Page 1

®

ENGINEERING COMPANY INC.

51 Winthrop Road

Chester, Connecticut 06412-0684

Phone: (860) 526-9504

Fax: (860) 526-4078

(with Beacons & Power Supply)

Models: G7M*, G7P*, G7M***, G7P***

Installation Guide:

Guardian™ Lightbar

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: autocan@whelen.com

Customer Service e-mail: custserv@whelen.com

Safety First

This document provides all the necessary information to allow your Whelen product to be properly and safely installed.

Before beginning the installation and/or operation of your new product, the installation technician and operator must

read this manual completely. Important information is contained herein that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of automotive electronics,

systems and procedures.

• If mounting this product requires drilling holes, the installer MUST be sure that no vehicle components or other

vital parts could be damaged by the drilling process. Check both sides of the mounting surface before drilling

begins. Also de-burr any holes and remove any metal shards or remnants. Install grommets into all wire

passage holes.

• If this manual states that this product may be mounted with suction cups, magnets, tape or Velcro®, clean the

mounting surface with a 50/50 mix of isopropyl alcohol and water and dry thoroughly.

• Do not install this product or route any wires in the deployment area of your air bag. Equipment mounted or

located in the air bag deployment area will damage or reduce the effectiveness of the air bag, or become a

projectile that could cause serious personal injury or death. Refer to your vehicle owner’s manual for the air bag

deployment area. The User/Installer assumes full responsibility to determine proper mounting location, based

on providing ultimate safety to all passengers inside the vehicle.

• For this product to operate at optimum efficiency, a good electrical connection to chassis ground must be

made. The recommended procedure requires the product ground wire to be connected directly to the NEGATIVE

(-) battery post.

• If this product uses a remote device to activate or control this product, make sure that this control is located in

an area that allows both the vehicle and the control to be operated safely in any driving condition.

• Do not attempt to activate or control this device in a hazardous driving situation.

• This product contains either strobe light(s), halogen light(s), high-intensity LEDs or a combination of these

lights. Do not stare directly into these lights. Momentary blindness and/or eye damage could result.

• Use only soap and water to clean the outer lens. Use of other chemicals could result in premature lens cracking

(crazing) and discoloration. Lenses in this condition have significantly reduced effectiveness and should be

replaced immediately. Inspect and operate this product regularly to confirm its proper operation and mounting

condition. Do not use a pressure washer to clean this product.

• It is recommended that these instructions be stored in a safe place and referred to when performing

maintenance and/or reinstallation of this product.

• FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND INSTRUCTIONS COULD RESULT IN DAMAGE TO

THE PRODUCT OR VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR PASSENGERS!

Automotive: Lightbars

For warranty information regarding this product, visit www.whelen.com/warranty

© 2003 Whelen Engineering Company Inc.

Form No.13750C (021407)

Page 1

Page 2

IMPORTANT! The lightbar should be located a minimum of 16"

from any radio antennas!

Installation:

• Since this installation will require drilling, It is absolutely

necessary to make sure that no other vehicle components

will be damaged in the process. Check both sides of the

mounting surface before starting and if damage is

possible, select a different mounting location.

• Always deburr all holes and remove any metal filings from

the vehicle.

CENTER MOUNTING

TOP MOUNTING

Optional

mounting

hole

Optional

mounting

hole

Gasket

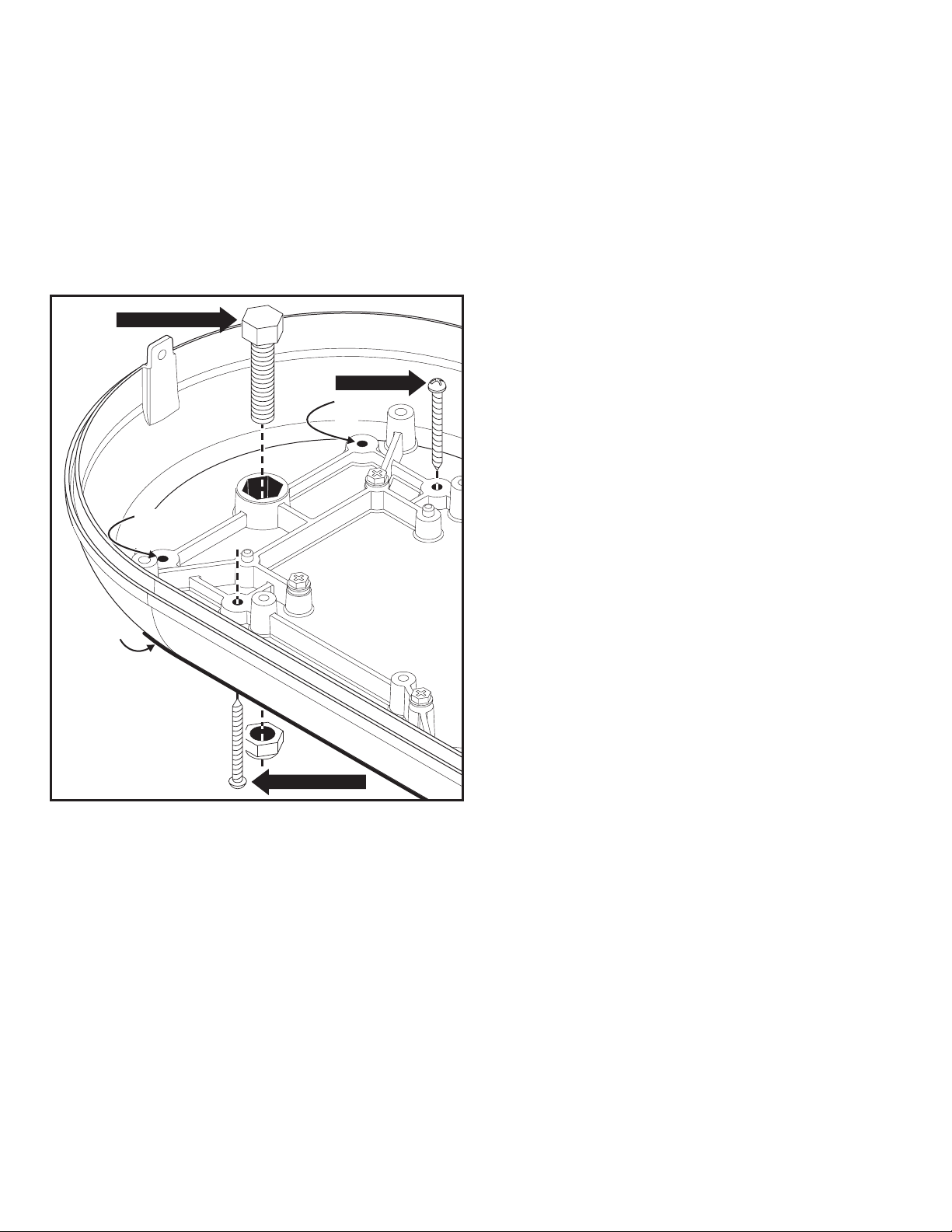

Fig. 1 Lightbar Base

BOTTOM MOUNTING

1. Drill the mounting holes you marked off in step 3 with a #29 drill bit

and the wire access hole with a 3/8” drill bit.

2. Install a 3/8” rubber grommet in the wire access hole and route the

wires through, then apply a silicone sealing compound around the

wires and grommet.

3. Carefully position the lightbar over the mounting holes and secure

the lightbar to the mounting surface using the #8 sheet metal

screws supplied.

4. Replace the dome with the 2 screws removed in step 1.

Bottom Mount:

1. Be sure the mounting area is relatively flat. Using the information

in figure 2 scribe the 4 mounting hole locations onto the mounting

surface.

2. Mark off the wire access hole, located right behind the lightbar.

3. Drill the mounting holes you marked off in step 1 with a 3/16” drill

bit and the wire access hole with a 3/8” drill bit.

4. Install a 3/8” rubber grommet in the wire access hole and route

the wires through, then apply a silicone sealing compound around

the wires and grommet.

5. Carefully position the lightbar over the mounting holes and secure

the lightbar to the mounting surface using the #8 sheet metal

screws supplied.

1. Be sure the mounting area is relatively flat. Using the information

in figure 2 scribe the 2 mounting hole locations onto the mounting

surface.

2. Mark off the wire access hole, located right behind the lightbar.

3. Drill the 2 mounting holes using an 11/32 drill bit and the wire

access hole using a 3/8” drill bit.

4. Tighten each locknut onto its bolt to draw the bolt head into the

base than remove the locknuts.

5. Align the bolts with the 2 mounting holes you drilled and position

the lighthead onto the mounting surface.

6. Install a 3/8” rubber access hole and route the wires through,

then apply a silicone sealing compound around the wires and

grommet.

7. Secure the lightbar with the locknuts provided.

Magnetic Mount:

Top Mount:

1. Remove the 2 screws at each end of the lightbar that secure the

dome to the base and remove the dome.

2. With a 3/16” drill bit, drill out the 4 mounting bosses in the base for

clearance holes for #8 sheet metal screws (Figs. 1 & 2).

3. Be sure the mounting area is relatively flat. Using the lightbar

base as a template, scribe the 4 mounting hole locations onto the

mounting surface.

4. Mark off the wire access hole located right behind the lightbar.

WARNING!The use of any magnetic or suction cup

mounted warning light on the outside of a vehicle, while in

motion, is not recommended and is at the sole discretion

and risk of the user.

Place the lightbar onto the vehicle, wire it to power and installation is

complete. If you have the cigarette plug model, just plug it into your

vehicle cigarette lighter and you are ready to go.

Page 2

Page 3

Fig. 2 Mounting Holes

Top view of base

WIRE EXIT HOLE HERE

4"

OPTIONAL

MOUNTING

CENTER

MOUNT

Fig. 3 Flash Tube

Replacement

MOUNTING

HOLES

LENS

SCREW

(QTY 2)

FRONT OF

LIGHTBAR

9"¾

12 "¾

Flash Tube Replacement:

1. Remove the 2 screws at each end of the lightbar that secure the

dome to the base and remove the dome.

WARNING!The strobe power supply is a high voltage device.

Do not remove flash tubes or dismantle strobe

light head assembly while in operation. Wait 10

minutes after turning power off before starting

work or trouble shooting.

FLASH TUBE

ASSY. SCREW

(QTY 2)

MOUNTING

SCREW

(QTY 3)

Note: If the edge of the base interferes with the screwdrivers

access to the lens screw, you may have to remove

the 3 mounting screws holding the beacon to the

base and lift the beacon.

2. Remove the beacons lens screws and remove the lens. If your

beacon is equipped with diamond mirrors, to gain access to the

beacon lens screws you may have to first remove the mirrors

3. Install the new flash tube making sure to align the 3 prongs on the

flash tube with the 3 slots in the power supply (Fig. 3).

4. Secure the new flash tube with its screws and reassemble the

beacon and lightbar.

Page 3

Page 4

The Guardian™ Power Supply:

If your lightbar comes equipped with the Guardian™ strobe power

supply, you will have a choice of 10 changeable flash patterns. This

power supply also comes with a Hi/Low feature to switch the beacons

from high to low power. These features are only available on

permanent mount models.

Wiring:

WARNING! The strobe light power supply is a high voltage

device. Do not touch or remove tube assembly in strobe light

head assemblies while in operation. Wait 10 minutes after

disconnecting the unit from its power source before starting

work or troubleshooting on power supply or system.

Pattern Selection

MOMENTARY

SWITCH

(For Programming)

Low Power Control

MOMENTARY

SWITCH

OR

SPST SWITCH

3 - VIOLET

4 - WHITE

WHITE

Option 1

VIOLET

Option 2

3 AMP FUSE

Fig. 4 Flash Patterns & Hi/Low

(Permanent Mount only)

1 - RED

2 - BLACK

RED

SPST SWITCH / 15 AMP

BLACK

12 VDC BATTERY

+12

VDC

10 AMP FUSE

WARNING! All customer supplied wires that connect to the

positive terminal of the battery must be sized to supply at

least 125% of the maximum operating current and FUSED

at

the battery to carry that load. DO NOT USE CIRCUIT

BREAKERS WITH THIS PRODUCT!

Note: All fuses and fuse blocks are customer supplied

1. Extend the 4 wires exiting the lightbar to the designations

shown in figure 4.

2. Connect the RED wire to a fuse block (customer supplied) and

then to the POSITIVE terminal on the battery. Do not install the

fuse until ALL of the wire connections are completed. Refer to

the wiring diagram for the appropriate fuse value needed.

3. Connect the black wire to the factory chassis ground typically

adjacent to the battery.

Low Power Control / Violet:

The type of switch used depends on how the operator wishes the Hi/

Low feature to function:

Latching Mode: By applying +voltage to the VIOLET power supply

wire for less than 1 sec., the power supply is “latched” into low power

operation. The unit must be turned off and then back on to restore

normal, Hi power operation. A momentary switch is desired for this.

Level Mode: Applying +voltage to the VIOLET power supply wire for

more than 1 sec. holds the power supply in low power mode until that

voltage is removed. A toggle switch is desired for this.

Pattern Selection / White:

This is a positive activation input. A momentary activation (less than 1

second) of the WHITE wire will change the default flash pattern to the

next available pattern. If the new pattern is active for more than 1

second, it will become the new default pattern. A momentary activation

(more than 1 second) will cause the power supply to change the

default flash pattern to the previous available pattern. If the input is tied

to positive while the unit is powered up, the default pattern will change

to CometFlash®.

Specifications: Guardian™ Power Supply

Input Voltage . . . . . . . . . . . . . . . . . . . . . 12.8 / 25.6 VDC ±20

Input Current . . . . . . . . . . . . . . . . . . . . . 3 AMP/ 1.6 AMP

Flash Rate . . . . . . . . . . . . . . . . . . . . . . . 120 CFPM

Fill Flash . . . . . . . . . . . . . . . . . . . . . . . . . 100ms

Energy . . . . . . . . . . . . . . . . . . . . . . . . . . HI 1.9/1.9/1.9/6 JOULES

LO 1.9/1.9/1.9/1.9 JOULES

Default Pattern . . . . . . . . . . . . . . . . . . . . CometFlash®

Available Flash Patterns:

1 - CometFlash® 120 . . . . . . . . . . . . . . 120 CFPM @ 200 mS/100mS

2 - TripleFlash™ 150. . . . . . . . . . . . . . . . 150 FPM @ 200 mS/100mS

3 - DoubleFlash 180 . . . . . . . . . . . . . . . . 180 FPM @ 230 mS/100mS

4 - Single Flash 400 . . . . . . . . . . . . . . . . . . . . . . 400 FPM @ 150 mS

5 - ActionFlash™ . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Comet 4 Singles

6 - ModuFlash™ . . . . . . . . . . . . . . . . . .175 FPM @ 384mS to 150mS

7 - MicroBurst II™. . . . . . . . . . . . . . . . . . .200 FPM @ 200mS/100mS

8 - MicroBurst III™ . . . . . . . . . . . . . . . . . .190 FPM @ 200mS/100mS

9 - LongBurst™. . . . . . . . . . . . . . . . . . . . . . . . . . 140 FPM @ 100 mS

10 - ActionScan™ . . . . . . . . . . . . . . . . . . . . . . . All Patterns / Random

Page 4

Loading...

Loading...