Page 1

®

ENGINEERING COMPANY INC.

51 Winthrop Road

Chester, Connecticut 06412-0684

Liberty™ and Freedom™ LC Lightbars

Installation Guide:

Phone: (860) 526-9504

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: canadiansales@whelen.com

Customer Service e-mail: custserv@whelen.com

Safety First

This document provides all the necessary information to allow your Whelen product to be properly and safely installed.

Before beginning the installation and/or operation of your new product, the installation technician and operator must

read this manual completely. Important information is contained herein that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of automotive electronics,

systems and procedures.

• Failure to use specified installation parts and/or hardware will void the product warranty!

• If mounting this product requires drilling holes, the installer MUST be sure that no vehicle components or other

vital parts could be damaged by the drilling process. Check both sides of the mounting surface before drilling

begins. Also de-burr any holes and remove any metal shards or remnants. Install grommets into all wire

passage holes.

• If this manual states that this product may be mounted with suction cups, magnets, tape or Velcro®, clean the

mounting surface with a 50/50 mix of isopropyl alcohol and water and dry thoroughly.

• Do not install this product or route any wires in the deployment area of your air bag. Equipment mounted or

located in the air bag deployment area will damage or reduce the effectiveness of the air bag, or become a

projectile that could cause serious personal injury or death. Refer to your vehicle owner’s manual for the air bag

deployment area. The User/Installer assumes full responsibility to determine proper mounting location, based

on providing ultimate safety to all passengers inside the vehicle.

• For this product to operate at optimum efficiency, a good electrical connection to chassis ground must be

made. The recommended procedure requires the product ground wire to be connected directly to the NEGATIVE

(-) battery post.

• If this product uses a remote device to activate or control this product, make sure that this control is located in

an area that allows both the vehicle and the control to be operated safely in any driving condition.

• Do not attempt to activate or control this device in a hazardous driving situation.

• This product contains either strobe light(s), halogen light(s), high-intensity LEDs or a combination of these

lights. Do not stare directly into these lights. Momentary blindness and/or eye damage could result.

• Use only soap and water to clean the outer lens. Use of other chemicals could result in premature lens cracking

(crazing) and discoloration. Lenses in this condition have significantly reduced effectiveness and should be

replaced immediately. Inspect and operate this product regularly to confirm its proper operation and mounting

condition. Do not use a pressure washer to clean this product.

• It is recommended that these instructions be stored in a safe place and referred to when performing

maintenance and/or reinstallation of this product.

• FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND INSTRUCTIONS COULD RESULT IN DAMAGE TO

THE PRODUCT OR VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR PASSENGERS!

Automotive: Lightbars

For warranty information regarding this product, visit www.whelen.com/warranty

©2003 Whelen Engineering Company Inc.

Form No.13745U (081010)

Page 1

Page 2

Insert foot into extrusion with locking plate

attached.

Twist mounting foot into

position

ANCHOR

PLATE

Loosely secure foot and locking plate.

IMPORTANT! The lightbar should be a minimum

Mounting

Pad

Adjustable

Mounting

Foot

Washer

Nut

Mounting

Foot

Base

Standard

Mounting

Foot

Mounting

Pad

Washer

Nut

Locking

Plate

Bolt

Bolt

of 16" from any radio antennas!

Permanent Mounting:

1. Locate the mounting foot, anchor plate and locking plate included with your

lightbar. If not already present, install the locking plate onto the mounting

foot. When properly positioned, this plate is centered from side-to-side on

the mounting foot.

2. Flip the lightbar upside-down to expose the bottom of the extrusion and

place the mounting foot onto the extrusion.

3. Rotate the mounting foot 90° counter-clockwise. Make sure that the edges

of the mounting foot swing into position under the extrusion mounting lip.

Install an anchor plate onto the extrusion in the same manner.

4. Repeat this procedure for the remaining mounting foot and anchor plate

and return the lightbar to its right side-up position.

5. Position the lightbar onto the vehicle roof in the desired mounting location.

One often selected location is directly above the B-pillars. This area is the

strongest part of the roof. Refer to your lightbar manual for cable exit

location, to be sure that the lightbar is facing the proper direction.

6. Adjust the two mounting feet outwards so that they are as close to the

edge of the roof as possible. Both mounting feet must be in full contact with

the roof. Be sure that there is no less than 1/2” clearance between roof and

lightbar at their closest point. When the mounting feet are in their proper

position, lightly tighten the locking plate allen head set screws.

7. Return the lightbar to an upside-down position. Slide each anchor plate

outwards until it is fully engaged with its corresponding mounting foot. With

the mounting feet and anchor plates in their proper positions firmly tighten

all of the set screws (2 or 4 per side). Flip the lightbar right side-up and

return it to its mounting position.

8. Open both drivers side doors. In the area directly below the mounting foot,

pull the weather-strip away from the vehicle so the area where the

mounting strap will be secured is exposed. Repeat for the other side.

9. Insert the mounting strap through the mounting foot. Be sure that the strap

fits flush against the area where it will be secured onto the vehicle. Insert

the tension bolt through the mounting strap and anchor plate, into the

tinnerman nut. Tighten slightly with a long-shafted, Phillips screwdriver.

Repeat procedure for passenger side.

10. If your mounting strap has mounting holes in the end of the strap, use

these holes as a template to drill appropriately sized pilot holes through the

strap and into the vehicle. Repeat for passenger side of the vehicle.

11. Firmly tighten the tension bolts to secure the lightbar to the vehicle.

Strap Mounting:

1. Locate the mounting foot, anchor plate and locking plate included with your

lightbar. If not already present, install the locking plate onto the mounting

foot. When properly positioned, this plate is centered from side-to-side on

the mounting foot.

2. Flip the lightbar upside-down to expose the bottom of the extrusion and

place the mounting foot onto the extrusion.

3. Rotate the mounting foot 90° in a counter-clockwise direction. Make sure

that the edges of the mounting foot swing into position under the extrusion

mounting lip. Install an anchor plate onto the extrusion in the same

manner.

4. Repeat this procedure for the remaining mounting foot and anchor plate

and return the lightbar to its right side-up position.

5. Position the lightbar onto the vehicle roof in the desired mounting location.

One often selected location is directly above the B-pillars. This area is the

strongest part of the roof. Refer to your lightbar manual for cable exit

location, to be sure that the lightbar is facing the proper direction.

6. Adjust the two mounting feet outwards so that they are as close to the

edge of the roof as possible. Both mounting feet must be in full contact with

the roof. Be sure that there is no less than 1/2” clearance between roof and

lightbar at their closest point. When the mounting feet are in their proper

position, lightly tighten the locking plate allen head set screws.

7. Return the lightbar to an upside-down position. Slide each anchor plate

outwards until it is fully engaged with its corresponding mounting foot. With

the mounting feet and anchor plates in their proper positions firmly tighten

all of the set screws (2 or 4 per side). Flip the lightbar right side-up and

return it to its mounting position.

8. Open both drivers side doors. In the area directly below the mounting foot,

pull the weather-strip away from the vehicle so the area where the

mounting strap will be secured is exposed. Repeat for the other side.

9. Insert the mounting strap through the mounting foot. Be sure that the strap

fits flush against the area where it will be secured onto the vehicle. Insert

the tension bolt through the mounting strap and anchor plate, into the

tinnerman nut. Tighten slightly with a long-shafted, Phillips screwdriver.

Repeat procedure for passenger side.

10. If your mounting strap has mounting holes in the end of the strap, use

these holes as a template to drill appropriately sized pilot holes through the

strap and into the vehicle. Repeat for passenger side of the vehicle.

11. Firmly tighten the tension bolts to secure lightbar to vehicle.

Page 2

Page 3

NOTE: Unless otherwise specified, the

lightbar mounting feet must be sitting as

close to the edge of the roof as possible.

Mounting feet must also be in full contact

with the roof and not be hanging off

the edge.

IMPORTANT: For strap mounted bars, be sure you have the right

sized lightbar for your vehicle. The lightbar should be about the

same width as the vehicle roof. If the

lightbar is too large or small it will not

mount properly to the vehicle and

may shift or come loose during driving.

1/2" Minimum Clearance at Closest Point

MOUNTING FOOT

TINNERMAN

NUT

FOOT

ANCHOR

PLATE

SET

SCREW

Plate slides into

lightbar extrusion

5" Mounting Foot

NUT

BOLT

SPLIT LOCK

WASHER

METAL SCREW

NOTE: The mounting straps are made to fit the contours of individual

vehicles. The strap

may look different. If your lightbar has a 5"

mounting foot, it will assemble differently than the standard

mounting foot. It also uses an extension to compensate for

the extra height. Follow these illustrations for assembly.

Mounting to the lightbar is the same.

shown here is for example only. The strap

for your vehicle

NOTE:

NOTE:

NOTE:

NOTE:

NOTE:

NOTE:

STRAP

SHEET

METAL

SCREWS

EXTENSION

VEHICLE ROOF

Locking

Plate

Mounting

Foot

Nut

Mounting

Pad

Adjustment

screws

Lock

Washer

Anchor Plate

Tinnerman

Nut

Tinnerman

Nut

Anchor

Plate

Locking

Plate

Mounting Strap

Mounting

Screw

Adjustable Foot

Model MKAJ

Standard Foot

Model MKEZ

Mounting

Strap

Mounting

Screw

Tension

Bolt

Tension

Bolt

Tighten screws

with torque wrench

set at 35 to 40 in/lbs

Model

MKAJ

Mounting

Foot

Allen

screws

Mounting

Foot Base

NOTE: Model MKAJ is an adjustable mounting foot. On this model you

DRILLING THE CABLE ACCESS HOLE

Drill cable access hole in appropriate area

for your lightbar (see note)

FRONT OF LIGHTBAR

For

cables exiting

the Driver-side

of the extrusion

lightbars

with

For

cables exiting

the Passenger-side

of the extrusion

lightbars

with

may loosen the screws on the rear of the foot and adjust the angle of the

lightbar. This feature can be used if the angle of the roof is not level with

the road.

IMPORTANT: To adjust the leveling screws you must use a torque wrench

set at 35 to 40 in./lbs.

Routing your Lightbar Cable(s)

1. To protect the headliner from damage caused by drilling the cable access

hole through the vehicle roof, allow a 5” to 7” distance between roof and

headliner by lowering the headliner before drilling.

WARNING! There may be a roof support member that spans the

distance between the driver’s and passenger’s side. DO NOT DRILL

THROUGH THIS MEMBER! Adjust the location until the hole can be

drilled without contacting this support member.

2. Using a 1” hole saw, drill the cable access hole. Use a round file to smooth

and de-burr the edges than insert a 1” grommet.

3. Insert the cable(s) through the cable access hole into the vehicle. Use

RTV silicone to weatherproof the access hole after the cable(s) are pulled

completely into the vehicle.

4. Route the cable(s) through the vehicle following manufacturers

recommendations.

WARNING: Many vehicles are now equipped with side curtain and Bpillar air bags. Alternate routing may be required.

Page 3

Page 4

Connecting the Cables:

WARNING! All Customer supplied wires that connect to the positive

terminal of the battery must be sized to supply at least 125% of the

maximum operating current and FUSED

load. DO NOT USE CIRCUIT BREAKERS WITH THIS PRODUCT!

at the battery to carry that

Level Mode: Applying +12 VDC voltage to the VIOLET wire for more than 1

second holds the lightbar in low power mode until voltage is removed (a toggle

switch is preferred).

IMPORTANT NOTE: The corner modules in your lightbar do not

switch to low power when this option is applied. They will always

remain in normal high power.

Power Cable:

1. Open the wiring shield lid and route the power cable into the wiring shield

and towards the firewall. Make sure you do not to pinch or crush any

wires when running them through the wire shield.

2. Follow the factory wiring harness through the firewall. It may be

necessary to drill a hole in the firewall. If so, be absolutely sure that there

are no components that could be damaged by drilling. After the hole has

been drilled, insert a grommet to protect the cable.

3. Route the cable along the factory wiring harness to the battery.

4. Install a 30 amp fuse block (customer supplied) on the end of the RED

wire in the power cable. Remove the fuse from the fuse block before

connecting any wires to the battery.

5. Connect the fuse block to the POSITIVE (+) terminal on the battery. There

can not be more than two feet of wire between the fuse block and the

battery. The wire between the fuse block and the battery is “unprotected”,

do not allow this wire to touch any other wires.

6. Connect the BLACK wire to the factory chassis ground.

Cruise Lights & AUX (WHITE/ORANGE):

The WHITE/ORANGE wire operates in one of 3 different modes. Selecting a

mode is controlled with the Scan-Lock™ wire. Using Scan-Lock™ (See ScanLock™), change between the 3 available modes as though you were changing

flash patterns. The three modes are as follows:

MODE 1 (Default) - Cruise Lights in Low Power and the AUX port is activated.

MODE 2 - Cruise Lights in High Power and the AUX port is activated.

MODE 3 - Cruise Lights are not activated and the AUX port is activated.

Hi/Low Power (VIOLET):

The type of switch used is dependant on how the operator wishes the Hi/Low

feature to function:

Latching Mode: By applying +12 VDC voltage to the VIOLET wire for less than

1 second, the lightbar is “latched” into low power operation. The unit must be

turned off and then back on to restore normal, high power operation (a

momentary switch is preferred).

Scan-Lock™ (WHITE/VIOLET):

TO CYCLE FORWARD THROUGH AVAILABLE PATTERNS: Activate ONLY

the control wire of the function you wish to effect and apply +12 volts to the

Scan-Lock™ wire (WHITE/VIOLET) for less than 1 second and release. This

will change the pattern. For example, to change the Front Outboard LED

pattern, apply +12VDC to the GREEN/WHITE wire and then momentarily apply

+12VDC to the WHITE/VIOLET wire. Repeat until the desired pattern is

displayed. Let this pattern run for 5 seconds to configure it as the pattern the

Front Outboard LEDs will display when activated. Important: Only ONE

function may be active while changing patterns. Repeat for next pattern.

TO CHOOSE A PATTERN: Allowing the desired pattern to run for more than 5

seconds makes it the default pattern.

TO RESET TO THE FACTORY DEFAULT PATTERN: Turn o ff all lightbar

functions. Apply +12 volts to the Scan-lock™ wire and turn the appropriate

function back on and it is now restored to its factory default pattern.

Available Flash Patterns:

Front Corner, Rear Corner, Outboard

Inboard and Center

1. SignalAlert™ 75

2. CometFlash® 75

3. DoubleFlash 150

4. DoubleFlash 75

5. SingleFlash 375

6. SingleFlash 150

7. SingleFlash 75

8. ActionFlash™ 150

9. ModuFlash™

10. ActionScan™

Front Outboard, Inboard and Center

1. SignalAlert™ 75

2. CometFlash® 75

3. DoubleFlash 150

4. DoubleFlash 75

5. SingleFlash 375

6. SingleFlash 150

7. SingleFlash 75

8. ActionFlash™ 150

9. ModuFlash™

10. Steady/SF75

11. Steady/Steady

12. ActionScan™

Take-Down / Alley

1. T-D & Alley - SingleFlash 240 ALT

2. T-D & Alley - DoubleFlash 120 ALT

3. T-D only - SingleFlash 240 SIM

4. T-D only - DoubleFlash 120 SIM

Traffic Advisor™ Sequence

1. Seq to Solid

2. Seq On - Seq Off

3. One Lamp Triple

4. Two Lamp Triple

Control Cable: Extend the control cable to your switch panel and make your connections using the information provided. The control cable connects

to your control head or switch box and is fused there. Applying +12VDC to a control wire activates its function. Fuse as noted below.

Wire Color Function Fuse

GREEN . . . . . .Front Corner LEDs . . . . . . 1 AMP

BLUE . . . . . . .Rear Corner LEDs . . . . . . 1 AMP

GRN/WHT . . . .Front Outboard LEDs . . . . 1 AMP

BLU/WHT . . . .Rear Outboard LEDs . . . . 1 AMP

GRN/BLK . . . .Front Inboard LEDs . . . . . 1 AMP

BLU/BLK . . . .Rear Inboard LEDs . . . . . 1 AMP

Special Order Lightbars:

Unicor Lightbar:

Wire Color Function Fuse

GREEN . . . . All Front LEDs . . . . . . . . . . . . 1 AMP

BLUE . . . . . Rear LEDs / RED-BLUE . . . . 1 AMP

VIOLET . . . . Flashing Ctr RED & Alleys . . . 1 AMP

ORANGE . . Take Downs . . . . . . . . . . . . . . 1 AMP

GREY . . . . . Rear AMBER . . . . . . . . . . . . . 1 AMP

YELLOW. . . Passenger Alley . . . . . . . . . . . 1 AMP

WHITE . . . .Driver Alley . . . . . . . . . . . . . . . 1 AMP

WHT/BLK . .Steady Center RED . . . . . . . . 1 AMP

WHT/GRN. . . Right TA . . . . . . . . . . . . . . 1 AMP

WHT/BLU . . . Flashing Alley & T.D.’s . . . 1 AMP

YELLOW . . . Pass.-Side Alley Lights . . . 1 AMP

WHITE . . . . . Driver-Side Alley Lights. . . 1 AMP

WHT/BLK . . . Take-Down Lights . . . . . . . 1 AMP

WHT/ORG . . Cruise Lights & AUX . . . . . 1 AMP

WHT/YEL . . . . . Left TA . . . . . . . . . . . . . 1 AMP

Philadelphia Lightbar:

BLU/BLK . . . End External Pods . . . . . . . 1 AMP

WHT/RED. . . Front External Pods . . . . . . 1 AMP

WHT/BRN . . Rear External Pods . . . . . . . 1 AMP

YELLOW . . . Passenger Alleys . . . . . . . . 1 AMP

WHITE . . . . . Driver Side Alleys . . . . . . . . 1 AMP

GREEN. . . . . Front Corners . . . . . . . . . . . 1 AMP

BLUE . . . . . . Rear Corners . . . . . . . . . . . 1 AMP

GRN/WHT . . Front Outboards . . . . . . . . . 1 AMP

BLU/WHT. . . Rear Outboards . . . . . . . . . 1 AMP

GRN/BLK . . . Front Outboards . . . . . . . . . 1 AMP

WHT/BLU. . . Flashing Alley & TDs. . . . . . 1 AMP

Page 4

WHT/BRN . . . . . Rear Center LEDs . . . 1 AMP

VIOLET . . . . . . .Hi/Low Power . . . . 0.5 AMPS

WHT-VIO . . . . . . Scan-Lock™. . . . . . 0.5 AMPS

WHT/RED. . . . . . Front Center LEDs . . . 1 AMP

NONE . . . . . . . . . RFI shield drain / to ground

Activating WHT/GRN + WHT/YEL = Split TA

WHT/BLK . . TakeDowns. . . . . . . . . . . . . 1 AMP

WHT/ORG . . . . Cruise Lts. & AUX . . . . . . 1 AMP

VIOLET . . . . . . Hi-Low Power . . . . . . . . 0.5 AMP

WHT/VIO . . . . . Scan-Lock™ . . . . . . . . . 0.5 AMP

WHT/GRN . . . . Right TA. . . . . . . . . . . . . . 1 AMP

WHT/YEL. . . . . Left TA . . . . . . . . . . . . . . . 1 AMP

Activating WHT/GRN + WHT/YEL = Split TA

Leader Lightbar:

GREEN . . . . . . Front Corner LEDs. . . . . . 1 AMP

GRN/WHT . . . . Front Outboards. . . . . . . . 1 AMP

GRN/BLK. . . . . Front Inboards . . . . . . . . . 1 AMP

WHT/RED . . . . Front Center LEDs . . . . . . 1 AMP

Page 5

Lighthead mounting holes

snap into the raised bosses

on the lighthead bracket.

Ears on lighthead bracket

slide into channels in

extrusion (base).

Snap lighthead

into bracket.

Endcap & Gasket

500 Series Alley Light

Mounting Lightheads to Extrusion

If lightbar has

no alley light,

use nuts to

hold lens in.

Halogen Lighthead

slides into extrusion here.

BASE

EXTRUSION

LR-11 Take-down and Alley Light

LR-11 Alley Light

Endcap

Lens

Screw

BASE EXTRUSION SIDE VIEW

LIGHTHEAD

Endcap, Gasket , Lenses & Spacers Installation

Gasket & Halogen Alley Light

BARB

BOSS

Halogen Lighthead

snaps into extrusion

Align lighthead

reflector up with 4

bosses in endcap.

Press reflector into

place.

Endcap with integrated gasket

Servicing: Liberty Lightbar

Servicing: Freedom™ Lightbar

Halogen Alley Light

Remove the screws (A) that hold the endcap on and pull the endcap and gasket (C) off.4 (B) Slide lenses

(D) out of the lightbar, to gain access to the extrusion. When reinstalling the lenses and spacers, install the

cord seal (NFPA / See below). When reinstalling the endcap, place the endcap gasket into it's position on

the endcap and line up all the tabs and holes. Spacers (not shown) mount the same as lenses.

D

D

C

Insert cord seal into track in lens

A

B

Seal Cord Installation / NFPA Only:

Cut the seal cord approx. 1-1/2" longer than the extrusion on each side.

Rub silicone over the cord seal leaving 3 to 4 inches on one end dry.

Begining with 1 corner lens, start the lens into the bottom

lens track. Place the cord seal onto the groove in the

top of the lens eav 1 to 2 inches

Hold onto the left end of the seal hanging

out and slide the corner lens into

position.

1 2 3 -

4 -

3 3 -

4 4 -

. L e free.

Inspect seal cord for any areas that have wrinkled.

Especially in the areas around the dividers.

Push the lenses together tight and trim excess seal

cord at each end.

6 -

7 -

6 -

7 -

From the opposite end of the

lightbar, pull the seal

cord tight and install

the remaining lenses

and divider.

5 -

5 5 5 5 -

NOTE: Lens dividers must

be installed as each lens is

put into position

Installing Corner Linear-LED®

Insert the tabs on the lighthead housing, into the channels in the extrusion.

Installing Lens and Lighthead

Lens

fits

here

Extrusion secures to Support Bracket.

SUPPORT

BRACKET

BASE EXTRUSION

SUPPORT

BRACKET

SECURE TO

EXTRUSION

TO SECURE

BRACKET

EXTRUSION

LR11 TAKEDOWN

LR11

ALLEY

LIGHT

BASE

EXTRUSION

LR-11 Take-down

A

D

J

U

S

T

A

N

G

L

E

Secure lighthead

bracket to extrusion

Snap lighthead

bracket into TD

bracket

Slide into

tracks in

extrusion

Page 5

Page 6

BROWN

REAR LED 1

BROWN

FRONT LED 1

BROWN

WHT/BRN

GRAY

ORANGE

WHT/ORG

GREEN

FRONT LED 5

YELLOW

FRONT LED 4

ORANGE

FRONT LED 3

RED

FRONT LED 2

REAR OF LIGHTBAR

BLUE

REAR LED 6

GREEN

REAR LED 5

YELLOW

REAR LED 4

ORANGE

REAR LED 3

RED

REAR LED 2

DRIVER'S

SIDE

PASSENGER

SIDE

YELLOW

WHT/YEL

WHITE /

BLACK

WHT

RED

WHT/RED

YELLOW

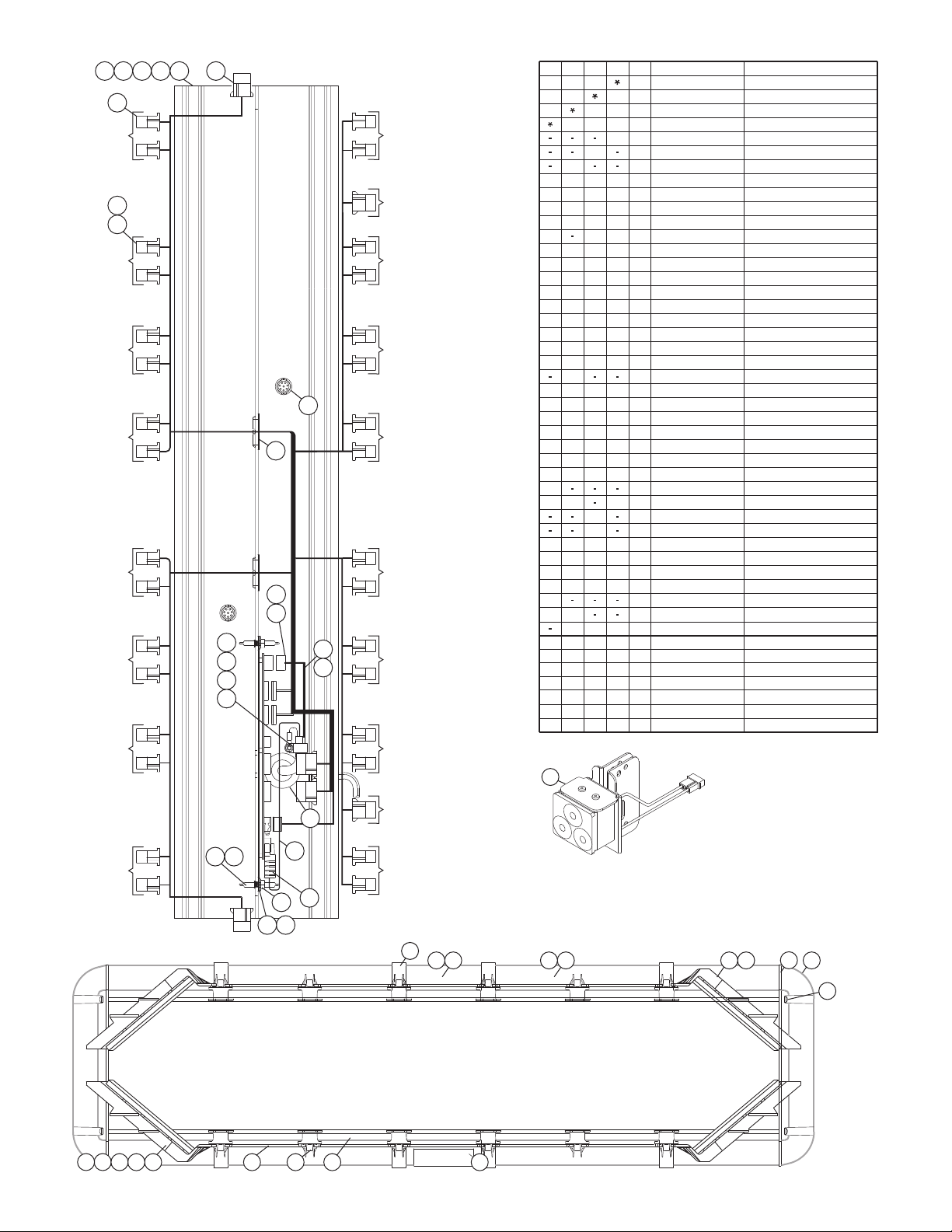

46

123

24

38

37

9

21

22

5

29

7

14

27

10

6

36

18

17

16

204

BLUE

FRONT LED 6

FRONT

11

35

34

31

32

3940

3930

45 3344

42

25

43

41

26

47

13

19

15

23

12

LR11 ALLEY

28

ITEM

PART NUMBER

DESCRIPTION

QTY QTY QTY QTY

1 1

1

1

2

2

1

212

1

212

1

1

2

3

2

4

2

1

1

5

6

7

1 14111

2

1

8188

2

1

1

11

8

11

2

1

9

10

1 12

4

2

1

1

111

1

242

4

1

11617

2

4

18

20

#10-24 x 1-1/4" TX. PHD. SCREW W/SHLDR

NUT, 1/4-20 ELASTIC STOP (316 SS)

BASE EXTRUSION (45.75")

BASE EXTRUSION (51.125")

BASE EXTRUSION (56.50")

MTG. STUD

BUSHING, 1-5/8"

CABLE, 2/C 10GA 17'

CABLE, 17/C 22GA 17'

HARNESS, 6 LIGHT

GROMMET, 1.562"

NUT, #10-24 WHIZ

CABLE CLAMP, 5/8"

PROTECTIVE COVER

HOUSING, 3 POS SOCKET

ASSEMBLY, I/O BOARD LC

A/RA/R A/R A/R

271111

1

6

12

18

11

2

8

2

2

8

12

101816

1 24

22

6

22

21

23

14

12

25

26

A/R

4

4

2

A/R1A/R

1

4 4

30

A/R

11

28

29

44

31

32

33

2

1

2

1

2

2

1

2

2

1

1

141

2

2

2

1

35

34

36

1

38

37

39

4

44

40

1111

HARNESS, ALLEY LIGHT

SINGLE LR11 ALLEY FREEDOM

HOUSING, 16 POS SCKT. CMNL

VENT, 3/4"

6 LIGHT HARNESS 60"

LENS, 5.00" CLEAR

LENS DIVIDER ASS'Y. (CLEAR)

LABEL, MODEL & SERIAL NO.

#10-24 x 1 PPHMS

FILLER PANEL, "400" SERIES

MOUNTING BRACKET

BRACKET, SPACER

LENS, 6.562" CLEAR

LENS, 9.25" CLEAR

CORNER REFLECTOR LED BLUE

CORNER REFLECTOR LED RED

HARNESS, 4 LIGHT 72"

LENS, 15.75" CLEAR

LENS, 10.375" CLEAR

BASE EXTRUSION (40.375")

HOUSING, 2 POLE

GASKET, ENDCAP

ENDCAP, CLEAR

LABEL, "FRONT"

Freedom™ Ext LC R/R/B/B 44"

Freedom™ Ext LC R/R/B/B 50"

Freedom™ Ext LC R/R/B/B 55"

Freedom™ Ext LC R/R/B/B 60"

42

45

46

47

11-363141-000

46-0742883-17

46-0742957-17

21-242401-000

22-0542701-00

11-363143-000

11-363142-000

26-0115663-10

13-104111-063

14-104286-16JB

21-11245004-1

46-0763941-00

01-0269881-00

39-0403023-04

22-0416982-00

13-130111-072

46-0763967-00

07-242815-000

14-104216-160

07-263103-000

09-1363158-00

10-0523067-02

02-0341448-30

46-0784223-00

21-7263998-00

68-1984104-30

68-1983817-30

68-1983816-30

01-026C368-30

39-0416323-04

68-1183369-30

38-0283381-00

39-0017188-08

11-363390-000

68-1183491C02

46-0763942-00

68-1984105-30

01-026B805550

01-026B805220

10-0322935-00

01-0684466-

01-0684466-

01-0684466-

01-0684466-

CORNER REFLECTOR LED AMBER

41

01-026B805110

CORNER REFLECTOR LED GREEN

44

01-026B805440

CORNER REFLECTOR LED WHITE

43

01-026B805330

A/RA/R A/R A/R

A/RA/R A/R A/R

A/RA/R A/R A/R

A/RA/R A/R A/R

A/RA/R A/R A/R

Page 6

Page 7

I.O. CARD ASSEMBLY

("LC" SERIES)

TD

ALLEY AUX

REAR FRONT

3 POS. CONN.

P1P2P3-

WHT-YEL

WHT-GRN

N/C

Cable EXIT

16 POS. CONN.

VIO

GRN-BLK

GRN-WHT

BLU-BLK

WHT-BLU

WHT-ORG

WHT-VIO

WHT-RED

P1P2P3P4P5P6P7P8-

P9- GRN

P10P11P12P13P14P15P16-

WHT-BRN

BLU-WHT

YEL

BLU

WHT

SHIELD

WHT-BLK

INPUT

CABLE

DETAIL

12

1

2

3

30

6

10

75

73

32

58 59

60 61

57

62

16

17

39

51

55.125

3726

43

11

38

FRONT

35

60.500

FRONT

26

37

38

34

43

42

49.750

FRONT

34

43

26

37

36

11

38

11

FRONT

44.375

34

42

26

37

38

33

48

BLU / REAR LED 6 GRN / REAR LED 5 YEL / REAR LED 4 ORG / REAR LED 3

YEL

WHT

40

BRN

ORG

YEL

RED

292929292929

40

29

18

4

29

29

29 29

5

8 9

44

45 46

RED

48

BRN

ORG

RT

YEL

49

RED / REAR LED 2 BRN / REAR LED 1

YEL / FRONT LED 4

ORG / FRONT LED 3 RED / FRONT LED 2 BRN / FRONT LED 3

56

BLU / FRONT LED 6 GRN / FRONT LED 5

GRY

WHT/

BLK

29

2

3

ITEM

PART NUMBER

DESCRIPTION

QTY QTY QTY QTY

11

12

14

4

5

6

7

8

9

10

1

01-0684194-03

01-026B807-20

01-026B807-50

26-0115663-10

13-104111-063

14-104286-16JB

21-11245004-1

46-0742883-17

46-0742957-17

21-242401-000

22-0542701-00

11-363143-000

11-363142-000

11-363141-000

01-0684194-18

01-0684194-13

01-0684194-08

2222

1

1

2

4

1

1

212

4

111

4

1

2

1

4

1

1111

2

1

8

1

88

212

1

11

8

2

1

1

Freedom™ Gen 3 LC R/R/B/B 44"

Freedom™ Gen 3 LC R/R/B/B 60"

Freedom™ Gen 3 LC R/R/B/B 55"

Freedom™ Gen 3 LC R/R/B/B 50"

#10-24 x 1-1/4" TX. PHD. SCREW-SHLDR

CORNER REFLECT. LED RED

CABLE, 17/C 22GA 17'

CABLE, 2/C 10GA 17'

BUSHING, 1-5/8"

MTG. STUD

BASE EXTRUSION (56.50")

BASE EXTRUSION (51.125")

BASE EXTRUSION (45.75")

CORNER REFLECT. LED BLU

CABLE CLAMP, 5/8"

NUT, #10-24 WHIZ

GROMMET, 1.562"

NUT, 1/4-20 ELASTIC STOP (316 SS)

16

17

18

26

27

28

29

30

31

20

21

22

23

24

25

32

33

34

35

01-0269881-00

39-0403023-04

22-0416982-00

13-130111-072

1

1

2

4

111

1

242

4

1

1

2

4

ASSEMBLY, I/O BOARD LC

HOUSING, 3 POS SOCKET

PROTECTIVE COVER

01-0286361244

01-0286361211

01-0286361233

01-0286361255

68-1983816-30

68-1983817-30

68-1984104-30

02-0341448-30

10-0523067-02

01-0286361222

20-0042765-00

14-104216-160

02-0363189-00

09-1363158-00

07-263103-000

1111

A/R

6

A/R

A/R

A/R

A/R

A/R A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R8A/R

8

A/R

A/R

A/R

A/R

A/R

6

4

12

A/R

18

11

12

101816

A/R

4

2

A/R

4

11

14

12

A/R

4

4

4

4 4

LINEAR LED 400 GRN GEN III AMP

LENS, 5.00" CLEAR

LENS DIVIDER ASS'Y. (CLR)

LABEL, MODEL & SERIAL NO.

LINEAR LED 400 AMB GEN III AMP

LINEAR LED 400 WHT GEN III AMP

LINEAR LED 400 RED GEN III AMP

LINEAR LED 400 BLU GEN III AMP

SPACER, CORNER STROBE

#10-24 x 1 PPHMS

REFLECTOR 400 HALOGEN

FILLER PANEL, "400" SERIES

MTG BRACKET

LENS, 6.562" CLEAR

LENS, 9.25" CLEAR

36

07-242815-0004BRACKET, SPACER

37

38-0283381-00

222 2

GASKET, ENDCAP

41

42

43

38

39

40

48

49

50

51

59

60

61

62

63

64

65

66

52

53

54

55

56

57

58

A/RA/RA/RA/R

A/R

A/RA/R

A/R A/R

A/R A/R

A/R

A/RA/RA/R A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/RA/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/RA/R

A/R

A/R

A/R A/R

A/R

A/R

A/R

A/R A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/RA/R

A/R

A/R A/R

A/R

A/R A/R

TIR3 LED STDY BLU VERT AMP

02-036B4942B2

TIR3 LED STDY AMB VERTAMP

SUB ASSY, MR11/TIR3 ALLEY

02-036B4942A2

02-0364229-00

SUB ASY, DUAL LR11 ALLEY 100lm

SUB ASY, DUAL LR11 TD 100lm

LED 400 SPLIT 3/3 GEN III AMB/NONE/AMP

LED 400 SPLIT 6/3 GEN III RED/AMB/AMP

LED 400 SPLIT 6/3 GEN III BLU/AMB/AMP

LED 400 SPLIT 3/3 GEN III AMB/RED/AMP

LED 400 SPLIT 3/3 GEN III AMB/BLU/AMP

LED 400 SPLIT 6/6 GEN III AMB/RED/AMP

LED 400 SPLIT 6/6 GEN III AMB/WHT/AMP

LED 400 SPLIT 6/6 GEN III AMB/BLU/AMP

LED 400 SPLIT 6/6 GEN III AMB/NONE/AMP

TIR3 LED STDY WHT VERT AMP

TIR3 LED STDY RED VERT AMP

01-028636125A

6 LIGHT HARNESS 60"

HARNESS "Y"

01-0286361212

01-0286361210

46-0784223-00

02-036B4942C2

02-036B4942R2

46-0722108-00

01-02863612A0

01-028636122A

01-02863612AR

01-02863612AB

01-0286361215

01-0286361213

SUB ASY, DUAL LR11 ALLEY

SUB ASSY, DUAL LR11 TD

01-026B047-31

01-026B047-30

01-026A936-01

01-026A936-00

46-0743719-00

46-0763967-01

46-0741346-17

46-0743106-00

21-7263998-00

39-0416323-04

46-0763967-00

46-0763941-00

46-0763942-00

68-1984105-30

68-1183491C02

11-363390-000

39-0017188-08

68-1183369-30

1

2212

1

2

1

1

44

1

1

4

1

2

4

1

A/RA/RA/R A/R

A/R

2

1

A/R

A/R

A/R A/R

A/R

1

A/R

2

1

A/R

2

A/R

A/R

1

A/R

2

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

HARNESS, 4 LIGHT 72"

LENS, 15.75" CLEAR

LENS, 10.375" CLEAR

BASE EXTRUSION (40.375")

HOUSING, 2 POLE

ENDCAP, CLEAR

HARNESS, "Y" LR11

HARNESS, TAKE DOWN

HOUSING, 12 POS CMNL

CABLE, 9/C 17'

HARNESS, TA

VENT, 3/4"

HOUS., 16 POS SCKT CMNL

HARNESS, ALLEY LIGHT

HARNESS, 6 LIGHT

39-0412014-14

71

72

73

74

75

76

67

68

69

70

Rear of Lightbar

69-72 64-68

21-25

11

14

74

76

28

63

20

7 54

41

Page 7

Page 8

DRIVER

PASSNGR

81 83

31

62

42

38

41

33

61

35

40

59

58

36

FRONT OF LIGHTBARFRONT OF LIGHTBAR

BRN

ORG

BROWN

LED 1

RED

LED 2

ORANGE

LED 3

FRONT LED 1

BROWN

FRONT LED 2

RED

FRONT LED 3

ORANGE

YELLOW

LED 4

GREEN

LED 5

BLUE

LED 6

FRONT LED 4

YELLOW

FRONT LED 5

GREEN

FRONT LED 6

BLUE

YEL

21

ENDCAP

LED

BRN

ORANGE

15

YEL

RED

FRONT

I.O. CARD ASSEMBLY

("LC" SERIES)

REAR

IAL

ITD

57

67

5614

18

37

84

23702471257226736674687869

79

20

43

67

43

17

FRONT OF 54" LIGHTBARFRONT OF 54" LIGHTBAR

RA

LTD

YEL

RED

RTD

Endcap Detail with Alley

22

39

28

37

22

27

74

66

20

23-26

68-73

64 65

48-55

LA

76

60

77

85

30

142

5

663

RED

WIRE

9

ITEM

DESCRIPTION

QTY QTY QTY

Liberty™ Gen 3 LC R/R/B/B 48"

Liberty™ Gen 3 LC B/B/B/B 43"

Liberty™ Gen 3 LC R/R/B/B 54"

PART NUMBER

LENS, ENDCAP (CLEAR) W/SEAL

#6 X 5/8" PPH PLASTI-LOC SS

EXTRUSION, TOP 44"

INSULATOR, FOAM PAD

ASS'Y., LENS DIVIDER (CLEAR)

GASKET, ENDCAP

#10-24 X 1-1/4" TX. PHD. W/SHOULDER

LENS, 500 SERIES, OPTIC (CLEAR)

SUB-ASS'Y, 500 LED, BLUE W/2POS

SUB-ASS'Y., 500 LED, AMBER, W/2POS.

SUB-ASS'Y., 500 HALOGEN W/3POS.

HOUSING, LIGHTHEAD (SNAP-IN)

HARNESS, INBOARD L.E.D. (LIBERTY)

EXTRUSION, BASE 44" W/HOLES

PLUG, VENT (3/4")

CABLE CLAMP, 5/8"

#10-24 WIZ NUT

INPUT CABLE ASS'Y., (2C-10GA.) 17'

GROMMET, 1.562"

LABEL, MODEL & SERIAL NO.

SUB-ASS'Y., 500 LED, CLEAR, W/2POS.

LENS, 15.800" LG. (CLEAR)

1

BRACKET, SPACER CORNER

LENS, 5.687" LG. (CLEAR)

PANEL, FILLER (500 SERIES)

#10-24 X 3/8 PPH SCREW

LABEL, "FRONT" LIGHTBAR ASS'Y.

1

HARNESS, CORNER L.E.D. (LIBERTY)

HARNESS, TAKE DOWN (LIBERTY)

HARNESS, ALLEY LIGHTS (LIBERTY)

LENS, 8.375" LG. (CLEAR)

SUB-ASS'Y., 500 LED, RED, W/2POS.

ASS'Y., I.O. CARD "LC"

CORNER 12 LED RED (LIBERTY)

SPACER, CORNER RETENTION

EXTRUSION, BASE 38.61" W/HOLES

EXTRUSION, BASE 49.39" W/HOLES

EXTRUSION, TOP 38.61"

EXTRUSION, TOP 49.39"

44

11

11

11

11

11

22

1

11

A/RA/R

A/RA/R

A/RA/R

12 12

11

A/R A/R

A/R

A/RA/R

A/R

A/R

A/R

A/R

A/R

12 12

A/R A/R

44

88

A/R A/R

66

11

1

A/R A/R

11

A/R A/R

1

1

22

22

11

4

44

4

4

LENS, 5.062" LG. (CLEAR)

LENS, 10.500" LG. (CLEAR)

CABLE, 17/C 22GA (17')

11

SUB-ASS'Y., 500 LED, GREEN, W/2POS.

A/RA/R

CORNER 12 LED BLUE (LIBERTY)

A/R A/R

SUB ASSY, LR11 T-D SINGL. FULL LBRTY

HARNESS, "Y"

A/RA/R A/R

A/R A/R

SUB-ASS'Y., 500 4 LED, AMB, W/2POS.

A/R A/R

SUB-ASS'Y., 500 4 LED, WHITE, W/2POS.

A/RA/R

A/R A/R

SUB-ASS'Y., 500 4 LED, GREEN, W/2POS.

SUB-ASS'Y., 500 4 LED, RED, W/2POS.

A/R A/R

SUB-ASS'Y., 500 AMBER-RED W/2POS.

A/R A/R

SUB-ASS'Y., 500 AMBER-BLUE W/2POS.

A/RA/R

A/R A/R

SUB ASSY, LR11 TD HALF LIBERTY

A/R A/R

SUB ASSY, LR11 T-D DUAL FULL LIBERTY

A/R A/R

SUB-ASS'Y., 500 RED-BLUE W/2POS.

A/R A/R

A/R A/R

SUB-ASS'Y., 500 AMB-AMB W/2POS.

A/R

A/R

A/R

A/R

SUB-ASS'Y, TIR LED TD, N/OPTIC

SUB-ASS'Y., 500 LED ALLEY LIGHT

SUB-ASS'Y, 500 4 LED, BLUE W/2POS.

SUB ASSY, LR11 ALLEY LT WHITE 20 DEG

A/R A/R

SUB-ASS'Y, TIR LED TAKEDOWN, OPTIC

TY-WRAP, 6" BLACK

A/RA/R

A/R A/R

LENS, 500 SERIES, NON OPTIC (CLEAR)

SUB ASSY, END SUPPORT BRACKET

22

A/R A/R

A/R A/R

A/R A/R

SUB ASSY, 500 6/6 BLU/RED INTRLVD

SUB ASSY, 500 6/6 AMB/RED INTRLVD

SUB ASSY, 500 6/6 AMB/BLU INTRLVD

1

1

4

1

1

1

1

1

2

1

A/R

A/R

A/R

10

A/R

A/R

A/R

A/R

A/R

10

A/R

4

8

A/R

8

1

A/R

1

A/R

1

1

4

1

4

4

2

1

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

2

A/R

A/R

A/R

222

40

39

37

36

35

33

32

31

30

29

28

27

26

25

24

23

22

21

20

18

17

16

15

14

12

9

6

5

4

2

1

41

42

43

44

49

51

38

56

57

59

58

60

62

61

63

66

67

68

69

70

71

72

73

74

75

76

77

78

79

81

80

82

83

84

85

86

87

88

89

01-0684191-13

01-0684191-09

01-0684191-16

68-1183566-3S

15-065410-100

11-26B607-044

38-0142783-00

02-0342791-30

38-0283572-00

14-104286-16JB

68-1963237-30

01-026B827650

01-026B827620

01-026B827610

02-0383577-03

11-483564-000

46-0963330-00

11-363312-044

21-7263998-00

39-0017188-08

14-0023347-00

26-0115663-10

13-104111-063

46-0742957-17

21-11245004-1

10-0522960-00

01-026B827630

68-1983567-30

07-243170-000

68-1983819-30

09-1363542-00

14-104216-06J

10-0322935-00

46-0743151-00

46-0783576-04

46-0783576-03

68-1963333C08

01-0269879-00

01-026B625220

01-026B625250

20-0042765-00

11-363312-038

11-363312-049

11-26B607-038

11-26B607-049

68-1983818-30

68-1963333C03

46-0744336-17

01-026B827640

01-026A749-05

46-0722108-00

01-026B827410

01-026B827420

01-026B827430

01-026B827440

01-026B827450

01-026B8276K0

01-026B8276M0

01-026A748-02

01-026A749-06

01-026B8276J0

01-026B8276A0

01-026A493-00

01-0264868-00

01-026B855-30

01-026A493-01

26-0215001-06

68-3963228-30

02-036B855-00

01-026B8272J0

01-026B8271K0

01-026B8271M0

02-036E683-30

SUB ASSY, OVERMOLD ENDCAP CLEAR

SCREW, 10-24 x 1.25" TX PHD.

HOUSING, 2 POLE

77

85

89

Page 8

Page 9

13

PASSENGER'S

SIDE

DRIVER'S SIDE

FRONT

LED 6 / BLU

14

RED

LED 2

BROWN

LED 1

18

16

ORANGE

LED 3

YELLOW

LED 4

GREEN

LED 5

17

FRONT

LED 3 / ORG

FRONT

LED 2 / RED

24

LTD

FRONT

LED 1 / BRN

20

52

8

19

FRONT

LED 4 / YEL

55

7

FRONT

LED 5 / GRN

BLUE

LED 6

RTD

10

2

40

39

38

41

42

5

6

4

LED TAKEDOWN

WORK LIGHT

60

LR11

TAKEDOWN

LIGHT

68

500 SERIES FILLER

21

15

1

67

332

48 49

50

34 3

27

33

12

31

25

47

29

30

Front of 54" Lightbar

72

71

70

73

74

RA

RED

YELLOW

LA

ORANGE

BROWN

11

56 57 582459

69

54

FRONT OF 54" LIGHTBAR

61

62

63

64

65

66

44

43

45

35

46

ITEM

PART NUMBER

DESCRIPTION

QTY QTY QTY QTY

Liberty Lightbar™ 60" LC01-0684458-

Liberty Lightbar™ 54" LC01-0684458-

Liberty Lightbar™ 48" LC01-0684458-

Liberty Lightbar™ 43" LC01-0684458-

2

1

A/R

16

16

PLUG, VENT (3/4")

21-7263998-00

SPACER, CORNER

PANEL, FILLER (500 SERIES)

HARNESS, CORNER LED

HARNESS, TAKE DOWN/WORK LIGHTS

HOUSING, LIGHTHEAD (SNAP-IN)

07-243170-000

46-0743151-00

46-0783576-04

11-483564-000

09-1363542-00

1

4

8

8

2

1

1

4

1

#10-24 X 1-1/4" TX. PHD. W/SHOULDER

LABEL, "FRONT" LIGHTBAR ASS'Y.

#10-24 X 3/8 PPH SCREW

ASS'Y, I/O CARD "LC"

LENS, 15.800" LG. (CLEAR)

ASS'Y., LENS DIVIDER (CLEAR)

INSULATOR, FOAM PAD

SUB ASSY, OVERMOLD ENDCAP CLEAR

38-0142783-00

14-104216-06J

14-104286-16JB

02-0342791-30

10-0322935-00

01-0269879-00

68-1983567-30

02-036E683-30

LABEL, MODEL & SERIAL NO.

10-0522960-00

HARNESS, INBOARD LED

46-0963330-00

2

A/R

A/R

A/R

A/R

A/R

01-026B693250

01-026B693230

01-026B693220

01-026B693210

01-026B693240

EXTENDED, CORNER 12 L.E.D. GREEN

EXTENDED, CORNER 12 L.E.D. AMBER

EXTENDED, CORNER 12 L.E.D. BLUE

EXTENDED, CORNER 12 L.E.D. WHITE

EXTENDED, CORNER 12 L.E.D. RED

TOP, EXTRUDED (54.78")

BASE, EXTRUDED (54.78")

11-26B607-054

11-363312-054

1

1

2

68-1963333C08

68-1983818-30

LENS, 5.062" LG (CLEAR)

LENS, 8.375" LG. (CLEAR)

LENS, 5.687" LG. (CLEAR)

68-1983819-30

4

2

1

A/R

4

12

2

1

12

4

8

A/R

A/R

A/R

A/R

4

6

1

2

1

1

4

A/R

22

11

A/R

44

A/R

10

12

22

11

10

12

44

88

A/R

A/R

A/R

A/R

86

11

22

11

2

11

4

A/R A/R

A/R

A/R

A/R

A/R

BASE, EXTRUDED (49.39")

1

BASE, EXTRUDED (44.00")

1

-

BASE, EXTRUDED (38.61")

---

1

TOP, EXTRUDED (49.39")

TOP, EXTRUDED (44.00")

TOP, EXTRUDED (38.61")

-

11-363312-049

11-363312-044

11-363312-038

1

1

1

11-26B607-038

11-26B607-044

11-26B607-049

HOUSING, 2 POLE

39-0017188-08

1111

A/R A/R A/R A/R

46-0783576-03

HARNESS, ALLEY LIGHT

CABLE, 17/C 22GA (17')

46-0744336-17

1111

SUB-ASS'Y, ADJ. LR-11 ALLEY LIGHT

01-026B855-30

A/RA/RA/RA/R

46-0743719-00

HARNESS, "Y"

A/RA/R A/R

SUB-ASS'Y, ADJ. LR-11 ALLEY LT AMBER

01-026B855-10

A/R

A/RA/R A/R

SUB-ASS'Y, ADJ. LR-11 ALLEY LT BLUE

01-026B855-20

A/R

A/RA/R A/R

SUB-ASS'Y, ADJ. LR-11 ALLEY LT RED

01-026B855-50

A/R

A/RA/R A/R

SUB-ASS'Y, TIR TAKE-DOWN NON OPTIC

02-036A493-00

A/R

A/RA/R

SUB-ASS'Y, 500 LIN6 AMBER

A/RA/R

01-026B827610

A/RA/R

SUB-ASS'Y, 500 LIN6 BLUE

A/RA/R

01-026B827620

A/RA/R

SUB-ASS'Y, 500 LIN6 WHITE

A/RA/R

01-026B827630

A/RA/R

SUB-ASS'Y, 500 LIN6 RED

A/RA/R

01-026B827650

A/RA/R

SUB-ASS'Y, 500 LIN6 RED/BLU

A/RA/R

01-026B8276J0

A/RA/R

SUB-ASS'Y, LR-11 TAKEDOWN LT HALF

A/RA/R

01-026A748-02

A/R A/R A/R A/R

A/R

A/R

A/R

A/R

SUB-ASS'Y, LR11 TAKEDOWN FULL DUAL

A/R

A/R

A/R

A/R

01-026A749-06

01-026A749-05

SUB-ASS'Y, LR11 TAKEDOWN FULL SINGLE

2

02-036B855-00

222

SUB ASSY, END SUPPORT BRACKET

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

A/R

EXTENDED, CORNER 18 L.E.D. WHITE

EXTENDED, CORNER 18 L.E.D. AMBER

EXTENDED, CORNER 18 L.E.D. GREEN

A/R

01-026B693830

A/R

01-026B693810

01-026B693820

A/R

A/RA/R

A/R

01-026B693840

01-026B693850

A/R

A/RA/R

A/R

13

11

10

12

14

15

17

19

20

24

21

25

27

35

29

30

31

32

33

34

39

38

40

42

41

44

43

45

46

47

48

49

50

53

54

55

56

57

58

59

60

61

62

63

64

65

66

68

67

69

72

70

71

73

74

EXTENDED, CORNER 18 L.E.D. BLUE

EXTENDED, CORNER 18 L.E.D. RED

1

4

1

1

1

1

11 11

1 1

111

1

2

132

1

1

5

4

111

6

INPUT CABLE, (2C-10GA.) 17'

GROMMET, 1.562"

#10-24 WIZ NUT

CABLE CLAMP, 5/8"

SCREW, 10-24 x 1.25" TX PHD

21-11245004-1

46-0742957-17

13-104111-063

26-0115663-10

14-0023347-00

LENS, 10.500 LG (CLEAR)

68-1963333C03

Page 9

Loading...

Loading...