Page 1

®

Installation Guide:

SA315 Swivel Mount

ENGINEERING COMPANY INC.

51 Winthrop Road,

Chester, Connecticut 06412-0684

Phone: (860) 526-9504

Fax: (860) 526-4078

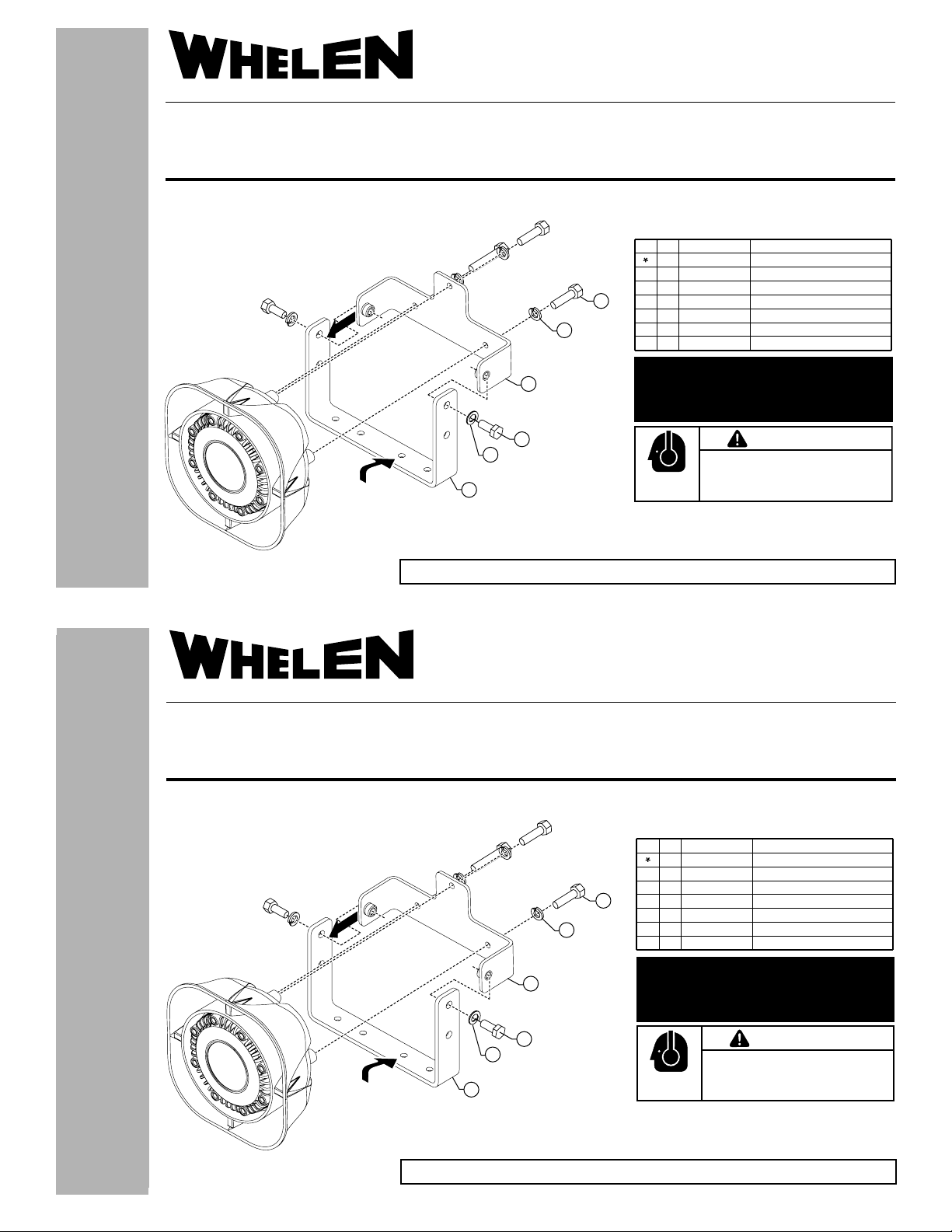

Assemble the bracket as shown below. Follow all warnings on the next page. Secure the bracket (with speaker) to the vehicle with

user supplied mounting hardware (See page 2 drainage hole warning). The mounting holes in the bracket are .280". Your mounting

hardware must fit these holes.

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: autocan@whelen.com

Customer Service e-mail: custserv@whelen.com

QTY

1

2

6

2

5

3

3

Siren Speaker Bracket

ITEM

PART NUMBER

01-046C639-00

11

07-26C585-023

2

07-26C586-023

16-1431920-08

3

14-148436-120

4

5

16-1331520-65

14-130436-240

6

DESCRIPTION

KIT, SPEAKER 315 SWIVEL MOUNT

BRKT. MTG. SWIVEL BASE

BRKT. SUPPORT SWIVEL MNT.

WASHER, 5/16 SPLIT LOCK

BOLT, 5/16-18 X 3/4 HEXD HD

WASHER, 1/4 SPLIT LOCK

SCREW, 1/4-20X11/2HEXHD

CUSTOMER

SUPPLIED

MOUNTING

HARDWARE

(QTY 4)

Automotive: Sirens & Switches

©2010 Whelen Engineering Company Inc.

Form No.14388 (060310)

For warranty information regarding this product, visit www.whelen.com/warranty

ENGINEERING COMPANY INC.

51 Winthrop Road,

Chester, Connecticut 06412-0684

Phone: (860) 526-9504

Fax: (860) 526-4078

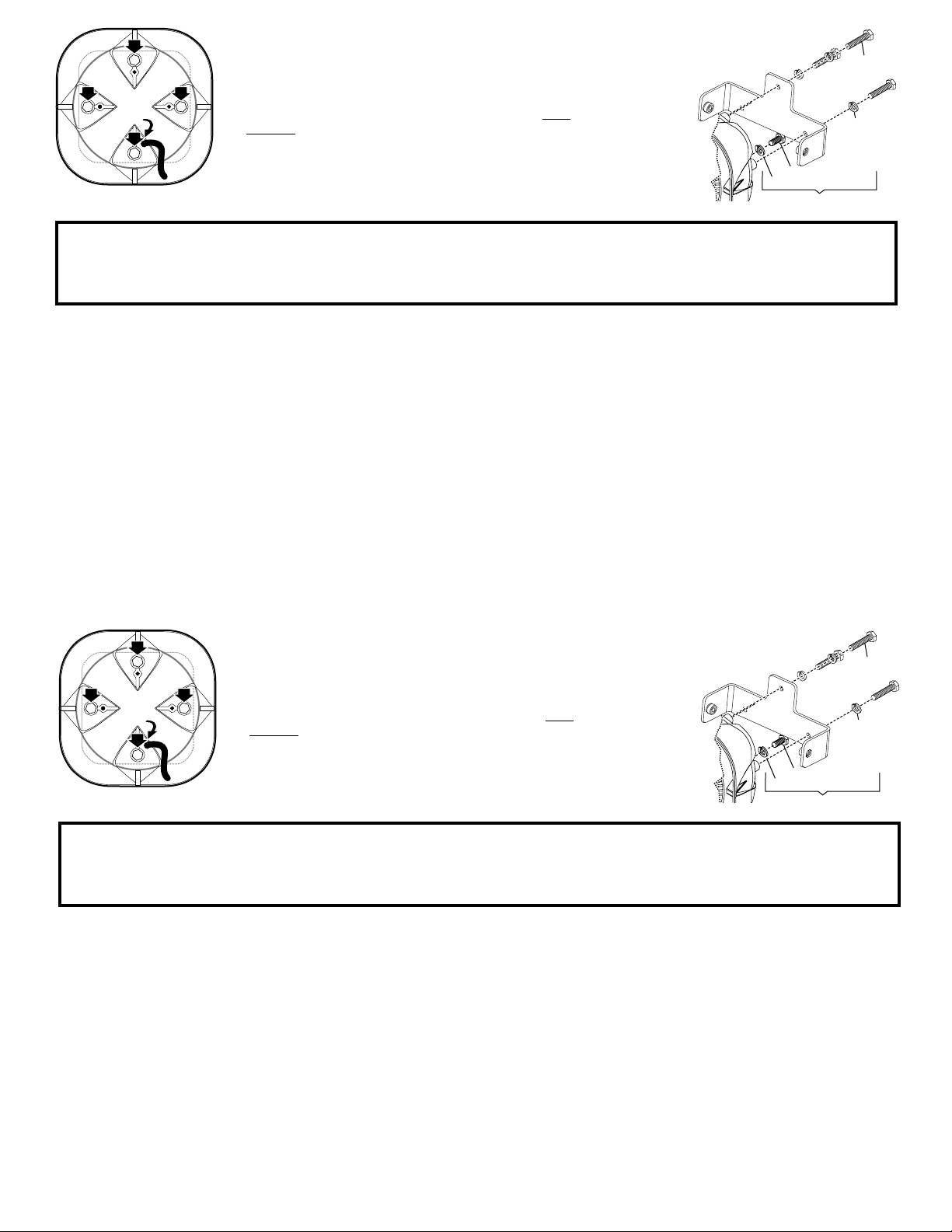

Assemble the bracket as shown below. Follow all warnings on the next page. Secure the bracket (with speaker) to the vehicle with

user supplied mounting hardware (See page 2 drainage hole warning). The mounting holes in the bracket are .280". Your mounting

hardware must fit these holes.

2

ACTIVATION OF THIS

SIREN MAY DAMAGE

UNPROTECTED EARS!

4

3

1

Wear

Protection!

Loud siren noise can cause

hearing damage and/or loss.

Refer to OSHA Section 1910.95 prior

to putting ANY siren into service!

®

CAUTION

Installation Guide:

SA315 Swivel Mount

Siren Speaker Bracket

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: autocan@whelen.com

Customer Service e-mail: custserv@whelen.com

QTY

ITEM

PART NUMBER

01-046C639-00

11

07-26C585-023

2

1

07-26C586-023

16-1431920-08

3

2

6

5

2

3

3

14-148436-120

4

5

16-1331520-65

14-130436-240

6

DESCRIPTION

KIT, SPEAKER 315 SWIVEL MOUNT

BRKT. MTG. SWIVEL BASE

BRKT. SUPPORT SWIVEL MNT.

WASHER, 5/16 SPLIT LOCK

BOLT, 5/16-18 X 3/4 HEXD HD

WASHER, 1/4 SPLIT LOCK

SCREW, 1/4-20X11/2HEXHD

Automotive: Sirens & Switches

©2010 Whelen Engineering Company Inc.

Form No.14388 (060310)

CUSTOMER

SUPPLIED

MOUNTING

HARDWARE

(QTY 4)

2

ACTIVATION OF THIS

SIREN MAY DAMAGE

UNPROTECTED EARS!

4

3

1

For warranty information regarding this product, visit www.whelen.com/warranty

Page 1

Wear

Protection!

Loud siren noise can cause

hearing damage and/or loss.

Refer to OSHA Section 1910.95 prior

to putting ANY siren into service!

CAUTION

Page 2

A

A A

wire

exit &

drain

hole

B

SA315 / Rear View

The SA315 siren speaker mounting kit comes with 3 long bolts (1/4-20 X 1-1/2” HEX HD) shipped

seperately. The longer bolts are necessary to go through the mounting bracket, siren housing and

into the siren driver ("A").

Your speaker is shipped with 2 short bolts installed on the top and

bottom of the speaker. Remove the short bolt on top and replace it with a long bolt

when mounting to the bracket

hold the driver and housing together. At

that go through the bracket so it will properly secure the driver to the housing.

does not

. Do not remove the bottom short bolt. This bolt will

least 1 short bolt be used in the hole

must

IMPORTANT: For drainage purposes, the speaker must be oriented so that the wire

passage hole is in the “6o’clock” position (closest to the road).This is also the drain

hole for the siren. Improper mounting will result in premature driver failure and void

the product warranty.

1/4-20X

1-1/2 HEX HD

(Speaker &

Bracket)

1/4" SPLIT

LOCKWASHER

(Speaker &

Bracket)

1/4 X 20 X 1-1/4 HEX HEAD

1/4" SPLIT LOCK WASHER

(Speaker Only) DO NOT REMOVE!

DANGER!

Sirens produce extremely loud emergency warning tones! exposure to these tones without proper and adequate hearing protection, could

cause ear damage and/or hearing loss! The Occupational Safety & Health Administration (www.osha.gov) provides information necessary to determine

safe exposure times in Occupational Noise Exposure Section 1910.95. Until you have determined the safe exposure times for your specific application,

operators and anyone else in the immediate vicinity should be required to wear an approved hearing protection device.

FAILURE TO FOLLOW THIS RECOMMENDATION COULD CAUSE HEARING LOSS!

IMPORTANT Before returning the vehicle to active service, confirm the proper operation of this product, as well as all vehicle components or

equipment. It is the responsibility of the installation technician to make sure that the installation and operation of this product will not interfere

with or compromise the operation or efficiency of any vehicle equipment!

A

A A

wire

exit &

drain

hole

B

SA315 / Rear View

The SA315 siren speaker mounting kit comes with 3 long bolts (1/4-20 X 1-1/2” HEX HD) shipped

seperately. The longer bolts are necessary to go through the mounting bracket, siren housing and

into the siren driver ("A").

Your speaker is shipped with 2 short bolts installed on the top and

bottom of the speaker. Remove the short bolt on top and replace it with a long bolt

when mounting to the bracket

hold the driver and housing together. At

that go through the bracket so it will properly secure the driver to the housing.

does not

. Do not remove the bottom short bolt. This bolt will

least 1 short bolt be used in the hole

must

IMPORTANT: For drainage purposes, the speaker must be oriented so that the wire

passage hole is in the “6 o’clock” position (closest to the road).This is also the drain

hole for the siren. Improper mounting will result in premature driver failure and void

the product warranty.

1/4-20X

1-1/2 HEX HD

(Speaker &

Bracket)

1/4" SPLIT

LOCKWASHER

(Speaker &

Bracket)

1/4 X 20 X 1-1/4 HEX HEAD

1/4" SPLIT LOCK WASHER

(Speaker Only) DO NOT REMOVE!

DANGER!

Sirens produce extremely loud emergency warning tones! exposure to these tones without proper and adequate hearing protection, could

cause ear damage and/or hearing loss! The Occupational Safety & Health Administration (www.osha.gov) provides information necessary to determine

safe exposure times in Occupational Noise Exposure Section 1910.95. Until you have determined the safe exposure times for your specific application,

operators and anyone else in the immediate vicinity should be required to wear an approved hearing protection device.

FAILURE TO FOLLOW THIS RECOMMENDATION COULD CAUSE HEARING LOSS!

IMPORTANT Before returning the vehicle to active service, confirm the proper operation of this product, as well as all vehicle components or

equipment. It is the responsibility of the installation technician to make sure that the installation and operation of this product will not interfere

with or compromise the operation or efficiency of any vehicle equipment!

Page 2

Loading...

Loading...