Page 1

®

ENGINEERING COMPANY INC.

Route 145, Winthrop Road,

Chester, Connecticut 06412

Phone: (860) 526-9504

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mai l: auto can@whelen.com

Customer Service e-mail: custserv@whelen.com

Important!!!

The Deutsch water-proof connector will not function properly

unless it is connected exactly as the manufacturer intended. A

Deutsch crimpi ng to o l (Wh elen p/n 66T05 164 35 119C) is requir ed f or

proper termina l crimp ing an d sh ould be us ed when ever poss ible. If

a non-Deutsch crimp tool is used, the cable wires must first be

pushed through the rubber connector grommet BEFORE the pin

terminal is crimped. This will reduce the possibility of damaging the

water-tight seal around the wires. Whelen Engineering does not

recognize the use of a non-Deutsch crimping tool, therefore any

resulting damage would void the warranty.

Wires coming from the lamp MUST

housing; NOT

overview of all related components.

If your current lighting system utilizes an AMP water-proof

connector, it will be necessary to remove th e AMP assembly from

the supply cable . The wire e nds must then be stripped so that the

correct “barrel”-style pins can be attatched using the Deutsch

crimping tool. T he Deuts ch rece ptacle c an then be atta tched t o the

cable as outlined in the following “Assembly” section. Be sure to

insert the wires into the receptacle so that they will connect with the

correct plug wire. Exa mple: The wir e in receptacle section A is the

wire that is designated to be connected to the wire in plu g section

A.

the receptacl e housing. Refer to Diagram 1 for an

be connected to the plug

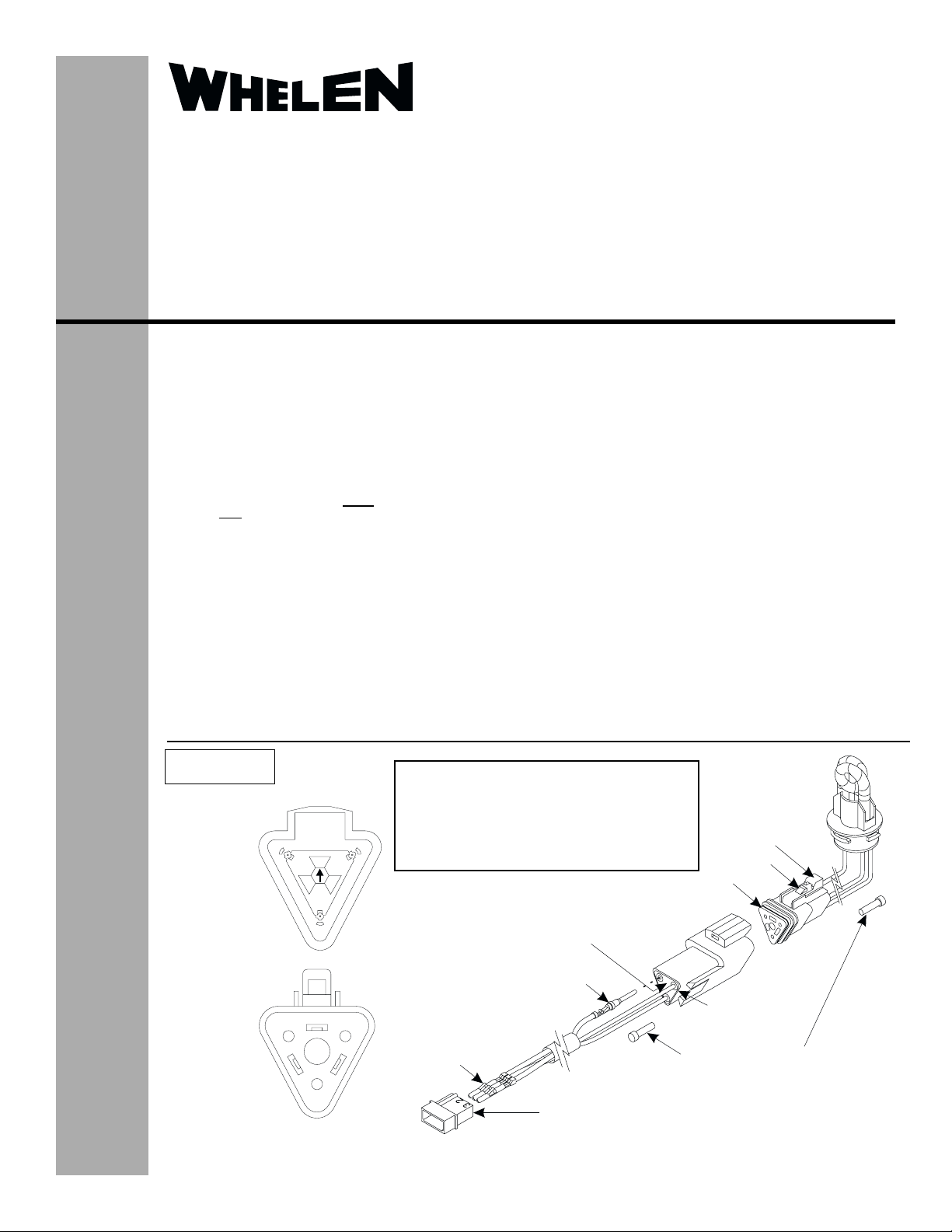

Assembly...

1. Locate the cable that will be used be tween the power supply and

the receptacle section of the water-proof connector.

Assembly/Disassembly

Deutsch Water-Proof Connectors

W441D (Receptacle)

W442D (Plug)

2. Locate the leads that h ave the “barr el”-style pi ns crimped onto the

wires.

3. Grasp the wire approximately 1 inch behind the contact barrel.

4. Hold the receptacle so that the rear grommet is facing you.

5. Push the pin straight into the grommet until a “click” is felt. A gentle

tug will confirm that it is properly locked into place.

6. Once all the pins are installed, insert the wedge into the receptacle.

Be sure that the arrow on the wedge is pointing towards the

exterior locking housing. If the wedge being used is rectangular, the

arrow alignment does not apply.

NOTE: Although the above text outlines the procedure for assembling

the receptacle, the same procedure is used for the Plug section. The plug

section utilizes a faceplate instead of a wedge. It can be removed with a

small screwdriver.

Contact Removal...

1. Remove the wedge with either a pair of needle nose pliers (if

removing contacts from the receptacle section) o r a small, reg ular

screwdriver (for the faceplate of the plug section).

2. To remove the contacts, gent ly pull the desired wire back away

from the grommet. At the sam e time, release the l ocking finger by

moving it away from the contact with a screwdriver.

3. Be sure to hold the rear seal in place, a s removing the contact will

disrupt its position.

Diagram 1

Receptacle

(W441D)

Plug

(W442D)

Automotive: Other

©1996 Whelen Engineering Company Inc.

Form No.13137H (030702)

A three-position Deutsch water-proof

connector is shown here for dem onstra tion

purposes only! The above procedure is not

limited to the three position connector and

applies to both larger and smaller

connectors.

Receptacle

Pin Terminal

(with barb)

Connector

Grommet

Pin Terminal

(with barrel)

To

Power

Supply

Connector:

1 = RED (OR GREEN)

2 = BLACK

3 = WHITE

Page 1

Hasp

Release

Hasp

Faceplate

B

Plug

B

Receptacle:

A = RED (OR GREEN)

B = BLACK

C = WHITE

Water Block

NOTE:In the event of a situation where the

number of wires to be inserted into either

the receptacle or the plug is fewer than the

number of available openings, insert the

water block into the unused opening.

Loading...

Loading...