Page 1

®

ENGINEERING COMPANY INC.

CAUTION

Loud siren noise can cause

hearing damage and/or loss.

Refer to OSHA Section 1910.95 prior

to putting ANY siren into service!

Wear

Protection!

ACTIVATION OF THIS

SIREN MAY DAMAGE

UNPROTECTED EARS!

51 Winthrop Road

Chester, Connecticut 06412-0684

Phone: (860) 526-9504

Self-Contained Siren Amplifier

Installation Guide:

Installation Guide:

GAMMA2™

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: canadiansales@whelen.com

Customer Service e-mail: custserv@whelen.com

DANGER! Sirens produce extremely loud emergency warning tones! Exposure to these tones without

proper and adequate hearing protection, could cause ear damage and/or hearing loss! The Occupational Safety &

Health Administration (www.osha.gov) provides information necessary to determine safe exposure times in

Occupational Noise Exposure Section 1910.95. Until you have determined the safe exposure times for your

specific application, operators and anyone else in the immediate vicinity should be required to wear an approved

hearing protection device. FAILURE TO FOLLOW THIS RECOMMENDATION COULD CAUSE HEARING LOSS!

Safety First

This document provides all the necessary information to allow your Whelen product to be properly and safely installed.

Before beginning the installation and/or operation of your new product, the installation technician and operator must

read this manual completely. Important information is contained herein that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of automotive electronics,

systems and procedures.

• Failure to use specified installation parts and/or hardware will void the product warranty!

• If mounting this product requires drilling holes, the installer MUST be sure that no vehicle components or other

vital parts could be damaged by the drilling process. Check both sides of the mounting surface before drilling

begins. Also de-burr any holes and remove any metal shards or remnants. Install grommets into all wire

passage holes.

• If this manual states that this product may be mounted with suction cups, magnets, tape or Velcro®, clean the

mounting surface with a 50/50 mix of isopropyl alcohol and water and dry thoroughly.

• Do not install this product or route any wires in the deployment area of your air bag. Equipment mounted or

located in the air bag deployment area will damage or reduce the effectiveness of the air bag, or become a

projectile that could cause serious personal injury or death. Refer to your vehicle owner’s manual for the air bag

deployment area. The User/Installer assumes full responsibility to determine proper mounting location, based

on providing ultimate safety to all passengers inside the vehicle.

• For this product to operate at optimum efficiency, a good electrical connection to chassis ground must be

made. The recommended procedure requires the product ground wire to be connected directly to the NEGATIVE

(-) battery post.

• If this product uses a remote device to activate or control this product, make sure this control is located in an

area that allows both the vehicle and the control to be operated safely in any driving condition. DO NOT

ATTEMPT TO ACTIVATE OR CONTROL THIS DEVICE IN A HAZARDOUS DRIVING SITUATION.

• It is recommended that these instructions be stored in a safe place and

referred to when performing maintenance and/or reinstallation of this

product.

• FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND

INSTRUCTIONS COULD RESULT IN DAMAGE TO THE PRODUCT OR

VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR PASSENGERS!

Automotive: Sirens/Switches

For warranty information regarding this product, visit www.whelen.com/warranty

©2011 Whelen Engineering Company Inc.

Form No.14302A (011713)

Page 1

Page 2

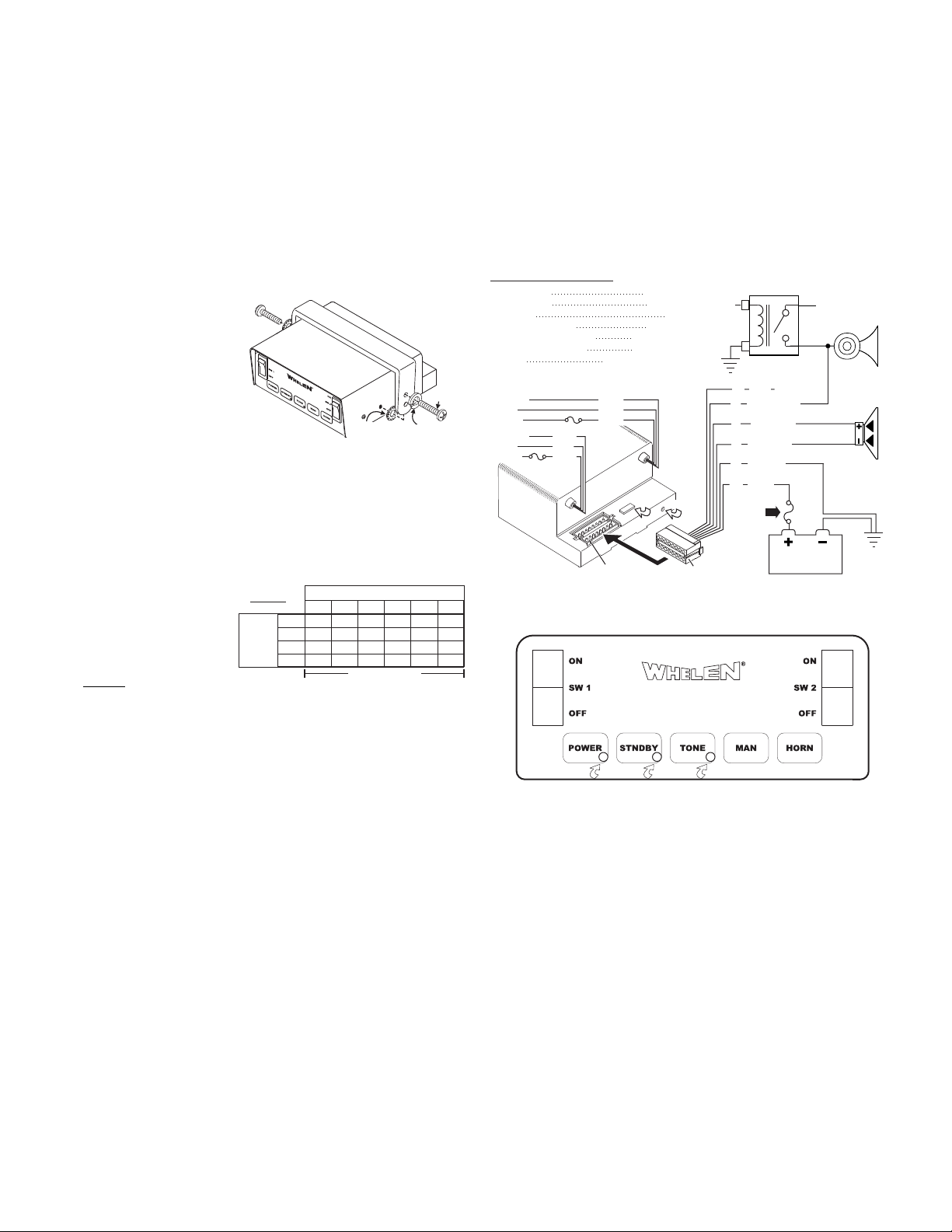

TABLE 1

Distance in Feet

INS = Insufficient

18

31

15.5

10.5

7.5

16

49

24.5

16.5

12.5

14

78

39

26

19.5

12 10 8

10

20

30

40

Wire Gage / AWG

INS.

INS.

7.5

4

12

6

4

3

19.5

9.5

6.5

5

Current

Draw

(

AMPS

)

Split Lock

Washer

Screw

Ext. Tooth

Lock Washer

LED 1

Indicators:

LED 2 LED 3

Front Panel

This siren offers a unique and distinctive collection of features designed to allow the user to customize the operation of this siren to

16 Position Connector

Fuses & Fuse

Blocks are

customer

supplied.

1

FUSE

0 AMP

CHASSIS

GROUND

100W

SPEAKER

HORN

RELAY

+12V

TO HORN

BUTTON

BATTERY

VEHICLE

HORN

16 Position Outlet

Rear view

of amplifier

WIRING DIAGRAM

INPUT VOLTAGE

INPUT CURRENT

INPUT FUSE

SPEAKER IMPEDANCE

OPERATING TEMPERATURE

STORAGE TEMPERATURE

HUMIDITY

OUTPUT VOLTAGE

OUTPUT POWER

12.8 VDC ±20%

8 AMPS MAX.

10 AMPS

11 OHMS MIN.

-30° C. TO +60° C.

-40° C. TO +70° C.

99% (NON CONDENSING)

@ 15 VDC @ 11 OHMS 34 V RMS MAX.

@ 15 VDC @ 11 OHMS 105 WATTS MAX.

Fuse

UnusedOutlets: 2-3-5-7-9-10-14&16

WHT/GRN

SIREN

IN USE(+

)

Load

Ground

YELLOW

BLACK

RED15

8

6

1

4

Power

Load

Ground

Power

Scan-Lock

BLK

BLK

WHT

VIO

BRN

BLU

BROWN

BLU

13

suit their individual needs. Features include:

• 100 watts of output power

• Scan-Lock™ siren tone programming

• Hands Free operation

• Compact design

• Harmonically rich composite air horn tones

• Title 13 compliant profiles

• Horn ring control inputs

Mounting:

This siren is designed to be mounted directly onto the dash or other

surface through the use of a bail-strap mounting bracket. The unit may

also be mounted into your vehicle’s console (if so equipped).

WARNING: Mounting this unit will require drilling. It is absolutely

necessary to make sure that no other vehicle components could be

damaged in the process. Check both sides of the mounting surface

before starting. If damage is likely, select a different location.

Bail-strap mount:

1. Position bail strap in selected

mounting location and drill

mounting holes, then secure

the bail strap to the vehicle.

2. Secure the siren to the bail

strap as shown. Tighten the

screws firmly.

Console Mount:

Console manufacturers offer

mounting kits that include all the necessary hardware and brackets

required to mount this unit into their console. The console mount brackets

are secured onto the unit the same way the bail bracket is. Please refer to

the manual included with your console.

4. Connect the WHITE/GREEN wire to the wire that runs from the horn

relay to the horn.

Operation:

Siren in use: This output will become active (+VBAT) whenever a tone is

being produced by the siren.

Wiring:

Siren Input Connector - RED: Power - BLACK: Ground

WARNING: All customer

supplied wires that connect

to the positive terminal of

the battery must be sized to

supply at least 125% of the

maximum operating current

and FUSED

carry that load. DO NOT USE CIRCUIT BREAKERS WITH THIS

PRODUCT!

1. Extend the RED and BLACK wires toward the vehicle battery. To pass

the RED and BLACK wires through, you may have to drill a hole in the

fire wall. Insert a grommet to protect the wires.

2. Route the RED and BLACK wires along the factory harness towards the

battery. Install a fuse block (user supplied) on the end of the RED wire.

Remove fuse from fuse block before connecting wires to battery.

3. Connect fuse block wire to POSITIVE terminal on battery. There must

not be more than 2 feet of wire between fuse block and battery. The

wire between the fuse and battery is “unprotected”, do not allow it to

chafe and short to ground.

4. Connect the BLACK wire to the factory chassis ground.

YELLOW & BROWN - Speaker:

1. Route the YELLOW and BROWN wires toward vehicle siren speaker,

along factory wire harness and through firewall at the same point as the

RED and BLACK wires.

2. Connect the YELLOW wire to the POSITIVE terminal on the SPEAKER

and the BROWN wire to NEGATIVE connection on the speaker.

WHITE/GREEN - Horn Relay:

1. Route WHITE/GREEN wire along factory wire harness and through

firewall at the same point as the RED and BLACK wires.

2. Route WHITE/GREEN wire to vehicle’s horn relay. If possible, follow

the factory wire harness to this relay.

3. Locate the wire that connects the vehicle horn to the horn relay.

at the battery to

PWR button: This button must be activated to enable any of the siren

tones. To activate this button press and release, the button's LED will

indicate a positive activation. To turn the siren off, press and release

again.

STNDBY button: To activate this button press and release, the button's

LED will indicate a positive activation. When this button is activated the

siren will be in a standby mode. No tones will be enabled until another

action is taken by the operator. Activating this button will also shut off an

activated TONE button.

TONE button: To activate this button press and release, the button's LED

will indicate a positive activation. When this button is activated the siren

will produce a Wail tone. Activating this button will also shut off an

activated STNDBY button.

MAN button: The MAN button generates a variety of tones, depending on

what mode of operation has been chosen by the user (See “Operations”).

HORN button: The Horn button generates an AIRHORN tone when

pressed, however if one of the Title 13 modes has been chosen,

AIRHORN does not override Wail and Yelp (See “Operations” section).

SW1 and SW2 Rocker Switches: Sw1 and Sw2 are Auxiliary Power

switches with LED indicators to be used at the customers discretion. Each

switch can handle up to 20 Amps at +Vbat. (See “WIRING DIAGRAM”).

Page 2

Page 3

= Title 13 Compliant

HF TONE LIST

WAIL

YELP

HI/LO

PIERCER

Y249

W

ARBLE

WHOOP

MECHANICAL

PULSED AIRHORN

AIRHORN-HI/LO

ALT. WAIL

ALT YELP

PULSED PIERCER

PULSE YELP/AIRHORN

●

●

●

●

●

●

●

●

●

●

●

●

●

●

TONE BUTTON PRIMARY TONE LIST

●

●

●

●

●

TONE OFF

WAIL

YELP

HI/LO

PIERCER

Y249

W

ARBLE

WHOOP

MECHANICAL

PULSED AIRHORN

AIRHORN-HI/LO

ALT. WAIL

ALT YELP

PULSED PIERCER

PULSE YELP/AIRHORN

= Title 13 Compliant

●

●

●

●

●

●

●

●

●

●

= Title 13 Compliant

TONE OFF

WAIL

YELP

HI/LO

AIRHORN-HI

AIRHORN-LO

PIERCER

Y249

W

ARBLE

W OOP

MECHANICAL

H

PULSED AIRHORN

Tone Button O

VERRIDETONE LIST

●

●

●

●

●

●

●

●

●

●

●

AIRHORN-HI/LO

ALT. WAIL

ALT YELP

PULSED PIERCER

PULSE YELP/AIRHORN

●

●

●

●

●

MANUAL Tone List

TONE OFF

WAIL-COAST

WAIL-STOP

MECHANICAL-COAST

MECHANICAL-STOP

HI-WAIL-COAST

HI-WAIL-STOP

AIRHORN-HI

AIRHORN-LO

●

●

●

●

●

●

●

●

●

LED 1

LED 2

LED 3 MODE #

ON

OFF

ON

OFF

OFF

ON

ON

OFF

OFF

OFF

OFF

ON

MODE 1

MODE 2

MODE 3

MODE 4

T

ABLE

2

BUTTON

OPERATION

MAN BUTTON OR HORN RING INPUT HORN*

STNDBY

TONE

HORN*

HF-Standby

Wail

Airhorn

HF cycle (Wail, Yelp, Piercer)**

YELP

Airhorn

Airhorn

Airhorn

Airhorn

** HF cycle: tones are activated by a single tap on the MAN button or HORN RING

input. The first tap produces a WAIL tone (a steady rise and fall tone). A second tap

produces a YELP tone (a fast rise and fall tone). A third tap produces a PIERCER tone

(a extremely fast rise and fall tone). The next tap returns the siren to a WAIL tone and

the cycle repeats itself. Two quick successive taps will stop the siren.

* The HORN button produces airhorn as a main tone as well as an override tone.

BUTTON

BUTTON

SWITCH

OPERATION

MAN BUTTON OR HORN RING INPUT

MAN BUTTON OR HORN RING INPUT

MAN BUTTON OR HORN RING INPUT

HORN*

HORN*

HORN*

STNDBY

TONE

HORN*

STNDBY

TONE

HORN*

STNDBY

TONE

HORN*

M -St byanual nd

Wail

Airhorn

O

PERATION

HF nd

Wail

Airhorn

-St by

O

PERATION

Manual-St bynd

Wail

Airhorn

Manual Wail

YELP

Airhorn

HF Cycle (Wail, Yelp, Y249)**

YELP

Airhorn

Manual Wail

YELP

Airhorn

Airhorn

Airhorn

Airhorn

Airhorn***

No Change

Airhorn

Airhorn***

No Change

Airhorn

* The HORN switch produces airhorn as a main tone as well as an override tone.

MODE 1

M

ODE 2

The following tables show the factory default tone settings. See the "tone

programming" section to make desired changes.

HF cycle: tones are activated by a single tap on the MAN button or HORN RING

input. The first tap produces a WAIL tone (a steady rise and fall tone). A second tap

produces a YELP tone (a fast rise and fall tone). A third tap produces a Y249 tone (a

extremely fast rise and fall tone). The next tap returns the siren to a WAIL tone and

the cycle repeats itself. Two quick successive taps will stop the siren.

**

Title 13 mode prevents Airhorn to override Wail and Yelp but will allow Airhorn

when in Standby

*** ,

.***

* The HORN button produces airhorn as a main tone as well as an override tone.

MODE 3 /TITLE 13***

* The HORN switch produces airhorn as a main tone as well as an override tone.

Title 13 mode prevents Airhorn to override Wail and Yelp but will allow Airhorn

when in Standby

*** ,

*** .

MODE 4/TITLE 13***

Operations:

TONE OFF AIR HORN-HI AIR HORN-LO

AIRHORN tone list

●● ●

Siren Tone Programing Procedures

Programming the Siren:

WARNING: Never try to program the siren while it is wired to the

vehicle. A low level audio device is built into the siren so siren tones

can be heard during programming.

There are two important operational characteristics of the siren that can be

reconfigured; Mode of Operation and Tone Selection. The Scan-Lock™

button is used to place the unit in configuration mode as well as to select

the desired changes. The Scan-Lock™ button is located as shown and

can be activated with a pen or similar object. Three LEDs (See front panel)

provide a visual indication of the currently selected mode of operation

during the configuration process. The configuration procedure used to

configure the Mode of Operation is different from the one used to

configure Tone Selection. The procedure for each is outlined below.

Tone Programming:

To change the over-ride tone for the TONE button (for all MODES):

Activate the siren by

pressing the TONE

button. Press and

hold the HORN

RING or the MAN

button. Press and

release the ScanLock™ switch. Each

time the Scan-Lock™ switch is pressed and re-leased, the next available

tone will be broadcast. When the desired tone is present, it will

automatically be saved as the override tone for that control switch.

Release the HORN RING or the MAN switch.

To change the primary tone for the TONE button (for all MODES):

Activate the siren

by pressing the

TONE button.

Press and release

the Scan-Lock™

switch. Each time

the Scan-Lock™

switch is pressed

and released, the next available tone will be broadcast. When the desired

tone is generated, it is automatically saved for that control switch position.

To change a tone in the hands free cycle (for MODE 1 & 3): Place the

siren in HF standby,

by Activating the

STNDBY button.

Using the HORN

RING or the MAN

button, advance to

the tone that you

wish to change. Press and release the Scan-Lock™ switch. Each time the

Scan- Lock™ switch is pressed and released, the next available tone will

be broadcast. When the desired tone is generated, it will automatically be

saved for that hands-free cycle position.

To change the tone for the manual cycle (for MODE 2 & 4): Place the

siren in MANUAL standby, by

Activating the STNDBY button.

Press and hold the HORN RING

or the MAN button. Press and

release the Scan-Lock™ switch.

Each time the Scan-Lock™

switch is pressed and re-leased,

the next available tone will be

broadcast. When the desired tone is present, it will automatically be saved

as the MANUAL tone. Re-lease the HORN RING or the MAN switch.

To change the tone for the HORN button (for all MODES): Press and

hold the AIRHORN button.

Press and release the ScanLock™ switch. Each time the

Scan-Lock™ switch is pressed

and released, the next available tone will be broadcast. When the desired

tone is present, it will automatically be saved as the AIRHORN tone.

Release the AIRHORN switch.

Mode Programming:

There are four modes of operation built

into this siren. Mode 1 is the factory

default mode, to change the “mode of

operation” follow the instructions

below. This section will outline how to

select the “mode of operation”.

1. Turn off the PWR button.

2. Press and hold the Scan-Lock™ button. Press and release the PWR

button.

3. Release Scan-Lock™ button. The unit is now in Configuration Mode.

4. Using the Scan-Lock™ button, cycle through the four different modes

of operation. The currently selected mode can be identified by the

LED indicators. Refer to Table 2 for LED display information.

5. When the desired mode of operation has been selected, press and

release the PWR button to exit the configuration mode.

Page 3

Loading...

Loading...