Page 1

®

ENGINEERING COMPANY INC.

Route 145, Winthrop Road,

Chester, Connecticut 06412

Phone: (860) 526-9504

Fax: (860) 526-2009

Internet: www.whelen.com

Sales/Service e-mail: aviation@whelen.com

Installati on Guide:

Model HDACF

Strobe Power Supply Assembly

FAA/PMA Approved.

Specifications

Model Number -HDACF

Part Number - 01-0770028-05

Current Draw - 7.0 Amps @ 14 Volts D.C.

3.5 Amps @ 28 Volts D.C.

Weight - 2.1 lbs.

Length - 5.50”

Height - 2.37”

Installation Procedures

Location

1. Consider areas or locations designated by the aircraft

manufacturer. Do not mount the strobe power supply

any closer than 3 feet from the ADF loop.

2. For alternate locations, consider areas such as the

cabin baggage compartment, the floor under the seat,

non-structural bulkheads, firewalls etc.

3. If necessary, fabricate support brackets or shelves, and

attach them to the aircraft structure to provide a

mounting surface that will withstand the inertia forces

stipulated in chapters 1 & 3 of AC 43.13-2A

4. An “IA” or other representative of the FAA must approve

documentation of structural integrity of the fabricated

installation.

5. When installing the strobe light power supply in an

inverted position, drill a 3/16” diameter hole in the

lowest corner of the cover to provide for moisture

drainage. Care must be taken not to let the drill protrude

into the power supply, for it will inflict damage to the

electronic components.

6. Specifically call out the location of the strobe light power

supply on FAA form 337.

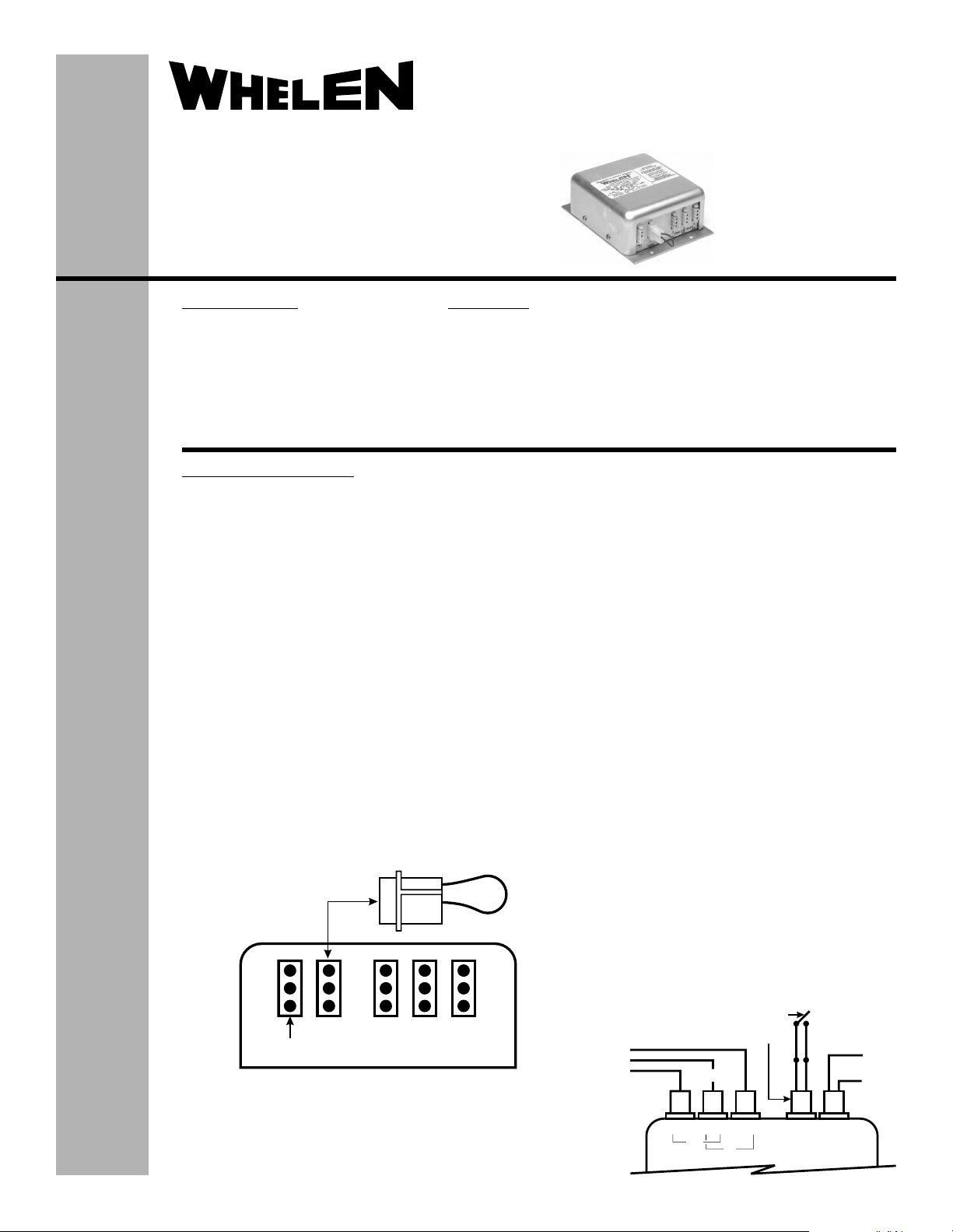

Jumper to be inserted

Fig. 1

in trigger selector outlet

(1) +

(2) -

(3)N/C

Connector for

input power cable

Aviation

©2001 Whelen Engineering Company Inc.

Form No.13603A (030303)

Operation

This power supply will operate up to 3 strobe light head assemblies.

When operating two lig hts in the alterna ting mode, 42 joul es of p ower are

produced for each l igh t. Wh ile in simultaneou s m od e, p ow er to ea ch l ig ht

is 21 joules. When operating 3 lights, strobe outlet 1 produces 42 joules

of power and alternates with strobe outlets 2 & 3 (producing 21 joules

each) that flash simultaneously (see Fig. 1).

32 1

Outlet1Outlet2Outlet

STROBE OUTLETS

TYPICAL STROBE HOOK-UP

PIN 1 - RED - ANODE

PIN 2 - BLACK - CATHODE

PIN 3 - WHITE - TRIGGER

3

Page 1

PIN

1 TYP.

2 TYP.

3 TYP.

Wiring

WARNING: STROBE LIGHT POWER SUPPLIES ARE

POLARITY SENSITIVE. REVERSING THE INPUT POLARITY WILL CAUSE SEVERE DAMAGE TO THE POWER

SUPPLY.

Steps below: “Ref. AC 43.13-1B, Chapter 11, Sections

1,2,3, & 7”.

1. Choosing wire size of A+ input lead, refer to Paragraph

444 “Electric Wire Chart” Figure 11.7 and 11.7A, with

reference to Strobe Light Model Current requirement

chart on page 6 and 11, and “Wire and Circuit

Protection Chart” Figure 11.1.

2. Shielded wire is not generally necessary, but has

proven effective in reducing the possibility of radio

interference.

3. The power supply shall acquire its power from a low

impedance source such as the alternator or generator

end of the electrical buss as close to the battery as

possible.

4. For penetrating pressure hull, refer to the aircraft

service manual.

5. Check all avionics systems for interference.

Trigger Function

Jumping pins 1 and 2 on the trigger plug will provide an

alternating flash pattern between strobe outlet 1 and strobe

outlet(s) 2 and/or 3. Installing a switch in series with the

jumper will allow strobe outlets 2 & 3 to be turned off, while

strobe outlet 1 remains on (see Fig. 2).

TRIGGER

SELECTOR

OUTLET

OFF

ON

POWER

IN

-

14V or 28V

+

Fig. 2

STROBE OUTLETS

#3

SYNC

Switch normally closed

1/10 amp rated

Jumper inserted into

trigger selector outlet

#1#2

ALT

Page 2

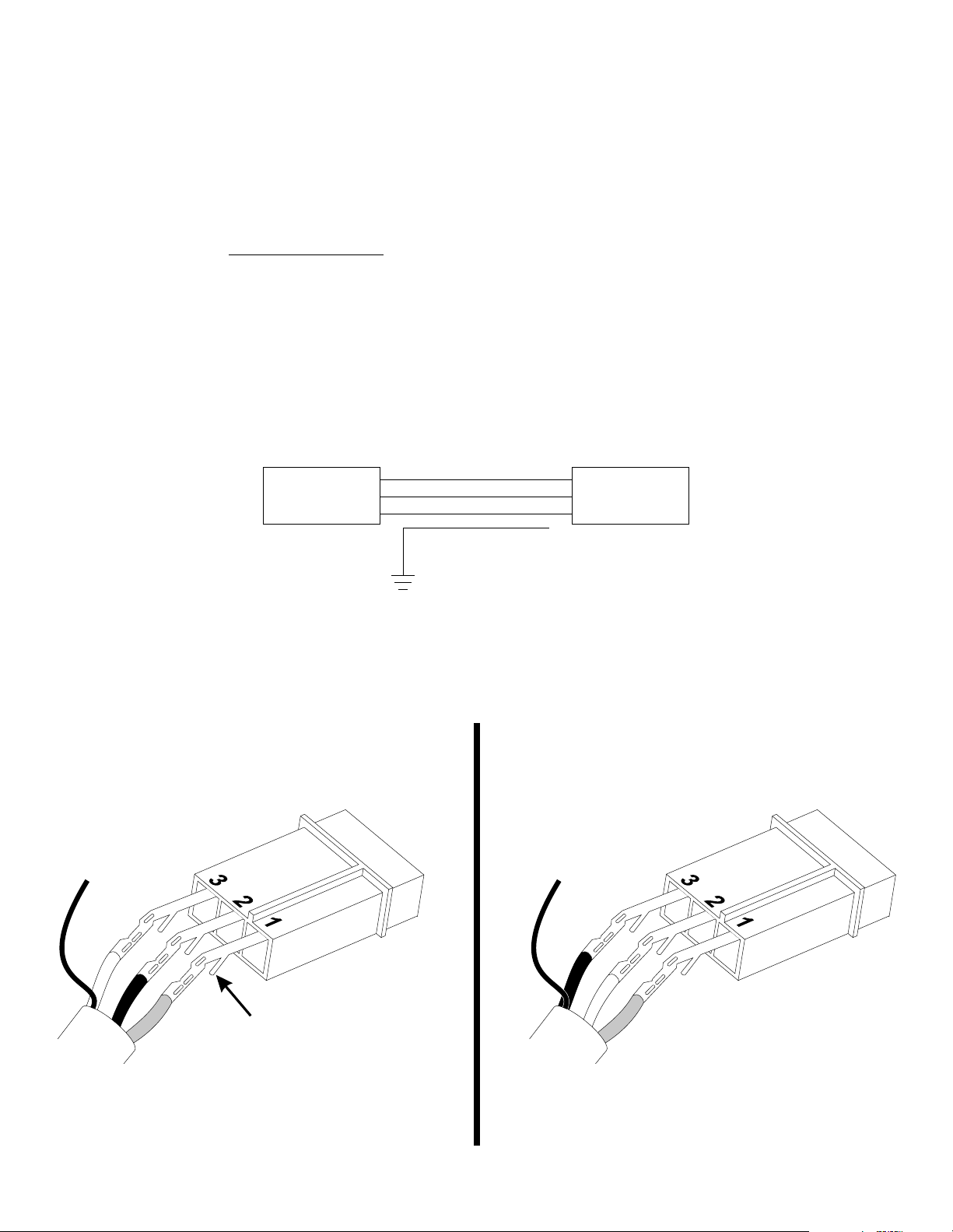

Interconnecting Cable

1. The Whelen interconnecting cable shall be secured in place with

approved aviation techniques.

2. The cable shall not parallel ADF, Gyro or Flux Gate compass leads

closer than 12 inches.

3. CABLE COLORING CODING (see Figure 3):

PIN 1 - RED (Anode)

PIN 2 - BLACK (Cathode, flash tube ground)

PIN 3 - WHITE (Trigger)

SHIELD - Ground at power supply end only

CAUTION: When pins 1 & 2 or pins 2 & 3 are reversed, the

system will appear to operate normally, however this condition will cause premature flash tube failure.

IMPORTANT NOTE:

Your new strobe power supply has an additional circuit

built-in to prevent self-ionization (steady glowing) of the

strobe tubes. In some cases, when replacing older power

supplies, the bare shield wire in the existing harness is

pinned together at each end with the black wire. The

following modification must be made to ensure proper

operation.

1. At the strobe tube end of the cable, cut the shield wire and tape it off

(DO NOT CUT THE BLACK WIR E).

2. At the power supply end of the cable, cut the shield wire and connect

it to a good ground (DO NOT CUT THE BLACK WIRE).

3. This must be done for each strobe light connection (see Fig. 3).

Fig. 3

PIN 1 = RED (ANODE)

PIN 2 = BLACK (CATHODE)

PIN3=WHITE (TRIGGER)

SHIELD = RFI DRAIN TO GROUND

3 POS. PIN HSG

POWER 1

SUPPLY

3 CONDUCTOR SHIELDED CABLE

22

END 3 3

SHIELD WIRE

GROUND SHIELD WIRE

AT POWER SUPPLY END

3 POS. SOCKET HSG

STROBE

1

TUBE

END

X

CUT AND TAPE SHIELD WIRE

AT STROBE TUBE END

INTERMIXING STROBE LIGHT SYSTEM EQUIPMENT

OBSERVE COLOR AND PIN NUMBERS. CABLES CONNECTING REMOTE

POWER SUPPLY TYPE STROBE LIGHTS MUST BE CONNECTED CORRECTLY!

Whelen Engineering and Aero-flash wiring

between light assemblies and remote

power supplies are identical as pictured

below.

Grimes and SDI (Hoskins) wiring between

light assemblies and remote power supplies are identical as pictured below.

SHIELD

WHITE

BLACK

RED

CLIP

Page 2

SHIELD

BLACK

WHITE

RED

Both Grimes and SDI sometimes use MS

(Cannon Type) Connectors:

AB

= RED (Anode), = WHITE (Trigger),

C

= BLACK (Ground)

Loading...

Loading...