Page 1

®

ENGINEERING COMPANY INC.

CAUTION

Loud siren noise can cause

hearing damage and/or loss.

Refer to OSHA Section 1910.95 prior

to putting ANY siren into service!

Wear

Protection!

ACTIVATION OF THIS

SIREN MAY DAMAGE

UNPROTECTED EARS!

51 Winthrop Road

Chester, Connecticut 06412-0684

Phone: (860) 526-9504

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: canadiansales@whelen.com

Customer Service e-mail: custserv@whelen.com

DANGER! Sirens produce extremely loud emergency warning tones! Exposure to these tones without proper and adequate hearing protection,

could cause ear damage and/or hearing loss! The Occupational Safety & Health Administration (www.osha.gov) provides information necessary to

determine safe exposure times in Occupational Noise Exposure Section 1910.95. Until you have determined the safe exposure times for your

specific application, operators and anyone else in the immediate vicinity should be required to wear an approved hearing protection device.

FAILURE TO FOLLOW THIS RECOMMENDATION COULD CAUSE HEARING LOSS!

Whelen’s emergency vehicle warning devices must be properly mounted and wired in order to be effective and safe. Read and follow all of Whelen’s

written instructions when installing or using this device. Emergency vehicles are often operated under high speed stressful conditions which must be

accounted for when installing all emergency warning devices. Controls should be placed within convenient reach of the operator so that he can operate

the system without taking his eyes off the roadway. Emergency warning devices can require high electrical voltages and/or currents. Properly protect and

use caution around live electrical connections.Grounding or shorting of electrical connections can cause high current arcing, which can cause personal

injury and/or vehicle damage, including fire. Many electronic devices used in emergency vehicles can create or be affected by electromagnetic

interference. Therefore, after installation of any electronic device it is necessary to test all electronic equipment simultaneously to insure that they operate

free of interference from other components within the vehicle. Never power emergency warning equipment from the same circuit or share the same

grounding circuit with radio communication equipment. All devices should be mounted in accordance with the manufacturer’s instructions and securely

fastened to vehicle elements of sufficient strength to withstand the forces applied to the device. Driver and/or passenger air bags (SRS) will affect the way

equipment should be mounted. This device should be mounted by permanent installation and within the zones specified by the vehicle manufacturer, if

any. Any device mounted in the deployment area of an air bag will damage or reduce the effectiveness of the air bag and may damage or dislodge the

device. Installer must be sure that this device, its mounting hardware and electrical supply wiring does not interfere with the air bag or the SRS wiring or

sensors. Mounting the unit inside the vehicle by a method other than permanent installation is not recommended as unit may become dislodged during

swerving; sudden braking or collision. Failure to follow instructions can result in personal injury. Whelen assumes no liability for any loss resulting from the

use of this warning device. PROPER INSTALLATION COMBINED WITH OPERATOR TRAINING IN THE PROPER USE OF EMERGENCY WARNING

DEVICES IS ESSENTIAL TO INSURE THE SAFETY OF EMERGENCY PERSONNEL AND THE PUBLIC.

Whelen’s emergency vehicle warning devices are intended to alert other operators and pedestrians to the presence and operation of emergency vehicles

and personnel. However, the use of this or any other Whelen emergency warning device does not guarantee that you will have the right-of-way or that

other drivers and pedestrians will properly heed an emergency warning signal. Never assume you have the right-of-way. It is your responsibility to proceed

safely before entering an intersection, driving against traffic, responding at a high rate of speed, or walking on or around traffic lanes. Emergency vehicle

warning devices should be tested on a daily basis to ensure that they operate properly. When in actual use, the operator must ensure that both visual and

audible warnings are not blocked by vehicle components (i.e.: open trunks or compartment doors), people, vehicles, or other obstructions. It is the user’s

responsibility to understand and obey all laws regarding emergency warning devices. The user should be familiar with all applicable laws and regulations

prior to the use of any emergency vehicle warning device. Whelen’s audible warning devices are designed to project sound in a forward direction away

from the vehicle occupants. However, because sustained periodic exposure to loud sounds can cause hearing loss, all audible warning devices should be

installed and operated in accordance with the standards established by the National Fire Protection Association.

Safety First

This document provides all the necessary information to allow your Whelen product to be properly and safely installed. Before beginning the installation

and/or operation of your new product, the installation technician and operator must read this manual completely. Important information is contained herein

that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of automotive electronics, systems and procedures.

• Whelen Engineering recommends the use of waterproof butt splices and/or connectors if that connector could be exposed to moisture.

• Failure to use specified installation parts and/or hardware will void the product warranty.

• If mounting this product requires drilling holes, the installer MUST be sure that no vehicle components or other vital parts could be damaged

by the drilling process. Check both sides of the mounting surface before drilling begins. Also de-burr the holes and remove any metal shards

or remnants. Install grommets into all wire passage holes.

• If this manual states that this product may be mounted with suction cups, magnets, tape or Velcro®, clean the mounting surface with a 50/50

mix of isopropyl alcohol and water and dry thoroughly.

• Do not install this product or route any wires in the deployment area of your air bag. Equipment mounted or located in the air bag deployment

area will damage or reduce the effectiveness of the air bag, or become a projectile that could cause serious personal injury or death. Refer to

your vehicle owner’s manual for the air bag deployment area. The User/Installer assumes full responsibility to determine proper mounting

location, based on providing ultimate safety to all passengers inside the vehicle.

• For this product to operate at optimum efficiency, a good electrical connection to chassis ground must be made. The recommended

procedure requires the product ground wire to be connected directly to the NEGATIVE (-)

battery post (this does not include products that use cigar power cords).

• If this product uses a remote device for activation or control, make sure that this device is

located in an area that allows both the vehicle and the device to be operated safely in any

driving condition.

• It is recommended that these instructions be stored in a safe place and referred to when

performing maintenance and/or reinstallation of this product.

• FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND INSTRUCTIONS COULD RESULT IN

Automotive: Sirens/Switches

DAMAGE TO THE PRODUCT OR VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR

PASSENGERS!

©2012 Whelen Engineering Company Inc.

Form No.14570E (040114)

Installation Guide:

CenCom™ Sapphire

Siren/Light Control System

Warnings to Installers

Warnings to Users

For warranty information regarding this product, visit www.whelen.com/warranty

Page 1

Page 2

Table of Contents

Specifications......................................................................................................................... page 3

Installation

CenCom Module ............................................................................................................ page 4

Control Head Mounting .................................................................................................. page 4

Microphone..................................................................................................................... page 4

Wiring

System Power ................................................................................................................ page8

Ignition Sense................................................................................................................. page 8

Outputs........................................................................................................................... page 8

Siren Speaker................................................................................................................. page 8

Radio Rebroadcast......................................................................................................... page 8

Backlighting ....................................................................................................................page8

Programmable Inputs ..................................................................................................... page 8

Park-Kill ......................................................................................................................... page 8

Hands-Free Siren ........................................................................................................... page 8

Control Head Cable........................................................................................................ page 8

CenCom Module Fuses.................................................................................................. page 9

Isolated Relay (Outlet 8)................................................................................................. page 9

Input Expansion Module (Optional) ................................................................................ page 9

Adjustments

Public Address (PA) Volume Adjustment........................................................................ page 9

Radio Repeat Volume Adjustment ................................................................................. page 9

Control Head Default Configuration Tables ........................................................................... page 5

LED Indicators

Traffic Advisor Indicators................................................................................................ page 10

Output Indicators ............................................................................................................ page 10

WC Diagnostic Indicators ............................................................................................... page 10

Illustrations

Bail Strap Mounting ............................................................................................................... page 4

Hands-Free Transfer Relay ................................................................................................... page8

Control Head Cable Strain Relief........................................................................................... page 4

CenCom Module Fusing Information..................................................................................... page 9

Isolated Relay (Outlet 8)........................................................................................................ page 9

Input Expansion Module Pin-Outs ......................................................................................... page 9

Wire Gage Chart.................................................................................................................... page 14

CenCom LED Indicators........................................................................................................ page 10

System Wiring ....................................................................................................................... page 11

CenCom Module Input/Output Wiring Identification............................................................... page 12

Configuration Record............................................................................................................. page 13

Page 2

Page 3

Specifications

General

Input Voltage 12.8 VDC ±20%

Negative Ground Only

Main Input Current 80 Amps Max.

Main Siren Fuse 20 Amps

Stand-by Current (backlight off) Ign.On - 80mA (typ) / Ign.Off - 100 uA (typ)

Operating Temperature -30°C to +60°C

Storage Temperature -40°C to +70°C

Humidity 99% (Non-condensing)

CenCom Module

Wail 725 to 1600 Hz (12 cycles/min.)

Yelp 725 to 1600 Hz (180 cycles/min.)

Piercer™ 725 to 1600 Hz (800 cycles/min.)

Hi/Low 550 & 650 Hz (60 cycles/min.)

Airhorn Composite (Constant)

Audio Bandwidth @25 Watts 300 to 10000 Hz ±3db

Distortion @25Watts 1% Maximum

Output Voltage @15VDC @11 ohms 24Vrms Maximum

Speaker Impedance 5.5 Ohms Minimum

Outlet Current

Outlet #1 40 Amps Max. (fused)

Outlet #2 20 Amps Max. (fused)

Outlet #3 20 Amps Max. (fused)

NOTE: Total current of Outlets 1, 2 & 3 not to exceed 50 Amps

Outlet #4 10 Amps Max. (fused)

Outlet #5 10 Amps Max. (fused)

Outlet #6 10 Amps Max. (fused)

Outlet #7 10 Amps Max. (fused)

Outlet #8 10 Amps Max. (fused)

NOTE: Total current of Outlets 4, 5, 6, 7 & 8 not to exceed 50 Amps

Dimensions (CenCom Module)

Height 3.20 inches

Width 8.22 inches

Depth 6.74 inches

Dimensions (Control Head)

Height 3.58 inches

Width 6.85 inches

Depth 1.32 inches

Page 3

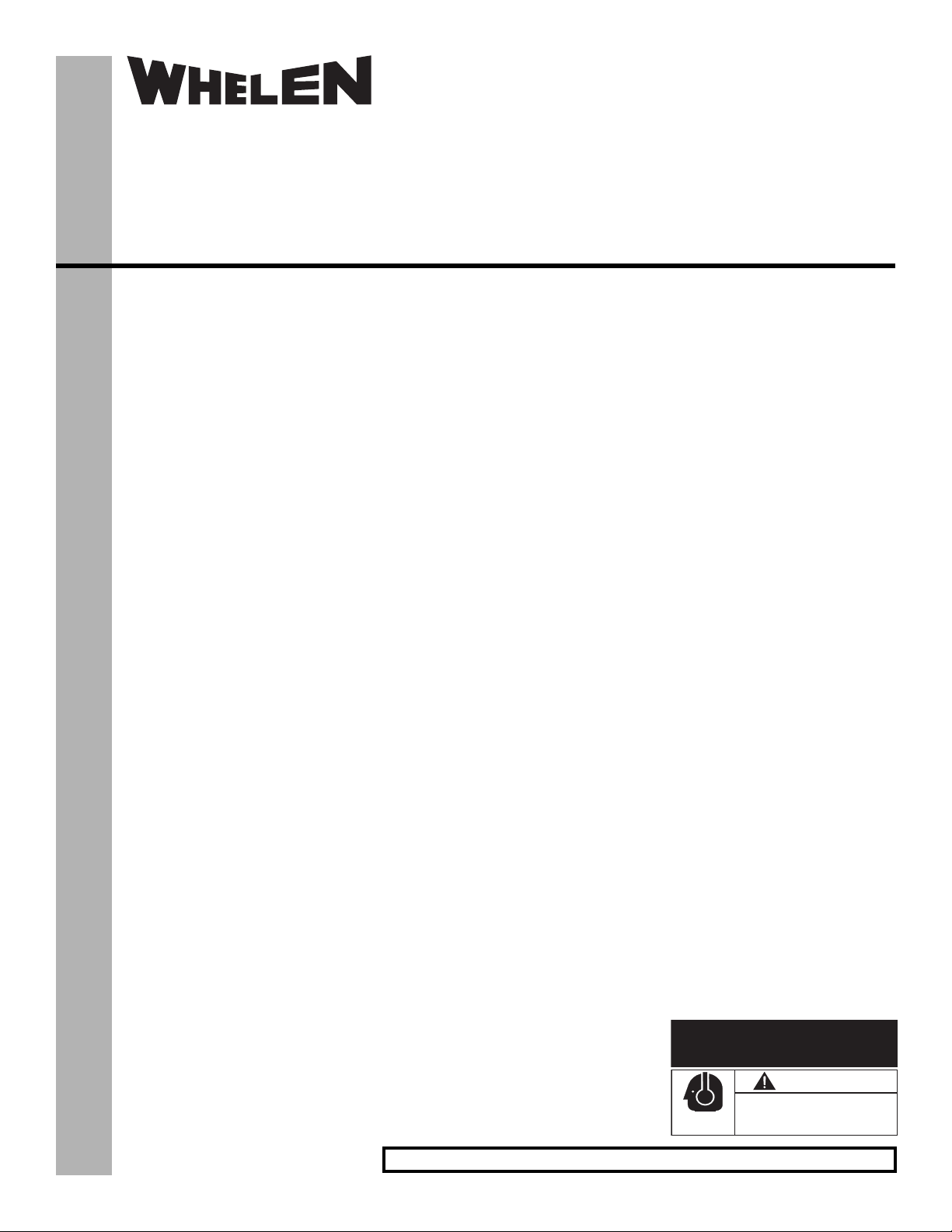

Page 4

Installation

Bail

Strap

Mount

Control head

shown for

reference-only

CenCom Module

1. Locate a suitable mounting location. A dry, cool compartment is a

good choice.

2. Position the CenCom module on the proposed mounting location.

Using an awl or similar tool, scribe the mounting surface where the

mounting holes are to be drilled. Make sure that this mounting area

allows sufficient ventilation for the CenCom module’s air vents and

fans.

Caution: As mounting the CenCom module will require drilling, it

is absolutely necessary to make sure that no other vehicle

components could be damaged in the process. Check both sides of

the mounting surface before starting. If damage is likely, select a

different mounting location.

3. Remove the module from its mounting area, and using a drill bit sized

for a #10 sheet metal screw, drill a hole in each of the areas scribed

in the previous step.

4. Return the module to its mounting location. Using #10 x 3/4” sheet

metal screws (provided), secure the module onto its mounting

surface. Be sure to install a #10 internal tooth lock washer (included)

onto each mounting screw. IMPORTANT: The CenCom module case

must be either mounted on, or grounded to the vehicle chassis.

Control Head

The following sections will outline the varrious mounting styles available

for the assorted CenCom control heads. The applicable mounting styles

for each control head are listed on pages 5 thru 7.

Regardless of the style selected, be sure to observe the air bag

warning on the cover of this manual.

Caution: As mounting the control head will require drilling, it is

absolutely necessary to make sure that no other vehicle components

could be damaged in the process. Check both sides of the mounting

surface before starting. If damage is likely, select a different

mounting location.

Bail Strap Mount

1. Position the bail strap in the selected mounting location. Using an awl

or other suitable tool, scribe the surface where the mounting holes

are to be drilled.

2. Drill the mounting holes in the areas scribed in step 1. The size of the

drill bit should be determined by the size of the mounting hardware (#10

sheet metal screw) and thickness of the mounting surface.

3. Using hardware provided (#10 x 3/4” sheet metal screw & #10

internal tooth lockwasher), secure the bail strap to the mounting

location.

Note: There are 3 sets of holes on the bail strap for positioning

the control head at 3 different heights.

4. With the bail strap in place, insert the #10 x 3/8” hex head bolt into

the assembly hole from the inner side of the bail strap as shown.

5. Place the #10 internal-tooth lock washer and the acorn nut on the

protruding bolt on the outer side of the bail strap. Loosely secure the

acorn nut to the hex head bolt.

Now slide the control head onto the bolt heads. Once it is in the position

that the customer has chosen, and the control head has fully engaged the

bolt heads, tighten the acorn nuts until the unit is firmly secured.

A third pair of mounting holes are provided that will enable the control

head to be located much closer to the bail strap than the other pairs allow.

If this closer location is used, the tips of the bail bracket may be broken off

at the notches shown.

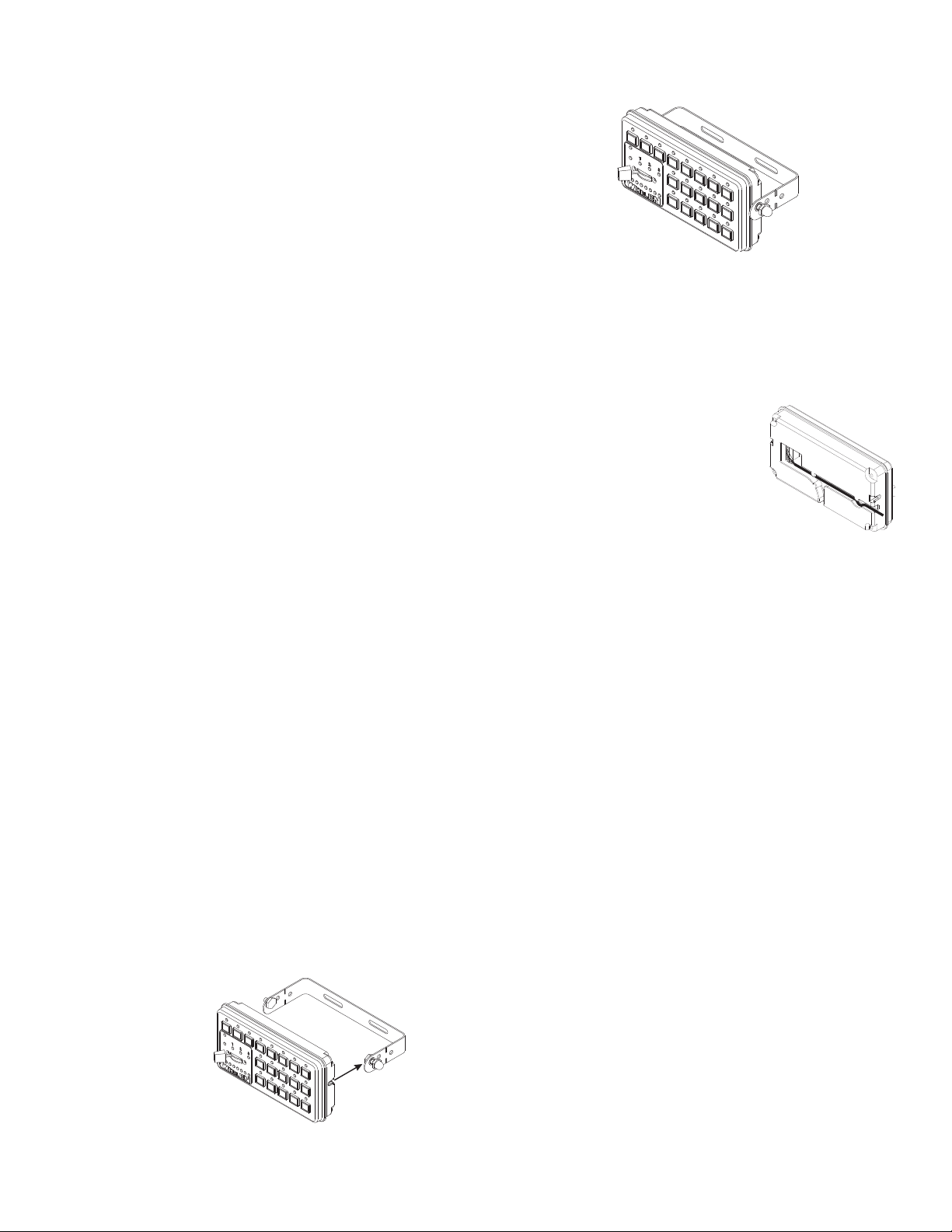

Route the control head cable (provided) from the

CenCom module to the designated mounting

location. Plug this cable securely into the rear of

the control head. Be sure to route the cable

through either of the two recessed pathways

(shown here).This will prevent the cable from

being accidentally disconnected or pinched by

the control head.

Cntrl Head

Cable Strain

Releif

Havis Console Mount

The Havis Console mounting kit includes all the necessary hardware

needed to secure the control head to the mounting bracket for installation

on a Havis Console. Please refer to the manual included with your console

for specific information on securing the control head/mounting bracket

assembly onto the console.

For installation into consoles by other manufacturers, a control head

bracket designed for your console must be obtained from the console

manufacturer.

Microphone Mount

A 1/4” microphone port is provided on the front of the Amp/Relay module.

After plugging the microphone cord into the microphone port, secure the

cord using the cable clamp and #8 x 3/8” machine screw (included with

microphone kit).

If the optional 20’ extension cord is used, install this cord as outlined

above. Install the mic plug bracket (included with kit) in the desired area

using #8 x 1/2” hardware (included). Route the cord to the plug bracket,

install the cable end thru the bracket hole and fasten using the hex nut

provided. Secure the cord to the bracket using the cable clamp, #8 x 3/8”

machine screw and lock washer.

Plate Mount (6 Button w/Slide Switch Only)

Secure the plate to the back of the control head using the #4 x 1/4”

hardware provided. Position the control head/plate assembly onto the

mounting surface and confirm that this location will not interfere with any

existing components or prevent safe operation of the vehicle.

With the control head in place, mark the two mounting holes. Remove the

control head/plate assembly and drill the mounting holes using a bit sized

for #6 sheet metal screw. De-burr the mounting holes and secure the

control head/plate assembly using the #6 x 1/2” hardware provided.

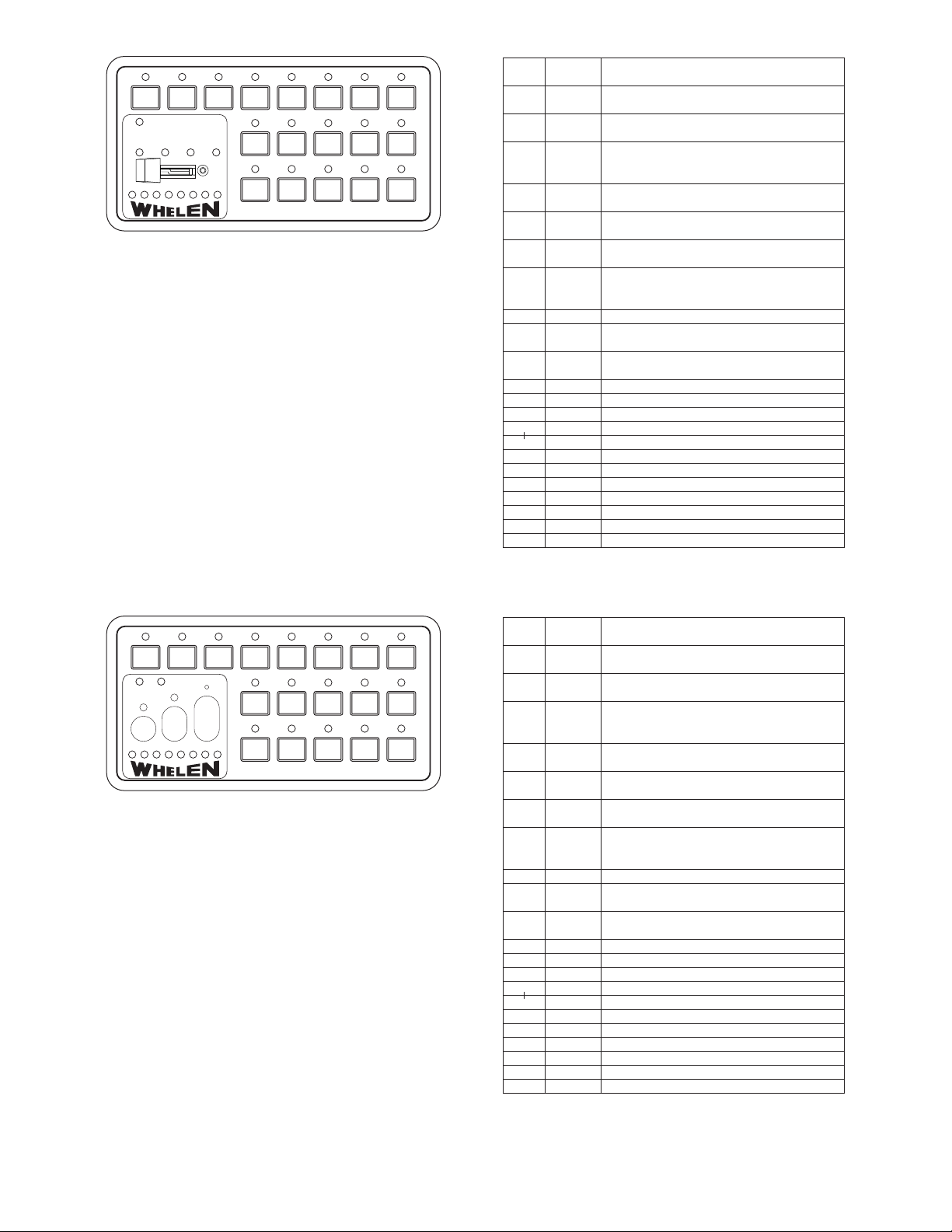

Default Control Head Configurations

The default operating configurations for the control heads available for the

CenCom Sapphire are listed in the following section.

Page 4

Page 5

Control

PB

1

PB3PB

4

PB

9

PB

14

PB

5

PB

10

PB

15

PB

6

PB

11

PB

16

PB

7

PB

12

PB

17

PB

8

ID

Description

PB 1

PB 2

PB 3

PB 4

PB 5

PB 6

PB 7

PB 8

PB 9

PB 10

PB 11

PB 12

PB 13

PB 14

PB 15

PB 16

PB 17

PB 18

SL 0

SL 1

SL 2

SL 3

Rebroadcast radio output through siren speaker.

Activates Horn Relay

Stand-by Mode, but Horn Ring or MAN button can

activate the siren and be used to cycle through the

Hands-Free buffer.

Activates Horn Relay.

Broadcasts the WAIL tone.

Activates Horn Relay.

Broadcasts the YELP tone.

Activates Horn Relay.

Broadcasts the PIERCER tone.

Activates Horn Relay.

Initiates MANUAL tone.

Applies OVERRIDE tone.

Can cycle tones for Hands Free.

Broadcasts the AIRHORN Tone.

Cycles through Traffic Advisor

(Left, Right, Split, Off) states.

Cycles through three available

Traffic Advisor flash patterns and Off.

Activates Output 9.

Activates Horn Relay.

Activates Output 10.

Activates Output 4.

Activates Output 5.

Activates Output 6.

Activates Output 7.

Activates Output 8.

Stops All Siren and T/A functions.

Activates Output 1.

Activates Output 1 + 2.

Activates Output 1 + 2 + 3.

Default

Function

STBY

RAD

HF

WAIL

YELP

T3

MAN

AH

DIR

FLSH

AUX1

AUX2

LP

SW14

SW15

SW16

SW17

GL

OFF

1

2

3

PB

13

PB

18

PB

2

SL

1SL0

SL2SL

3

Clears all siren operations.

Activates Horn Relay.

PB

1

PB

19

PB

20

PB

21

PB3PB

4

PB

9

PB

14

PB

5

PB

10

PB

15

PB

6

PB

11

PB

16

PB

7

PB

12

PB

17

PB

8

ID

Description

PB 1

PB 2

PB 3

PB 4

PB 5

PB 6

PB 7

PB 8

PB 9

PB 10

PB 11

PB 12

PB 13

PB 14

PB 15

PB 16

PB 17

PB 18

PB 19

PB 20

PB 21

Rebroadcast radio output through siren speaker.

Activates Horn Relay

Stand-by Mode, but Horn Ring or MAN button can

activate the siren and be used to cycle through the

Hands-Free buffer.

Activates Horn Relay.

Broadcasts the WAIL tone.

Activates Horn Relay.

Broadcasts the YELP tone.

Activates Horn Relay.

Broadcasts the PIERCER tone.

Activates Horn Relay.

Initiates MANUAL tone.

Applies OVERRIDE tone.

Can cycle tones for Hands Free.

Broadcasts the AIRHORN Tone.

Cycles through Traffic Advisor

(Left, Right, Split, Off) states.

Cycles through three available

Traffic Advisor flash patterns and Off.

Activates Output 9.

Activates Horn Relay.

Activates Output 10.

Activates Output 4.

Activates Output 5.

Activates Output 6.

Activates Output 7.

Activates Output 8.

Activates Output 1.

Activates Output 1 + 2.

Activates Output 1 + 2 + 3.

Default

Function

STBY

RAD

HF

WAIL

YELP

T3

MAN

AH

DIR

FLSH

AUX1

AUX2

LP

SW14

SW15

SW16

SW17

GL

1

2

3

PB

13

PB

18

PB

2

Clears all siren operations.

Activates Horn Relay.

Control Head:

w/

18 Button

Slide Switch

Bail Mount

Console Mount

Mounting Style(s):

Control Head:

Mounting Style(s):

Bail Mount

Console Mount

18+3 Button

head

Configura

tions

Page 5

Page 6

PB

1

PB

19

PB3PB

4

PB

9

PB

14

PB

5

PB

10

PB

15

PB

6

PB

11

PB

16

PB

7

PB

12

PB

17

PB

8

ID

Description

PB 1

PB 2

PB 3

PB 4

PB 5

PB 6

PB 7

PB 8

PB 9

PB 10

PB 11

PB 12

PB 13

PB 14

PB 15

PB 16

PB 17

PB 18

PB 19

Rebroadcast radio output through siren speaker.

Activates Horn Relay

Stand-by Mode, but Horn Ring or MAN button can

activate the siren and be used to cycle through the

Hands-Free buffer.

Activates Horn Relay.

Broadcasts the WAIL tone.

Activates Horn Relay.

Broadcasts the YELP tone.

Activates Horn Relay.

Broadcasts the PIERCER tone.

Activates Horn Relay.

Initiates MANUAL tone.

Applies OVERRIDE tone.

Can cycle tones for Hands Free.

Broadcasts the AIRHORN Tone.

Cycles through Traffic Advisor

(Left, Right, Split, Off) states.

Cycles through three available

Traffic Advisor flash patterns and Off.

Activates Output 9.

Activates Horn Relay.

Activates Output 10.

Activates Output 4.

Activates Output 5.

Activates Output 6.

Activates Output 7.

Activates Output 8.

Activates Output 1 + 2 + 3.

Default

Function

STBY

RAD

HF

WAIL

YELP

T3

MAN

AH

DIR

FLSH

AUX1

AUX2

LP

SW14

SW15

SW16

SW17

GL

1

PB

13

PB

18

PB

2

Clears all siren operations.

Activates Horn Relay.

PB

1

PB3PB4PB5PB6PB7PB

8

PB

9

PB

10

R1

SL0 SL1 SL2 SL3

R7

R2 R6

R3

R4

R5

PB

11

PB

12

PB

13

PB

2

ID

Description

PB 1

PB 2

PB 3

PB 4

PB 5

PB 6

PB 7

PB 8

PB 9

PB 10

PB 11

PB 12

PB 13

R1

R2

R3

R4

R5

R6

R7

SL0

SL1

SL2

SL3

Activates Output 5

Activates Output 6.

Activates Output 7.

Activates Output 9.

Activates Horn Relay.

Activates Output 10.

Activates Output 8

Initiates Manual Tone.

Applies Override Tone.

Can cycle tones for Hands-Free.

Broadcast the Airhorn Tone.

Activates ‘Sequence Left’ Traffic Advisor pattern.

Activates ‘Sequence Right’ Traffic Advisor pattern.

Sequence through three available Traffic Advisor

flash patterns and “OFF”.

Rebroadcast radio output through the siren speaker.

Activates Horn Relay.

Activate PA Feature.

Turns off Hands-Free.

Changes functionality of Horn Ring Input.

Stand-By mode except that the Horn Ring (or the

MAN button) can activate the siren and be used to

cycle through the Hands-Free buffer.

Activates Horn Relay.

Broadcast WAIL tone.

Activate Horn Relay.

Broadcast YELP tone.

Activate Horn Relay.

Broadcast PIERCER tone.

Activate Horn Relay.

Stops All Functions.

Activates Output 1.

Activates Output 1 + 2.

Activates Output 1 + 2 + 3.

Default

Function

SW1

SW2

SW3

SW4

AUX1

AUX2

LP

GL

MAN

AH

LT T/A

RT T/A

FLSH

RAD

PA

MAN

HF

T1

T2

T3

OFF

1

2

3

Activates Output 4.

Control Head:

Mounting Style(s):

Bail Mount

Console Mount

18+1 Button

Control Head:

Mounting Style(s):

Bail Mount

Console Mount

13 Button

w/Knob & Slide Switch

Page 6

Page 7

ID

Description

PB 1

PB 2

PB 3

PB 4

PB 5

PB 6

SL0

SL1

SL2

SL3

No Default

No Default

Broadcast the Airhorn Tone.

Sequence through three available Traffic Advisor

flash patterns and “OFF”.

Changes functionality of Horn Ring Input.

Stand-By mode except that the Horn Ring (or the

MAN button) can activate the siren and be used to

cycle through the Hands-Free buffer.

Activates Horn Relay.

Stops All Functions.

Activates Output 1 + Horn Relay.

Activates Output 1 + 2 .+ Horn Relay

Activates Output 1 + 2 + 3 .+ Horn Relay

Default

Function

SW3

SW5

AH

DIR

MAN

HF

OFF

1

2

3

PB

1

PB

4

PB

7

PB

10

PB

5

PB

8

PB

11

PB

6

PB

9

PB

12

PB

2

PB

3

PB

4

PB

2

PB

1

PB

5

PB

3

PB

6

SL0

SL1

SL2

SL3

ID

Description

PB 8

PB 4

PB 7

PB 5

PB 6

PB 9

PB 10

PB 11

PB 12

PB 1

PB 2

PB 3

Rebroadcast radio output through siren speaker.

Activates Horn Relay

Stand-by Mode, but Horn Ring or MAN button can

activate the siren and be used to cycle through the

Hands-Free buffer.

Activates Horn Relay.

Broadcasts the WAIL tone.

Activates Horn Relay.

Initiates MANUAL tone.

Applies OVERRIDE tone.

Can cycle tones for Hands Free.

Broadcasts the AIRHORN Tone.

Cycles through Traffic Advisor

(Left, Right, Split, Off) states.

Activates Output 4.

Activates Output 5.

Activates Output 6.

Activates Output 1.

Activates Output 1 + 2.

Activates Output 1 + 2 + 3.

Default

Function

RAD

HF

WAIL

MAN

AH

DIR

SW10

SW11

SW12

SL1

SL2

SL3

Control Head:

Mounting Style:

Plate Mount

6 Button

w/Slide Switch

Control Head:

Mounting Style:

12 Button (

Microphone Clip

Hand-held)

Page 7

Page 8

Wiring

Hands-Free Transfer

Relay

Horn Ring

Transfer Relay

(Customer Supplied)

Bosch™

Style

(Tyco-P&B P/N:VF4-45F11)

Generic

Style

To Vehicle

Car Horn

N.O.

N.C.

From Vehicle

Horn Relay

To

Outlet #12

(Item 35)

To

Input #4

(Item 33)

From Vehicle

Horn Relay

To Vehicle

Car Horn

To

Input #4

(Item 33)

To

Outlet #12

(Item 35)

30

87A

85 86

87

WARNING! All customer supplied wires that connect to the positive

terminal of the battery must be sized to supply at least 125% of the

maximum operating current and FUSED

load. DO NOT USE CIRCUIT BREAKERS WITH THIS PRODUCT! (see

wire chart on page 14).

NOTE: Item numbers reference the illustration found on page 12.

IMPORTANT! Wires connecting to the Amp/Relay Module have the

proper terminals pre-installed. If the customer needs to re-terminate

these wires for any reason, the proper tool MUST be used to insure

proper crimping.

System Power (Items 43-46)

1. Locate the 4-position Molex™ connector (items 43 thru 46).

2. Using appropriately sized wire, extend the two RED wires (45 & 46)

to the Positive (+) battery terminal. Fuse each wire independently @

50 Amps. DO NOT install these fuses until the wiring for the entire

system has been completed.

3. Using appropriately sized wire, extend the two BLACK wires (43 &

44) to the vehicle’s chassis ground (typically adjacent to the battery).

4. Complete the connections and plug the connector into the

CenCom™ module.

Ignition Sense (Item 38)

1. Locate the RED/BLK wire at Connector C, Pin 14.

2. Connect this wire to the ignition switch to allow the CenCom™

system to be turned off with the ignition switch. See Shutdown

Module for optional connection

Outputs

CenCom™ offers the following outlets: (1) 40 amp, (2) 20 amp, (5) 10 amp

and (4) 0.25 amp. See page 12 for more information.

Siren Speaker (Items 30 & 37)

1. Route the ORANGE and BROWN 16 gage wire (included) from

Connector C, Pins 6 &13, to the siren speaker.

2. Connect ORANGE wire to the WHITE speaker wire (speaker high).

3. Connect BROWN wire to BLACK speaker wire (speaker low).

NOTE: For dual speaker installation, connect the second speakers wires

to the same destinations as the first speakers wires (see page 11).

at the battery to carry that

Backlighting (Item 31)

Note: The CenCom backlight circuit has been designed to accept any of

the following:

• 0 VDC input (off)

• 12VDC input (on)

• A Pulse Width Modulated (PWM) input with a range of 0% - 100%

duty cycle @ 100Hz (i.e. dimmer circuit).

1. Route the WHT/BLK wire (included) from Connector C, Pin 7, to the

vehicle’s marker light circuit.

2. Splice this wire into this circuit to enable the control head backlighting

to be active whenever the vehicle’s marker light is active.

Programmable Inputs (Item 25, 26, 32, 33)

There are 4 programmable inputs in the CenCom system. The output

signal line from devices such as a K-9 temperature sensor may be

connected to these inputs. Two of these inputs (items 26 & 33) are

designated for use when the Park-Kill or Hands-Free system options are

used (see below).

Park-Kill (Optional) (Item 26)

CAUTION! Always consult your vehicle’s technical manual before

altering your vehicle’s wiring. Wiring modifications may compromise

your vehicle’s safety and/or performance. Use of the Park-Kill option

may require the installation of the Whelen WPKM1 Park-Kill module.

Consult your vehicle’s technical manual before using this feature.

Using appropriately sized wire, extend and connect the WHT/ORN wire

from Connector C, Pin 2, to the vehicle’s transmission neutral safety

switch signal wire. NOTE: For programming purposes, it is necessary to

know whether this signal wire is switching the positive or negative side of

the circuit.

Hands-Free Siren (Items 33 & 35) (Optional)

1. Using a customer supplied relay capable of handling the current of

your vehicle horn, connect as shown below.

Radio Rebroadcast (Items 29 & 36)

Two (2) BLU wires are used to connect your two-way radio’s external

speaker for radio rebroadcast. This is an optional connection and will not

effect the other operations. Note: Radio rebroadcast will NOT work with

amplified remote speakers! If your remote speaker is amplified (i.e.:

contains a power amp circuit in the speaker assembly), do not enable the

radio rebroadcast feature.

1. Locate the two wires that connect the external speaker to the twoway radio, cut one of them and splice one of the BLU wires into this

circuit.

2. Cut the remaining speaker wire and splice the remaining BLU wire

into this circuit.

Page 8

Page 9

PA Volume Adjustment

F1

(POS.1)

Common (Orange/21)

Normally

Closed (Red/22)

Normally

Open (Brown/23)

Fuse in

Dry-Contact

Position

Fuse in

10 Amp Outlet

Position

F1

(POS.2)

+12VDC

LIGHTBAR

CTRL

HEAD

OUTPUT 2 20A

20A

MAIN P

20A

OUTPUT 3 20A

OUTPUT 4 10A

OUTPUT 5 10A

OUTPUT 6 10A

OUTPUT 7 10A

T/A FUSE 20A

OUTPUT 7

10A

OUTPUT

10A

POSITION

DRY

CONTACT

POSITION

OUTPUT 1

40A

ERR

HS

USB

L

WC POW

PA

SYSTEM

I/O

- 20 -

- 20 -

- 20 -

- 20 -

- 20 -

- 10 -

- 10 -

- 10 -

- 10 -

- 10 -

Top

View

SIREN FUSE

20A

- 20 -

Front

View

Positive Input 2

Positive Input 8

RED

GREY

2

8

3

9

13

5

11

15

4

10

14

6

12

16

Positive Input 6

Negative Input 4

Negative Input 8

BLUE

WHT/YEL

WHT/GRY

GREEN

WHT/ORG

WHT/VIO

ORANGE

WHT/BRN

WHT/GRN

YELLOW

WHT/RED

WHT/BLU

Positive Input 4

Negative Input 2

Negative Input 6

Positive Input 5

Negative Input 3

Negative Input 7

Positive Input 3

Negative Input 1

Negative Input 5

1

7

BROWN

VIOLET

COLOR FUNCTION

Positive Input 1

Positive Input 7

WIRE CHARTWIRE SIDE VIEW

POS

192345678

10

11

12

13

141516

Locate the PA adjustment potentiometer on the right side of the

CenCom module. Using a small, flat-blade screwdriver, set the

potentiometer to its middle position. With the CenCom™ system on,

activate the PTT (Push To Talk) feature on the optional microphone.

Adjust the potentiometer until a satisfactory PA volume level is achieved

using a normal speaking voice.

Radio Repeat Volume Adjustment

To Adjust the Radio Repeat Levels: Before placing this unit into service,

the Radio Repeat output volume must be adjusted to satisfactory

operating levels. To adjust this level, a small, flat-blade screwdriver is

needed. Locate the Radio Repeat adjustment potentiometer on the

right side of the CenCom module. Set the volume of the vehicle’s twoway radio to its normal operating level. Press the RAD button on the

control head to activate Radio Repeat. As incoming transmissions are

received, adjust the Radio Repeat potentiometer to set the desired

level. Turn the potentiometer clockwise to increase the level and

counter-clockwise to decrease the level.

Input Expansion Module (optional)

The optional input expansion module enables up to eight (8) non-CenCom

vehicle components and/or equipment to be integrated into the CemCom/

Cantrol network.

As shown in the tables below, connect the input wire of the desired device

to the appropriate wire. For example, if the device in question requires a

Positive input signal, that input wire would be connected to the BROWN

expansion module pigtail wire. In this example, that device would be

recognized as “INPUT 1” by the Cantrol system. However, if that device

requires a Negative input signal, that input wire would be connected to the

WHT/BRN expansion module pigtail wire. Note that this device would be

recognized as “INPUT 1” by the Cantrol system.

Amp/relay Module

Fusing Information

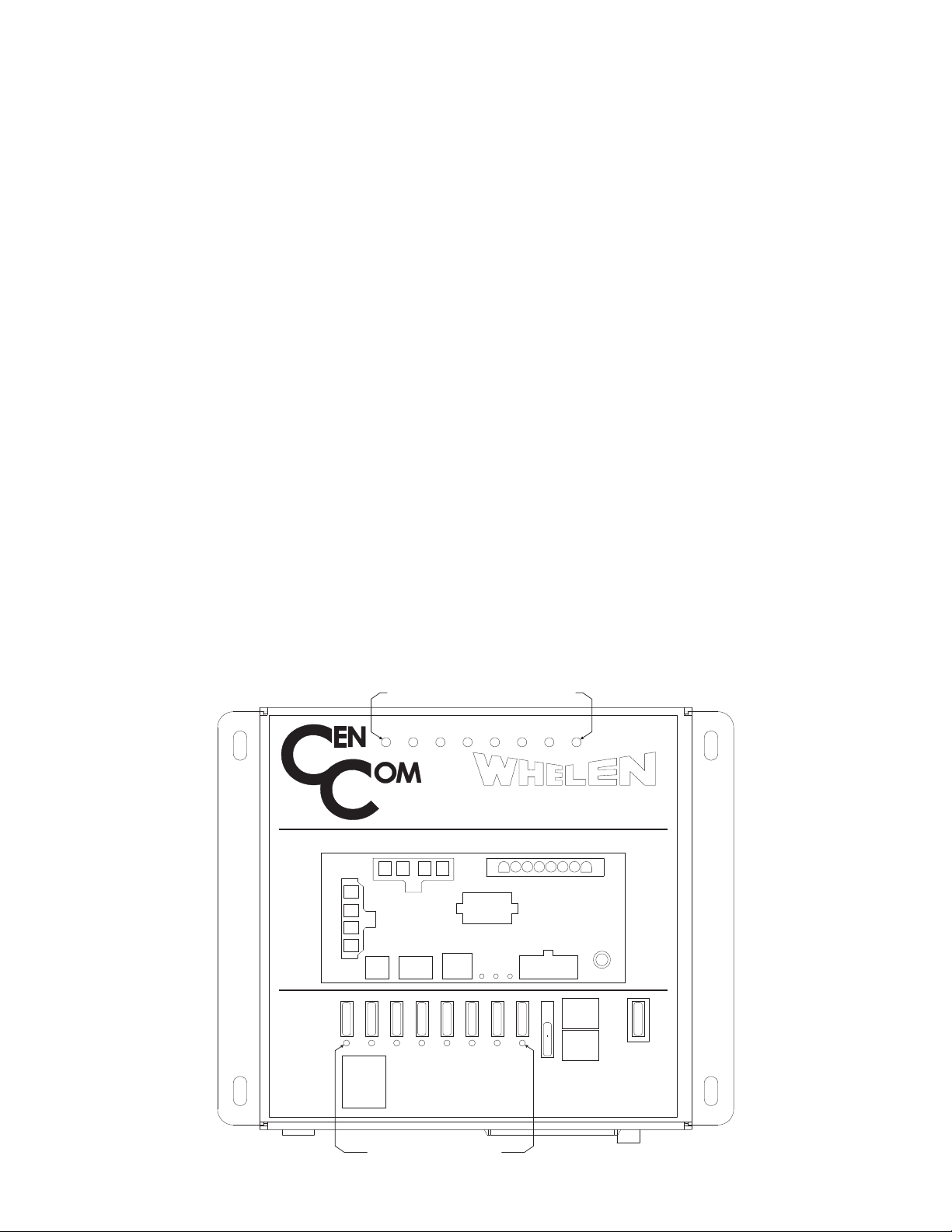

CenCom Module Fuses

For ease of access, all of the amp/relay module fuses are accessible from

outside the case.

Input Expansion Table

Control Heads....

A wide variety of control heads are available for use with this system.

The specific function of any button, slide switch or rotary knob can be

customized via the CenCom configuration software program. The

following pages will present all of the available control heads and their

default operating configuration.

Isolated Relay (Outlet 8)

The position of the Output 8 fuse determines the function of the Brown,

Red and Orange wires. When the fuse is in Position 1, these wires act as

a Isolated 10 Amp Relay. When the fuse is in Position 2, the Brown and

Red wires act as Outlet #8. Refer to the schematic shown for the

electronic properties of this circuit.

Isolated Relay (Outlet

8)

Page 9

Page 10

+

-

+

-

40A

OUTPUT

WC

LIGHTBAR

CTRL

HEAD

OUTPUT 2 20A

20A

MAIN POWER

20A

OUTPUT 3 20A

OUTPUT 4 10A

OUTPUT 5 10A

OUTPUT 6 10A

OUTPUT 7 10A

T/A FUSE 20A

OUTPUT 7

10A

OUTPUT

10A

POSITION

DRY

CONTACT

POSITION

OUTPUT 1

40A

1213

20A

OUTPUT

ERR

HS

USB

L

WC POW

PA

SYSTEM

I/O

10A OUTPUTS

SYSTEM CONNECTION MAP

4567 CNCNO

TRAFFIC

ADVISOR

MANUFACTURED IN AMERICA

®

- 20 -

- 20 -

- 20 -

- 20 -

- 20 -

- 10 -

- 10 -

- 10 -

- 10 -

- 10 -

SAPPHIRE

TA1 TA2 TA3 TA4 TA5

Traffic Advisor Indicators

Output Indicators

TA6 TA7 TA8

LED Indicators

LED Indicators provide valuable information regarding the operational state of your CenCom system. There are 3 different sets of

LED’s for 3 different CenCom functions.

Traffic Advisor Indicators - These LEDs represent Traffic Advisor Output 1 (TA1) thru Traffic Advisor Output 8 (TA8). When a given

output is active or flashing, the state of its corresponding indicator will be one of the following, based on the condition of that particular

output:

On (steady) - Indicates the output is active and not flashing (normal).

On (flashing) - Indicates the output is active and flashing (normal).

Off - Indicates the output is shorted. Turn the CenCom system off, locate and remove the short. Restore power to the system

and activate the output to confirm its proper operation.

Output Indicators - These represent Outputs 1 thru 7. Each indicator is located directly adjacent to the fuse for that output.When a

given output is active, the state of its corresponding indicator will be one of the following, based on the condition of that particular

output:

On - Indicates the output is active (normal).

Off - Indicates the output is shorted. Turn the CenCom system off, locate and remove the short. Replace the fuse for that output

(with correct amperage rating) and restore power to the system. Activate the output to confirm its proper operation.

WC Diagnostic Indicators - These indicators provide the following diagnostic information about the CenCom system:

ERR (Error) LED

Steady CenCom Controller Bus is set to OFF. Check Interface Box.

Off No Error

Single Flash Bad CenCom connection. Check lightbar I/O or Interface Box for proper operation.

Double Flash Error Control Event. Check lightbar I/O.

WC (CenCom Serial Data Bus) LED

Steady Good communication received from lightbar.

Off Check power LED; If Off, turn on controller. If On, check connections.

Fast Blink Pre-operational State (Boot-up)

Single Flash Bad CenCom connection or CenCom off. Check lightbar I/O or interface box for proper operation.

POW (Power) Status LED

Steady CenCom system is On

Off CenCom system is Off.

CenCom LED Indicators

Page 10

Page 11

50A (each)

(GRN) - Output #3 (20A Max.)

(WHT) - Output #1 (20A Max. Each)

(BLU) - Output #2 (20A Max.)

(WHT) - Output #1 (20A Max. Each)

OR Output #1 (40A Max. Total)

(+)

Battery

(-)

CenCom™ Sapphire System Wiring Guide

USB

1. (WHT/BRN) - Logic Input 1 +/-

2. (WHT/ORG) - Logic Input 3 +/-

3. (RED) - Output #10 (250mA Max.)

4. (BRN) - Output #9 (250mA Max.)

5. (BLU) - Radio

6. (ORG ) - Siren Speaker

7. (WHT/BLK) - Backlight Input (12VDC)

8. (WHT/RED) - Logic Input 2 +/-

9. (WHT/YEL) - Logic Input 4 / Horn Ring +/-

10. (ORG) - Output #11 (250mA Max.)

11. (YEL) - Output #12 / Horn Transfer (250mA Max.)

12. (BLU) - Radio

13. (BRN ) - Siren Speaker

14. (RED/BLK) - Ignition (12VDC)

*

*

*16AWG

1. (GRY) - Output #4 (10A Max.)

2. (VIO) - Output #5 (10A Max.)

3. (BLU) - Output #6 (10A Max.)

4. (GRN) - Output #7 (10A Max.)5.6. (ORG) - Output #8 DCR Common

7. (RED) - Output #8 DCR N/C

8. (BRN) - Output #8 DCR N/O

Not Used

1. (BRN) - T/A Lamp #1

2. (RED) - T/A Lamp #2

3. (ORG) - T/A Lamp #3

4. (YEL) - T/A Lamp #4

5. (GRN) - T/A Lamp #5

6. (BLU) - T/A Lamp #6

7. (VIO) - T/A Lamp #7

8. (GRY) - T/A Lamp #8

9. (WHT) - T/A 12VDC Lamp Voltage

10.

11.

12.

Not Used

Not Used

Not Used

1. (BRN) - Expansion Input #1 (POS)

2. (RED) - Expansion Input #2 (POS)

3. (ORG) - Expansion Input #3 (POS)

4. (YEL) - Expansion Input #4 (POS)

5. (GRN) - Expansion Input #5 (POS)

6. (BLU) - Expansion Input #6 (POS)

7. (VIO) - Expansion Input #7 (POS)

8. (GRY) - Expansion Input #8 (POS)

9. (WHT/BRN) - Expansion Input #1 (NEG)

10. (WHT/RED) - Expansion Input #2 (NEG)

11. Expansion Input #3 (NEG)

12. Expansion Input #4 (NEG)

13. Expansion Input #5 (NEG)

14. Expansion Input #6 (NEG)

15. Expansion Input #7 (NEG)

16. Expansion Input #8 (NEG)

(WHT/ORG) -

(WHT/YEL) -

(WHT/GRN) -

(WHT/BLU) -

(WHT/VIO) -

(WHT/GRY) -

CONTROL HEAD

WC Lightbar

123

Optional Microphone Extension

Cord Shown For Reference Only

System Wiring Guide

Page 11

Page 12

Amp Relay Module I/O

16. PIN 1 - Output #4 (10A / GRY)

17. PIN 2 - Output #5 (10A / VIO)

18. PIN 3 - Output #6 (10A / BLU)

19. PIN 4 - Output #7 (10A / GRN)

20. PIN 5 - Unused

21. PIN 6 - Output #8 (Dry Contact Relay - Common)

22. PIN 7 - Output #8 ( Normally Closed)

23. PIN 8 - Output #8 ( Normally Open)

Dry Contact Relay -

Dry Contact Relay -

1. Output #1

(40A / WHT)

40A Max. Total

20A Max. Each

2. Output #2

(20A / BLU)

24. Microphone Port

39. Diagnostic LEDs41. WC Lightbar Port

PIN 1 - CAN A (Green)

PIN 2 - Shield (Bare)

PIN 3 - CAN B (Grey)

40. Control Head42. USB Port

46. System Power

50A

50A

45. System Power

44. System Ground

43. System Ground

3. Output #3

(20A / GRN)

4. PIN 1 -

5. PIN 2 -

6. PIN 3 -

7. PIN 4 -

8. PIN 5 -

9. PIN 6 -

10. PIN 7 -

11. PIN 8 -

12. PIN 9 - (+) Lamp Voltage (WHT)

13. PIN 10 - No Connection

14. PIN 11

T/A Lamp #1 (BRN)

T/A Lamp #2 (RED)

T/A Lamp #3 (ORN)

T/A Lamp #4 (YEL)

T/A Lamp #5 (GRN)

T/A Lamp #6 (BLU)

T/A Lamp #7 (VIO)

T/A Lamp #8 (GRY)

- No Connection

15. PIN 12 - No Connection

. PIN 1

. PIN 2

. PIN 3

. PIN 4

. PIN 5

. PIN 6

. PIN 7

. PIN 8

33. PIN 9 Logic Input 4 / Horn Ring +/- WHT/YEL

34. PIN 10 Output #11 (250 mA) ORG

. PIN 11

25 Logic Input 1 +/- WHT/BRN

26 Logic Input 3 +/- WHT/ORG

27 Output #10 - 250 mA RED

28 Output #9 - 250 mA BRN

29 Radio BLU

30 Siren Speaker ORG (16 AWG)

31 Backlight Input 12VDC WHT/BLK

32 Logic Input 2 +/- WHT/RED

35 Output #12 / Horn Transfer (250 mA) YEL

36. PIN 12 Radio BLU

37. PIN 13 Siren Speaker BRN (16 AWG)

38. PIN 14 Ignition +12VDC RED/BLK

CenCom™ Module

Input/Output Identification

12345678

12

3

4

5

6

78

910

11

12

13

14

1516

1

8

2

9

3

10

4

11

5

12

6

13

7

14

12 9 6 3

11852

10741

123

PIN 1 (BRN) - Expansion Input #1 (POS)

PIN 2 (RED) - Expansion Input #2 (POS)

PIN 3 (ORG) - Expansion Input #3 (POS)

PIN 4 (YEL) - Expansion Input #4 (POS)

PIN 5 (GRN) - Expansion Input #5 (POS)

PIN 6 (BLU) - Expansion Input #6 (POS)

PIN 7 (VIO) - Expansion Input #7 (POS)

PIN 8 (GRY) - Expansion Input #8 (POS)

PIN 9 (WHT/BRN) - Expansion Input #1 (NEG)

PIN 10 (WHT/RED) - Expansion Input #2 (NEG)

PIN 11 (WHT/ORG) - Expansion Input #3 (NEG)

PIN 12 (WHT/YEL) - Expansion Input #4 (NEG)

PIN 13 (WHT/GRN) - Expansion Input #5 (NEG)

PIN 14 (WHT/BLU) - Expansion Input #6 (NEG)

PIN 15 (WHT/VIO) - Expansion Input #7 (NEG)

PIN 16 (WHT/GRY) - Expansion Input #8 (NEG)

Note:

The optional Input Expansion Module is

programed using the CenCom Software

program.

Wiring ID

Page 12

Page 13

Configuration Record

Description:

For future reference, record the

destination of each outlet and

programmable input.

Configuration Record:

Assigned To:

Connector / Pin #

Connector

B

Connector

D

Connector

C

Connector

A

Output #1 - 40 Amp (WHT)

Output #2 - 20 Amp (BLU)

Output #3 - 20 Amp (GRN)

Output #4 - 10 Amp (GRY)

Output #5 - 10 Amp (VIO)

Output #6 - 10 Amp (BLU)

Output #7 - 10 Amp (GRN)

Output #8 - 10 Amp Dry Contact Relay: Common (ORN)

Output #8 - 10 Amp Dry Contact Relay: N/C (RED)

Output #8 - 10 Amp Dry Contact Relay: N/O (BRN)

Output #9 - 250 mA (BRN)

Output #10 - 250 mA (RED)

Output #11 - 250 mA (ORN)

Output #12 - 250 mA / Horn Relay (YEL)

Programable Input #1 (WHT/BRN)

Programable Input #2 (WHT/RED)

Programable Input #3 / Park Kill (WHT/ORN)

Programable Input #4 / Horn Ring (WHT/YEL)

External Input #1 - Pos. (BRN)

External Input #1 - Neg. (WHT/BRN)

External Input #2 - Pos. (RED)

External Input #2 - Neg. (WHT/RED)

External Input #3 - Pos. (ORN)

External Input #3 - Neg. (WHT/ORN)

External Input #4 - Pos. (YEL)

External Input #4 - Neg. (WHT/YEL)

External Input #5 - Pos. (GRN)

External Input #5 - Neg. (WHT/GRN)

External Input #6 - Pos. (BLU)

External Input #6 - Neg. (WHT/BLU)

External Input #7 - Pos. (VIO)

External Input #7 - Neg. (WHT/VIO)

External Input #8 - Pos. (GRY)

External Input #8 - Neg. (WHT/GRY)

Connector A / Pins #1&2

Connector A / Pin #3

Connector A / Pin #4

Connector B / Pin #1

Connector B / Pin #2

Connector B / Pin #3

Connector B / Pin #4

Connector B / Pin #6

Connector B / Pin #7

Connector B / Pin #8

Connector C / Pin #4

Connector C / Pin #3

Connector C / Pin #10

Connector C / Pin #11

Connector C / Pin #1

Connector C / Pin #8

Connector C / Pin #2

Connector C / Pin #9

Connector D / Pin #1

Connector D / Pin #9

Connector D / Pin #2

Connector D / Pin #10

Connector D / Pin #3

Connector D / Pin #11

Connector D / Pin #4

Connector D / Pin #12

Connector D / Pin #5

Connector D / Pin #13

Connector D / Pin #6

Connector D / Pin #14

Connector D / Pin #7

Connector D / Pin #15

Connector D / Pin #8

Connector D / Pin #16

112

23344

5

6

78

21

3

9

4

5

11

6

12

7138

14

1516 10

213

9

4

5

11612

7

13

8

14

10

Page 13

Page 14

5 Amps

55 Amps

10 Amps

60 Amps

15 Amps

65 Amps

20 Amps

70 Amps

25 Amps

75 Amps

30 Amps

80 Amps

35 Amps

85 Amps

40 Amps

90 Amps

45 Amps

95 Amps

50 Amps

100 Amps

6 Feet 3 Feet Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient

22 AWG

20 AWG

18 AWG

16 AWG

14 AWG

12 AWG

10 AWG

8AWG

6AWG

4AWG

2AWG

9.5 Feet 5 Feet 3 Feet Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient

15 Feet 7.5 Feet 5 Feet 4 Feet 3 Feet Insufficient Insufficient Insufficient Insufficient Insufficient

24.5 Feet 12 Feet 8 Feet 6 Feet 5 Feet 4 Feet 3.5 Feet 3 Feet Insufficient Insufficient

39 Feet 19.5 Feet 13 Feet 9.5 Feet 8 Feet 6.5 Feet 5.5 Feet 5 Feet 4.5 Feet 4 Feet

62 Feet 31 Feet 20.5 Feet 15.5 Feet 12.5 Feet 10.5 Feet 9 Feet 7.5 Feet 7 Feet 6 Feet

98 Feet 49 Feet 32.5 Feet 24.5 Feet 19.5 Feet 16.5 Feet 14 Feet 12.5 Feet 11 Feet 10 Feet

156 Feet 78 Feet 52 Feet 39 Feet 31 Feet 26 Feet 22.5 Feet 19.5 Feet 17.5 Feet 15.5 Feet

248.5 Feet 124 Feet 82.5 Feet 62 Feet 49.5 Feet 41.5 Feet 35.5 Feet 31 Feet 27.5 Feet 25 Feet

395 Feet 197.5 Feet 131 Feet 98.5 Feet 79 Feet 66 Feet 56.5 Feet 49.5 Feet 44 Feet 39.5 Feet

629 Feet 314 Feet 209 Feet 157 Feet 125.5 Feet 104.5 Feet 89.5 Feet 78.5 Feet 69.5 Feet 63 Feet

Maximum Current Draw Through The Wire

Wire Gauge

22 AWG

20 AWG

18 AWG

16 AWG

14 AWG

12 AWG

10 AWG

8AWG

6AWG

4AWG

2AWG

Maximum Current Draw Through The Wire

Wire Gauge

Wire Gauge Calculation Chart

Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient

Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient

Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient

Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient

3.5 Feet 3 Feet 3 Feet 3 Feet Insufficient Insufficient Insufficient Insufficient Insufficient Insufficient

5.5 Feet 5 Feet 5 Feet 4.5 Feet 4 Feet 4 Feet 3.5 Feet 3.5 Feet 3.5 Feet 3 Feet

9 Feet 8 Feet 7.5 Feet 7 Feet 6.5 Feet 6 Feet 6 Feet 5.5 Feet 5 Feet 5 Feet

14 Feet 13 Feet 12 Feet 11 Feet 10.5 Feet 10 Feet 9 Feet 8.5 Feet 8 Feet 8 Feet

22.5 Feet 20.5 Feet 19 Feet 17.5 Feet 16.5 Feet 15.5 Feet 14.5 Feet 14 Feet 13 Feet 12.5 Feet

36 Feet 33 Feet 30.5 Feet 28 Feet 26.5 Feet 24.5 Feet 23 Feet 22 Feet 21 Feet 19.5 Feet

57 Feet 52.5 Feet 48.5 Feet 45 Feet 42 Feet 39 Feet 37 Feet 35 Feet 33 Feet 31.5 Feet

Wire Gauge Chart

Page 14

Loading...

Loading...