Page 1

Installation Guide:

®

®

Dominator™ mounting bracket

Model DBKT6 / 2012 Tahoe Hatchback

ENGINEERING COMPANY INC.

51 Winthrop Road,

Chester, Connecticut 06412-0684

Phone: (860) 526-9504

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: canadiansales@whelen.com

Customer Service e-mail: custserv@whelen.com

Installation:

This bracket mounts to the

rear window latch housing.

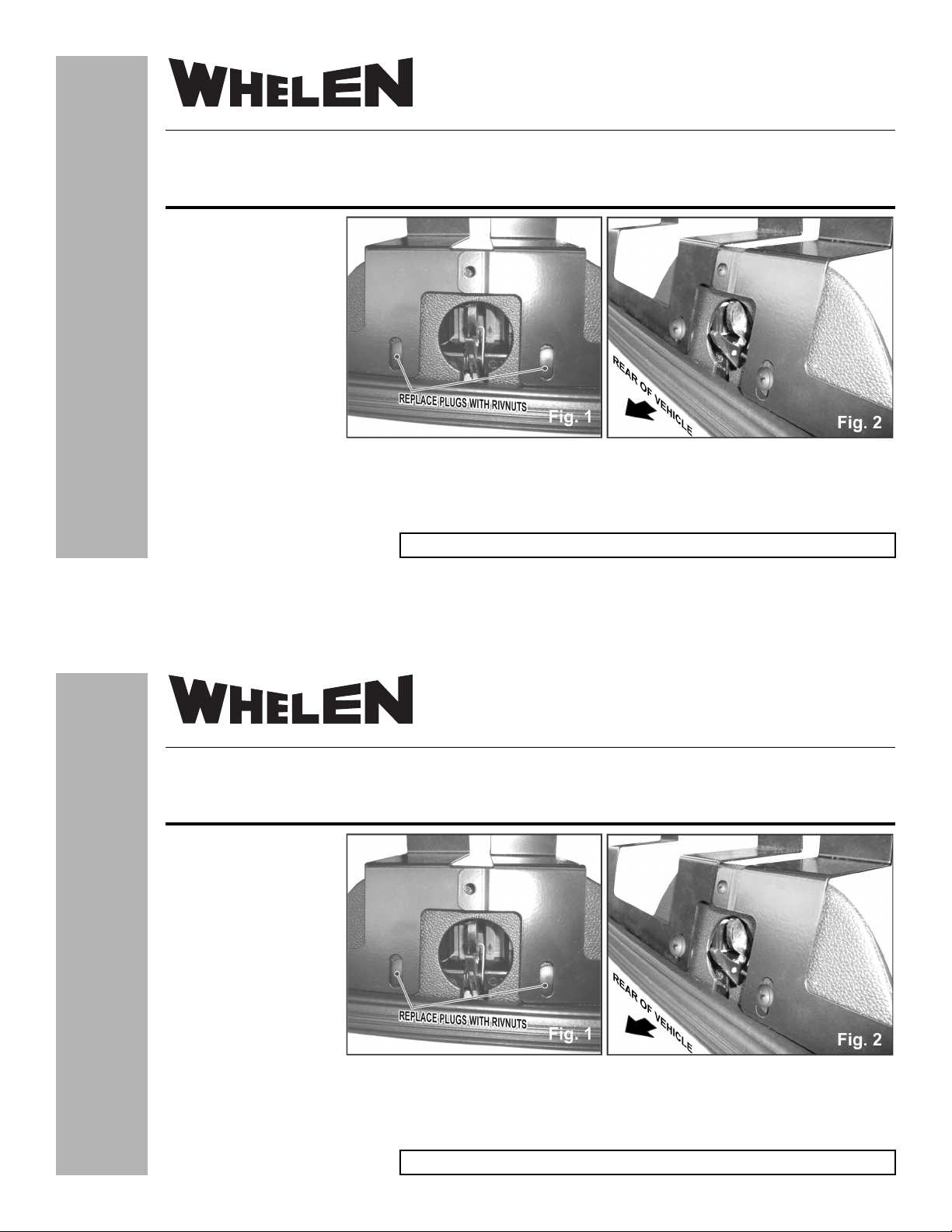

1. Remove the end cap on

the Dominator™ and add a

fourth carriage bolt, then

replace the end cap (Fig.

3).

2. Remove the 2 existing

christmas tree plugs on

either side of the window

latch and install 2 rivnuts.

3. Install the bracket onto the

vehicle and install the

Dominator™ lightbar onto the bracket using the supplied mounting hardware (Figs. 2 & 4).

IMPORTANT! It is the responsibility of the installation technician to make sure that the installation and operation of this

product will not interfere with or compromise the operation or efficiency of any vehicle equipment. Before returning the

vehicle to active service, visually confirm the proper operation of this product, as well as all vehicle components/equipment.

Automotive: Lightbars

©2012 Whelen Engineering Company Inc.

Form No.14616 (091212)

For warranty information regarding this product, visit www.whelen.com/warranty

Installation Guide:

Dominator™ mounting bracket

Model DBKT6 / 2012 Tahoe Hatchback

ENGINEERING COMPANY INC.

51 Winthrop Road,

Chester, Connecticut 06412-0684

Phone: (860) 526-9504

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: canadiansales@whelen.com

Customer Service e-mail: custserv@whelen.com

Installation:

This bracket mounts to the

rear window latch housing.

1. Remove the end cap on

the Dominator™ and add a

fourth carriage bolt, then

replace the end cap (Fig.

3).

2. Remove the 2 existing

christmas tree plugs on

either side of the window

latch and install 2 rivnuts.

3. Install the bracket onto the

vehicle and install the

Dominator™ lightbar onto the bracket using the supplied mounting hardware (Figs. 2 & 4).

IMPORTANT! It is the responsibility of the installation technician to make sure that the installation and operation of this

product will not interfere with or compromise the operation or efficiency of any vehicle equipment. Before returning the

vehicle to active service, visually confirm the proper operation of this product, as well as all vehicle components/equipment.

Automotive: Lightbars

©2012 Whelen Engineering Company Inc.

Form No.14616 (091212)

For warranty information regarding this product, visit www.whelen.com/warranty

Page 1

Page 2

#10 FLAT

WASHER

(4)

DISK GASKET

#10-24

ELASTIC

STOP NUT

(4)

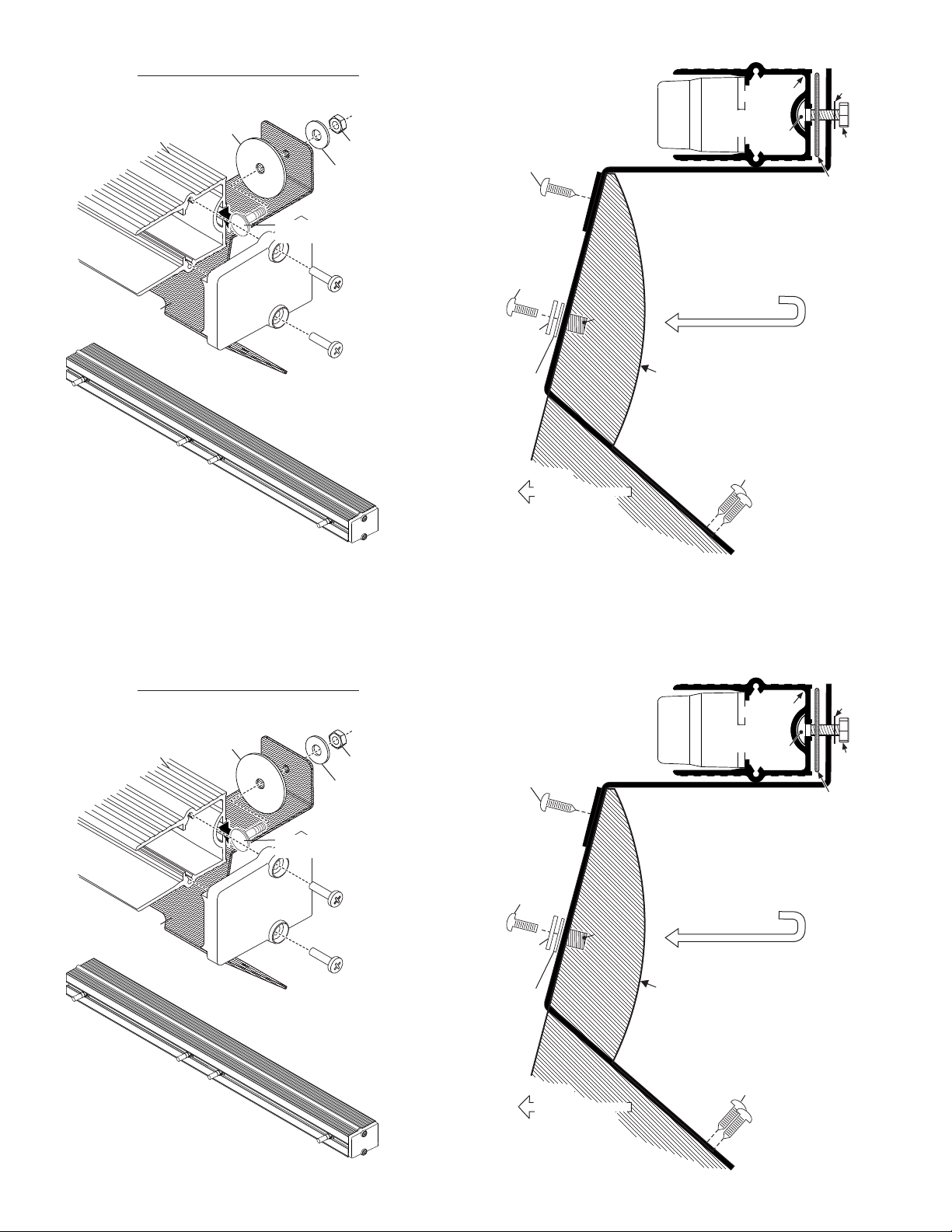

MOUNTING THE LIGHTBAR TO THE BRACKET

#10 FLAT

WASHER

DISK GASKET

EXTRUSION

BRACKET

#10-24

ELASTIC

STOP NUT

#10-24 X 5/8

CARRIAGE BOLT

1/4 - 20 X 1-1/4

PHILLIPS PAN

HEAD METAL

SCREW (2)

#10 X 1/2" PHILLIPS

PAN HEAD SHEET

METAL SCREW (1)

#10 X 1/2" PHILLIPS

PAN HEAD SHEET

METAL SCREW (2)

1/4X .328 ID

FLATWASHER

(2)

1/4 " INTERNAL

TOOTH LOCK

WASHER (2)

1/4 - 20 X .580"

RIV NUT (2)

1/4 - 20 X .580"

RIV NUT (2)

1/4 - 20 X .580"

RIV NUT (2)

10 - 24 X 5/8"

CARRIAGE

BOLT (4)

IMPORTANT NOTE:

This installation uses Rivnuts® to secure

the brackets to the vehicle. This type of

hardware requires the use of a specialized

installation tool. Refer to the owners manual

included with this tool for proper installation.

Be sure to follow the mounting hole

specifications precisely.

En d v i e w of

extrusion with

endcap removed.

BASE

EXTRUSION

WINDOW

LATCH

HOUSING

REAR OF VEHICLE

Fig. 3 Fig. 4

#10 FLAT

WASHER

(4)

DISK GASKET

#10-24

ELASTIC

STOP NUT

(4)

MOUNTING THE LIGHTBAR TO THE BRACKET

#10 FLAT

WASHER

DISK GASKET

EXTRUSION

BRACKET

#10-24

ELASTIC

STOP NUT

#10-24 X 5/8

CARRIAGE BOLT

1/4 - 20 X 1-1/4

PHILLIPS PAN

HEAD METAL

SCREW (2)

#10 X 1/2" PHILLIPS

PAN HEAD SHEET

METAL SCREW (1)

#10 X 1/2" PHILLIPS

PAN HEAD SHEET

METAL SCREW (2)

1/4X .328 ID

FLATWASHER

(2)

1/4 " INTERNAL

TOOTH LOCK

WASHER (2)

1/4 - 20 X .580"

RIV NUT (2)

1/4 - 20 X .580"

RIV NUT (2)

1/4 - 20 X .580"

RIV NUT (2)

10 - 24 X 5/8"

CARRIAGE

BOLT (4)

IMPORTANT NOTE:

This installation uses Rivnuts® to secure

the brackets to the vehicle. This type of

hardware requires the use of a specialized

installation tool. Refer to the owners manual

included with this tool for proper installation.

Be sure to follow the mounting hole

specifications precisely.

En d v i e w of

extrusion with

endcap removed.

BASE

EXTRUSION

WINDOW

LATCH

HOUSING

REAR OF VEHICLE

Fig. 3 Fig. 4

Page 2

Loading...

Loading...