), causing

the motor relay to stay on, or the

motor relay feedback circuit is bad.

Exhaust thermistor open, temperature

drops below 18°F (>50 kO) for 1

minute in Run mode, or immediately

in Factory Diagnostic Mode.

F 23

Exhaust thermistor shorted,

temperature above 250°F (<500Q) for

i minute in Run mode, or immediately

in Factory Diagnostic Mode.

F 70

F71

F 73

F 74

UI is not receiving communications

from CCU (cycles and price display

disabled while error persists or is

manually cleared).

CCU is not receiving communications

from UI (cycles and price display

disabled while error persists or is

manually cleared).

UI Microprocessor is not able to read

or verify EEPROM (cycles and price

display disabled until diagnostic code

is manually cleared).

UI EEPROM memory is a CRC failure

(cycles and price display disabled until

diagnostic code is manually cleared).

31

Page 32

ELECTRONICCONTROL SETUP INSTRUCTIONS

Dryer Diagnostic Mode

This mode is entered by depressing COLORS/DELICATESfor one

second while in either of the set-up codes 6 xx or 7 xx or with

a diagnostic code present. Diagnostic codes are cleared on

entry and all display segments should flash. If a diagnostic code

persists, it must be corrected before the diagnostic cycle can

be entered.

All Models:

With all segments flashing, the diagnostic cycle is started by

depressing the PERM PRESS button. The cycle consists of

7 minutes of heat and 1 minute of cooldown.

The COTTON/WHITES button will increment the diagnostic

cycle minutes up to 99, then roll over to 2 minutes. The

COLORS/DELICATES button will cancel this cycle and exit

the diagnostic mode.

Dryer Help Mode

Dryer help mode is entered by pressing the COTTON/WHITES

button while in special pricing option 2.XX. In help mode, the

software revision is displayed. The help mode is advanced by

pressing the PERM PRESS button. See Help Mode Submenu

below for the order in which items are displayed. Press the

COTTON/WHITES button at any time to exit help mode.

Help Codes

71

Generation 2 debit card

cycle polling message out of

sequence.

74

Generation 2 debit card

remaining balance message

out of sequence.

75

Generation 2 debit card new

card balance message out of

sequence.

88

Invalid messaging state

found in data acquisition

communications comm

suprv ( ) routine.

Help Mode Submenu

lh.XX Help Code 1, where XX isthe help

code number. *

2 2h.XX Help Code 2, where XX isthe help

code number. *

3 3h.XX Help Code 3, where XX isthe help

code number. *

4 1.X## Error history code 1, where X is

the F or d code, and ## is the code

number. **