Page 1

®

ENGINEERING COMPANY INC.

51 Winthrop Road

Chester, Connecticut 06412-0684

TA8852H Traffic Advisor™ System

Installation Guide:

Phone: (860) 526-9504

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: autocan@whelen.com

Customer Service e-mail: custserv@whelen.com

Safety First

This document provides all the necessary information to allow your Whelen product to be properly and safely installed.

Before beginning the installation and/or operation of your new product, the installation technician and operator must

read this manual completely. Important information is contained herein that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of automotive electronics,

systems and procedures.

• If mounting this product requires drilling holes, the installer MUST be sure that no vehicle components or other

vital parts could be damaged by the drilling process. Check both sides of the mounting surface before drilling

begins. Also de-burr any holes and remove any metal shards or remnants. Install grommets into all wire

passage holes.

• If this manual states that this product may be mounted with suction cups, magnets, tape or Velcro®, clean the

mounting surface with a 50/50 mix of isopropyl alcohol and water and dry thoroughly.

• Do not install this product or route any wires in the deployment area of your air bag. Equipment mounted or

located in the air bag deployment area will damage or reduce the effectiveness of the air bag, or become a

projectile that could cause serious personal injury or death. Refer to your vehicle owner’s manual for the air bag

deployment area. The User/Installer assumes full responsibility to determine proper mounting location, based

on providing ultimate safety to all passengers inside the vehicle.

• For this product to operate at optimum efficiency, a good electrical connection to chassis ground must be

made. The recommended procedure requires the product ground wire to be connected directly to the NEGATIVE

(-) battery post.

• If this product uses a remote device to activate or control this product, make sure that this control is located in

an area that allows both the vehicle and the control to be operated safely in any driving condition.

• Do not attempt to activate or control this device in a hazardous driving situation.

• This product contains either strobe light(s), halogen light(s), high-intensity LEDs or a combination of these

lights. Do not stare directly into these lights. Momentary blindness and/or eye damage could result.

• Use only soap and water to clean the outer lens. Use of other chemicals could result in premature lens cracking

(crazing) and discoloration. Lens in this condition have significantly reduced effectiveness and should be

replaced immediately. Inspect and operate this product regularly to confirm its proper operation and mounting

condition. Do not use a pressure washer to clean this product.

• It is recommended that these instructions be stored in a safe place and referred to when performing

maintenance and/or reinstallation of this product.

• FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND INSTRUCTIONS COULD RESULT IN DAMAGE TO

THE PRODUCT OR VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR PASSENGERS!

Automotive: Traffic Advisor

For warranty information regarding this product, visit www.whelen.com/warranty

©2002 Whelen Engineering Company Inc.

Form No.13703A (080107)

Page 1

Page 2

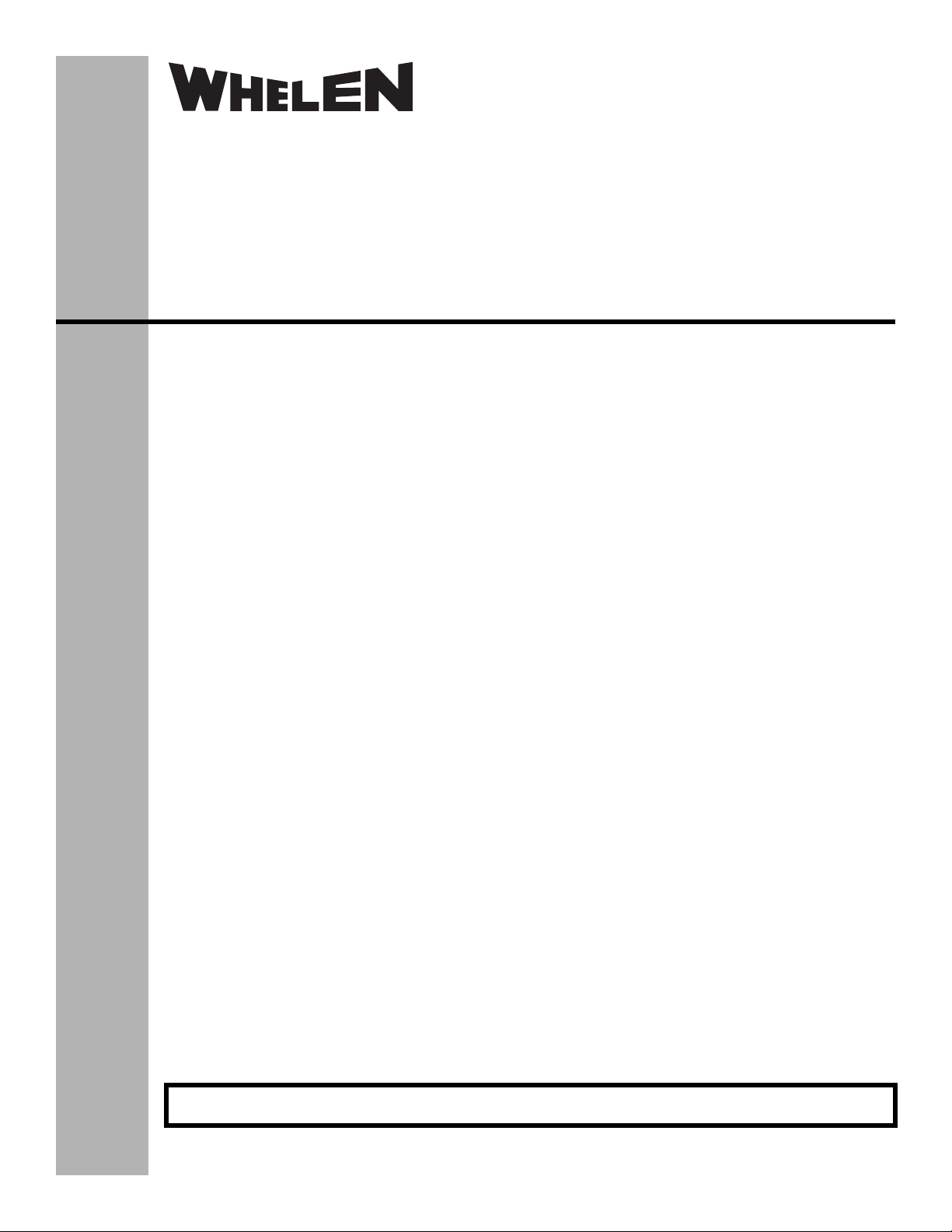

Mounting

Surface

Mounting

Surface

Installation:

Install the Traffic Advisor arrow light array as shown in Figures

1-3 depending on which mounting style you will use.

Fig. 1

Fig. 2

Standard Mounting Kit

3/8" - 16 X 1" Hex Head Bolt

3/8" Split Lockwasher

3/8" Flatwasher

Mounting

Mounting

Surface

Surface

3/8" - 16 X 1" Hex Head Bolt

Arrow End Mounting Kit

3/8" Flatwasher

Mounting

Mounting

Surface

Surface

3/8" - 16 X 2"

Hex Head Bolt

3/8" Split

Lockwasher

IMPORTANT: When you are routing any wires, the

existing, factory wire harness should be followed

whenever possible. The existing harness has been

carefully positioned so that the wires will not be

damaged by vehicle operation for example; if your

vehicle is equipped with a dump body, the harness is

positioned so that the dumping action will not crush

or pinch the wires. The factory harness may include a

service loop that will keep the wires from being

damaged or broken by the movement of the dump

body. Also, if you purchased an optional end

mounting kit (Fig 2) be sure that no more than 7/8” of

the bolt protrudes into the base casting.

Wiring:

WARNING! All customer supplied wires that connect

to the positive terminal of the battery must be sized

to supply at least 125% of the maximum operating

current and FUSED

DO NOT USE CIRCUIT BREAKERS WITH THIS

PRODUCT!

Power Connector / P1

1. Plug the power connector into the back of the control head

as shown in the wiring diagram.

Splice the 2 RED wires together, then extend this single RED

wire to the battery and install a 15 amp fuse block (customer

supplied) to the end of the wire (remove the fuse before

connecting any wires to the battery). Connect the RED wire to

the POSITIVE (+) terminal on the battery .

IMPORTANT: There must not be more than 2 feet of

wire between the fuse block and the battery. The wire

between the fuse and battery is “unprotected”, don’t

allow this wire to come in contact with other wires.

at the battery to carry that load.

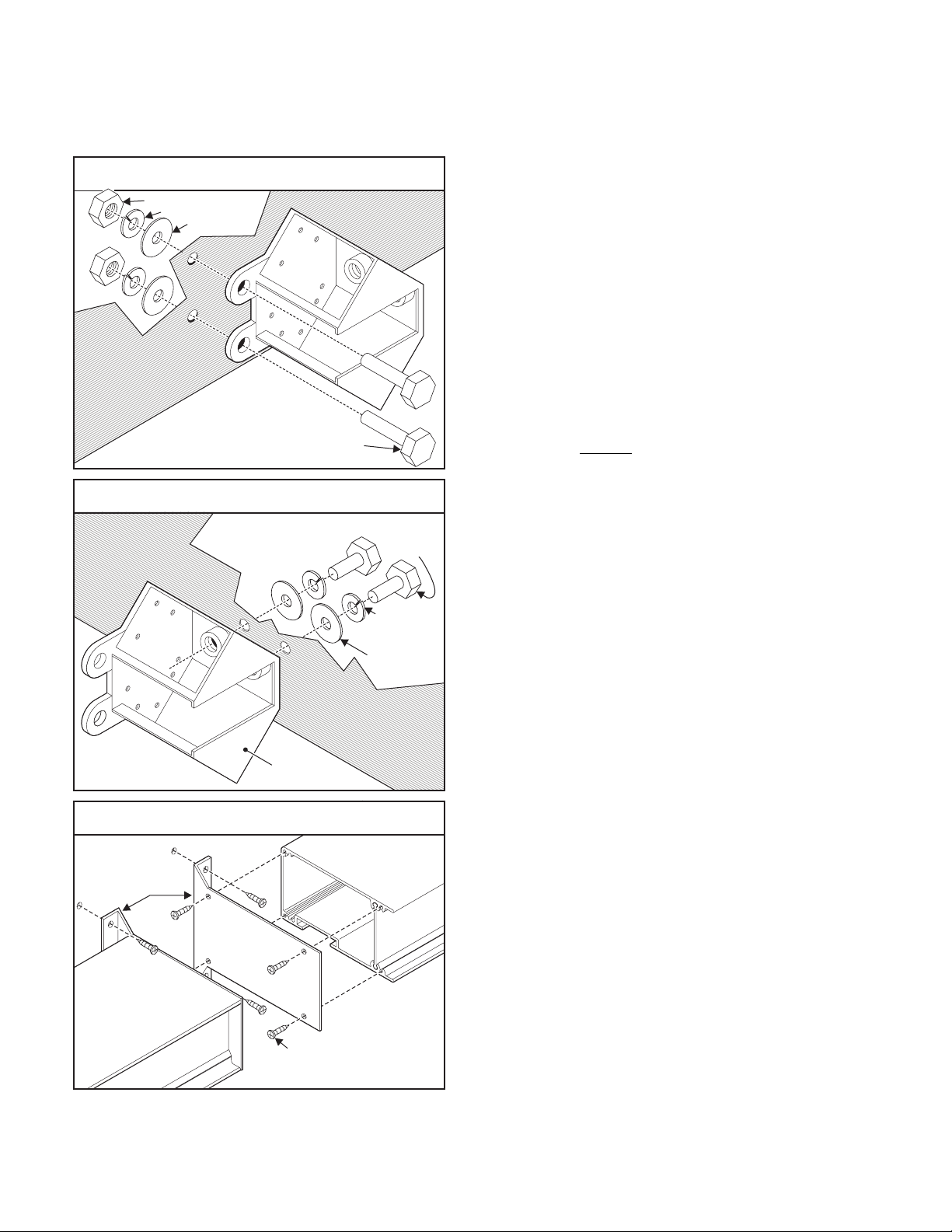

Fig. 3

Base

Casting

Endcap Mounting Bracket

Mounting

Bracket

#10 X 3/4"

PPHSMS

2. Splice the 2 BLACK wires together, then extend this single

BLACK wire to the battery and connect it to the battery

ground. If your vehicle has a cable extending from the

negative terminal of the battery to the chassis, it is best to

attach the black wire at the chassis connection.

Control Connectors / P2 & P3

1. Route the control cables from the TA to the control head.

2. Plug the connector(s) into the back of the control head.

3. Refer to the control head manual for operation.

The installation of your system will be complete after the fuse

block wire is connected to the POSITIVE (+) terminal of the

battery. After this connection has been made, inspect the fuses

at the control head and at the battery. If either of these fuses are

blown, carefully inspect all of the circuit wires and make sure

they are wired correctly. Replace blown fuses with one of an

identical amp rating. If these fuses blow after installation or

activation, contact Whelen Engineering Technical Support.

Page 2

Page 3

3"

LAMP 6BLAMP 6ALAMP 5BLAMP 5A

23.25"

30 AMP FUSE

(SUPPLIED BY CUSTOMER)

NEG POS

N/C

BLUE

101211

N/C

YELLOW

243

N/C

BROWN

13

N/C

ORANGE

5

RED

POS. COLOR

9

BATTERY

GRAY

16-POSITION HOUSING

POS. COLOR

1

N/C

GREEN

151614

N/C

VIOLET

786

N/C

N/C

RIGHT

LAMP 8A LAMP 7A

27.69"

FRONT VIEW

24

RED

GREEN

243

26

BLUE

23

RIGHT

VIOLET

ORANGE

5

7

6

GRAY

YELLOW

786

N/C

9

RED

RED

BLACK

P1

F1

15 AMP

BLACK

FUNCTIONCOLORPOS

F2

15 AMP

GROUND

+25.6VDC

+25.6VDC

RED

RED

BLACK

123

GROUNDBLACK

4

SECTION VIEW

RIGHT SIDE

REF

17

BROWN

HOUSING

POS. COLOR

9-POSITION

1

25

LAMP 8B LAMP 7B

P1P2P3

3"

GRAY

YELLOW

786

N/C

9

CONTROL

DIP SWITCH

45

32

1

See Control Head Manual for

functions and programming

CONTROL HEAD

REAR VIEW

BROWN

HOUSING

1

POS. COLOR

9-POSITION

GREEN

243

25

RED

BLUE

VIOLET

ORANGE

5

LEFT

TA8852H

WIRING DIAGRAM

TRAFFIC ADVISOR™ SYSTEM

LAMP 1ALAMP 2A

LAMP 4BLAMP 4ALAMP 3B

LAMP 3A

16

6

7

23

SECTION VIEW

LEFT SIDE

24

26

LEFT

N/C

LAMP 1BLAMP 2B

ORANGE

POS. COLOR

9

BROWN

Page 3

16-POSITION HOUSING

POS. COLOR

1

VIOLET

101211

N/C

GREEN

243

N/C

N/C

YELLOW

13

RED

5

GRAY

BLUE

N/C

151614

N/C

786

N/C

N/C

Page 4

26

19

1

2

17

16

DESCRIPTION

8 9

ASSEMBLY / TAARROW 16 LIGHT AMBER 24VDC 26' CABLE STD MT

ASSEMBLY / TAARROW 16 LIGHT AMBER 24VDC 26' CABLE END MT

ASSEMBLY / TAARROW 16 LIGHT AMBER 24VDC 51' CABLE STD MT

ASSEMBLY / TAARROW 16 LIGHT AMBER 12VDC 51' CABLE END MT

ASSEMBLY / TAARROW 16 LIGHT AMBER 12VDC 51' CABLE STD MT

ASSEMBLY / TAARROW 16 LIGHT AMBER 12VDC 26' CABLE END MT

ASSEMBLY / TAARROW 16 LIGHT AMBER 12VDC 26' CABLE STD MT

ASSEMBLY / TAARROW 16 LIGHT AMBER 24VDC 51' CABLE END MT

BLACK - RIGHT HOUSING

BLACK - LEFT HOUSING

BASE BLACK END TAPPED CASTING

BASE BLACK STANDARD CASTING

SCREW - 1/4-20 X 1/2" SOCKET SET CUP POINT SS

SCREW 6-32 X 1/2" PPHMS SELF TAP-

GROMMET

SCREW - #10 X 3/4" PPHSMS

CABLE CLAMP 3/8"

16 POS SOCKET AMP HOUSING

9 POS PIN AMP HOUSING

CORROSION PREVENTATIVECOMPOUND / Not Shown

1/8" ALLEN WRENCH

10 11

PART NUMBER

01-06836130A0

2

15

12

22

21

7

6

ITEM

QTY

QTYQTY QTYQTY QTY

QTYQTY

01-0683613010

01-0683613110

01-06836131A1

01-06836130A1

01-06836131A0

13

22

20

18

21

01-0683613011

01-0683613111

11-463403-001

11-463402-001

11-382096-003

11-382096-002

17

16

15

14

1111111

1

2

2

1

1

2

1

2

1

2

1

2

1

2

1

1

2

14-062216-083

14-130526-080

26-0121053-00

21-11121603-0

15-101416-120

19

20

18

21

22

2

2

44444

8888888

20

222

20

222

20

2

2

20

222

20

2

2

20

2

2

20

222

444

8

20

66-1415940-00

39-0409313-04

39-0416323-04

66T0516435102

26

25

24

23

2

2

A/R

2

11

A/R

11

2

A/R

2

2

A/R

11

2

A/R

2

2

A/R

1

2

2

A/R

1

2

A/R

7

6

13

STANDARD MOUNT

END MOUNT

MOUNTING STYLE0=1=

14

DESCRIPTION

ASSEMBLY / TAARROW 16 LIGHT AMBER 12VDC 51' CABLE STD MT

ASSEMBLY / TAARROW 16 LIGHT AMBER 12VDC 26' CABLE END MT

ASSEMBLY / TAARROW 16 LIGHT AMBER 12VDC 26' CABLE STD MT

PART NUMBER

01-06836130A1

01-06836131A0

01-06836130A0

ITEM

QTY

QTY

QTYQTY QTYQTY

QTYQTY

ASSEMBLY / TAARROW 16 LIGHT AMBER 24VDC 26' CABLE STD MT

ASSEMBLY / TAARROW 16 LIGHT AMBER 24VDC 26' CABLE END MT

ASSEMBLY / TAARROW 16 LIGHT AMBER 24VDC 51' CABLE STD MT

ASSEMBLY / TAARROW 16 LIGHT AMBER 12VDC 51' CABLE END MT

01-06836131A1

ASSEMBLY / TAARROW 16 LIGHT AMBER 24VDC 51' CABLE END MT

01-0683613010

01-0683613110

01-0683613011

01-0683613111

ASSEMBLY / HALOGEN SNAP-IN 2 WIRE 2 POS 28V-35W AMBER

ASSEMBLY / HALOGEN SNAP-IN 2 WIRE 2 POS 12V-20W AMBER

ARROW END MOUNTING KIT

STANDARD MOUNTING KIT

01-06835772A2

01-0416047-00

01-0416050-00

01-06835772A4

1

2

3

4

-

1

8

1-8

1

8

1

8

1

8

-

1

8

1

8

-

1

8

WING UPPER LEFT / LOWER RIGHT 14.062" BLACK AMBER 24 VDC

WING UPPER LEFT / LOWER RIGHT 14.062" BLACK AMBER 12 VDC

ASSEMBLY / INPUT CABLE - 51'

ASSEMBLY / INPUT CABLE - 26'

ASSEMBLY / INTERNAL HARNESS

02-0363392-12

02-0363392-A2

02-0262521-51

02-0262521-26

02-0262501-00

9

8

7

6

5

1

1

2

1

1

2

1

1

2

1

1

2

1

1

2

1

1

1

1

2

1

2

1

2

WING UPPER RIGHT / LOWER LEFT 14.062" BLACK AMBER 24 VDC

WING UPPER RIGHT / LOWER LEFT 14.062" BLACK AMBER 12 VDC

END CAP MOUNTING BRACKET

FILLER PANEL

11-241779-006

02-0363391-12

02-0363391-A2

09-1321667-01

11

12

10

13

2

2222222

2

22

2

22

2

2

22

2

2

2

222

AMBER 12 VDC

AMBER 24 VDC

COLOR & VOLTAGEA=1=

26' CABLE

51' CABLE

CABLE LENGTH0=1=

CABLE LENGTH

COLOR - VOLTAGE

HOUSING - MOUNTING

01-0683613___

PART NUMBER KEY:

Page 4

This parts list shows both the 12

NOTE:

and 24 volt TA arrow for reference.

The TA8852H2 control head, may

onlybeusedwiththe12voltarrow.

12

11

4

3

5

9

8

1

17

16

Loading...

Loading...