Page 1

®

ENGINEERING COMPANY INC.

51 Winthrop Road

Chester, Connecticut 06412-0684

Phone: (860) 526-9504

M4 Series LED Lighthead

Installation Guide:

2- & 5-Wire (12 Volt)

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: autocan@whelen.com

Customer Service e-mail: custserv@whelen.com

Safety First

This document provides all the necessary information to allow your Whelen product to be properly and safely installed.

Before beginning the installation and/or operation of your new product, the installation technician and operator must

read this manual completely. Important information is contained herein that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of automotive electronics,

systems and procedures.

• Failure to use specified installation parts and/or hardware will void the product warranty!

• If mounting this product requires drilling holes, the installer MUST be sure that no vehicle components or other

vital parts could be damaged by the drilling process. Check both sides of the mounting surface before drilling

begins. Also de-burr any holes and remove any metal shards or remnants. Install grommets into all wire

passage holes.

• If this manual states that this product may be mounted with suction cups, magnets, tape or Velcro®, clean the

mounting surface with a 50/50 mix of isopropyl alcohol and water and dry thoroughly.

• Do not install this product or route any wires in the deployment area of your air bag. Equipment mounted or

located in the air bag deployment area will damage or reduce the effectiveness of the air bag, or become a

projectile that could cause serious personal injury or death. Refer to your vehicle owner’s manual for the air bag

deployment area. The User/Installer assumes full responsibility to determine proper mounting location, based

on providing ultimate safety to all passengers inside the vehicle.

• For this product to operate at optimum efficiency, a good electrical connection to chassis ground must be

made. The recommended procedure requires the product ground wire to be connected directly to the NEGATIVE

(-) battery post.

• If this product uses a remote device to activate or control this product, make sure that this control is located in

an area that allows both the vehicle and the control to be operated safely in any driving condition.

• Do not attempt to activate or control this device in a hazardous driving situation.

• This product contains either strobe light(s), halogen light(s), high-intensity LEDs or a combination of these

lights. Do not stare directly into these lights. Momentary blindness and/or eye damage could result.

• Use only soap and water to clean the outer lens. Use of other chemicals could result in premature lens cracking

(crazing) and discoloration. Lenses in this condition have significantly reduced effectiveness and should be

replaced immediately. Inspect and operate this product regularly to confirm its proper operation and mounting

condition. Do not use a pressure washer to clean this product.

• It is recommended that these instructions be stored in a safe place and referred to when performing

maintenance and/or reinstallation of this product.

• FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND INSTRUCTIONS COULD RESULT IN DAMAGE TO

THE PRODUCT OR VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR PASSENGERS!

Automotive: Lightheads

For warranty information regarding this product, visit www.whelen.com/warranty

©2008 Whelen Engineering Company Inc.

Form No.14190F (012913)

Page 1

Page 2

To +VBAT

M4

Lighthead

(2-Wire)

LED Color

BLACK

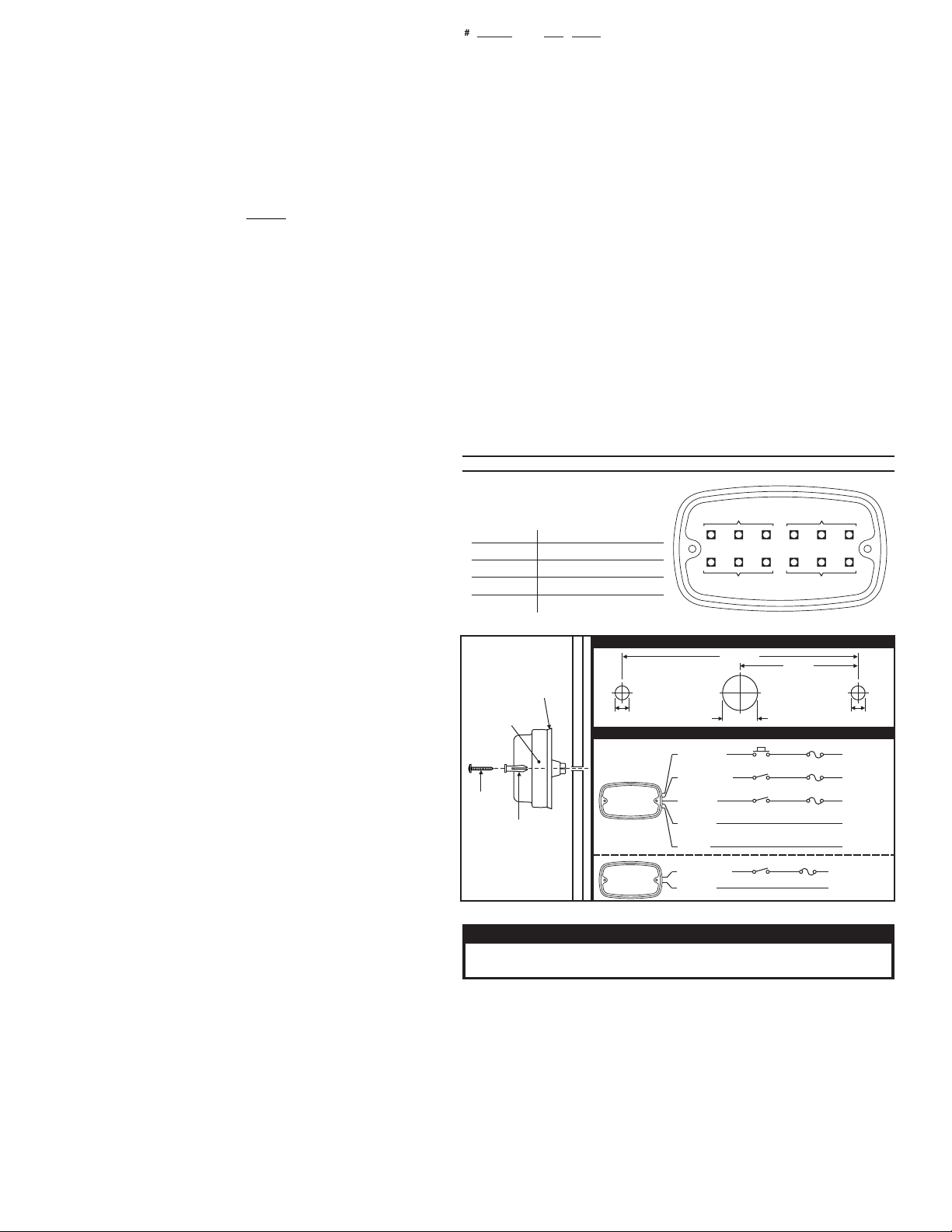

MOUNTING DIMENSIONS

4.20"

2.10"

0.25"

0.625"

0.25"

WIRING DIAGRAM

To +12V

To +12V

To +12V

WHT/VIO

LED Color

BLACK

VIOLET

GREY

SYNC

Ground

Ground

1A Fuse

1A Fuse

3A Fuse

3A Fuse

SP/ST

SP/ST

SP/ST

MOM. SW

M4

Lighthead

(5-Wire)

M

O

U

N

T

I

N

G

S

U

R

F

A

C

E

Gasket-

Use formed gasket on

flat, smooth surfaces

only.

#8 x 1"

PPHSMS

M4 Assembly

Slotted Hole

Screw Grommet

Set 3

Set 1

Set 4

Set 2

Sequences Operation of LED sets

Solid

T

Left to Right

op to Bottom

Diagonal

All On All Off

1-3 2-4

1-2 3-4

1-4 2-3

Alternates with

Alternates with

Alternates with

Alternates with

M4 Sequencing & Phasing: The M4

lighthead has4 sets of3 LEDs.These sets

cycle through the 4 sequencesshown.

Pattern

Seq.

Phase

1 SignalAlert™ Solid PH.1

2 SignalAlert™ Solid PH.2

3 SignalAlert™ L/R PH.1

4 SignalAlert™ L/R PH.2

5 SignalAlert™ T/B PH.1

6 SignalAlert™ T/B PH.2

7 SignalAlert™ Diag PH.1

8 SignalAlert™ Diag PH.2

17 DoubleFlash 75 Solid PH.1

18 DoubleFlash 75 Solid PH.2

19 DoubleFlash 75 L/R PH.1

20 DoubleFlash 75 L/R PH.2

21 DoubleFlash 75 T/B PH.1

22 DoubleFlash 75 T/B PH.2

23 DoubleFlash 75 Diag PH.1

24 DoubleFlash 75 Diag PH.2

25 SingleFlash 75 Solid PH.1

26 SingleFlash 75 Solid PH.2

27 SingleFlash 75 L/R PH.1

28 SingleFlash 75 L/R PH.2

29 SingleFlash 75 T/B PH.1

30 SingleFlash 75 T/B PH.2

31 SingleFlash 75 Diag PH.1

32 SingleFlash 75 Diag PH.2

9 CometFlash®75 Solid PH.1

10 CometFlash®75 Solid PH.2

11 CometFlash®75 L/R PH.1

12 CometFlash®75 L/R PH.2

13 CometFlash®75 T/B PH.1

14 CometFlash®75 T/B PH.2

15 CometFlash®75 Diag PH.1

16 CometFlash®75 Diag PH.2

33 ComAlert™ Solid PH.1

34 ComAlert™ Solid PH.2

35 ComAlert™ L/R PH.1

36 ComAlert™ L/R PH.2

37 ComAlert™ T/B PH.1

38 ComAlert™ T/B PH.2

39 ComAlert™ Diag PH.1

40 ComAlert™ Diag PH.2

41 LongBurst™ Solid PH.1

42 LongBurst™ Solid PH.2

43 LongBurst™ L/R PH.1

44 LongBurst™ L/R PH.2

45 LongBurst™ T/B PH.1

46 LongBurst™ T/B PH.2

47 LongBurst™ Diag PH.1

48 LongBurst™ Diag PH.2

49 PingPong™ Solid PH.1

50 PingPong™ Solid PH.2

51 PingPong™ L/R PH.1

52 PingPong™ L/R PH.2

53 PingPong™ T/B PH.1

54 PingPong™ T/B PH.2

55 PingPong™ Diag PH.1

56 PingPong™ Diag PH.2

58 SingleFlash 60 L/R

59 SingleFlash 60 T/B

60 SingleFlash 60 Diag

61 SingleFlash 90 Solid

62 SingleFlash 90 L/R

63 SingleFlash 90 T/B

64 SingleFlash 90 Diag

65 SingleFlash 120 Solid

66 SingleFlash 120 L/R

67 SingleFlash 120 T/B

68 SingleFlash 120 Diag

69 SingleFlash 300 Solid

70 SingleFlash 300 L/R

71 SingleFlash 300 T/B

72 SingleFlash 300 Diag

73 DoubleFlash 150 Solid

74 DoubleFlash 150 L/R

75 DoubleFlash 150 T/B

76 DoubleFlash 150 Diag

77 ComAlert™ 150 Solid

78 ComAlert™ 150 L/R

79 ComAlert™ 150 T/B

80 ComAlert™ 150 Diag

81 ActionFlash™50 Solid

82 ActionFlash™50 L/R

83 ActionFlash™50 T/B

84 ActionFlash™50 Diag

85 ActionFlash™150 Solid

86 ActionFlash™150 L/R

57 SingleFlash 60 Solid

87 ActionFlash™150 T/B

88 ActionFlash™150 Diag

89 ModuFlash™ Solid

90 ModuFlash™ L/R

91 ModuFlash™ T/B

92 ModuFlash™ Diag

117 PinWheel SLOW

118 PinWheel MEDIUM

119 PinWheel FAST

120 PinWheel VARIABLE

121 PinWheel MEDIUM w/Solid

123 ActionScan™

124 SignalAlert™ Steady

93 DoubleFlash 120 Solid

94 DoubleFlash 120 L/R

95 DoubleFlash 120 T/B

96 DoubleFlash 120 Diag

97 PingPong™120 Solid

98 PingPong™120 L/R

99 PingPong™120 T/B

100 PingPong™120 Diag

101 TripleFlash™75 Solid

102 TripleFlash™75 L/R

103 TripleFlash™75 T/B

104 TripleFlash™75 Diag

105 TripleFlash™120 Solid

106 TripleFlash™120 L/R

107 TripleFlash™120 T/B

108 TripleFlash™120 Diag

109 Action SF 60/120 Solid

110 Action SF 60/120 L/R

111 Action SF 60/120 T/B

112 Action SF 60/120 Diag

113 Action SF 60/TF 120 Solid

114 Action SF 60/TF 120 L/R

115 Action SF 60/TF 120 T/B

116 Action SF 60/TF 120 Diag

122 CalScan

*

*125 Steady

*No low power for this pattern.

ITALIC = SYNCBOLD = Cal Title XIII Compliant.

L/R=Left/Right T/B=Top/Bottom

CAUTION! DO NOT LOOK DIRECTLY AT THESE LEDS WHILE THEY ARE ON.

MOMENTAR Y BLINDNESS AND/OR EYE DAMAGE COULD RESULT!

IMPORTANT WARNING!

Installation and Wiring:

External Flasher Models: This product draws significantly less current than

a standard incandescent automotive bulb. If your flasher does not operate

properly, it may be necessary to replace your flasher module with a

Whelen® flasher module. Contact your sales representative for application.

Caution: Permanent mounting of this product will require drilling. It is

absolutely necessary to make sure that no other vehicle components

could be damaged by this process. Check both sides of the mounting

surface before starting. If damage is likely, select a different location.

WARNING! All customer supplied wires that connect to the positive

terminal of the battery must be sized to supply at least 125% of the

maximum operating current and FUSED at the battery to carry that

load. DO NOT USE CIRCUIT BREAKERS WITH THIS PRODUCT!

NOTE: The color of the Positive Wire is determined by the color of the

LED. In this manual, RED is used as a reference color.

1. Using the dimensions shown, mark the 2 mounting hole locations and

wire access hole location onto the mounting surface.

2. Drill the two, 0.250” diameter mounting holes and a 0.625” (minimum)

wire access hole into the mounting surface.

3. Place the gasket into position on the rear of the M4 assembly. Insert

the slotted hole screw grommet through the mounting holes on the M4/

Gasket assembly.

4. Feed the M4 wires through the wire access hole in the mounting

surface. Press the M4/Gasket/Grommet assembly onto its mounting

location so that it is flat against the mounting surface. With the

assembly in position and using the hardware provided, tighten the

mounting screws until the lighthead assembly is drawn firmly against

the mounting surface. DO NOT OVERTIGHTEN!

5. Using appropriately sized wires (minimum 18 AWG), extend the M4

wires to their designated connections. Refer to the diagram below for

wiring and fusing information.

Operation:

Flash Mode / RED:

Apply +VBAT to the RED wire to activate the lighthead in “flash mode”.

In flash mode, you may change the flash pattern using Scan-Lock™.

Low Power / VIOLET:

The type of switch used depends on how the operator wishes the Low

Power feature to function:

Latching Mode: By applying +VBAT to the VIO wire for less than 1 sec., the

lighthead is “latched” into low power. The unit must be turned off and then

back on to restore normal operation. (A momentary switch is preferred)

Level Mode: Applying +VBAT to the VIO wire for more than 1 sec. holds the

lighthead in low power mode until voltage is removed.

(A toggle switch is preferred)

SYNC / GREY

To SYNC two lightheads, configure both lightheads to display the same

Phase 1 (Simultaneous) pattern. Turn the power off and connect the GREY

wire from each lighthead together. When the lightheads are activated their

patterns will be synchronized. To configure two lightheads to alternate their

patterns, advance the pattern of either lighthead to Phase 2 (Alternating) of

the current pattern.

NOTE: You can also program the 2 banks of LEDs inside the lighthead

to flash in different configurations (See M4 Sequencing and Phasing).

Scan-Lock™ / WHT/VIO / Flash Pattern Selection:

This feature allows the user to select from several available flash patterns.

The lighthead must be switched on for Scan-Lock™ to work.

TO CYCLE THROUGH ALL PATTERNS: Apply +VBAT to the WHT/VIO

wire for less than 1 second and release. To cycle backward through patterns

apply +VBAT to the WHT/VIO wire for over 1 second and release.

TO SET A PATTERN AS DEFAULT: Allow the pattern to run for more than 5

seconds. The lighthead will flicker slightly when the pattern locks in. This flicker may be difficult to see with some patterns. The lighthead will now display this pattern

when activated.

TO RESET TO THE FACTORY DEFAULT PATTERN: Turn off power. While applying +VBAT to the WHT/VIO wire, turn power on. This will reset the lighthead to it’s

factory default flash pattern.

IMPORTANT! It is the responsibility of the installation technician to make sure that the installation and operation of this product will not interfere with or

compromise the operation or efficiency of any vehicle equipment!

Page 2

Loading...

Loading...