Page 1

®

www. .com

ENGINEERING COMPANY INC.

ION™ Light (Split)

51 Winthrop Road,

Chester, Connecticut 06412-0684

Phone: (860) 526-9504

Fax: (860) 526-4078

Sales Email:autosale@whelen.com

Canadian Sales:canadiansales@whelen.com

Customer Service:custserv@whelen.com

Safety First

This document provides necessary information to allow your Whelen product to be properly and safely installed. Before beginning the installation and/or operation of this

product, the installation technician andoperator must read thismanual completely. Important information is containedherein that could preventserious injury or damage.

!

Proper installation of this product requires the installer to have a good understanding of

automotive electronics, systemsand procedures.

!

Failure to usespecified installation partsand/or hardware will voidthe product warranty!

!

The installer MUST be sure that no vehicle components or other vital parts could be

damaged by the drilling process. Check both sides ofthe mounting surface before drilling

begins. Also de-burr any holes and remove any metal shards or remnants. Install

grommets into allwire passage holes.

!

Do not install this product or route any wires in the deployment area of your air bag.

Equipment mounted or located in the air bag deployment area will damage or reduce the

effectiveness ofthe air bag, orbecome a projectilethat could cause seriouspersonal injury

or death. Refer to your vehicle owner's manual for the air bag deployment area. The

User/Installer assumesfull responsibility to determine proper mountinglocation, based on

providing ultimate safetyto all passengersinside the vehicle.

!

If this product uses a remote device to activate or control this product, make sure that this

control is located in an area that allows both the vehicle and the control to be operated

safely in anydriving condition.

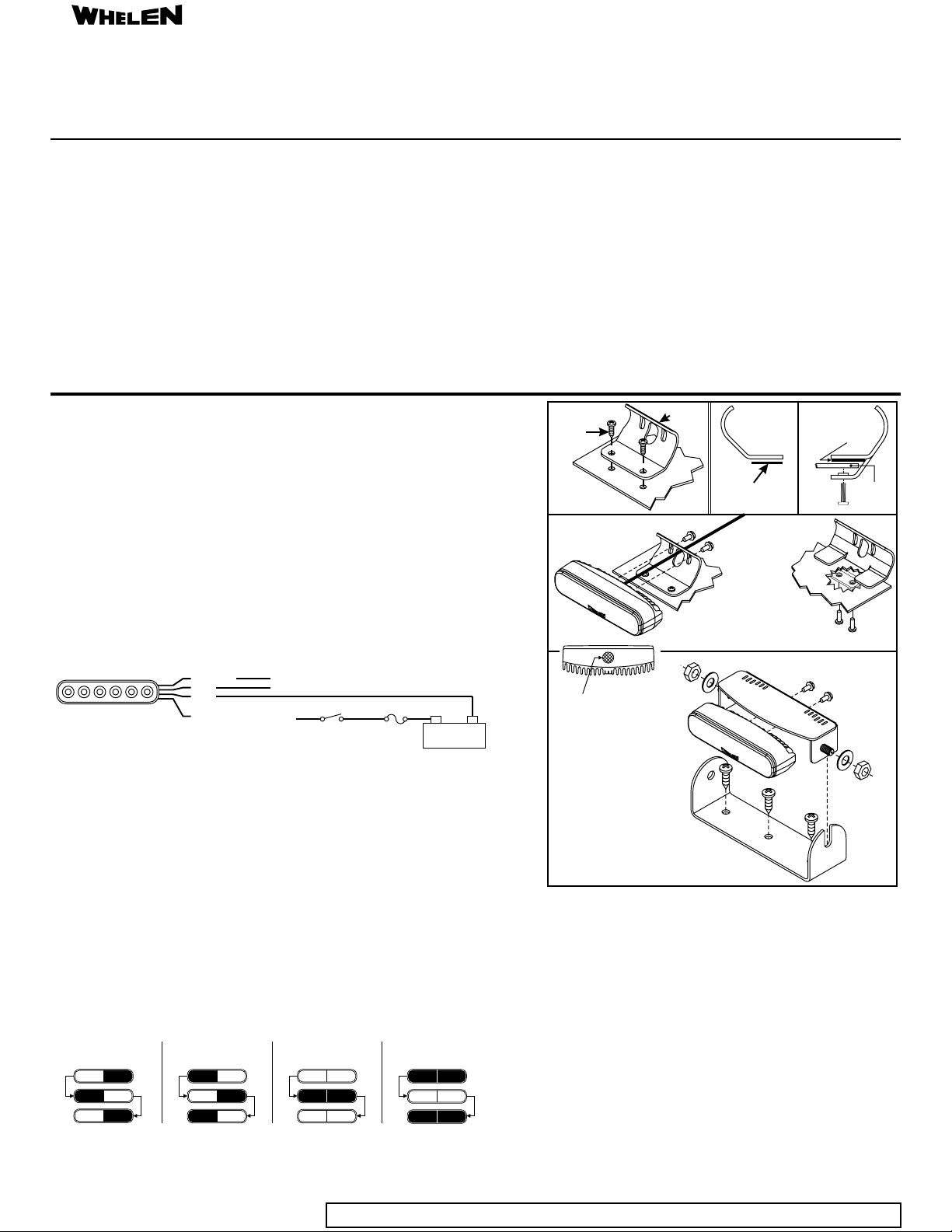

Mounting (Standard Bracket)

1. Place the bracket against the mounting surface and mark the two mounting hole locations.

2. Drill two mounting holes sized for a #8 sheet metal screw. A wire passage hole may also be needed. De-burr this

hole and installa grommet toprotect the wires.

NOTE:

If VHB tape (provided) is used, remove the protective backing from this tape and press it firmlyonto the bottom

of the bracketas shown. Cleanthe mountingsurface with a 50/50mix of isopropyl alcoholand water and drythoroughly

before mounting thebracket onto themounting surface.

3. Route thewires through thehole in thebracket and throughthe wirepassage hole. Securethe ION™ tothe bracket

using the hardwareprovided. Wire asoutlined below.

Mounting (Gripper Bracket)

1. Apply the protective pads to the bracket in the location shown (side view). Secure the ION™ to the bracket in

the same fashion as outlined for the standard bracket.

2. Position the bracket onto the proposed mounting surface as shown. Apply a drop of Loctite 222 to the threads

of the #6 x ½" PPHMS provided.

3. Thread these screws into the underside of the bracket as shown and secure the bracket to the mounting

surface.

Mounting (Bail Bracket)

1. Secure the bail bracket to the desired surface using the hardware provided. Mount the ION onto the shield

bracket and install this assembly onto the bail bracket as shown.

Wiring

W

HT / VIO

G

RY

B

LK

RED/WHT (2-color Split)

or

WHT/RED (1-color Split)

Operation

Scan-Lock™(WHT/VIO) - To advance to the next pattern

than 1second. , apply+VDC for morethan 1 second.

pattern

Continue to applyvoltage for 5seconds.

Lightheads configured to display the Phase 1 mode of a pattern will flash simultaneously. Any lightheads

configured to displaythe Phase 2mode will alternatewith any Phase1 lightheads withthe same pattern.

Sync (GREY) -

With the power off, connect the GREY wires from each lighthead together. When the lightheads are

activated, their patterns will be synchronized. To configure the two lightheads to alternate their patterns,

advance the pattern of either lighthead to the Phase 2 mode of the current pattern. The same concept

applies to Phases3 & 4.

To understandhow to usethe sync featurewith morethan two lightheads,the principles willbe applied toa

sample system consisting of 4 lightheads with 2 mounted on the rear, driver-side and 2 mounted on the

rear, passenger-side. With all the wiring complete, turn on all 4 lightheads. As shipped from factory, the

lightheads willall display SignalAlert™75 - Phase1. To configureone side toalternate with theother side,

change the patternfor either thepassenger or driverside to Phase2 mode forthat pattern.

IMPORTANT!

(such as the CS240S or UPS64LXA) by wiring their GREY wires together. When connected, LED

lightheads in Phase 1 of a pattern will flash with strobe lightheads connected to the

GREEN wire outputs. LED lightheads set to Phase 2 of a pattern will with strobe lightheads

connected to theWHITE wire outputs.GREEN wire outputsalways alternate withWHITE wire outputs.

Split Lighthead Operation:

IMPORTANT! It is the responsibility of the installation technician to make sure that the installation

and operation of this product will not interfere or compromise the operation or efficiency of any

vehicle equipment!

Before returningthe vehicle to activeservice, visually confirm theproper operation of this product,

as well asall vehicle componentsand/or equipment.

©2010 Whelen Engineering Company Inc.

Form No. 14436D (061411)

Tocycle backwards Toreset tothe factory default

, turn off power to the lighthead. While applying +VDC to the WHT/VIO,turn the lighthead back on.

To sync two lightheads, configure both lightheads to display the same Phase 1 pattern.

SYNC-capable LED lightheads can be SYNCed to a SYNC-capable strobe power supply

PHASE 1 - LEFT

ON

OFF ON

ON OFF

with side.alternates

RIGHT

OFF

side

PHASE2-RIGHT

with side.alternates

OFF ON

ON OFF

OFF ON

simultaneously

side

LEFT

Scan-Lock™

SYNC

Switch*

(SP/ST)

*Customer Supplied

, apply +VDC to the WHT/VIO wire for less

Phases3&4arevisually indistinguishable.

PHASE 3 - BOTH sides flash

together (ON-OFF-ON).

alternate

Fuse*

(3 AMP)

ONONON

OFF OFF

ON

(+)

12V Battery

PHASE 4 - BOTH sides flash

together (OFF-ON-OFF).

OFF OFF

ON ON

OFF OFF

For warranty information regarding this product, visit www.whelen.com/warranty

Do not attemptto activate orcontrol this devicein a hazardous drivingsituation.

!

This product contains high-intensity LEDs. Do not stare directly into these lights.

!

Momentary blindness and/oreye damage couldresult.

Use only soap and water to clean the outer lens. Use of other chemicals could result in

!

premature lens cracking (crazing) and discoloration. Lenses in this condition have

significantly reduced effectiveness and should be replaced immediately. Inspect and

operate this product regularly to confirm its proper operation and mounting condition.

Do not usea pressure washerto clean thisproduct.

!

WARNING! All customer supplied wires that connect to the positive (+) terminal of the

battery must be sized to supply at least 125% of the maximum operating current and

FUSED “at the battery” to carry that load. DO NOT USE CIRCUIT BREAKERS WITH THIS

PRODUCT!

!

Failure to follow these precautions and instructions could result in damage to the

product or vehicleand/or serious injuryto you and yourpassengers!

Mounting

Bracket

24. LongBurst 75 (PH 4)

25. PingPong™ 75 (PH 1)

26. PingPong 75 (PH 2)

27. PingPong 75 (PH 3)

28. PingPong 75 (PH 4)

29. SSNF 75 (PH 1)

30. SSNF 75 (PH 2)

31. SingleFlash 60 (Alt.)

32. SingleFlash 60 (Sim.)

33. 90 Alt.)

SingleFlash (

34. 9

SingleFlash 0 (Sim.)

35. SingleFlash 120 (Alt.)

36. SingleFlash 120 (Sim.)

37.

SingleFlash 300 (Alt.)

38. SingleFlash 300 (Sim.)

39.

DoubleFlash 150 (Alt.)

40. DoubleFlash 150 (Sim.)

41. ComAlert™ 150 (Alt.)

42. ComAlert™ 150 (Sim.)

43. ActionFlash™ 50 (Alt.)

44. ActionFlash™ 50 (Sim.)

45. ActionFlash™ 150 (Alt.)

46. ActionFlash™ 150 (Sim.)

Cable

Bail

Bracket

Standard

Bracket

(side view)

VHB Tape

(optional)

#6-32 x 5/16

Screw

Gripper Bracket

Gripper

Bracket

#6-32 x 1/2

Screw

Shield

Bracket

47. ModuFlash™ (Alt.)

48. ModuFlash™ (Sim.)

49. DoubleFlash 120 (Alt.)

50. DoubleFlash 120 (Sim.)

51. PingPong™ 120 (Alt.)

52. PingPong 120 (Sim.)

53. TripleFlash™ 75 (Alt.)

54. TripleFlash 75 (Sim.)

55. TripleFlash 120 (Alt.)

56. TripleFlash 120 (Sim.)

57. SigAlert Cal.™ (Alt.)

58. SigAlert Cal. (Sim.)

59. Action SF 60/120 (Alt.)

60. Action SF 60/120 (Sim).

61. Action SF60/TF120 (Alt.)

62. Action SF60/TF120 (Sim.)

63. CalScan™ (Alt./Sim.)

64. ActionScan™ (Alt./Sim.)

65. SteadyFlash 60

66. SteadyFlash 75

67. SteadyFlash 90

68. SteadyFlash 120

69. Steady & Steady

#10x1/2

PPHSMS

#6-32 x 5/16

Screw

(-)

Flash Patterns:

BOLD . /NOTE: = CA Title XIII Compliant Pattern = SYNC PatternItalic / PH 1 = Phase 1, PH 2 = Phase 2

1. SignalAlert™ 75 (PH 1)

2. SignalAlert 75 (PH 2)

3. SignalAlert 75 (PH 3)

4. SignalAlert 75 (PH 4)

5. CometFlash® 75 (PH 1)

6. CometFlash 75 (PH 2)

7. CometFlash 75 (PH 3)

8. CometFlash 75 (PH 4)

9. DoubleFlash 75 (PH 1)

10. DoubleFlash 75 (PH 2)

11. DoubleFlash 75 (PH 3)

12. DoubleFlash 75 (PH 4)

13. SingleFlash 75 (PH 1)

14. SingleFlash 75 (PH 2)

15. SingleFlash 75 (PH 3)

16. SingleFlash 75 (PH 4)

17. ComAlert™ 75 (PH 1)

18. ComAlert 75 (PH 2)

19. ComAlert 75 (PH 3)

20. ComAlert 75 (PH 4)

21. LongBurst™ 75 (PH 1)

22. LongBurst 75 (PH 2)

23. LongBurst 75 (PH 3)

#8 x 1/2

Sheet Metal

Screw

Standard

Bracket

IMPORTANT!

The membrane shown must

always face downwards!

Do not cover, obstruct or

remove this membrane

regardless of mounting style!

(side view)

Protective

Pad

Mounting

Flat

Washer

1/4-20 Elastic

Stop Nut

Surface

Loading...

Loading...