Page 1

T&+1 01

3

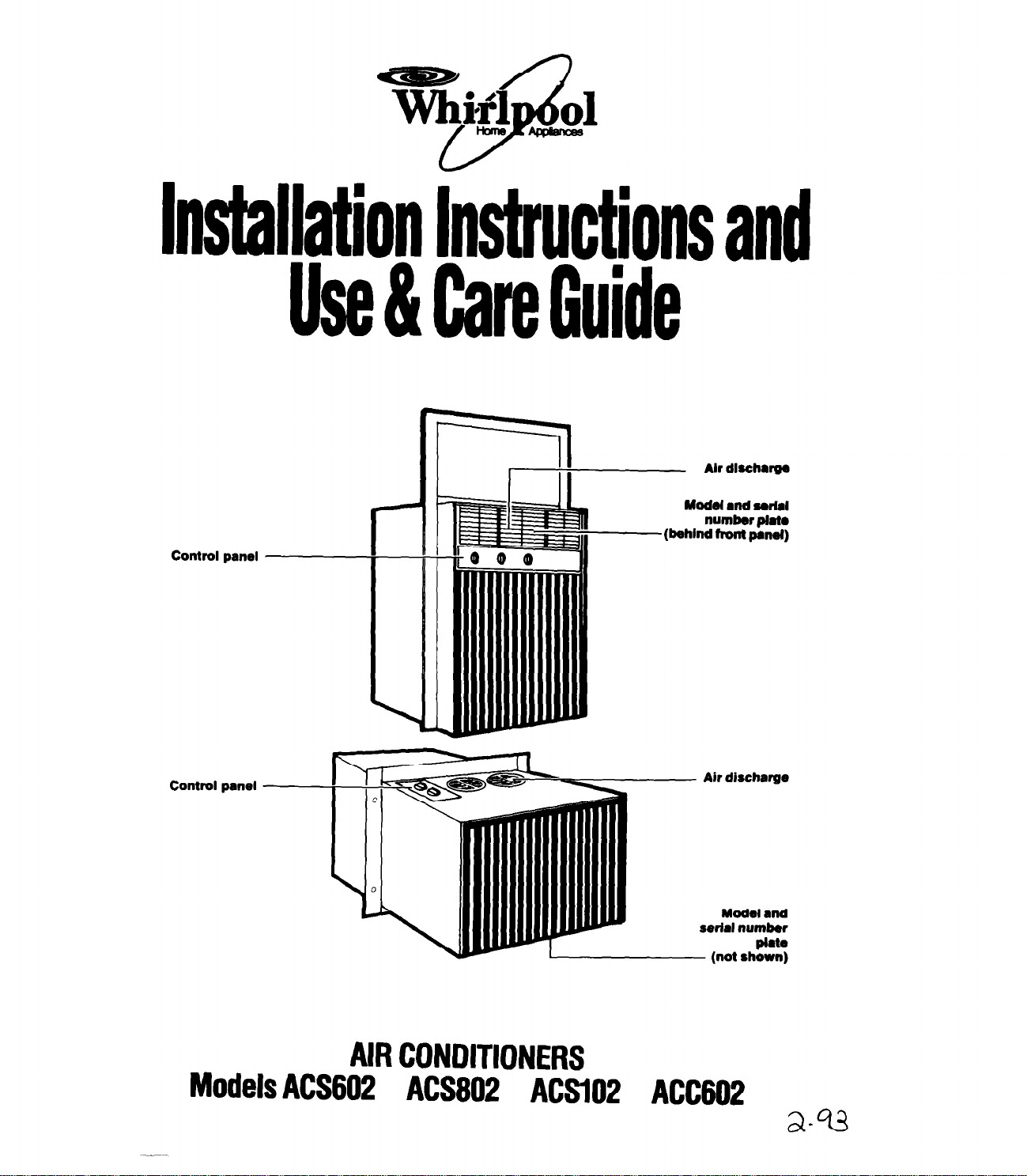

Installation hiLtions and

UseMareGuide

Model and serkl

number plate

-(behlndfrontpanel)

Control panel

r

I

Control panel

Model and

serial number

AIR CONDITIONERS

Models ACS602 ACS802 ACSlOP ACC602

a-%

Page 2

Contents

P&N

Important Safety Instructions. . . . , . . . .

Electrical Requlnments . . . . . . . . . , . . . .

Receptacle wiring . . . . . . . . . . . . . . . , . . . .

Electrical requirements . . . . . . . . . . . , . . . .

Elect&al connection . . . . . . . . . . . . . . . . .

Instsllatlon Instructions. . . . . . . . . . . . . ,

Installation instructions for models

ACS602, ACS602 and ACS102 . . . . . .

Installation instructions for

model ACC602 . . . . . . . . . . . . . . . . . . . .

Operating Instructions . . . . . . . . . . . . . . .

Starting your air conditioner . . . . . . . . . . .

The exhaust control . . . . . . . . . . . . . . . . . .

Changing air direction . . . . . . . . . . . . . . . . .

Cleaning and caring for your

air conditioner . . . . . . . . . . . . . . . . . . . . .

H You Need Service Or Assistance . . . .

WhIrlpool Room Alr Conditioner

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . .

01990 Whirlpool Corporation

Thank you for buylng a Whirlpool appliance.

Piease complete and mall the Owner

Aeglstratlon Card provided wlth this prod-

uct. Then complete the form below. Have this

information ready if you need service or call with

a question.

l Copy model and serial numbers from plate

(see diagram on page 12) and purchase date

from sales slip.

l Keep this book and sales slip together in a

handy place.

M-1 Number

Sertrl Number

Purchaee Date

Ssrvka Com~nny Phone Number

-2

11

11

11

11

12

15

16

3

:

3

4

4

6

mportant Safety

nstrudions

r0 reduce the rtsk of firs, Mctrksl shock of

mraonai injury wbeh using your air condi:ioner, follow these basic precautions:

1 Read ail instructions i&ore using your

air conditioner.

1 Complete the installation requirements as

described in the instaliatlon Instructions.

) Never allow chlidren to operate or piay

with the air conditioner.

) Do Not operate the alr conditioner with tbs

front panel removed.

1 Never clean air conditioner parts with

flammable fluids. The fumes can create a

fire hazard or explosion.

l FOR YOUR SAFETY.

DO NOT STORE OR USE GASOLINE OR

DTHER FLAMMABLE VAPORS AND LIGUIDS IN THE VICINITY OF THIS OR ANY

DTHER APPLIANCE. THE FUMES CAN

CREATE A FIRE HAZARD OR EXPLOSION.

t is your responsibility to be sure your

air conditioner:

) Is installed in a window that will hold the

weight, and is secured according to the

Installation Instructions.

B Is connected only to the proper kind of

outlet, with the correct electrical supply and

grounding. (See Installation Instructions.)

) Is the right size for the area you want to cool.

D Is used only to do what window air condi-

tioners are designed to do.

) Is not used by anyone unable to operate

it properly.

B Is properly maintained.

) Also, remove the Energy Label and Buy

Guide. Use a damp cloth to take off any glue

residue. Do not use sharp instruments, flam-

mable fluids or abrasive cleaners. These can

damage the material.

- SAVE THESE INSTRUCTIONS -

Page 3

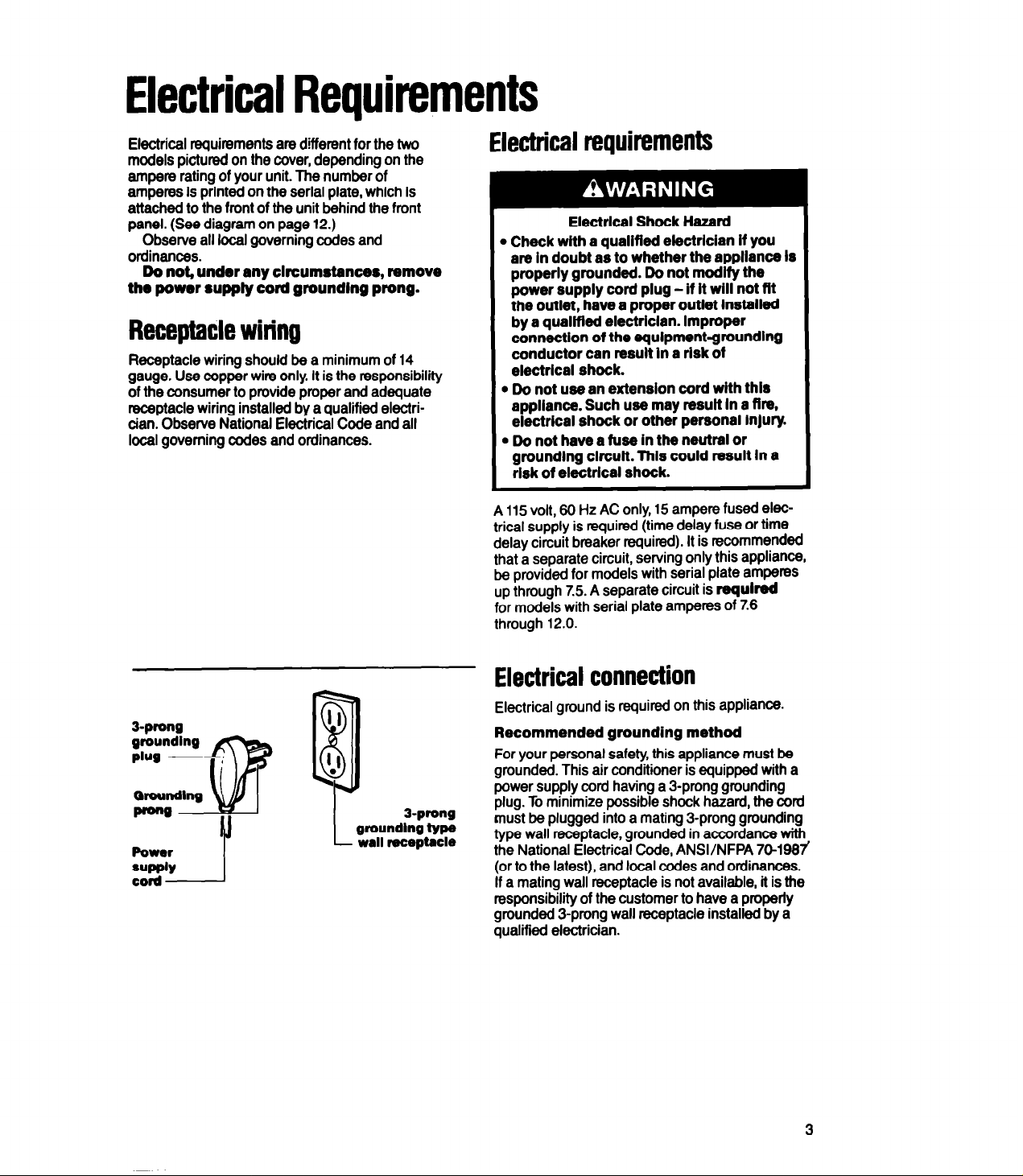

Electrical Requirements

Electrical requirements are different for the two

models pictured on the cover, depending on the

ampere rating of your unit. The number of

amperes is printed on the serial plate, which is

attached to the front of the unit behind the front

panel. (See diagram on page 12.)

Observe all local governing codes and

ordinances.

Do not, under any circumstances, remove

the power supply cord grounding prong.

Receptade wiring

Receptacle wiring should be a minimum of 14

gauge. Use copper wire only. It is the responsibility

of the consumer to provide proper and adequate

receptacle wiring installed by a qualified electrician. Observe National Electrical Code and all

local governing codes and ordinances.

Electrical requirements

Electrical Shock Hazard

l Check with a qualified electrician if you

are in doubt as to whether the appliance Is

properly grounded. Do not modify the

power supply cord plug - if it will not fft

the outlet, have a proper outlet installed

by a qualified electrician. improper

connection of the equipment-grounding

conductor can result In a risk of

eiectrlcai shock.

l Do not use an extension cord with this

appliance. Such use may resuit In a fire,

eiectrlcai shock or other personal Iniuw.

l Do not have a fuse in the neutral or

grounding circuit. This could result In a

risk of eiectrlcai shock.

A 115 volt, 60 Hz AC only, 15 ampere fused electrical supply is required (time delay fuse or time

delay circuit breaker required). It is recommended

that a separate circuit, serving only this appliance,

be provided for models with serial plate amperes

up through 7.5. A separate circuit is required

for models with serial plate amperes of 7.6

through 12.0.

&Prong

Electrical connection

Electrical ground is required on this appliance.

Recommended grounding method

For your personal safety, this appliance must be

grounded. This air conditioner is equipped with a

power supply cord having a 3-prong grounding

plug. To minimize possible shock hazard, the cord

must be plugged into a mating 3-prong grounding

type wall receptacle, grounded in accordance with

the National Electrical Code, ANSVNFPA 70-l&

(or to the latest), and local codes and ordinances.

If a mating wall receptacle is not available, it is the

responsibility of the customer to have a properly

grounded 3-prong wall receptacle installed by a

qualified electrician.

3

Page 4

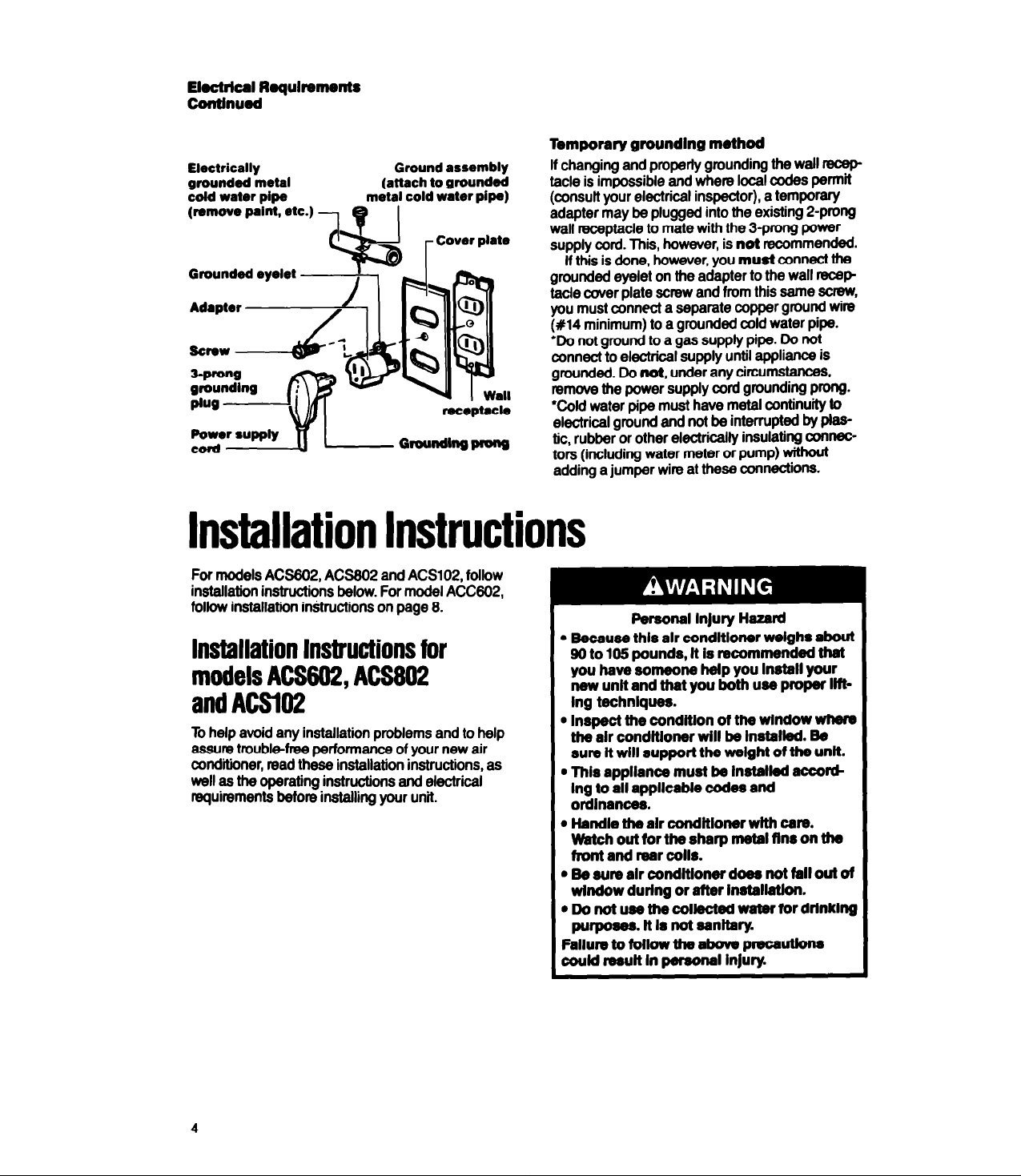

Eloctrlcal Rsqulramsnts

Continusd

Temporary grounding msthod

Electrically

grounded

coid water pipe

(removepelnt,etc.) 7 f 1

Grounded eyelet

~‘- 1

metal

t--Gmundlng-

Ground assembly

(attach to grounded

metal cold water pipe)

receptacle

all

If changing and property grounding the wall recap

tacle is impossible and where local codes permit

(consuft your electrical inspector), a temporary

adapter may bs plugged into the existing P-prong

wall receptacle to mate with the 3-prong power

supply cord. This, however, is not recommended.

If this is done, however, you must connect the

grounded eyelet on the adapter to the wall mcep

tacfe cover plate screw and from this same screw,

you must connect a separate copper ground wire

(Xl4 minimum) to a grounded cold water pipe.

‘Do not ground to a gas supply pipe. Do not

connect to electrfcal supply until appliance is

grounded. Do not, under any circumstances,

remove the power supply cord grounding prong.

‘Cold water pipe must have metal continuity to

electrical ground and not be interrupted by pIastic, rubber or other electrically insulating corlneCtors (including water meter or pump) wfthout

adding a jumper wire at these connections.

Installation Instructions

For models ACS602, ACS802 and ACSlOP, follow

installation instructions below. For model ACC802,

follow installation instructions on page 8.

Installation Instructions for

models ACS602, ACM02

and ACSIM

To help avoid any installation problems and to help

assure trouble-free perfomtance of your new air

conditioner, read these installation instructions, as

well as the operating instructions and electrical

requirements before installing your unit.

Personal InJury Hazard

l Because thls air conditioner wslghs about

90 to 105 pounds, it is recommended that

you have somsons hsip you Install your

nsw unit and that you both uss propsr lifting techniques.

l Inspect the condition of ths wlndow whefa

ths air condftionsr will be Installed. Bs

sure it wlii support the weight of ths unit.

l mh appliance must be Instalisd accord

ing to ail applicable codes and

ordinances.

0 Handle ths air wndttlonsr wlth care.

Watch out for the sharp metal ffns on ths

front and rear colis.

l Be sum air conditioner doss not fall oui of

window during or aftsr lnstaliatlon.

m Do not uss ths collected watsr for drinking

purposes. It is not sanitary.

Faiiurs to follow ths abovs prsoautions

could msuit In psrsonal Injury.

Page 5

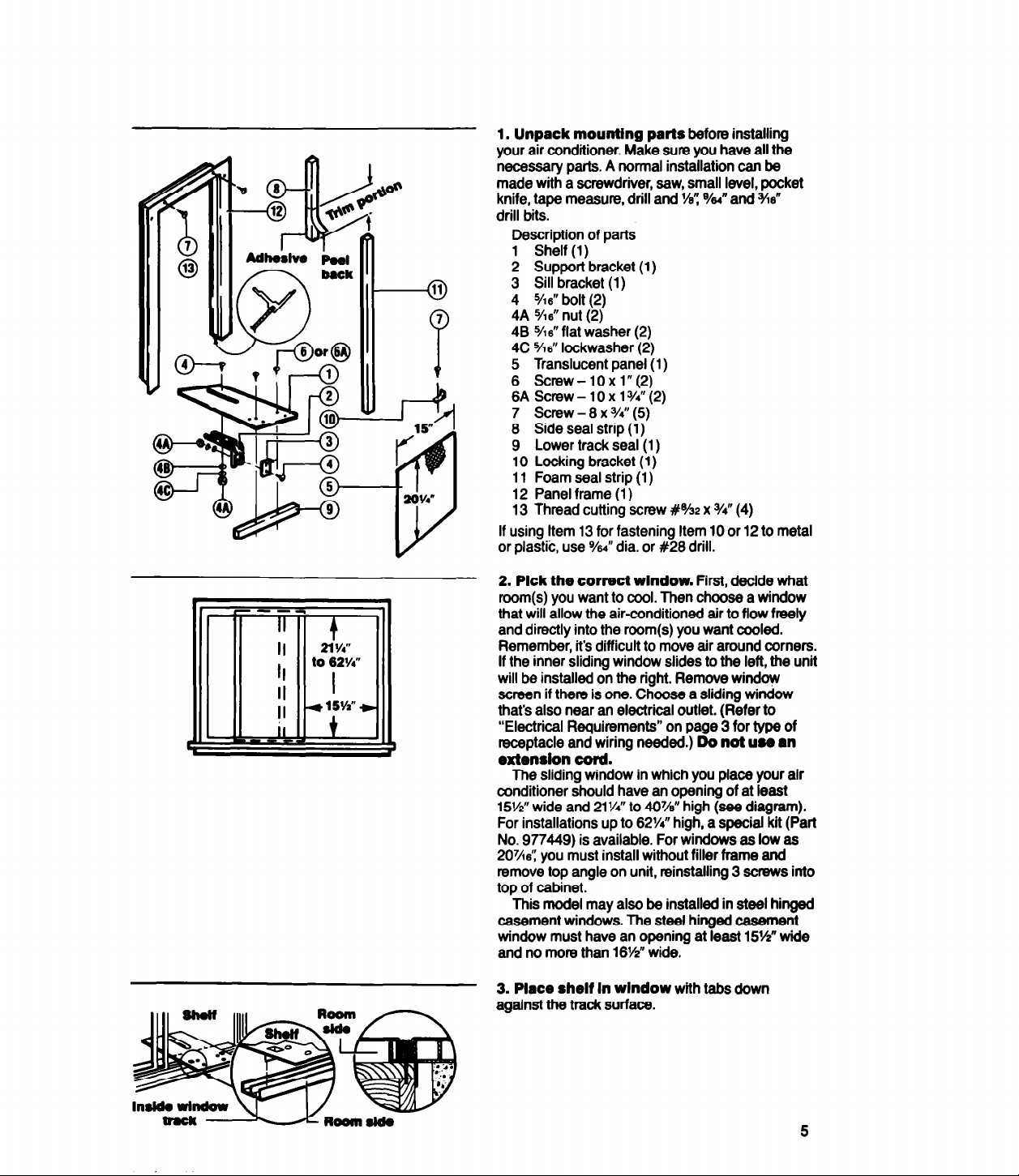

1. Unpack mounting parts before installing

your air conditioner. Make sure you have all the

necessary parts. A normal installation can be

made with a screwdriver, saw, small level, pocket

knife, tape measure, drill and Ye: VW” and %s”

drill bits.

Description of parts

1 Shelf (1)

2 Support bracket (1)

3 Sill bracket (1)

4

VW” bolt (2)

4A %s” nut (2)

48 W’ flat washer (2)

4C

%6’

lockwasher (2)

5 Translucent panel (1)

6 Screw-10x1”(2)

6A screw - 10 x

7

Screw - 8 x Vi” (5)

8

Side seal strip (1)

9

Lower track seal (1)

13/4”

(2)

10 Locking bracket (1)

11 Foam seal strip (1)

12 Panel frame (1)

13 Thread cutting screw

#B/J2 x W’

(4)

If using Item 13 for fastening Item 10 or 12 to metal

or plastic, use VW” dia. or #28 drill.

2. Pick the correct window. First, decide what

room(s) you want to cool. Then choose a window

that will allow the air-conditioned air to flow freely

and directly into the room(s) you want cooled.

Remember, it’s difficult to move air around corners.

If the inner sliding window slides to the left, the unit

will be installed on the right. Remove window

screen if there is one. Choose a sliding window

that’s also near an electrical outlet. (Refer to

“Electrical Requirements” on page 3 for type of

receptacle and wiring needed.) Do not use an

extension cofd.

The sliding window in which you place your air

conditioner should have an opening of at least

15%” wide and 21%” to 40%” high (see diagram).

For installations up to 62%” high, a special kit (Part

No. 977449) is available. For windows as low as

20%~‘: you must install without filler frame and

remove top angle on unit, reinstalling 3 screws into

top of cabinet.

This model may also bs installed in steel hinged

casement windows. The steel hinged casement

window must have an opening at least 15%” wide

and no more than 18%” wide.

3. Place shelf in window wlth tabs down

against the track surface.

5

Page 6

Instdlsth InstmcUoms

Contlnwd

Room side

t

Uw screws 5 or 5A

-It=-“‘”

4. Attach support bracket (Item 2) loosely to

the underside of shelf with either short or long leg

down and with end of bracket either toward or

away from window, depending upon con&uction

and depth of wall and window sill (see diagram).

Attach sill bracket (Item 3). Each bracket is

attached using one %s” bolt, nut and washers

(Items 4,4A, 48 and 4C).

5. With the assembled shelf and brackets still

in the window opening, adjust brackets until she8

is firmly seated and sloping down to outsiie. If you

use a level, be sure you have ?I2 bubble of slope.

Wtiout a level, place the translucent panel (Item

5) on shelf. The top of long side of the panel will be

%s” back from the window line (see diagram).

5. If slope back is correct, tighten all nuts

securely. Install lower track seal (Item 9) shown in

diagram. This track seal has two holes which line

up with matching screw holes in shelf.

Prodrill ‘Hu” holes

if truks are metal

7. install shelf 2%” from side of window opening, securing it in place with screws 6 or 8A.

8. Measure height of opening (see diagram).

Subtract 20%~” from measured height. This will be

the actual height of translucent panel.

9. Measure out the distance determined in

Step 8 and mark it along the 20%” side of translucent panel. Clamp panel between a board and an

appropriate supporting surface close to the mark

and cut with fine tooth saw. Remove burrs.

10. Lift vertically removing panel frame from

unit. Slide translucent panel into groove in frame,

keeping honeycomb side to the face side of frame

(see diagram). Slide frame back into place on unit.

Panel should enter the top angle groove.

8

Page 7

seal strip

Slldlng

sash

sod

strip

IL

. sesl

strip

11. Peel backing from seal strip (Item 8) and

press it onto side filler frame guides on each side

of unit.

12. Place unit in window by testing unit on

shelf. Push unit toward window so side angles are

sealing against the side jamb stop (see diagram).

Slide the opened window sash firmly to make certain the frame and unit sealing strips are sealing.

Slldlng sash

Thck

(room side)

13. Using %I” drill, install locking screws

(Item 7). Use two screws in top jamb and in the

side bottom flanges. If you need additional holding

strength, add two more screws at upper sides of

filler frame (marked “A’). Also, two screws can be

added at unit sides (marked “6”). However, if you

add screws at “6,” you must use a %I$ drill bit to

predrill through the plastic sides of air conditioner.

14. Lock the sliding sash at bottom using lock

bracket (Item 10) and screw (Item 7) as shown in

diagram at left. Use a W’ drill bit to drill through

track before inserting screw.

15. Cut seal strip (Item 11) to length. Install it

between space of opened sash and glass of the

closed sash (see diagram).

7

Page 8

Mdsngk Addwood

16ort66au6a

ushown towoodstop

Add l

ngt8

16. For lnstallatlon In windows havlng no

side flanges or with wood stops.

The flanges (top and two sides) on the air conditioner must mate against companion flanges on

the window, not more than %s” (.2 cm) in thickness.

On the side with the opened sash, the leading

edge of the sash becomes the flange. On the top

and jamb side of most metal windows, the flange

is there.

In windows where there are no flanges or where

there are thick wood flanges or stops, use metal

angles or wood to provide a stop for the unit

flange. Diagrams at left show three suggested

methods.

17. For installation in steel casement

windows.

Follow Steps 2 and 3 on page 5. NOTE In

Step 3, the shelf tabs must butt to the front of fhe

bottom angle on the casement (see diagram

at left).

When Step 3 Is flnlshed, follow Steps 4

through 10 on page 6, and Steps 11 and 12 on

page 7. Then proceed with the final two paragraphs in this Step 17, which immediately follow.

Open wlndow at least 18(p to allow room for

unit cabinet. If necessary, remove window crank

handle so the window will open wide enough. Tii

opened window to the wall or frame to prevent the

window from swinging.

8

14%”

y

Center unlt In

l

valkbk eponhq

I

RI

i Room

Drill Vu” holes in the window jamb top to

line up with holes in filler frame (see diagram at

left). Use two thread cutting screws (Item 13) to

secure unit. If you need additional holding

strength, add screws at the bottom of the unit

side channels (see Step 13 diagram).

Installation instructions for

model ACC602

To help avoid any installation problems and to help

assure trouble-free performance of your new air

conditioner, mad these installation instructions, as

well as the operating instructions and electdcal

requirements before installing your unit.

Inspect the condition of the window where

the air conditioner will be installed. Be sure it will

support the weight of the unit.

Personal InJury Hazard

Bewraalrcondltlonerdoesnotfalloutof

window during InsfallaUon. Pomona1 InJury

ordamagecoufdruult.

I

I

Page 9

Fersonal InJury M

l Becauss this alr condltloner weighs &out

78 to 75 pounds, it Is recom- that

you have somsone help you Install your

newunltandthatyoubothuse~llftlng techniques.

l This appliance must be Installad

according to all appllcabla codes and

ordinances.

l Handle the air condltloner wlth care.

Watch out for the sharp metal flns on ths

front and rear tolls.

l Do not use the collected water for

drlnklng purposes. lt Is not sanitary.

Fallum to follow ths above precautkns

could result In parsonal InJury.

1. Unpack mounting parts before installing

your air condiiioner. Be sure you have all the netessary parts (see top two diagrams at left). This air

conditioner will fit most steel casement windows. A

nom-rat installation can be made with a screwdriver, W socket driver, tape measure and drill.

Description of parts (top two diagrams at left)

1 #lO x 3/e” long s.m. screw

2 #l O-32 x 3/e long math. screw

3 Bottom mounting bracket

4 Knurled knob screw

5 Top mounting bracket

NOTE: Above parts (not shipped loose) installed

on unit by factory.

2. Pick the correct window. First, decide what

room(s) you want to cool. Then choose a window

that will allow the air-conditioned air to flow frwfy

and directly into the room(s) you want cooled.

Remember, its diiicult to move air around comers.

Choose a window that’s alao near an ektrical

outlet. (Refer to “Electrical Flequirlements” on

page 3 for type of mceptacle and wiring needed.)

Do not use an extension cord.

To be able to use the window mounting parts

shown in the diagram to the left of Step 1 aboW,

the window should have a minimum width of 14%”

and a maximum width of 16” (see “A” in bottom

diagram). Ths window shoufd have a minimum

height of 10%” and a maximum height of 11W

(see 9” in bottom diagram).

3. Remove the glass from the frame opening

selected. Clear away any hardened putty.

4. Before slldlng unit through the casement

opening, remove the bottom window bra&t

(Item 3) on both sides of the unit. NOTE: Only the

topscmws(lteml)needtoberemoved.

9

Page 10

Inst8lktlon In-s

Continued

5. Check the knurled knob screws to see that

the top mounting brackets (Item 5) are Mracted to

the center of the unit. They must not interfere witft

the window frame when the unit is installed.

6. Lift the unit into the window opening and

slide it back until the mounting frame comes into

contact with the window frame.

7. Replace the bottom mounting brackets

(Item 3) by hooking the bracket over the window

frame. Replace the top screws (Item 1) in the

mounting bracket, leaving them loose enough so

them is about %s” of play Tighten the bottom

screws (Item 2). This will pull the unit mounting

flange tightly to the window frame, sealing and

locking the air conditioner in place.

shestlnsw

SWOWS-

Y4”

Max.

-I I_

Back of air

condltlonor

8. Loosen the two knurled knob screws and

slide the top mounting bracket (Item 5) toward the

outside of the unit, engaging the window frame.

Tighten the knurled knob screw in this position.

This will lock the unit in place so it cannot tftt into

the room. The Installation Is now complete.

9. Optional mounting instructions. If the window thickness will not allow you to use the four

mounting brackets provided with the unit, remove

brackets and fasten flanges of unit with sheet

metal screws. These screws are not included with

your air conditioner. The window opening for your

installation must not be wider than 151

10

Page 11

Operating. Instructions

Starting your air conditioner

l.Setexhaustcont~0I(iiyourunitisso

equipped) to CLOSED for maxfmum cooling.

2.ChooseeitherLOCOOLorHICOOLfan

speed aetling.

LOCOOL . . . . . . . . . . . . . . fors&epklgcomfort

HICOOL . . . . . . . . . . . . . . formaxfmumcooflng

FANONLY . . . . . . . . . . . . forcim&tfngroomeir

3. lbrn the thermostat

(mid-setting). You can a@st the air amWooer

cooling performance

control to a higher number for IM&UTI cooling.

Lower the number setting for less arolfng. Mu wfll

need to experiment to find the setting which s&3

you best.

NOTE: If you turn your air conditioner off or if the

compressor shuts off, wait at least tfuee minutes

before turning it back on or you may blow a fuse or

trip a circuit breaker.

whennocoolinglsdealled

conb’olto06

by-%l*

L

CLDWD

WEW

CLDSED

“Ml, OFF

LO Coo(

Fan

only

WIT DFF

The exhaust control

The exhaust control setting draws stale or smoky

air from the room.

1. To exhaust room alr

Set exhaust control to OPEN. Adjust fan control

to speed desired. If no cooling is desired, use FAN

ONLY setting.

2. To circulate room alr

Set exhaust control to CLOSED. Adjust fan control

to FAN ONLY

Changing air direction

The louvers in the grille area at the top of the air

conditioner control the direction of the coofed air

If your untt looks Ike Flgure A, move

the lever at the top of the grille to the right, feft or

straight ahead. Simply move the lever in the

direction you want the air to go.

louvers in the grille can be adjusted left, rfght or

straight ahead. The front set is fixed and directed

upward.

If your unit looks Ike Figure B, turn the

circular air discharge grilles on top of the unit. Both

grillescanbeadjustedtotherfghtorfeft+oradjusted indivfdually.

me rear verkal

11

Page 12

Model and

wrlal number

Mod.1 and

urlal numkr

plate

Cleaning and caring for your air conditioner

Proper use and care of your air condiiner will

help ensure lonaer life of the unit and lower operating’costs. Follow these instructions carefully.CalI

your Whirlpool servicing dealer for an annual

checkup.

Cleaning front panel

ElectrIcal Shock and

Flra Hazard

l Unplug power cord from receptacle before

cleaning unlt. Failure to do so could mlt

In electrical shock or personal Injury.

l Do not use flammable flulds, solvents,

abrasive cleaners, or strong detergents.

Fire or product damage could result.

1.

Remove the front panel from unit when clean-

ing. Press down at top edge of the front, as

shown in diagrams at left (depending on your

model).

2. When the front moves away from top of cabinet,

pull top of front toward you.

3. Lift up and away from the bottom spring clips.

4. Clean front panel with warm water and mild

soap or detergent. Use a soft cloth. Rinse and

dry. Replace front panel.

5. Wipe control panel clean with a soft dry cloth.

Cleaning air conditioner filter

The filter is cleanable. A clean filter helps remove

dust, lint and other particles from the air. Check

every two weeks to see if filter needs cleaning.

1. Remove front panel as shown above.

2. Remove filter by releasing it from plastic clips

as shown in diagrams at left (depending on your

model).

3. Clean filter, using a vacuum cleaner.

-OR-

4. If very dirty, wash filter with warm water and mikf

detergent. Air dry thoroughly before replacing.

Page 13

Annual maintenance for your air

condttloner

Your air conditioner needs annual maintenance to

help ensure steady, top performance throughout

the year.

Call the service company recommended by your

dealer to:

l

Inspect and clean the coils and condensate

water passages.

l

Check fan and oil the fan motor.

l

The compressor is sealed and needs no oiling.

Expense of annual inspection is customer’s

responsibility.

-OR-

lf you are familiar with electrical appliances, you

can do the cleaning and maintenance yourself. If

you choose to do so, follow these steps:

EbctrlcalShockand

Personal Injury Hazard

l Dbconnwtpowercordfromreceptwb

before performlng any maintenance. Be

sure no llquld gets Into the motor,

ebctrkal control box or compwsor

ebctrkal termlnab.

l

Ebcause your alr condltloner weighs fmm

70to105pounds,ltbrecommendEdtha

youhavetxBmaonahelpyouwhenyou

remove and reinstall your unlt and that

yoUbothll&9propMllftlngbChfIlq~.

l

Handb the alr

Watchoutforthesharpmetalflnsonthe

front and reer colb.

l

Donotu6ethecolbctedwaferfordrlnklng

purposea. ft Is not sanltafy.

Fallure to follow the above precmutlona

couldmsultInebcWcal

Ww

condmmrwtthcare.

-or-

1. Disconnect power supply.

2. Remove unit from cabinet. Wrap the motor,

electrical control box and electrical terminals

boxinplasticfilmandmakesumnowateror

other liquid gets inside any of these parts. lt

could damage the insulation and cause serious

trouble.

3. Carefully clean and hose out the base, coils and

condensate pans. Clean at least once a year or

more often if the condenser coils and pans collect dirt, sand, leaves, insects or algae. Also,

cleanifyoudetectanodorfmmtheaircondftioner. While the cabinet is open, this is a goal

time to oil the fan motor. See page 14.

4. Remove plastic film from motor and elecfri&

parts.

5. Replace unit in cabinet.

6. Reconnect power supply.

NOTE: II is a good idea to wait 24 hours before

starting the unit again. This albws time for all

amastodryout.

13

Page 14

Olllng the fan motor

Electrlcal Shock Hazard

Disconnect power cord from receptacle

before oiling motor. Fallure to do so could

result In personal InJury.

1. Oil the fan motor per instructions on the motor.

To add oil, pull out the oil hole plug at each end

of the motor (see diagram). An easy-to-use

one-ounce capsule of especially recommended

oil (Part No. 10943) can be ordered from your

Whirlpool servicing dealer, or use SAE X20

non-detergent oil.

2. Replace the plug to keep dirt from motor

bearings.

3. Reinstall the unit in cabinet after performing

maintenance. Refer to the “Installation instructions” section for your unit.

Energy saving tips

l Improve home insulation (seal doors, windows,

and close fireplace flue).

l Close blinds or drapes on sunny side of house;

add window awnings.

l Keep air filter clean. Don’t block air flow with

drapes or furniture.

l Ventilate attic (high temperature levels add to

normal cooling load).

l Try not to use heat producing appliances during

the honest part of the day. Turn lights, radios,

televisions, and other appliances off when not

needed.

l Keep heat registers and cool air returns closed

or blocked off so cooled air won’t escape.

l Use a vent fan in areas where cooking, laundry,

or bathing is done to pull out extra heat and

moisture near its source.

14

Page 15

If You Need Service Or Assistance

We suggest you follow

these steps:

1. gefore calling for assistance...

Performance problems often result from little things you

can Lnd and fix your& without tools of any kind.

Air oendWonor won?

l

Is unit plugged into a live circuit with proper voltage?

l

Is swttch turned on?

l

Is thermostat set correctly?

l

Has a fuse blown or a circuit breaker tripped?

l

Has the local power failed?

Unit blows fuses or trips circuit breaker:

l

Am time-delay fuses being used?

l

Is an extension cord being used? (Do

extensfon cwd to run your air condltloner.)

l

Are you waiting three minutes after turning cooling

circuft off before trying to restart unit?

Unittumsonandoff,ordoesnotcooiroom:

l

Is fitter clean?

l

Am coils clean (both evaporator [inside] and condenser

b-w)?

l

Is there excessive moisture or heat (open vessel cooking, showers, etc.)?

l

Try setting fan to higher speed.

l

Try setting thermostat to a cooler setting.

operating sounds:

l

When your room air conditioner is

nomuiiy,

l

Droplets of water hitting the condenser, causing a

you will hear sounds such as:

‘pinging” or “clicking” sound. Water droplets help to

coolthe condenser.

l

Air movement from the fan, especially on high fan

speed -%I.

l

Clicks from the thermostat cycle.

l

Sounds also may be caused by house construction such as vibration of the unit due to wall construction or

unsteady window mounting area.

2. if you need assistance’...

Call WhIrlpool COOL-LINE@ wrvlco assistance

w numkr. Dfai free from a-r,

. IntheU.&

andtatkwkhoneofourtrainedconsuttants.Theconsultantcaninstructyouinhowtoobtafnsattsfactoryoperattonfromyourapptianceor,ifsewiceisneceeaary,

tecomrnencl a qualified senrice company in your area.

run:

not use an

operatfng

l-am-253-1301

3. if you need service?..

Whirtpoolhasanationwide -

- workof-Whi&

vkf 01

l9

(KRVICE servicetechniciansar9batned

ssnriceannpaniw3.whirlpool

tofllHilltheprodlGt~and

provide after-warranty servtce, anywhere in the united

States. To locate the authorized Whfdpool m con+

pany in your area, call our COOL-LINE0 m as&tante telephone number (see Step 2) or bok In your

telephone directory Yellow Pages under:

SERVICE COMPANIES

XYf2;EMy;; CO

.%9-m

4. if you have a problem:..

Call our COOL-LINE service assistance telephone

number (see Step 2) and talk with one of our cons~fMM%

or if you prefer, write to:

Mr. Donald Skinner

Director of Consumer Relations

Whirlpool Corporation

2ow M-63

Senton Harbor, MI 49022

Please include a daytime phone number in your

correspondence.

6. if you need FSP@ replacement parts?..

FSP is a registered trademark of Whirlpool Corporation

for qualii parts. Look for this symbol of quatii w

you need a replacement part for your Whirtpool

appliance. FSP replacement parts will fit rtgM and ti

right, because they are made to the same exacting specifications used to build every new Whirlpoot appliance.

To locate FSP replacement parts in your area, refer to

Step 3 above or call the Whirtpool COOL-LINE m

assistance number in Step 2.

6. if you are not satisfied with how the pro&km

was soived~..

l

Contact the Major Appliance Consumer Action Panef

(MACAP). MACAP is a group of independent amsumer experts that voices consumer views at the highest levels of the major appliance industry.

l

Contact MACAP only when the dealer, authorized sewicer or Whirlpool have failed to resofve your problem.

Major Appliance Consumer Actton Panet

20 North Wacker Drive

Chicago, IL 6CNO6

l

MACAP will in turn inform us of your actton.

‘When requesting assistance, please provtde: model

number, serial number, date of purchase, and a

oompietedeacripiionoftheprobtem.Thle~

isrwededinordertob&errespondtoyourrequeet.

15

Page 16

Whirlpool” Room Air Conditioner

Warranty

LENGTH OF WARRANTY

FULL OWE-YEAR WARRANTY

From Date of Purchase

FULLFIVE-YEAR WARRANTY

From Date of Purchase

WHIRLPOOL WILL NOT PAY FOR

A sefvice calls to:

1. Correct the installation of the air conditioner.

2. Instruct you how to use the air conditioner.

3. Replace house fuses or correct house wiring.

4. Clean or replace air filter.

B. Pi up and delivery. This product is designed to be repaired in the home.

C. Damage to the air conditioner caused by accident, misuse, fire, flood, acts of God or use of

pmhcts not approved by Whirlpool.

’

D. The removal and reinstallation of the air conditioner if it is installed in an overhead or other

ineccessible location or not installed in accordance with published installation instructions.

Bewke under the full warranties must be provided by an authorized Whirfpoolsu service company.

WHIRLPOOL CORPORATION SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES. Some states do not allow the exclusion or limitation of incidental or consequential damages so

thii limitation or exclusion may not apply to you. This warranty gives you specific legal rights, and you may

alao have other rights which vary from state to state.

Gutside the United States, a different warranty may apply. For details, please contact your franchised

Whirlpod distributor or military exchange.

lf you need servfce, first see the ‘Service and Assistance” section of this book. After checking ‘Service

and As&tan& additional help can be found by calling our COOL-LINE@ service assistance telephone

number, 1-8OOk-13Ol, from anywhere in the U.S.

1 WHIRLPOOL WILL PAY FOR

FSP@ replacement parts and repair labor to correct defects

in materials or workrnanshib.

FSP replacement parts and repair labor to correct defects in

materials or workmanship in the sealed refrigeration system.

These parts are:

1. Compressor 4. Drier-Strainer

2. Evaporator 5. Connecting Tubing

3. Condenser

Part No. 511664/4316224

91990 Whirlpool Corporation

WP JAN. 90

Loading...

Loading...