Page 1

®

ENGINEERING COMPANY INC.

51 Winthrop Road

Chester, Connecticut 06412-0684

DOT-LED® All LED DOT System

Installation Guide:

Phone: (860) 526-9504

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: canadiansales@whelen.com

Customer Service e-mail: custserv@whelen.com

Safety First

This document provides all the necessary information to allow your Whelen product to be properly and safely installed.

Before beginning the installation and/or operation of your new product, the installation technician and operator must

read this manual completely. Important information is contained herein that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of automotive electronics,

systems and procedures.

• Failure to use specified installation parts and/or hardware will void the product warranty!

• If mounting this product requires drilling holes, the installer MUST be sure that no vehicle components or other

vital parts could be damaged by the drilling process. Check both sides of the mounting surface before drilling

begins. Also de-burr any holes and remove any metal shards or remnants. Install grommets into all wire

passage holes.

• If this manual states that this product may be mounted with suction cups, magnets, tape or Velcro®, clean the

mounting surface with a 50/50 mix of isopropyl alcohol and water and dry thoroughly.

• Do not install this product or route any wires in the deployment area of your air bag. Equipment mounted or

located in the air bag deployment area will damage or reduce the effectiveness of the air bag, or become a

projectile that could cause serious personal injury or death. Refer to your vehicle owner’s manual for the air bag

deployment area. The User/Installer assumes full responsibility to determine proper mounting location, based

on providing ultimate safety to all passengers inside the vehicle.

• For this product to operate at optimum efficiency, a good electrical connection to chassis ground must be

made. The recommended procedure requires the product ground wire to be connected directly to the NEGATIVE

(-) battery post.

• If this product uses a remote device to activate or control this product, make sure that this control is located in

an area that allows both the vehicle and the control to be operated safely in any driving condition.

• Do not attempt to activate or control this device in a hazardous driving situation.

• If this product contains strobe light(s), halogen light(s) or high-intensity LEDs, do not stare directly into these

lights at a close distance. Momentary blindness and/or eye damage could result.

• Use only soap and water to clean the outer lens. Use of other chemicals could result in premature lens cracking

(crazing) and discoloration. Lens in this condition have significantly reduced effectiveness and should be

replaced immediately. Inspect and operate this product regularly to confirm its proper operation and mounting

condition. Do not use a pressure washer to clean this product.

• It is recommended that these instructions be stored in a safe place and referred to when performing

maintenance and/or reinstallation of this product.

• FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND INSTRUCTIONS COULD RESULT IN DAMAGE TO

THE PRODUCT OR VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR PASSENGERS!

Automotive: DOT

For warranty information regarding this product, visit www.whelen.com/warranty

©2003 Whelen Engineering Company Inc.

Form No.13861G (110812)

Page 1

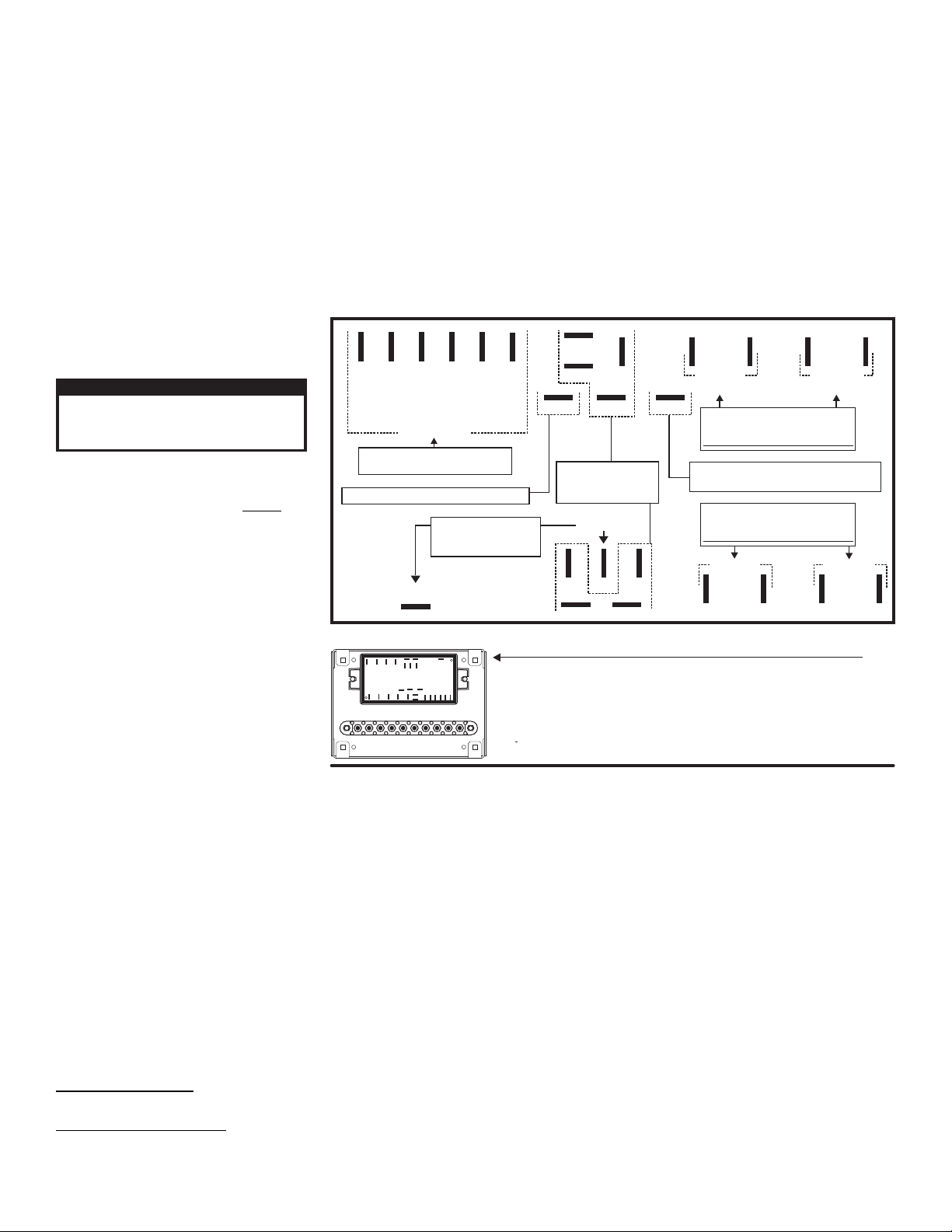

Page 2

CAUTION! DO NOT LOOK DIRECTLY AT

THESE LED’S WHILE THEY ARE ON.

MOMENTAR Y BLINDNESS AND/OR EYE

DAMAGE COULD RESULT!

IMPORTANT WARNING!

Mounting the Flasher: One of the most common places chosen is against the rear wall of the cab. This is a good choice for several reasons, such

GND

GND

GND GND

GND

GND

GND

GND

Connect to the Negative Battery Terminal(-)

Plug Positive (+) wires from lighting

options into the output terminals.

MAXIMUM 5 AMPS PEAK EACH OUTPUT

Plug Negative (-) wires

from lighting options

into the GND terminals.

These terminals are to be

used for connecting the

optional Photocell.

(-) BAT

Photocell (+)

Photocell (-)

Scan-Lock

Low Power

Outputs

1&2

Outputs

3&4

Outputs

5&6

Outputs

7&8

Outputs

3&4

4

6

1

7

2

8

3

5

Outputs

7&8

Outputs

1&2

Outputs

5&6

Control Wires

(+) BAT

Connect to user supplied switches.

Fuse each control wire @ 1 AMP.

IMPORTANT: Outputs 1 thru 8 will handle a maximum of 5 AMPS Peak each.

IMPORTANT! Do NOT mount the Junction Box where it could be

exposed to moisture. The recommended mounting location

is within the passenger compartment.

Fig. 1 Flasher

WARNING: All Customer supplied wires that connect to the positive terminal of the battery

must be sized to supply at least 125% of the maximum operating current and fused "at the

battery" to carry that load. DO NOT USE CIRCUIT BREAKERS WITH THIS PRODUCT!

Plug Positive (+) wires from lighting

options into the output terminals.

Connect to the Positive (+) Battery Terminal

Fuse @ 25 AMPS.

MAXIMUM 5 AMPS PEAK EACH OUTPUT

as good air circulation and heat dissipation.

• The flasher is not waterproof. The mounting area must be dry and free from elements that could damage the unit (road salt, sand, snow).

• The flasher should not be exposed to excessive heat.

• The mounting area should be easily accessible for wiring and service purposes.

• Mounting the flasher to a metal surface is recommended for optimum heat dissipation.

• Be sure that the backside of the proposed mounting surface does not hide any wires, cables, fuel lines, etc., that could be damaged by

drilling the mounting holes.

• Select a location towards the middle of the cab.

• Be sure that the mounting location is a minimum of 8” from the cab floor.

• The flasher should be mounted on as flat a surface as possible.

DOT-LED®: Included are two, 10-12 gauge and

twenty four, 14-16 gauge Faston connectors to

connect your lighting options to the flasher and to

connect your power wires.

WARNING! All customer supplied wires that

connect to the positive terminal of the battery

must be sized to supply at least 125% of the

maximum operating current and FUSED

battery to carry that load. DO NOT USE CIRCUIT

BREAKERS WITH THIS PRODUCT!

IMPORTANT! Before returning the vehicle to

active service, visually confirm the proper

operation of this product, as well as all vehicle

components/equipment

Flasher Connection & Operation:

Connect your lighting options (Lightheads, beacons

etc...) to the flasher as shown. Connect the positive

wire of the lighting option to outputs 1 thru 8

(Each outlet will handle 5 AMPS PEAK). Connect

the negative wires of your lighting options to any of

the ground terminals. All terminals take a Faston

connector (supplied). Applying +12V DC to the

positive wire will activate its outlet or function (See

wiring diagram).

NOTE: Keep in mind that each control wire

activates two outlets each. Be sure to connect

lights that need to be on the same circuit accordingly, such as 2 front lightheads or both rear options would be. Fuse the control wires at 1 AMP each.

Hi/Low Power: This feature allows the user to step the unit down to low power operation for nighttime use

Option 1 / Latching Mode: By applying +12V DC to the "Hi/Low Power Control Wire” for less than 1 second, the system is latched into low power operation. The unit

must be turned off and then back on to restore normal high power (Momentary Switch).

Option 2 / Level Mode: Applying +12V DC to the "Hi/Low Power Control Wire” for more than 1 second holds the system in low power until the voltage is removed

(Toggle Switch).

Photocell (optional): If you have the photocell option, plug the BLACK wire into the negative photocell terminal, the RED wire into the positive photocell terminal and

the VIOLET wire into the low power terminal of the flasher (see wiring diagram). With the photocell hooked up, the system will switch to low power automatically at

night. Mount the photocell where it will be exposed to daylight, away from any vehicle lighting.

Scan-Lock™:

Scan-Lock allows the user to choose from several flash patterns. The entire system will display the pattern you choose (All outputs will display the same pattern).

TO CYCLE FORWARD THROUGH FLASH PATTERNS: Activate any of the outputs by applying power. With the outputs activated apply +VBAT to the Scan-Lock wire

for less than 1 second and release. Repeat to advance to next pattern.

TO CHOOSE A PATTERN: While cycling through the available flash patterns allowing a pattern to run for at least 5 seconds will configure it as the default pattern.

Now when activated the entire system will display this flash pattern.

TO RESET TO THE FACTORY DEFAULT PATTERN: Turn off all functions. Apply +VBAT to the Scan-lock wire while turning any of the functions back on. The system

is now restored to its factory default pattern.

Available Flash Patterns:

SignalAlert™ All outputs flash simultaneously > 4 - CometFlash® 75 Outputs 1, 2, 3 & 4 alternate with 5, 6, 7 & 8 > 5 - CometFlash® 75 Outputs 1, 3, 5 & 7 Alternate

with 2, 4, 6 & 8 > 6 - CometFlash® 75 All outputs flash simultaneously.

Available SSNF Flash Patterns:

with 3, 4, 5 & 6 > 8 - SSNF: Outputs 1, 4, 5 & 8 alternate with 2, 3, 6 & 7 > 9 - SSNF: All outputs flash simultaneously

1 - SignalAlert™ Outputs 1, 2, 3 & 4 alternate with 5, 6, 7 & 8 > 2 - SignalAlert™ Outputs 1, 3, 5 & 7 alternate with 2, 4, 6 & 8 > 3 -

at the

(Outputs 1, 2, 3 & 4 display CometFlash® and Outputs 5, 6, 7 & 8 display SingleFlash) 7 - SSNF: Outputs 1, 2, 7 & 8 alternate

Page 2

Page 3

REAR / 400 Series

FRONT OPTIONS:

FRONT LIGHTING OPTIONS FOR THE SYSTEMS

COVERED BY THIS MANUAL

A L L W I R E S C O N N E C T D I R E C T L Y

T O F L A S H E R .

BLK RED -

GROUND

POSITIVE

L31 Series Super-LED® Beacon

01-0684467-A6B

Micro Edge® 400 DOT Remote (3 Lt.)

01-06869641A2

01-0686929-1A1

01-06869641A0

01-0686929-1A2

GRN REAR: + POS. /GRN REAR: + POS. /

BLK: GND / FRNT & SIDEBLK: GND / FRNT & SIDE

RED: + POS. / FRNT & SIDERED: + POS. / FRNT & SIDE

WHT REAR: GND /WHT REAR: GND /

FRONTFRONT

RED:

BLK:

GRN:

WHT:

POSITIVE / FRONT

GROUND / FRONT

POSITIVE / REAR

GROUND / REAR

RED:

BLK:

GRN:

WHT:

POSITIVE / FRONT

GROUND / FRONT

POSITIVE / REAR

GROUND / REAR

Ultra Freedom Micro Edge®

01-0686900-A2

01-0686900-A3

FRONT FRONT

Micro 400 "3" Light DOT 01-06869291_1

BLK GND: / FRNT & SIDE

WHT GND REAR LEDs: /

GRN: + POS. / REAR LEDs

RED: + POS. / FRNT & SIDE

BLK GROUND: / FRNT & SIDE

WHT GND REAR LEDs: /

GRN: + POS. / REAR LEDs

RED: + POS. / FRNT & SIDE

FRONTFRONT

TO

VEHICLE

01-0686731-AXA / SQUARE

BRAKE-TAIL-TURN

400 SERIES

SPLIT

400 SERIES

SPLIT

400 SERIES

SPLIT

46-0764073-30

(

5/C

)

POS B

POS C

POS A

YEL GRN

WHITE

BROWN

-

-

-

/

46-076D170-02A (4/C)

TO

FLASHER

46-076D185-30 (2/C)

POS POS 21 - -RED BLK

POS 2 - RED

POS 4 - BLK

POS 5 - BLK

POS 6 - RED

POS 1 - RED

POS 3 - BLK

(+ POS.)

GROUND

YEL/GRN

WHITE

BROWN

BLU & WHT/BLK Not Used

(+ POSITIVE)

BRAKE/TURN

GROUND

(+ POS.) TAIL

6 POSITION SOCKET

CONNECTOR

WEDGE / 6 POS SOCKET

BUSSED CONNECTOR

With TIR3

400 SERIES

SPLIT

400 SERIES

SPLIT

400 SERIES

SPLIT

TO

FLASHER

TIR3

01-0686731-AOA

SQUARE

46-076D184-00 (6/C) 46-076D185-30 (2/C)

POS

POS 2

1 --RED

BLK

POS 1 - RED

POS 4 - BLK

(+ POS.)

GROUND

POS POS 21 - -RED BLK

8 POSITION SOCKET

CONNECTOR

WEDGE / 8 POS SOCKET

BUSSED CONNECTOR

POS 2 - RED

POS 3 - BLK

POS 5 - BLK

POS 6 - BLK

POS 7 - RED

POS 8 - RED

400 SERIES

BRAKE-TAIL-TURN

01-0686731-AXA

SQUARE

46-0764073-30

(

5/C

)

TO VEHICLE

400 SERIES

SPLIT

400 SERIES

SPLIT

400 SERIES

SPLIT

POS B

POS C

POS A

YEL GRN

WHITE

BROWN

-

-

-

/

With TIR3

TO

FLASHER

8 POSITION SOCKET

CONNECTOR

WEDGE / 8 POS SOCKET

BUSSED CONNECTOR

TIR3

46-076D184-00 (6/C) 46-076D185-30 (2/C)

POS

POS 2

1 --RED

BLK

POS 1 - RED

POS 4 - BLK

(+ POS.)

GROUND

POS POS 21 - -RED BLK

YEL/GRN

WHITE

BROWN

BLU & WHT/BLK Not Used

(+ POSITIVE)

BRAKE/TURN

GROUND

(+ POS.) TAIL

POS 2 - RED

POS 3 - BLK

POS 5 - BLK

POS 6 - BLK

POS 7 - RED

POS 8 - RED

46-0764073-30

(

5/C

)

TO

VEHICLE

400 SERIES

BACK-UP

400 SERIES

BACK-UP

400 SERIES

BACK-UP

400 SERIES

BRAKE-TAIL-TURN

01-0686731-AXVA / SQUARE

400 SERIES

SPLIT

400 SERIES

SPLIT

400 SERIES

SPLIT

POS B

POS C

POS A

YEL GRN

WHITE

BROWN

-

-

-

/

POS A

POS C

BLUE

WHT BLK

-

- /

With TIR3

8 POSITION SOCKET

CONNECTOR

WEDGE / 8 POS SOCKET

BUSSED CONNECTOR

TO

FLASHER

TIR3

46-076D184-00 (6/C) 46-076D185-30 (2/C)

POS

POS 2

1 --RED

BLK

BLU

WHT BLK

BACK-UP

GROUND/

(+ POS.)

YEL/GRN

WHITE

BROWN

(+ POS.)

BRAKE/TURN

GROUND

(+ POS.) TAIL

POS 2 - RED

POS 3 - BLK

POS 5 - BLK

POS 6 - BLK

POS 7 - RED

POS 8 - RED

POS 1 - RED

POS 4 - BLK

(+ POS.)

GROUND

01-0686731-AOA

SQUARE

46-076D170-02A (4/C)

400 SERIES

SPLIT

400 SERIES

SPLIT

400 SERIES

SPLIT

TO

FLASHER

46-076D185-30 (2/C)

POS 1 - RED

POS 3 - BLK

(+ POS.)

GROUND

POS POS 21 - -RED BLK

6 POSITION SOCKET

CONNECTOR

WEDGE / 6 POS SOCKET

BUSSED CONNECTOR

POS 2 - RED

POS 4 - BLK

POS 5 - BLK

POS 6 - RED

46-0764073-30

(

5/C

)

TO

VEHICLE

POS B

POS C

POS A

YEL GRN

WHITE

BROWN

-

-

-

/

POS A

POS C

BLUE

WHT BLK

-

- /

6 POSITION SOCKET

CONNECTOR

WEDGE / 6 POS SOCKET

BUSSED CONNECTOR

46-076D170-02A (4/C)

TO

FLASHER

46-076D185-30 (2/C)

POS 2 - RED

POS 4 - BLK

POS 5 - BLK

POS 6 - RED

POS 1 - RED

POS 3 - BLK

(+ POS.)

GROUND

BLU

WHT BLK

BACK-UP

GROUND/

(+ POS.)

YEL/GRN

WHITE

BROWN

(+ POS.)

BRAKE/TURN

GROUND

(+ POS.) TAIL

01-0686731-AXVA / SQUARE

BRAKE-TAIL-TURN

400 SERIES

BACK-UP

400 SERIES

BACK-UP

400 SERIES

BACK-UP

400 SERIES

SPLIT

400 SERIES

SPLIT

400 SERIES

SPLIT

POS POS 21 - -RED BLK

POS POS 21 - -RED BLK

Page 3

Page 4

REAR / 500 Series

TIR3

INSTALLATION

STRAIN

RELIEF

REAR / 700 Series

TO FLASHER

RED

B

LACK

(+ POSITIVE)

GROUND

500 SERIES

SPLIT

500 SERIES

SPLIT

500 SERIES

SPLIT

01-0683918-A0 / ANGLED

46-076D185-30

(

2/C

)

POS

POS 2

1 --RED

BLK

700 TIR LINEAR LED700 TIR LINEAR LED700 TIR LINEAR LED

01-0686737-A0 / SQUARE

TO FLASHER

RED

BLACK

(+ POSITIVE)

GROUND

46-076D185-30

(

2/C

)

POS

POS

1 2 -

RED

BLK

4 X 5/8 PLASTI

LOC SCREW

#4 FLAT

WASHER

TIR3 LIGHTHEAD

GROMMET

1/4 - 20 X 1 PFHMS

1/4 - 20 ELASTIC

STOP NUT

DOT TIR3

MOUNTING

PLATE

NUT

FLAT WASHER

CLIP

TO VEHICLE

BRAKE-TAIL-TURN

700 TIR LINEAR LED700 TIR LINEAR LED700 TIR LINEAR LED

01-0686737-AX / SQUARE

46-0764073-30

(

5/C

)

46-076D185-30

(

2/C

)

TO FLASHER

RED

BLACK

(+ POSITIVE)

GROUND

POS B

POS C

POS A

YEL GRN

WHITE

BROWN

-

-

-

/

POS POS 21 - -RED BLK

YEL/GRN

WHITE

BROWN

BLU & WHT/BLK Not Used

(+ POSITIVE)

BRAKE/TURN

GROUND

(+ POS.) TAIL

TO

FLASHER

46-076D185-30 (2/C)

With TIR3

700 TIR LINEAR LED700 TIR LINEAR LED700 TIR LINEAR LED

01-0686737-AO

SQUARE

TIR3

46-076D170-02A(4/C

)

POS 2 - RED

POS 4 - BLK

POS 5 - BLK

POS 6 - RED

6 POSITION SOCKET

CONNECTOR

WEDGE / 6 POS SOCKET

BUSSED CONNECTOR

POS 1 POS 2 -

RED

BLK

POS 1 - RED

POS 3 - BLK

(+ POS.)

GND

SOCKET

CONNECTOR

With TIR3

01-0686737AXV / SQUARE

TO VEHICLE

BRAKE-TAIL-TURN

700 TIR LINEAR LED700 TIR LINEAR LED

700 LED BACK-UP

700 LED BACK-UP700 LED BACK-UP

46-0764073-30

(

5/C

)

POS B

POS C

POS A

YEL GRN

WHITE

BROWN

-

-

-

/

POS

POS

BLUE

2 WHT BLK

1 -

- /

POS POS 21 - -RED BLK

6 POSITION SOCKET

CONNECTOR

WEDGE / 6 POS SOCKET

BUSSED CONNECTOR

TO

FLASHER

46-076D185-30 (2/C)

TIR3

46-076D170-02A(4/C

)

POS 2 - RED

POS 4 - BLK

POS 5 - BLK

POS 6 - RED

POS 1 - RED

POS 3 - BLK

(+ POS.)

GND

YEL/GRN

WHITE

BROWN

(

+12V BRAKE

)

(

GROUND

)

(

+12V TAIL

)

BLUE

WHT/BLK

(

+12V)BACK-UP

(

GROUND

)

500 SERIES

SPLIT

500 SERIES

SPLIT

500 SERIES

SPLIT

BRAKE-TAIL-TURN

01-0683918-AXU/ ANGLED

500 SERIES/ STEADY

TO VEHICLE

46-0764073-30

(

5/C

)

46-0764546-30(2/C

)

TO FLASHER RED

BLACK

(+ POSITIVE)

GROUND

POS B

POS C

POS A

YEL GRN

WHITE

BROWN

-

-

-

/

POS

POS

BLUE

2 WHT BLK

1 -

- /

POS POS 21 - -RED BLK

YEL/GRN

WHITE

BROWN

(

+12V BRAKE

)

(

GROUND

)

(

+12V TAIL

)

BLUE

WHT/BLK

(

+12V)BACK-UP

(

GROUND

)

TO FLASHER RED

BLACK

(+ POSITIVE)

GROUND

TO VEHICLE

46-0764073-30

(

5/C

)

POS B

POS C

POS A

YEL GRN

WHITE

BROWN

-

-

-

/

46-0764546-30(2/C

)

POS POS 21 - -RED BLK

YEL/GRN

WHITE

BROWN

BLU & WHT/BLK Not Used

(+ POSITIVE)

BRAKE/TURN

GROUND

(+ POS.) TAIL

500 SERIES

SPLIT

500 SERIES

SPLIT

500 SERIES

SPLIT

BRAKE-TAIL-TURN

01-0683918-AX / ANGLED

With TIR3

01-0686737-AX 700

SQUARE

46-0764073-30

(

5/C

)

POS B

POS C

POS A

YEL GRN

WHITE

BROWN

-

-

-

/

TO VEHICLE

YEL/GRN

WHITE

BROWN

BLU & WHT/BLK Not Used

(+ POSITIVE)

BRAKE/TURN

GROUND

(+ POS.) TAIL

6 POSITION SOCKET

CONNECTOR

WEDGE / 6 POS SOCKET

BUSSED CONNECTOR

TO

FLASHER

46-076D185-30 (2/C)

TIR3

46-076D170-02A(4/C

)

POS 2 - RED

POS 4 - BLK

POS 5 - BLK

POS 6 - RED

POS 1 - RED

POS 3 - BLK

(+ POS.)

GND

BRAKE-TAIL-TURN

700 TIR LINEAR LED700 TIR LINEAR LED

POS POS 21 - -RED BLK

DOT

HOUSING

DOT

HOUSING

CLIP

PIN CONNECTOR

MOUNTING

STUD

MOUNTING

STUD

MOUNTING

STUD

01-0686737-AXV / SQUARE

TO VEHICLE

46-0764073-30

(

5/C

)

46-076D185-30

(

2/C

)

TO FLASHER

RED

BLACK

(+ POSITIVE)

GROUND

POS B

POS C

POS A

YEL GRN

WHITE

BROWN

-

-

-

/

POS

POS

BLUE

2 WHT BLK

1 -

- /

POS

POS

1 2 -

RED

BLK

YEL/GRN

WHITE

BROWN

(

+12V BRAKE

)

(

GROUND

)

(

+12V TAIL

)

BLUE

WHT/BLK

(

+12V)BACK-UP

(

GROUND

)

BRAKE-TAIL-TURN

700 TIR LINEAR LED700 TIR LINEAR LED

700 LED BACK-UP700 LED BACK-UP

DOT

HOUSING

Page 4

Page 5

3.

RUN BACK ALONG

FRAME RAIL, INTO CAB

AND HOOK TO FLASHER

(SAME FOR OTHER SIDE)

1.

RUN WIRE FROM , DOWN FRONT AND ALONG

UNDERSIDE OF DUMP BODY TO HINGE POINT . . .

LIGHTS

2.

AT THE HINGE POINT,

LEAVE A12 INCH SERVICE LOOP

RUN WIRE FROM DOWN DUMP

BODY, ALONG FRAME RAILS, TO FLASHER.

REMOTE HEAD

(SAME INSTALLATION FOR OTHER SIDE)

DUMP HINGE POINT

Locking

Fixture

Locking

Cuff

Flex Tube

Ty-Wrap

Locking

Nut

Primary

Shaft

Housing

Plastic

Washer

Flex Tube Assembly:

1.

2.3.4.5.6.

7.

8.

9.

Insert the harness cables into the flex tube.

Be sure there is enough length of cable

pulled through the other end of the flex tube.

Fit the locking cuff onto the flex tube.

Slide the locking fixture onto the cables.

Slide the primary shaft housing onto the cables.

Position the locking fixture inside the primary

shaft housing.

Fit the flex tube completely around the end

of the primary shaft housing.

Tighten the locking cuff around the primary

shaft housing.

Insert the harness-flex tube assy. through

the wire opening in the remote head.

Secure the assembly with the locking

nut and install plastic washer and Ty-wrap

for strain relief then tighten securely.

White plastic

washer and

Ty-wraps for

strain relief

Housing

Cable

Cable

SIDE

VIEW

6 X 1-1/2"

PPHSMS

TRIPLE HOUSING

400 OPTIC

LENS

400 SERIES

LIGHTHEAD

MOUNTING FACE PLATE

400 SERIES

IMPORTANT! Rear housings should be mounted in a full upright, vertical position

BACK PLATE

MOUNTING FACEPLATE

#6 X 1/2" PPHSMS

700 SERIES LIGHTHEAD

700 SERIES

REAR HOUSING ASSEMBLY:

FLANGE

500 SERIES

LIGHTHEAD

GASKET

GROMMET

TRIPLE HOUSING

500 SERIES

#10 X 3/4"

PPHSMS

IMPORTANT: ALL CAPS

MUST BE INSTALLED IN

UNUSED HOLES.

Page 5

Loading...

Loading...