Page 1

®

ENGINEERING COMPANY INC.

51 Winthrop Road

Chester, Connecticut 06412-0684

Phone: (860) 526-9504

M6 Series Surface Mount Housing

Installation Guide:

2-, 3- & 4-Light

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: canadiansales@whelen.com

Customer Service e-mail: custserv@whelen.com

Safety First

This document provides all the necessary information to allow your Whelen product to be properly and safely installed.

Before beginning the installation and/or operation of your new product, the installation technician and operator must

read this manual completely. Important information is contained herein that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of automotive electronics,

systems and procedures.

• If mounting this product requires drilling holes, the installer MUST be sure that no vehicle components or other

vital parts could be damaged by the drilling process. Check both sides of the mounting surface before drilling

begins. Also de-burr any holes and remove any metal shards or remnants. Install grommets into all wire

passage holes.

• If this manual states that this product may be mounted with suction cups, magnets, tape or Velcro®, clean the

mounting surface with a 50/50 mix of isopropyl alcohol and water and dry thoroughly.

• Do not install this product or route any wires in the deployment area of your air bag. Equipment mounted or

located in the air bag deployment area will damage or reduce the effectiveness of the air bag, or become a

projectile that could cause serious personal injury or death. Refer to your vehicle owner’s manual for the air bag

deployment area. The User/Installer assumes full responsibility to determine proper mounting location, based

on providing ultimate safety to all passengers inside the vehicle.

• For this product to operate at optimum efficiency, a good electrical connection to chassis ground must be

made. The recommended procedure requires the product ground wire to be connected directly to the NEGATIVE

(-) battery post.

• If this product uses a remote device to activate or control this product, make sure that this control is located in

an area that allows both the vehicle and the control to be operated safely in any driving condition.

• Do not attempt to activate or control this device in a hazardous driving situation.

• This product contains either strobe light(s), halogen light(s), high-intensity LEDs or a combination of these

lights. Do not stare directly into these lights. Momentary blindness and/or eye damage could result.

• Use only soap and water to clean the outer lens. Use of other chemicals could result in premature lens cracking

(crazing) and discoloration. Lenses in this condition have significantly reduced effectiveness and should be

replaced immediately. Inspect and operate this product regularly to confirm its proper operation and mounting

condition. Do not use a pressure washer to clean this product.

• It is recommended that these instructions be stored in a safe place and referred to when performing

maintenance and/or reinstallation of this product.

• FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND INSTRUCTIONS COULD RESULT IN DAMAGE TO

THE PRODUCT OR VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR PASSENGERS!

Automotive: Lightheads

For warranty information regarding this product, visit www.whelen.com/warranty

©2009 Whelen Engineering Company Inc.

Form No.14307 (092010)

Page 1

Page 2

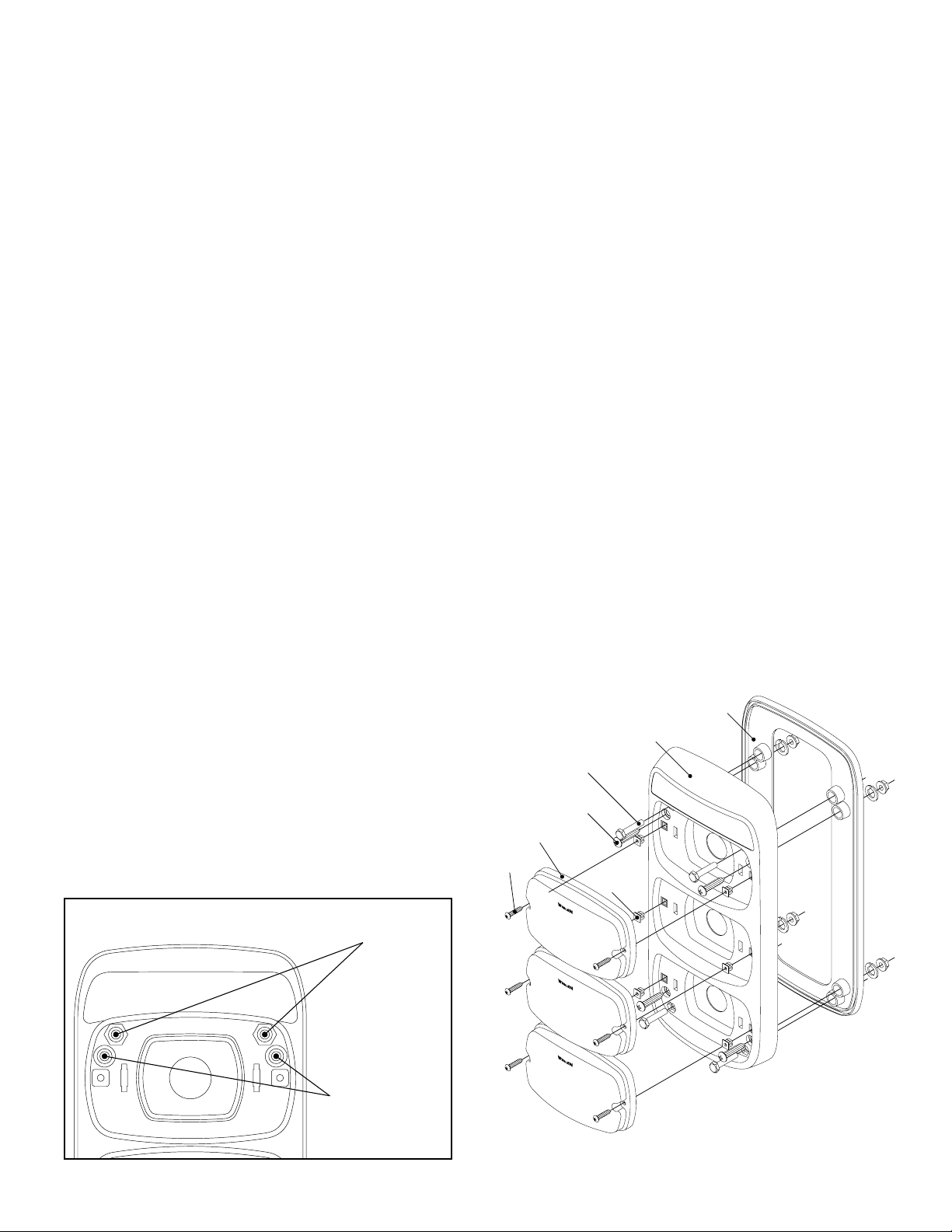

Mounting...

Position the housing onto the mounting surface in the proposed

mounting location. The mounting surface used must be perfectly

flat. This will determine the exact mounting location and allow the

installer to determine the most appropriate mounting style for their

specific installation.

Mounting Style #2 is best suited for applications where there is

access to the backside of the mounting surface. The style

requires 4, 1/4-20 Hex Head bolts, split-lock washers and nuts

(customer provided). Bolts should be of a length appropriate for

your specific installation.

Note: As mounting this product will require drilling, it is

absolutely necessary to make sure that no other vehicle

components could be damaged by this process. Check both

sides of the mounting surface before starting. If damage is

likely, select a different location.

The housing may be secured to the vehicle in one of two styles:

Mounting Style #1 is best suited for applications where there is

limited access to the backside of the mounting surface. The style

requires four, 1/4” x 1 1/4” phillips pan head sheet metal screws

(included)

1. Using the housing in its mounting location as a guide, scribe

the mounting surface behind the 4 areas shown using an awl or

suitable tool.

2. Remove the housing. Using a drill bit sized for 1/4” sheet

metal screw and the thickness of the mounting surface, drill four

mounting holes in the areas marked in the previous step.

3. Drill appropriately sized wire passage hole into the mounting

surface. A good location for this hole is between the top lighthead

and the top of the housing. De-burr this hole and install an

appropriately sized grommet.

4. Using appropriately sized wire, extend the wires for each

lighthead through the housing, though the wire passage hole and

to their ultimate destinations for power, ground, switch control,

etc.

5. Position the housing/gasket assembly onto the mounting

surface. Confirm that the lighthead wires are not being pinched

and that the mounting gasket is properly seated onto the housing

and in full and proper contact with the mounting surface. Secure

the housing to the mounting surface using the hardware

previously indicated.

6. Complete the wire connections using the information

provided in the lighthead manual.

IMPORTANT! Before returning the vehicle to active service,

visually confirm the proper operation of this product, as well

as all vehicle components/equipment.

1. Using the housing in its mounting location as a guide, scribe

the mounting surface behind the 4 areas shown using an awl or

suitable tool.

2. Remove the housing. Using a drill bit sized for 1/4-20 bolts

(customer supplied), drill four mounting holes in the areas marked

in the previous step.

3. Drill appropriately sized wire passage hole into the mounting

surface. A good location for this hole is between the top lighthead

and the top of the housing. De-burr this hole and install an

appropriately sized grommet.

4. Using appropriately sized wire, extend the wires for each

lighthead through the housing, though the wire passage hole and

to their ultimate destinations for power, ground, switch control,

etc.

5. Position the housing/gasket assembly onto the mounting

surface. Confirm that the lighthead wires are not being pinched

and that the mounting gasket is properly seated onto the housing

and in full and proper contact with the mounting surface. Secure

the housing to the mounting surface using the hardware

previously indicated.

6. Complete the wire connections using the information

provided in the lighthead manual.

IMPORTANT! Before returning the vehicle to active service,

visually confirm the proper operation of this product, as well

as all vehicle components/equipment.

Mounting

3 Light housing shown

for reference.

1/4-20

Hex Head

Bolt

1/4" PPHSMS

M6-series Lighthead

(Customer Supplied)

#8x1"

PPHSMS

Fastex

Grommet

Housing

Gasket

For use with

Mounting Style

#2

(2 shown/

4 total)

For use with

Mounting Style

#1

(2 shown/

4 total)

Page 2

Loading...

Loading...