Page 1

FIRST AND ROUTINE WASHES

GB

BEFORE USING THE APPLIANCE FOR THE FIRST TIME:

• IMPORTANT:

1. MAKE SURE YOU HAVE READ THE INSTALLATION INSTRUCTIONS.

2. REMOVE THE TRANSIT SCREWS AND TRANSIT BAR BEFORE USING THE

MACHINE FOR THE FIRST TIME.

• First wash cycle without laundry:

Open the tap.

1.

Close the door.

2.

Pour a little detergent (about 30 ml) into the detergent compartment .

3.

Select a short wash programme (see programme chart).

4.

Switch on the appliance.

5.

This will remove any water remaining in the machine from the manufacturer's test run.

ROUTINE WASHES:

Open the tap.

1.

Sort the laundry according to fabric type and colour and load the machine (see “Sorting

2.

the wash”).

Close the door.

3.

Add detergent and any additives required (see “Detergent and additives”).

4.

Select the programme, temperature and special options

5.

(see programme chart).

Make sure to meet exactly the starting point of the programme. Otherwise the first part

of the programme will not be executed: washing results will not be as good as after a

complete programme cycle.

Switch on the appliance.

6.

15

Page 2

GB

CONTENTS

APPLIANCE AND ACCESSORIES

INSTALLATION

PROTECTING THE ENVIRONMENT

SAFETY INSTRUCTIONS

MOVING AND TRANSPORTING THE APPLIANCE

SORTING THE WASH

DETERGENT AND ADDITIVES

LIQUID BLEACH (HYPOCHLORITE)

DYEING

PAGE

PAGE

PAGE

PAGE

PAGE

PAGE

PAGE

PAGE

PAGE

17

18

20

20

20

21

22

23

24

REMOVING THE FILTER

DRAINING RESIDUAL WATER

WASHING MACHINE INSTALLED IN ROOM

EXPOSED TO FREEZING TEMPERATURES

CARE AND MAINTENANCE

TROUBLESHOOTING GUIDE

AFTER-SALES SERVICE

PAGE

PAGE

PAGE

PAGE

PAGE

PAGE

24

25

25

26

27

27

16

Page 3

APPLIANCE AND ACCESSORIES

Worktop

1.

Control panel

2.

Detergent drawer

3.

After-Sales Service sticker (inside door)

4.

Door

5.

Door handle

6.

To open: pull handle

-

To lock: press the door firmly (the lock will click into place)

-

Filter (inside compartment door).

7.

17

Page 4

.

INSTALLATION

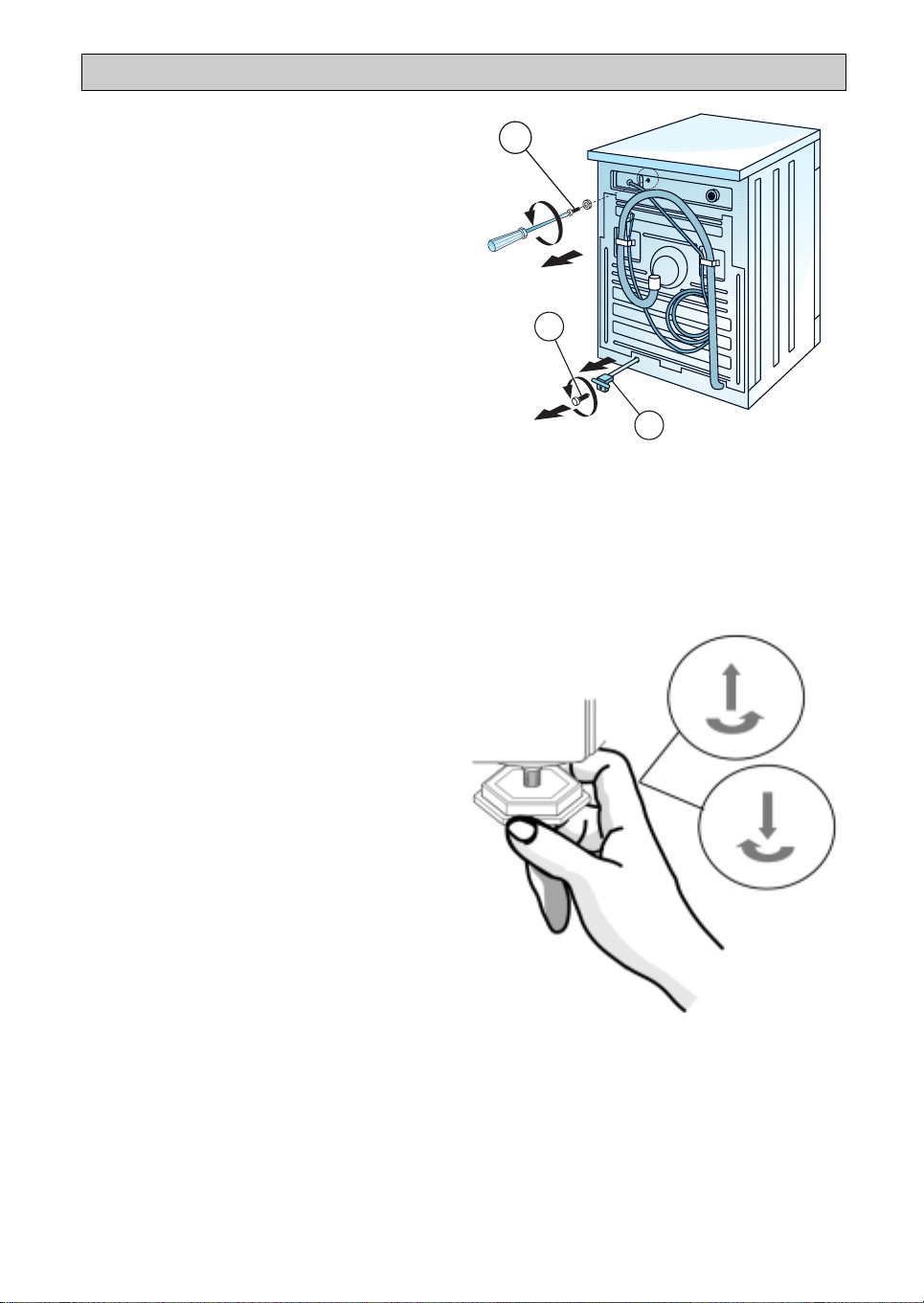

TRANSIT SCREWS

The appliance is fitted with two transi t screws and

a transit bar to prevent inte rnal damage whil e it is

being moved.

Before using the appliance the transit screws

and transit bar MUST be removed.

The appliance is fitted with two screws and a

transit bar.

1.

Remove the black screw

(A)

with a

screwdriver.

2.

Unscrew the screw

(B)

on the red transit bar

with a screwdriver.

3.

Completely withdraw and remove the transit

(C)

bar

by pulling firmly on the red handle.

Keep the screws and the bar for future use.

Note:

Refit the transit screws and transit bar b efore t ransport ing t he app lianc e by repe atin g the a bove

steps in reverse order. In order to locate the screws and bar correctly, it wil l be necessary to remove the

appliance top, having first made sure that the ap plian ce is disc onnec ted from wat er and elec tricit y

supplies.

INSTALLATION

•

Install the appliance on a solid and level floor

surface, preferably in a corner of the room.

•

Make sure that all four feet are resting firmly

on the floor and check that the appliance is

perfectly level (use a spirit level).

•

If the floor is uneven, adjust the levelling feet

as required (do not insert pieces of wood,

cardboard etc. under the feet).

Adjust the feet:

•

Adjust the right foot by turning it by hand to

assure that all four feet touch properly the

floor.

If the appliance is to be installed on a wooden

floor, distribute the weight by placing it on a

60 x 60 cm sheet of plywood at least 3 cm in

thickness. Secure the plywood sheet to the floor.

A

B

C

t

WATER SUPPLY

•

Water supply: only cold water.

•

Tap: 3/4” threaded hose connector.

•

Water pressure (mains pressure):

100-1000 kPa (1-10 bar).

INLET HOSE

•

Carefully screw the inlet hose to the tap.

•

Turn the tap on fully and check that the joints

at the washing machine and the tap are

watertight.

• Make sure that there are no kinks in the

hose and that it is not crushed.

18

•

If the hose is not long enough, replace it with

a suitable length of pressure-resistant hose

(approved under EN 500 65 to withstand a

minimum of 1000 kPa).

•

Check the hose regularly for brittleness and

cracks and replace if necessary.

•

The washing machine may be connected

without a non-return valve.

•

Observe any special local regulations

regarding connection to the water supply.

Page 5

INSTALLATION

DRAIN HOSE

•

Drain hose connection to water outlet.

1.

Unhook the drain hose from the left clip;

see arrow

Important:

Do NOT loosen the drain hose connection;

see arrow

leakage (danger of scalding with hot water)

and the normal filling and draining functions

of the machine cannot be guaranteed.

2.

Fit the drain hose either to the siphon or hook

it over the edge of a sink or bath tub with the

“U” bend. Small hand basins are not suitable.

3. Minimum drain height: 60 cm.

Maximum U-bend drain height: 90 cm.

4.

If you need to add an extension, use a

flexible hose of the same type and secure the

union with screw-on hose clips. Maximum

overall drain hose length 2.5 m.

Important:

•

Make sure that there are no kinks in the drain

hose run.

•

Take precautions against it falling while the

appliance is running.

(A)

.

(B)

, otherwise there is the risk of

CONNECTION TO THE MAINS

•

Observe local utility company regulations.

•

The connection must be made with a

correctly installed, earthed and insulated

socket.

•

The system must be earthed.

The manufacturer declines all responsibility

for injury to persons or pets and damage to

property caused by disregarding the above

instructions.

•

The data concerning voltage, consumption

and necessary fuse are supplied on the

inside of the appliance door.

•

The mains connection cable may only be

replaced by original power cable by

authorised customer service.

•

The appliance conforms to European safety

regulations 73/23/EC, 89/336/EC and 93/68/

EC.

•

Do not use extension leads or multisockets.

19

Page 6

PROTECTING THE ENVIRONMENT

• Packing

The packaging is marked with the recycling

symbol , signifying that it can be

100% recycled.

• Appliance

The appliance is made of recyclable

materials. Dispose of the appliance in

conformity with environmental regulations.

Make it inoperable: pull out the plug and cut

off the power cable so that the appliance

cannot be connected to the mains.

SAFETY INSTRUCTIONS

The appliance must only be used in the

•

household for the prescribed uses.

All connections to the water and electrical

•

mains must be made in accordance with the

manufacturer's instructions and following

local utility company safety regulations

(see “Installation”).

Before any cleaning and maintenance,

•

switch off the machine or disconnect it from

the mains.

Switch off the washing machine and turn off

•

the tap whenever the machine is not in use.

• Eco-tips

A full load (depending on the programme

-

selected) gives the best energy and water

consumption.

Laundry which is lightly to moderately soiled

-

does not require a prewash.

Lightly soiled laundry should be washed at a

-

low temperature or with a short programme.

When washing small loads press the “Lightly

-

Soiled” / “Half load” button (if present)

and use less detergent.

Do not exceed the recommended dosages

-

on the detergent packet.

Only use bleach or stain remover if

-

absolutely necessary.

Never use excessive force to open the door.

•

Children must not be allowed to play with or

•

inside the machine. Do not rest any weight on

the door.

Packaging materials can be dangerous for

•

children. Keep the packaging material

(plastic bags, polystyrene, etc.) well out of

their reach.

The appliance conforms to European safety

•

regulations 73/23/EC, 89/336/EC and 93/68/

EC.

MOVING AND TRANSPORTING THE APPLIANCE

Pull out the mains plug.

1.

Shut off the water tap.

2.

Disconnect the inlet and drain hoses.

3.

Drain residual water from the appliance and

4.

hoses (see “Draining Residual Water”).

Fit the transit screws and transit bar

5.

(see “Installation”).

20

Page 7

SORTING THE WASH

1. Sort the load according to:

• Fabric type / care label symbol

Cotton, mixed fibres, easy care/delicates, wool.

• Colours

Separate coloured and white articles. Wash new

coloured articles separately.

• Article size

Washing articles of different sizes together

improves wash efficiency and distributes the load

better in the drum.

• Fabric delicacy

Wash delicates separately. Select the approp riat e

special programme for machine - washable

wool , curtains or delicates. Either remove curtain

hooks or tie into a cloth bag. O nly wa sh mach in ewashable fabrics. Wash small articles (e.g. nylon

stockings, belts etc.) and art ic les wi th h ooks (e.g.

bras) in a cloth bag or pillow case with zip.

2. Empty all pockets

Coins, safety pins etc. can damage the laundry,

drum and tub.

3. Closures

Close zips and hooks and eyes. Loose belts or

ribbons should be tied together.

LOADING THE WASH

Open the door.

1.

Load the articles one at a time loosely into the

2.

drum, without overfilling.

Close the door.

3.

LOAD CAPACITY

See the programme overview.

Overloading the machine reduces the wash

Note:

efficiency and encourages creasing.

1

2

3

21

Page 8

DETERGENT AND ADDITIVES

CHOOSING THE RIGHT DETERGENT

The type of detergent depends on:

•

the type of fabric (cottons, synthetics,

delicates, wool);

Note:

Use only specific detergents for

washing wool.

•

colour;

•

wash temperature;

•

degree and type of soiling.

Note:

•

Whitish residues on dark fabrics are due to

the insoluble detergents components in

modern phosphate-free detergents. If this

occurs, shake or brush out the fabric or use

liquid detergents.

•

Keep detergents and additives in a safe,

dry place out of the reach of children.

•

Use only detergent and fabric conditioner

specifically produced for automatic domestic

washing machines.

•

When you use descaling agents, dyes or

bleaches, make sure that they are suitable

for washing machines use. Descaler could

contain components which can attack parts

of your washing machine.

•

Do not use solvents in the machine (e.g.

turpentine, benzine, etc.). Do not wash

fabrics in the machine which have been

treated with solvents or flammable liquids.

STAIN REMOVAL

•

Blood, milk, egg, and other organic

substances are generally removed by the

enzyme phase of the programme.

•

To remove red wine, coffee, tea, grass and

fruit stains, etc. add a biological stain

removing agent to the main wash in chamber

of the detergent drawer.

•

Particularly stubborn stains can be treated

with stain remover before the wash.

DETERGENT DOSAGES

Do not exceed manufacturers’ recommended

dosages as shown on the detergent package.

The amounts depend on:

•

degree and type of soiling;

•

size of wash;

-

full load: according to manufacturers’

instructions;

-

half load: 3/4 of the normal amount;

-

minimum load (about 1 kg): 1/2 the amount

used for full load;

•

water hardness in your area (request

information from the water company): soft

water requires less detergent than hard

water.

Note:

•

Overdosing the detergent results in

excessive foaming and reduces the wash

efficiency.

•

Using insufficient detergent results in grey

laundry. The heating elements and drum also

build up scale.

•

If using chlorine bleach, follow the bleach

instructions carefully. Overdosing the bleach

can damage the wash.

WATER HARDNESS

WATER HARDNESS

AREA

1

2

3

4

22

CHARACTERISTICS

soft

medium

hard

very hard

GERMAN

°dH

0-7

7-14

14-21

over 21

FRENCH

°fH

0-12

12-25

25-37

over 37

ENGLISH

°eH

0-9

9-17

17-26

over 26

Page 9

DETERGENT AND ADDITIVES

FILLING THE DETERGENT AND

ADDITIVES

1.

Pull out the detergent drawer.

2.

Filling the detergent.

•

Programmes with pre- and main

wash.

•

Main wash programme without

prewash.

•

Add fabric softeners and

conditioners no further than the

“MAX” mark printed on the

chamber.

•

Fill chlorine bleach only to the

“MAX” mark.

•

Stain remover.

•

Water softener

(water hardness 4).

•

Starching.

Dissolve/dilute the starch, powder

or liquid, in approximately 1 litre of

water in a container. Load the

machine, close the door, select

“Rinse and Spin” and start. Once

the machine has started filling, pour

the dissolved starch into detergent

dispenser chamber . Flush the

chamber straight away by adding

about half a litre of water.

Notes:

•

When using highly concentrated detergents,

use the detergent ball provided with the

detergent and place it directly in the drum to

avoid dispensing problems (for programmes

without pre-wash only).

•

Liquid detergent can be used for the main

wash, if a programme without prewash is

chosen.

Liquid detergent can be also used for the

prewash but in this case a powder detergent

has to be used for the main wash.

•

Dose the correct amount of concentrated

fabric softener and dilute with water up to the

maximum level marked in the softener

compartment.

Detergent drawer with 3 chambers.

3.

Slide the drawer in until it clicks shut.

LIQUID BLEACH (HYPOCHLORITE)

There are two possible ways to use liquid bleac h

(hypochlorite).

IMPORTANT:

In a machine without a specific bleach

dispenser chamber , only the pre-bleach

method can be used (see point 2).

1. Traditional way:

•

Add bleach into the bleach dispenser

chamber

.

Detergent drawer with 4 chambers.

•

Add detergent in the main wash dispenser

chamber .

•

Select a programme and temperature and

start the machine.

•

The machine will automatically deliver both

products to the laundry at the appropriate

time, the detergent is added in the main

wash, the bleach is added during the second

cold rinse.

23

Page 10

LIQUID BLEACH (HYPOCHLORITE)

2. Pre-bleach method:

Laundry with heavy stains may be

PRE-BLEACHED in the machine prior to carrying

out a normal wash programme. Proceed by

diluting the bleach in approximately 1l water

outside of the washing machine in a small

container.

For a machine with temperature selector:

Turn the programme selector to programme 4.

•

Turn the temperature selector to

•

Warning:

wash, otherwise your laundry and your appliance

will be damaged.

For a machine without temperature selector:

•

•

Bleaching is only possible in a cold

Turn the programme selector to programme 5.

Press the special option button “cold wash”

(if available).

Min

.

DYEING

Commercially available products usually consist

of a dye colour, fixing agent and salt.

Pour the dye colour, fixing agent and salt directly

into the empty drum, and only then load the

laundry.

Warning:

wash, otherwise your laundry and your appliance

will be damaged.

Poor the diluted bleach into chamber and start

the machine.

After this pre-bleach wash, do a normal wa sh, i n

which more not bleachable laundry can be adde d.

Add detergent into chamber and start a wash

programme. For this subsequent wash a lower

temperature wash programme (for example 40°C)

can be sufficient because of the pre-bleac h

treatment. In this way energy can be saved.

Note:

Bleach should only be used with ble ac hab le

fabrics.

•

•

•

Bleaching is only possible in a cold

Only use products designed for use in

washing machines.

Follow the manufacturer’s instructions.

Plastic and rubber components of the

machine can be stained by dyes.

REMOVING THE FILTER

WHEN TO REMOVE THE FILTER

Check and clean the filter at least 2 or 3 times

•

a year.

When the appliance does not drain or spin

•

properly.

When the pump is blocked by an object

•

(buttons, coins, safety pins).

Important:

cooled before draining.

REMOVING THE FILTER

Switch off the appliance and drain the water (see

1.

next paragraph “Draining residual water”).

Open the filter cover with a coin.

2.

Place a tray or container beneath the cover.

3.

Slowly turn the filter anticlockwise without

4.

unscrewing it completely (using pliers to

handle the filter grip makes screwing easier).

Wait until all the water has drained off.

5.

Now unscrew the filter completely and

6.

remove it.

Remove any foreign material from the filter.

7.

Check that the pump rotor moves freely.

8.

Insert the filter and screw it in clockwise firmly

9.

until it locks.

Make sure that the water has

Pour 1/2 litre of water into the detergent

10.

drawer and check that water does not leak

from the filter.

Close the cover.

11.

2

4

6

24

Page 11

DRAINING RESIDUAL WATER

WHEN TO DRAIN RESIDUAL WATER

•

If the filter needs to be cleaned during a

programme.

Note:

Make sure that the water has cooled

before draining.

•

When transporting or moving the machine.

•

If there is danger of freezing in the installation

room. In this case the machine and the hoses

should be drained after every wash.

DRAINING RESIDUAL WATER

1.

Switch off the appliance.

2.

Unplug the machine from the mains.

3.

Unclip the drain hose connection on the rear

part of the machine (see arrow A and B).

4.

Place a container in suitable size beside the

machine.

Note:

After a correct draining cycle the residual

water amounts about up to 1 litre but there can

be up to 20 litres of water in the machine if

stopped during a programme and even 40 litres

if the pump is blocked.

5.

Lower the drain hose into a container and let

the water drain.

Note:

Make sure that the water has cooled

before draining.

6.

Wait until the flow stops.

7.

Fix again the drain hose on the rear side of the

machine (see arrow B) otherwise there is the

risk of leakage and the normal filling and

draining functions of the machine cannot be

guaranteed.

8.

Replace the drain hose with the “U” bend and

fix it.

WASHING MACHINE INSTALLED IN ROOM

EXPOSED TO FREEZING TEMPERATURES

Drain residual water from the machine, and

the inlet hose after every wash cycle.

1.

Switch off the appliance.

2.

Unplug the machine from the mains.

3.

Close the tap, loosen the inlet hose from the

machine and let the water drain out.

4.

Open the filter, let the water drain out and

close it again.

Note:

Before a new wash cycle screw the inlet

hose to the machine by hand. Check watertightness of washing machine c on nec tions by

turning the tap completely on.

25

Page 12

CARE AND MAINTENANCE

APPLIANCE EXTERIOR AND CONTROL

PANEL

•

Clean using normal household detergent

(do not use abrasive products).

•

Dry with a soft cloth.

Do not use petrol or petroleum pro duc ts t o cle an

plastic parts.

DETERGENT DRAWER

Disengage the drawer by pressing down the

1.

release lever and extract it.

Remove the siphon from the softener

2.

compartment.

3.

Wash all the parts under running water

eventually using a soft sponge.

4.

Reposition the inserts, fit in the drawer until

it locks.

DOOR SEAL

•

Clean with a damp cloth when necessary.

•

Check the seal folds for foreign bodies

periodically.

2

1

Detergent drawer with 3 chambers.

WATER HOSE MESH FILTER

•

Check and clean periodically

1.

Turn off the tap.

2.

Unscrew the hose from the tap.

3.

Remove the mesh filter from the inlet hose at

tap and clean it.

4.

Refit the filter and screw the hose connection

to the tap.

5.

Unscrew the hose from the machine.

6.

Remove the filter from the washing machine

valve with pliers and clean it.

7.

Replace the filter and screw the hose

connection back on to the machine.

8.

Turn on the tap and ensure that the

connections are completely water-tight.

APPLIANCE FILTER

•

Check the filter at least two or three times a

year and clean if necessary (see “Removing

the Filter”).

26

Detergent drawer with 4 chambers.

Page 13

TROUBLESHOOTING GUIDE

The appliance will not switch on.

Power plug properly inserted in mains

•

socket?

Mains fuse OK?

•

Power failure?

•

Tap turned on? Is water coming through?

•

Door closed?

•

Programme selected?

•

Appliance switched on?

•

No water or insufficient water supply.

Tap turned on completely?

•

Kink in water hose?

•

Water hose filter clogged? (See “Care and

•

Maintenance”).

Water hose frozen up?

•

Waste water not pumped out.

Drain hose installed correctly? (See

•

“Installation”).

Filter clogged? (See “Removing the filter”/

•

“Draining residual water”).

Drain hose frozen up?

•

Is the rinse hold button pressed?

•

If yes, press the rinse hold button again and

the programme will continue with draining

and spinning.

Detergent and additive product residues in

detergent drawer at end of wash.

Siphon installed correctly?

•

The siphon must be pushed down until the

stoppers are in touch.

Siphon clogged?

•

Remove the siphon and clean it under

running water.

Not enough water delivered? (See above

•

paragraph “No water or insufficient water

supply”).

Also see “Detergent and Additives” and

•

“Care and Maintenance”.

Machine vibrates during spin cycle.

Machine perfectly horizontal with all four feet

•

on ground? (See “Installation”).

Transit screws and bar removed? The transit

•

screws and bar must be removed before the

machine is used (see “Installation”).

Final spin results are poor.

Pump impeller obstructed? (See “Removing

•

the filter”/“Draining residual water”).

Washing results are poor.

Make sure to meet exactly the starting point

•

of the programme, otherwise the first part of

the programme will not be executed (and this

will reduce water filling, heating and

washing).

Machine does not spin.

Is the no spin button pressed?

•

If yes, press the no spin button again and the

programme will continue with spinning.

AFTER-SALES SERVICE

Before contacting After-Sales Service:

Try to remedy the problem

1.

(see “TroubleShooting Guide”).

Restart the programme to see if the fault is

2.

repeated.

If the malfunction persists, call After-Sales

3.

Service and specify:

The nature of the problem.

•

The exact model of the appliance.

•

The service code

•

(number after the word SERVICE).

The After-Sales Service sticker is on the inside

of the door.

Your full address.

•

Your telephone number and area code.

•

The After-Sales Service telephone number

•

and address can be found in the warranty or

on application to the retailer.

27

Loading...

Loading...