I

CONSUMER SERVICES TECHNICAL

EDUCATION GROUP PRESENTS

R-93

JOB AID

Part No. 4322657

SURROUND

COOL

AIR

CONDITIONERS

MODELS:

ACG052XJ

ACG072XJ

28

II

INTRODUCTION

This Job Aid,

“Surround Cool Air Conditioners

,” (Part No. 4322657), has been compiled to provide the

most recent information on design, features, troubleshooting, service and repair procedures of the

surround cool air conditioner.

Procedures for diagnosing and troubleshooting the sealed system can be found in Whirlpool Consumer Services publication

R-65, Basic Refrigeration Diagnosis

, Part No. 4314066, Rev. C.

Procedures for servicing the sealed system can be found in Whirlpool Consumer Services publication,

R-77, Sweep Charge Procedures for the 90’s

, Part Number 4321717 Rev. A. A companion VHS video

tape,

Sweep Charge Procedures for the 90’s

, Part Number 4321718V is also available.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair of the Surround Cool Air Conditioner.

The objectives of the Job Aid are:

The service technician will -

• Understand proper safety precautions.

• Successfully troubleshoot and diagnose malfunction.

• Successfully perform necessary repairs.

• Successfully return the air conditioner to proper operational status.

WHIRLPOOL CORPORATION ASSUMES NO RESPONSIBILITY

FOR ANY REPAIRS MADE ON OUR PRODUCTS BY ANYONE

OTHER THAN AUTHORIZED SERVICE TECHNICIANS.

© 1999 Whirlpool Corporation, Benton Harbor, MI 49022

27

III

TABLE OF CONTENTS

INTRODUCTION .......................................................................................... II

TABLE OF CONTENTS .................................................................................. III

SAFETY..... .................................................................................................. IV

SECTION ONE

INSTALLATION CONSIDERATIONS

Important Safety Instructions ...................................................................................... 1

Installation Instructions ............................................................................................... 1

SECTION TWO

THEORY OF OPERATION

Unique Operating Features.......................................................................................... 3

Sealed System .......................................................................................................... 3

Air Flow...................................................................................................................... 3

Electronic Controls .................................................................................................... 4

SECTION THREE

COMPONENT ACCESS

Component Location .................................................................................................... 7

Accessing Components at the Front of the Air Conditioner..................................... 8

Accessing the Electronic Control Assembly .............................................................. 8

Accessing Components Behind the Divider Wall .................................................... 10

Accessing the Component Compartment................................................................ 10

Removing the Fan Motor Assembly ........................................................................ 10

SECTION FOUR

TROUBLESHOOTING AND DIAGNOSIS

Component Testing .................................................................................................... 15

Troubleshooting.......................................................................................................... 16

Compressor Specifications ....................................................................................... 19

Fan Motor Specifications ........................................................................................... 19

Proper Location of Thermistor .................................................................................. 19

Servicing Information ................................................................................................. 20

SECTION FIVE

TECH TIPS

Wiring Diagram ........................................................................................................... 21

Strip Circuits ............................................................................................................... 22

Model and Serial Number Designators ..................................................................... 23

Warranty Information.................................................................................................. 24

26

CONFIRMATION OF LEARNING EXERCISE ANSWERS

1. C 6. C

2. D 7. B

3. C 8. A

4. B 9. B

5. C 10. B

IV

SAFETY

! WARNING

ELECTRICAL SHOCK HAZARD

Disconnect power before servicing the air conditioner.

Replace all panels before operating the air conditioner.

Failure to do so can result in death or electrical shock.

25

CONFIRMATION OF LEARNING EXCERCISE

1. How do you change the temperature setting from “F” (Fahrenheit) to “C” (Celsius)?

A. Press and hold the Temperature

Select “+” pad for 3 seconds?

B. Press and hold the Temperature

Select “-” pad for 3 seconds?

C. Press and hold the Mode pad for 3

seconds?

D. Press and hold the Time pad for 3

seconds?

2. When the Fan Speed is changed while the

unit is in AUTO COOL Mode:

A. The unit cycles off.

B. Only the fan cycles off.

C. Only the compressor cycles off.

D. Cooling Mode changes from AUTO

COOL to COOL.

3. During SLEEP Mode:

A. The fan runs at HI speed.

B. The display intensity decreases.

C. The fan runs at LOW speed.

D. B and C are correct.

4. When the preset temperature for any cool

ing mode is reached:

A. Only the fan cycles off.

B. Only the compressor cycle off.

C. Both the fan and compressor cycle off.

D. The unit cycles off.

5. If the thermistor fails::

A. Only the thermistor needs to be

replaced.

B. Only the control board assembly

needs to be replaced.

C. The thermistor and control board

assembly need to be replaced.

D. The compressor needs to be replaced.

6. During the AUTO COOL Mode::

A. Fan always runs at HI speed.

B. Fan always runs at LOW speed.

C. Fan speed automatically varies.

D. Fan always tuns at TURBO speed.

7. The sealed system is warranted for:

A. Full 1 year only.

B. Limited 5 years part only.

C. Limited 2 years parts and labor.

D. Limited 3 years part only.

8. Before replacing the Electronic Control

Board Assembly:

A. Follow all Troubleshooting procedures

and test all individual components.

B. Change the Thermistor and check for

proper operation.

C. Change the Touch Pad Board and

check for proper operation..

D. Change the Thermistor and Touch

Pad Board and check for proper

operation.

9. The preset temperature set range is:

A. 50°F to 95°F

B. 64°F to 86°F

C. 50°F to 86°F

D. 64°F to 95°F

10. During FAN ONLY Mode the fan runs

continuously to circulate the room air:

A. Runs at HI speed only

B. Is manually adjustable.

C. Automatically varies

D. Runs at TURBO speed only.

1

SECTION ONE

INSTALLATION CONSIDERATIONS

IMPORTANT SAFETY INSTRUCTIONS:

! WARNING

TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK, INJURY OR SICKNESS WHEN USING THE AIR CONDITIONER, FOLLOW THESE BASIC PRECAUTIONS:

• Plug into a grounded 3-prong outlet.

• Do not remove ground prong.

• Do not use an adapter.

• Unplug the air conditioner before servicing.

• Do not drink the water collected inside the cabinet.

• Install the air conditioner in a window that will hold the weight, and secure the air conditioner according to the Installation Instructions.

• Connect the air conditioner to the proper kind of outlet with the correct electrical supply and ground.

(See Installation Instructions).

• Make sure the air conditioner is the correct size for the area to be cooled.

• Use the air conditioner only to do what a window air conditioner is designed to do.

• Make sure the air conditioner is not used by anyone unable to operate it properly.

• Maintain the air conditioner properly.

• Remove the Energy Label. Use a damp cloth to take off any glue residue. DO NOT use sharp

instruments, flammable fluids or abrasive cleaners. These can damage the air conditioner finish.

INSTALLATION INSTRUCTIONS

Follow the Installation Instructions provided with the air conditioner carefully.

24

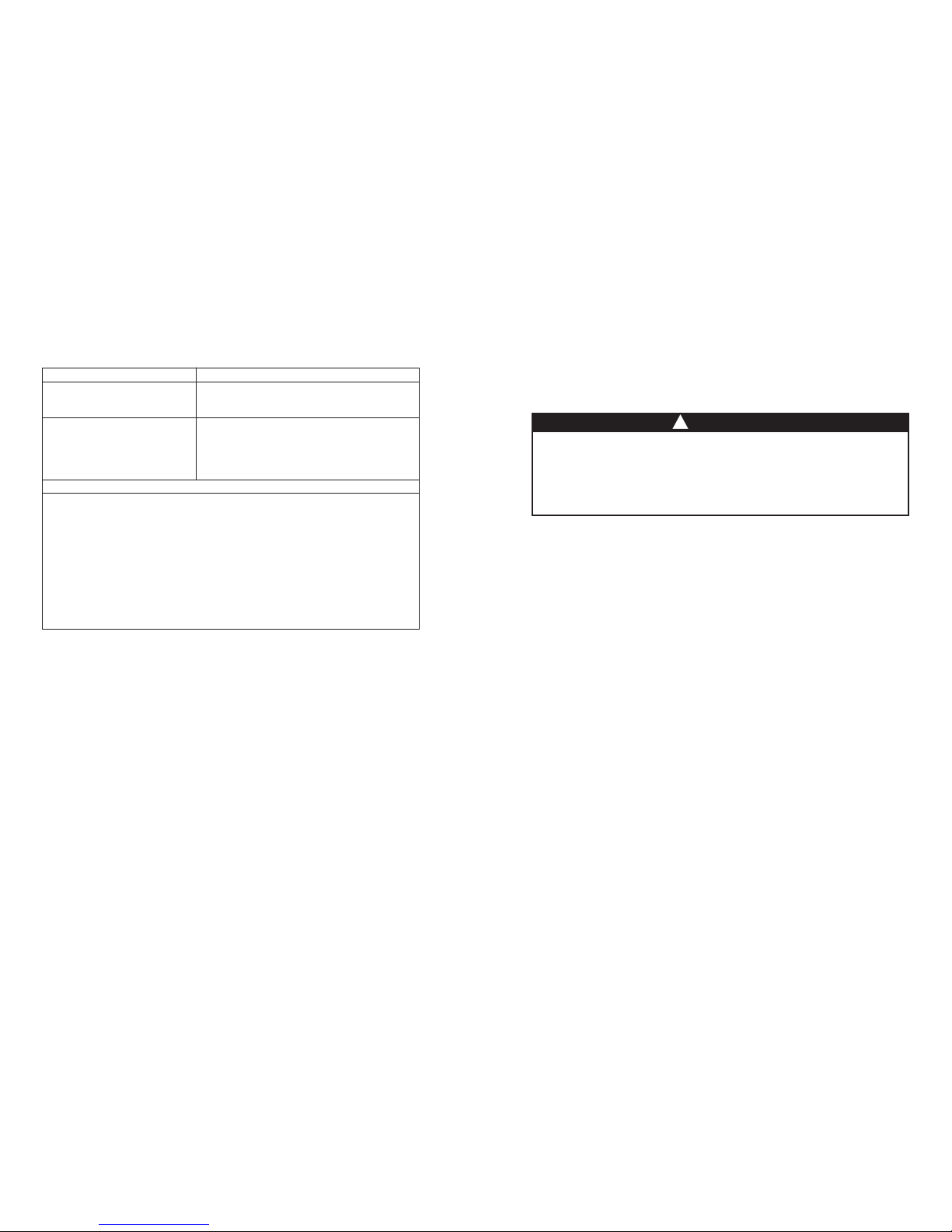

LENGTH OF WARRANTY WHIRLPOOL WILL PAY FOR

FULL ONE-YEAR WARRANTY FROM

DATE OF PURCHASE

Replacement parts and repair labor to correct defects in materials or workmanship. Service must be provided by a designated

service company.

LIMITED FIVE-YEAR WARRANTY FROM

DATE OF PURCHASE

Replacement parts to correct defects in materials or workmanship in the sealed refrigeration system. These parts are:

1. Compressor 4. Strainer

2. Evaporator 5. Connecting Tubing

3. Condenser

Servicing must be provided by a designated service company.

WHIRLPOOL WILL NOT PAY FOR

A. Service calls to:

1.Correct the installation of your air conditioner.

2.Instruct you how to use your air conditioner.

3.Replace house fuses or correct house wiring.

4.Clean or replace the air filter.

5.Preventative Maintenance

B. Pickup and delivery. Your air conditioner is designed to be repaired in the home.

C. Damage to your air conditioner caused by accident, misuse, fir, flood, acts of God, or use of

products not mentioned in the Use and Care Guide.

D. the removal and reinstallation of your air conditioner it it is installed in an overhead or other

inaccessible location or is not installed in accordance with published installation instructions.

E. Repairs to parts or systems resulting from unauthorized modifications made to the appliance.

F. any labor costs during limited warranty.

G. Replacement parts or repair labor costs for units operated outside the United States or Canada.

WHIRLPOOL CORPORATION SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES. Some state or provinces do not allow the exclusion or limitation of incidental or consequential

damages, so this exclusion or limitation may not apply to you. The warranty gives you specific legal rights,

and you may also have other rights which vary from state to state or province or province.

Outside the United State and Canada a different warranty may apply. For details, please contact your

authorized dealer.

If you need service, first see the “Troubleshooting” section of the Use and Care Guide. After checking

“Troubleshooting,” additional help can be found by checking the “Requesting Assistance or Service” section, or

by calling the Manufacturer’s Consumer Assistance Center telephone number, 1-800-253-1301, from

anywhere in the U.S.A. For service in Canada, see “If you need assistance or service in Canada” for the

service branch in your area.

WHIRLPOOL WARRANTY

2

-- NOTES --

23

Serial Number Designator

SERIAL NUMBER

MANUFACTURING SITE

G = Manos, Brazil

Q = LaVergne, TN

YEAR OF MANUFACTURE

J = 1999

WEEK OF MANUFACTURE

PRODUCT SEQUENCE NUMBER

MODEL/SERIAL NUMBER DESIGNATORS

The Model/Serial Number plate is located behind the

front panel above the coil area.

Q J 36 50001

Model/Serial

Number Plate

Model Number Designator

MODEL NUMBER

INTERNATIONAL SALES or

MARKETING CHANNEL

PRODUCT GROUP

A = Air Conditioner

PRODUCT IDENTIFICATION

C = Warranty

MODEL TYPE

G = Surround Cool

APPROXIMATE CAPACITY: XX • 1,000 BTU’s

ELECTRICAL CODE

2 = 115VAC, 60 Hz, 1-Phase

FEATURE CODE

X = Features Not Defined

YEAR OF INTRODUCTION

J= 2000

ENGINEERING CHANGE

ACG 05 2 X j 0

3

UNIQUE OPERATING FEATURES

SEALED SYSTEM

• More Efficient Condenser - Higher heat exchange due to single row

condenser coil providing greater surface area to dissipate heat.

AIR FLOW

• Quieter Operation - Sound dampening material on the divider wall and

sealed system tubing isolates sound from entering the room.

• 270° Air Flow Out of The Air Conditioner - Provides cool air more space to

exit the Surround-Cool resulting in less air noise. This system evenly

distributes the air to all sections of the room without having to adjust the

louvers.

SIDE VIEW

TOP VIEW

TOP VIEW

SECTION TWO

THEORY OF OPERATION

22

STRIP CIRCUITS

1. Power Supply to Control Board

2. Compressor Run Circuit

3. 3-Speed Evaporator Fan Circuit

4

ELECTRONIC CONTROLS

• Thermistor Temperature Control - Solid-State electronic controls with

thermistor temperature sensing for more efficient and accurate cooling.

• Auto-Cool Cycle - Cools room to a preset temperature while automatically

controlling the fan speed.

• Fully Intrgrated Electronic Controls with Clock - Simple push button

operation with full LCD display allows for a wide variety of operations choices.

Clock provides for setting automatic on and off times. System is capable of

remote control. (Remote control sold separately.)

CONTROL PANEL

Press any control key to turn on the air conditioner.

TIMER

1. Press the TIMER key

to set the ON TIME.

The indicator light

and “--:--” will flash.

Press the “+” or “-” key to set the ON TIME.

2. Select MODE, FAN SPEED or SLEEP. If

an OFF time is desired, go to step 3. If

not, press the TIMER key twice to accept

the setting. The ON TIME indicator light

will stay on.

3. Press the TIMER key a second time to

set the OFF TIME. The ON TIME indicator light will stay on and the OFF TIME

indicator light and “--:--” will flash. Press

the “+” or “-” key to set OFF TIME.

4. Press the TIMER key a third time to accept settings. The indicator light or lights

stay on until each setting is reached.

To cancel ON TIME and/or OFF TIME, press

and hold TIMER key for 3 seconds.

To review settings, press once to view ON TIME, press a

second time to view OFF TIME, and press a thrid time to

exit.

CLOCK

1. If the air conditioner is in the FAN ONLY

mode or OFF:

• press the CLOCK key to set the time. The

colon will flash.

If the air conditioner is in the AUTO

COOL or COOL mode:

• press the CLOCK key one time to display

the time of day.

• Press the CLOCK key again to set the

time. The colon will flash.

2. Press the “+” or “-” keys to set the correct

time. After setting the time, press the

CLOCK key again to start the clock.

TEMPERATURE SELECTION

Press the “+” key to raise the temperature.

Each time the “+” key is pressed, the

temperature will go up 1° to a maximum of 86°F. Press the “-” key to

lower the temperature. Each time

the ”-” key is press the temperature

will go down 1° to a minimum of 64°F.

In the OFF mode, to view current preset temperature selection, press the “+” or “-” key.

NOTE: To change from “F” to :C: or from “C” to “F”, press

and hold the MODE key for 3 seconds.

21

SECTION FIVE

THEORY OF OPERATION

WIRING DIAGRAM

WIRING SCHEMATIC

5

• If a power failure occurs, all pre-set operating programs will be removed from the

electronic control board’s memory. They

must be reset before the unit will operate

properly.

• During Auto Cool, Cool and Sleep Modes,

once the preset temperature is reached,

only the compressor will cycle OFF. The

fan will remain running.

• Operating the air conditioner when the

outside air temperature is below 70°F will

result in the evaporator icing up.

CHECK FILTER

The CHECK FILTER indicator

light comes on every 720

hours of air conditioner operation indicating that the standard filter needs to be

cleaned. The 3M Filtrate filter must be replaced.

Press the FILTER RESET key to reset the CHECK

FILTER indicator light. The indicator light will turn

off.

OFF mode

Press the OFF key to turn the

air conditioner off. Once turned

off, the mode, fan speed and

temperature at the time the

air conditioner is turned off

are all stored in the electronic control and are returned to the display the next time the air conditioner is turned on.

MODE SELECTION

Press the MODE key until the

indicator light comes on for the

setting desired. Choose AUTO

COOL, COOL, or FAN.

AUTO COOL - Cools room to

a preset temperature while it

automatically controls the fan speeds. The preset temperature can be changed.

COOL - Cools the room to a preset temperature. Adjust the fan speed to LOW, HIGH or

TURBO.

FAN ONLY - Fan runs continuously to circulate

the air. No cooling takes place. Adjust the fan

speed to LOW, HIGH or TURBO.

FAN SPEED SELECTION

Press the FAN SPEED key until

the indicator light comes on for the

desired setting. Choose LOW,

HIGH or TURBO. When the fan

is operating at LOW, HIGH or

TURBO, the fan circulates air

continuously.

LOW - Sleeping comfort

HIGH - Normal cooling

TURBO - Maximum cooling

Select the FAN SPEED during the COOL or FAN

modes. If the fan speed is changed during AUTO

COOL mode, the mode will change to COOL

mode.

SLEEP MODE

Press the SLEEP key to select

the SLEEP mode. The SLEEP

indicator light will light up. Press

SLEEP again to turn it off, and

the indicator light will go off.

SLEEP mode operates the cooling mode at LOW

fan speed. This mode allows the room temperature in the first two hours to increase 3°F above

the preset temperature. It will remain this temperature until SLEEP mode is turned off. During

this mode the display’s light intensity will decrease.

SLEEP mode is available in COOL mode only,

not in AUTO COOL or FAN ONLY.

FILTER

RESET

! NOTE

REMOTE CONTROL (Optional)

A Remote Control is available for the Surround

Cool Air Conditioner and is sold separately. Both

the 5,000 BTU and 7,000 BTU models use the

same remote control. (P/N 8040252)

20

SERVICING INFORMATION

1. Refrigerant charge must be applied to the high side only.

2. This unit operates on 115 VAC core board and touch pad board.

3. The core board and touch pad board remain energized at all times when air conditioner is

plugged into an electrical supply.

4. The electronic control assembly does not contain serviceable parts. The entire electronic con-

trol assembly must be replaced if any part of it has failed.

BEFORE REPLACING ELECTRONIC CONTROL ASSEMBLY:

• Follow all troubleshooting procedures to determine if an individual component may be

defective first.

• Test individual components (compressor, fan motor, capacitor) before replacing electronic

control assembly.

IF ALL COMPONENTS TEST O.K., IT CAN SAFELY BE ASSUMED THE ELECTRONIC

CONTROL ASSEMBLY HAS FAILED AND SHOULD BE REPLACED.

! NOTE

SERVICEABLE ELECTRICAL COMPONENTS

SERVICEABLE PARTS

COMPRESSOR

(5,000btu)

Run Winding

Start Winding

COMPRESSOR (7,000btu)

Run Winding

Start Winding

OVERLOAD (5,000btu)

OVERLOAD (7,000btu)

3-SPEED EVAP FAN

Lo Speed

Hi Speed

Turbo Speed

ELECTRONIC

CONTROL ASSEMBLY

Includes:

Core Board

Touch Pad Board

Thermistor

Plastic Enclosure

Wire Assembly

Part No.

8040122

8040126

8011281

951779

8040173

8040023

Wattage

465

615

Resistance

1.469Ω

2.37Ω

1.13Ω

2.712Ω

40.4Ω

32.4Ω

20.4Ω

Amperage

1.2

1.5

1.1

1.6

2.8

3.5

5.6

6

-- NOTES --

19

PROBABLE CAUSE CORRECTIONPROBLEM

11. Moisture dripping

into room

12. Excess condensation running outside

11a. Extreme humidity

11b. Inadequate seal

11c. Improper level

12. Extreme humidity

11a. Advise customer of possible sweating formations under

abnormal conditions. Check and

improve all possible seals.

11b. Check and improve all

sealed areas.

11c. Check for proper side to

side level of unit. Check for (½”

rear slope (or 1 full bubble) on

level.

12. This condition is normal in

areas of extreme humidity.

TROUBLESHOOTING CHART

COMPRESSOR SPECIFICATIONS

Part Number

8040122

8040126

Capacity (Btu/hr)

5,160

6,745

Watts

465

615

Run Resistance

1.469

1.130

Start Resistance

2.373

2.712

Table 1

Table 2

PROPER LOCATION OF THERMISTOR

The thermistor must be properly mounted on

the front surface of the evaporator.

VERTICAL LOCATION: The plastic thermistor

mounting bracket should be located on the

fourth tube from the top as shown in the illustration.

HORIZONTAL LOCATION: The right end of

the plastic thermistor mounting bracket should

be located 6½” from the evaporator frame as

shown in the illustration. The end of the thermistor should be located 7½” from the evaporator frame.

7½”

6½”

FAN MOTOR SPECIFICATIONS

Part Number

8040173

Capacity (Btu/hr)

5,160 to 6,745

Turbo Speed

32.4Ω

Hi Speed

40.4Ω

Low Speed

20.4Ω

7

SECTION THREE

COMPONENT ACCESS

Component Location

Compressor

Dual

Capacitor

Condenser

Fan Blade

Control

Assembly

Control

Panel

Evaporator

Fan Blade

Fan

Motor

Evaporator

Condenser

Fig. 3-1

Strainer

(In bottom tube

behind return

bend)

18

PROBABLE CAUSE CORRECTIONPROBLEM

8. Noisy operation

9. Evaporator frosts

up

NOTE: 90% frosting of evaporator is normal under low-ambient, high humidity conditions

and 70% ice blockage is to be

considered normal.

NOTE: Initial start-up on rotary

compressor equipped units

may cause frosting on the first

2 or 3 evaporator passes (for

approximately 20 minutes) until refrigerant is driven out of the

oil by heating.

10. Remote control

does not oper-

ate unit.

8a. Loose parts

8b. “Ping” noticed as fan hits drops of

water in air stream

8c. Mounting area not firm

8d. Compressor could be overloaded

due to high ambient temperatures

or air flow restriction

8e. Fan motor

9a. Low outside air temperature

(below 65°F)

9b. Thermistor failed

9c. Improper air flow

9d. Fan motor slow

10a. Batteries dead

10b. Remote failed

8a. Check fan blades, cabinet,

washers, tubing contact or vibration, loose screws, etc.

8b. Normal operation

8c. Add support kit or improve

installation

8d. Loose internally, inadequate

lubrication, improper voltage

8e. Fan blades loose or hitting,

bad bearing or out of balance

9a. Instruct customer that operation at ambient temperatures

below 65°F is not considered a

normal requirement of the unit.

Adjust controls to warmer setting.

9b. Check thermistor location

(see pg. 19) and response to

temperature change by submerging it in ice water (compressor should cycle OFF) or holding it in your closed hand (compressor should START). If response is O.K., instruct customer.

9c. Clean or replace air filter.

Check for obstructed or restricted air passage. Check for

dirty evaporator or condenser

coil. Check for dirty blower

wheel, loose seals or missing

from back of front panel.

9d. Check for binding of fan

blade, blower wheel or motor

bearings. Using low fan speed,

instruct customer.

10.a. Check that unit operates

manually at control panel. If it

does, replace batteries in remote.

10b. Replace remote control.

TROUBLESHOOTING CHART

8

ACCESSING THE CONTROL BOX ASSEMBLY

ACCESSING COMPONENTS AT THE FRONT

OF THE AIR CONDITIONER

Components accessible from the front of the unit include:

• The Control Box Assembly: This assembly contains the electronic control board, the key

touch/display printed circuit board and the thermistor. If it is necessary to replace these components, the entire control box assembly must be replaced. The service replacement control

box assembly must be ordered by using the specific model number of the air conditioner being

serviced.

! WARNING

ELECTRICAL SHOCK HAZARD

Disconnect power before servicing the air conditioner.

Replace all panels before operating the air conditioner.

Failure to do so can result in death or electrical shock.

INSET

In most situations, access to the control box

assembly can be accomplished with the air

conditioner installed in the customer’s window.

! NOTE

1. Disconnect power from the air conditioner.

2. Remove the four (4) screws securing the front panel.

(Fig. 3-2)

3. Disconnect the wiring harness connectors from the control panel wiring plugs.

(Fig. 3-2, INSET)

These connectors are:

• WHITE Fan Motor Connector (3-wires:

black, blue and red)

• 2-Power Cord Connectors (black and

white)

• WHITE Compressor/Capacitor Connector

(2 Wires)

4. Remove the two (2) screws securing the

control box assembly to the front panel.

(Fig. 3-3)

Screws

Fig. 3-2

Fig. 3-3

17

PROBABLE CAUSE CORRECTIONPROBLEM

5. Insufficient cooling

- Compressor and

Fan run

(continued)

6. Compressor stops

and starts: too

short running time

7. House circuit

blowing

5d. Low voltage

5e. Improper seals

5f. Improper use

5g. Fan speed too slow

6a. Incorrect voltage

6b. Temp Controls set too warm

6c. Failed thermistor

6d. Failed compressor, controls

controlling compressor, incorrect

wiring

6e. Fan motor too slow

7a. Improper fuses

7b. Failed component or incorrect

wiring

5d. Check power supply. See

1b.

5e. Insulating seals out of place

or missing on unit. Doors or windows open.

5f. Excessive load. Advise customer if load is excessive or installation is incorrect or inadequate. Instruct on proper operation of controls.

5g. Check for wrong motor,

blower wheel or fan blade.

Check for binding of fan blade,

blower wheel or motor shaft.

Check for low voltage and correct capacitor.

6a. Check for proper voltage

6b. Instruct customer

6c. Check thermistor location

(see pg. 19) and response to

temperature change by submerging it in ice water (compressor should cycle OFF) or holding it in your closed hand (compressor should START).

6d. Check compressor windings, all wiring, overload and capacitor for shorts.

6e. Check for wrong motor,

blower wheel or fan blade.

Check for low voltage, binding of

fan blade, blower wheel or motor bearings.

7a. Check for correct size of

fuse or breaker. Check amp

draw.

7b. Check wiring and connections. Check operation of all

components.

TROUBLESHOOTING CHART

9

REPLACING THE CONTROL BOX ASSEMBLY

1. Place the thermistor wire in the locator slot

at the left bottom of the control box.

(Fig. 3-5, INSET)

1. Slide the new control box assembly into

place in the front half of the front panel.

(Fig. 3-5)

2. Tabs at each end of the control box

assembly will slide into the wide slots in

the front panel.

3. Locator pins on the bottom edge of the

con- trol box assembly fit into slots in

the front panel.

4. Replace the two (2) screws securing the

control box assembly to the front panel.

5. Reconnect the wiring harness connectors

to the control panel wiring plugs.

5. The control box assembly can now be removed from the front panel. Pull it straight up and away

from the front panel.

(Fig. 3-4)

When reconnecting the two power cord connectors:

• Be sure the RIBBED power cord wire is connected to the connector with the single WHITE

wire.

• Be sure the SMOOTH power cord wire is connected to the single BLACK wire.

Failure to do so will result in damage to the electronic control board

and the unit will not operate.

! NOTE

Fig. 3-4

Fig. 3-5

Locator

Slot

INSET

Wide Slot

at Each

End

16

PROBABLE CAUSE CORRECTIONPROBLEM

1. Unit does not run.

2. Fan runs - Compressor does not

run.

3. Compressor runs Fan does not run

4. No cooling - Compressor and Fan

running

5. Insufficient cooling

- Compressor and

Fan running.

1a. No power to unit.

1b. Low voltage

1c. Failed component or incorrect

wiring.

2a. Incorrect power supply.

2b. Failed components or incorrect

wiring.

3a. Blower wheel or fan blade binding

3b. Incorrect wiring.

3c. Motor windings shorted or motor

shaft stuck.

4a. Air flow restriction

4b. Compressor not pumping.

5a. Improper air flow

5b. Compressor not pumping at full

capacity.

5c. Operating 60 Hz unit on 50 Hz

current.

1a. Check for power at receptacle, good plug contact, fuses

of correct size and time delay

types. (Have customer contact

electrician if no power is available at receptacle.)

1b. Customer should contact a

qualified electrician to correct

this problem.

1c. Check all wiring and con-

nections, overload, compressor, fan motor, and

capacitor.

2a. Check for proper voltage.

2b. Check all wiring connec-

tions, overloads, compres-

sor, fan motor, capacitors,

etc.

3a. Check for proper clearance.

3b. Check wiring.

3c. Check for open or shorted

motor windings or check for

motor shaft rotation.

4a. Check air flow through condenser and evaporator.

4b. Check amp draw, restriction

in sealed system, loss of refrigerant.

5a. Clean or replace air filter.

Check for air passage restriction

or obstruction. Check for dirty

condenser, evaporator or fan

blades.

5b. Check amp draw, restriction

in sealed system or loss of refrigerant.

5c. Advise customer that the

unit should be operating on a 60

Hz electrical supply.

TROUBLESHOOTING CHART

10

ACCESSING COMPONENTS BEHIND THE DIVIDER WALL

Components accessible in the component compartment behind the divider wall include:

• Sealed Refrigeration System: This system includes the compressor, strainer, all sealed

system tubing, the condenser and the evaporator.

• Air Circulation System: This system includes the fan motor and the condenser and evapo-

rator fan blades.

• The Capacitor: The dual-electrolytic capacitor in this air conditioner contains the start capaci-

tor for the compressor motor and the start capacitor for the fan motor.

ACCESSING THE COMPONENT COMPARTMENT

1. Disconnect power from the air conditioners.

2. Remove the air conditioner from its installed position.

3. Remove the three (3) Phillips head screws securing the curtains to each side of the air conditioner.

(Fig. 3-6)

Slide the curtains from the channel rails at the top and bottom of the air condi-

tioner.

4. Remove the three (3) Phillips head screws securing the top channel rail to the top of the air

conditioner.

(Fig. 3-6)

5. Remove the four (4) Phillips head screws securing the top of the component compartment to the

air conditioner.

(Fig. 3-7)

6. Discharge the dual-capacitor with a 20,000 ohm resistor.

INSET

Removing the Fan Motor Assembly

1. Remove the four (4) screws securing the

front panel.

(Fig. 3-8)

2. Disconnect the wiring harness connectors

from the control panel wiring plugs.

(Fig. 3-8, INSET)

Fig. 3-6 Fig. 3-7

Fig. 3-8

15

Section Four

DIAGNOSIS and TROUBLESHOOTING

COMPONENT TESTING

! WARNING

ELECTRICAL SHOCK HAZARD

• Disconnect power before servicing the air conditioner.

• Replace all panels before operating the air conditioner.

Failure to do so can result in death or electrical shock.

TEST PROCEDURE RESULTSCOMPONENT

CAPACITOR

COMPRESSOR

FAN MOTOR

ELECTRONIC

CONTROL BOARD

Set a volt-ohmmeter to the Rx1 scale. Disconnect all wire leads. Discharge Capacitor.

1. Place probes on F and C terminals.

2. Place probes on H and C terminals.

Set volt-ohmmeter to Rx10 scale.

1. Place probes on each terminal and

outer case of capacitor.

Set a volt-ohmmeter to the Rx1 scale. Disconnect all wire leads.

1. Place the probes on the R and C

terminals.

2. Place the probes on the S and C

terminals.

Set a volt-ohmmeter to the Rx10 scale.

1. Place probes on each terminal and

outer case of compressor.

Set a volt-ohmmeter to the Rx1 scale.

Disconnect all wire leads.

1. Place probes on the BK and BR

motor terminals. (Phase Winding

and Overload)

2. Place probes on R and W.

3. Place probes on BK and W.

4. Place probes on BL and W.

Set volt-ohmmeter to Rx10 scale.

1. Place probes on each terminal

(except W) and motor housing.

There are no test points at the control board.

all soldered edge connections are covered with

a silicone sealant.

1. Meter should deflect momentarily and then show some minimal resistance.

2. Meter should deflect momentarily and then show some minimal resistance.

1. Meter should read infinity.

1. See Table 1 (page 19).

2. See Table 1 (page 19).

1. Meter should read infinity.

1. See Table 2 (page 19). If phase winding is shorted, meter will read no resistance. If overlaod is open, meter will read

infinity.

2. See Table 2 (page 19).

3. See Table 2 (page 19).

4.

See Table 2 (page 19).

1. Meter should read infinity.

The control board is powered by 115 VAC .

Output from the control board to the

compresor, condenser fan motor and capacitor is 115 VAC.

11

3. Remove the Hex head screw securing the

green ground wire to the evaporator frame.

(Fig. 3-9)

4. Remove the air director vanes from each

side of the evaporator shroud by first lifting

the large tab ( ). then slide the vane back

to release the end tabs from the slots in the

evaporator shroud ( ). Last, pull the

vane away from the air conditioner ( ).

(Fig. 3-10)

5. Remove the four (4) screws securing the

evaporator shroud to the evaporator frame.

(Fig. 3-11)

6. Carefully remove the styrofoam liner from

the back portion of the front panel assembly.

(Fig. 3-12)

If, during this step, the top edge of the tape

securing the styrofoam liner is damaged, remove the tape carefully, turn it upside down

and replace it during reassembly. The tape

is visible when the unit is assembled.

Failure to do this may result

in customer complaints.

! NOTE

7. Remove the five (5) screws securing the

back portion of the front panel assembly to

the divider wall. Then, slide the assembly

forward and off of the base plate.

(Fig. 3-13)

8. Remove the screen surrounding the component compartment by pulling it straight up

and away from the air conditioner.

(Fig. 3-14)

Back Portion

of Front Panel

Assembly

Fig. 3-9

Fig. 3-10

Fig. 3-11

Fig. 3-12

Fig. 3-13

Fig. 3-14

14

-- NOTES --

12

9. Remove the two (2) hex head screws securing the divider wall to the base plate of

the air conditioner.

(Fig. 3-15)

10. Remove the two (2) hex head screws securing the condenser shroud to the base

plate of the air conditioner.

(Fig. 3-15)

11. Remove the two (2) nuts securing the fan

motor mounting bracket to the bolts on the

base plate of the air conditioner.

(Fig.3-15)

12. Confirm that the capacitor is discharged.

13. Remove nut and washer securing the compressor terminals cover to the compressor.

(Fig. 3-16)

14. Disconnect the wiring harness connectors

from the compressor terminals.

15. The entire fan motor assembly, including the

fan motor, wiring harness, evaporator and

condenser fan blades,motor mounting

bracket and the unit support bracket can now

be lifted from the air conditioner. The capacitor will remain attached to the unit support bracket.

(Fig. 3-17)

When replacing the screen surrounding

the component compartment:

• Be sure the screen fits into the three (3) tabs

on each side of the divider wall.

• Be sure the screen seats flat on the base

plate of the air conditioner.

Failure to do so will result in damage to

the screen, undesirable noises during

operation and customer complaints.

! NOTE

1 of 2

Screws

Securing

Divider Wall

to Base Plate

1 of 2

Screws

Securing

Condenser Shroud

to Base Plate

1 of 2

Nuts Securing

Motor Bracket

to Base Plate

Fig. 3-15

Fig. 3-16

Fig. 3-17

13

When replacing the fan motor assembly:

• Be sure the fan motor mounting bracket is

properly located so that the base plate bolts

protrude through the holes in the motor

mounting bracket.

Failure to do so will result in damage to

the air conditioner, undesirable noises

during operation and customer com-

plaints.

! NOTE

Base Plate Bolt

protruding through Hole in

Fan Motor Mounting Bracket

Loading...

Loading...