Page 1

®

ENGINEERING COMPANY INC.

51 Winthrop Road

Chester, Connecticut 06412-0684

Installati on Guide:

Centurion™ Lightbar

Phone: (860) 526-9504

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mai l: auto can@whelen.com

Customer Service e-mail: custserv@whelen.com

Safety First

This document provid es all the nec es sa ry in form at ion to allow your Whelen prod uc t to b e pro perl y a nd s afe ly ins tal le d.

Before beginning the installation and/or operation of your new product, the installation technician and operator must

read this manual completely. Important information is contained herein that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of automotive electronics,

systems and proced ur es.

• If mounting this product requires drilling holes, the installer MUST be sure that no vehicle components or other

vital parts could be damaged by the drilling process. Check both sid es of the mo unting sur f ace bef ore drilling

begins. Also de-burr any holes and remove any metal shards or remnants. Install grommets into all wire

passage holes.

• If this manual states that this product may be mounted with suction cups, magnets, tape or Velcro®, clean the

mounting surface with a 50/50 mix of isopropyl alco hol and wa te r and dry thoroughly.

• Do not install this product or route any wires in the deployment area of your air bag. Equipment mounted or

located in the air bag deployment area will damage or reduce the effectiveness of the air bag, or become a

projectile that could cause serious personal injury or death. Refer to your vehicle owner’s manual for the air bag

deployment area. The User/Installer assumes full responsibility to deter m ine pr oper mounting location, based

on providing ultimate safet y t o al l passenge rs ins id e the vehicle.

• For this product to operate at optim u m ef f icie ncy, a good electrical connec tion t o chassis ground must be

made. The recommended procedure requires the product ground wire to be connected directly to the NEGATIVE

(-) battery post.

• If this product uses a rem ote d evice to activate or control th is product, make sure that th is control is located in

an area that allows both the vehicl e a nd th e control to be operated safely in any dr i vi ng co ndi tion.

• Do not attempt to activate or con trol this device in a hazardous driving si tu at io n.

• This product contains either strobe light(s), halogen light(s), high-intensity LEDs or a com bination of these

lights. Do not stare directly into these lights. Momentary blindness and/or eye damage could result.

• Use only soap and water to clean the outer lens. Use of other chemicals could result in premature lens cracking

(crazing) and discoloration. Lenses in this cond ition hav e sign ificantly reduced effectiveness and should be

replaced immediately. Inspect and operate this product regularly to confirm its proper operation and mountin g

condition. Do not use a pre ss u re w asher to clean this product.

• It is recommended tha t th ese instructions be stored i n a safe place and referred t o w hen performing

maintenance and/or reinstallation of this product.

• FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND INSTR UCTIONS COUL D RESULT IN DAMAGE TO

THE PRODUCT OR VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR PASSENGERS!

Automotive: Lightbars

For warranty information regarding this product, visit www.whelen.com/warranty

©1998 Whelen Engineering Company Inc.

Form No.13317F (062210)

Page 1

Page 2

IMPORTANT! The lightbar should be located a minimum of

16" from any radio antennas!

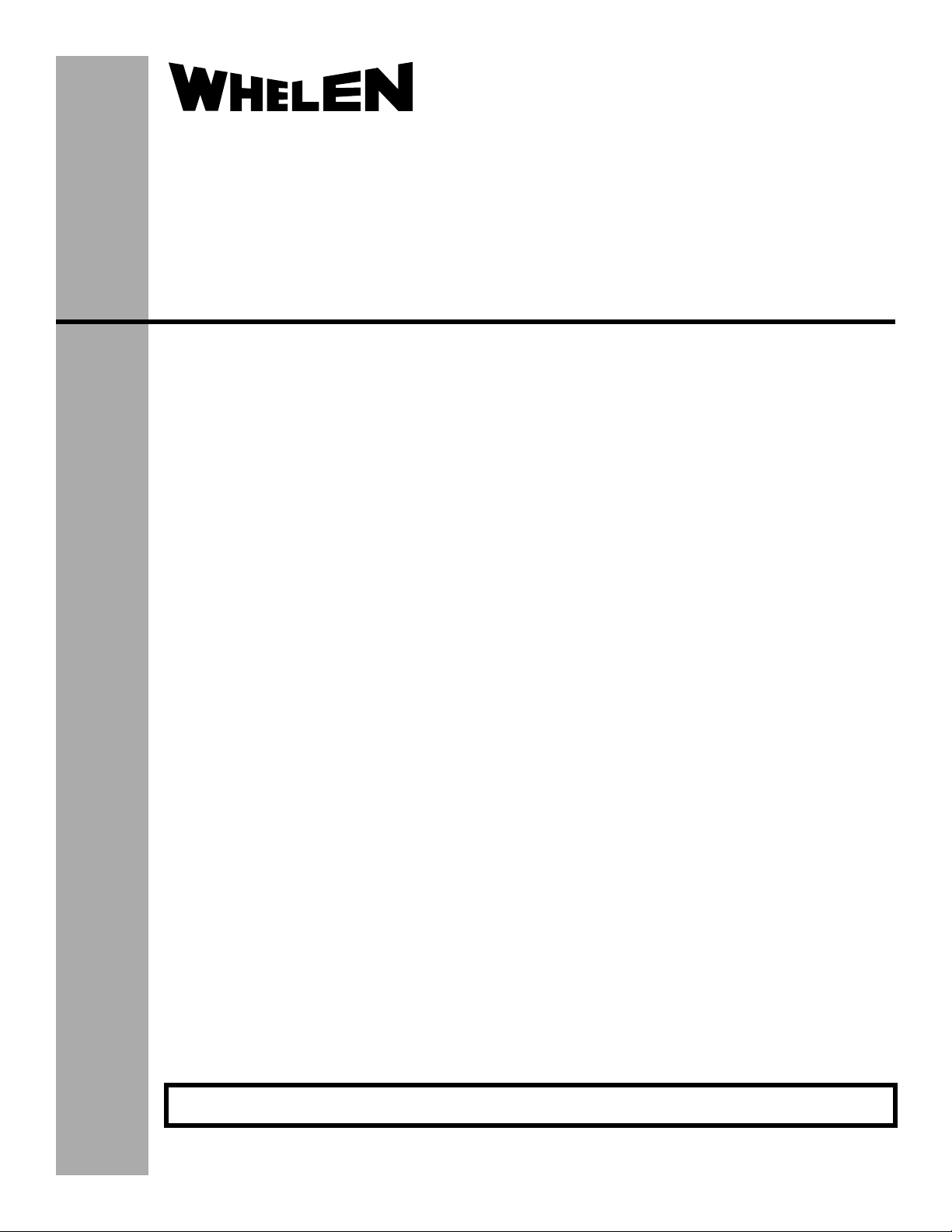

Permanent Mounting:

1. Locate the mounting foot and locking plate included with your

lightbar. If not already present, install the locking plate onto the

mounting foot. When properly positioned, this plate is centered from

side to side on the mounting foot.

2. Flip the lightbar upside-down to expose the bottom of the extrusion

and place the mounting foot onto the extrusion.

3. Rotate the mounting foot 90° in a counter-clockwise direction. Make

sure that the edges of the mounting foot swing into position under the

extrusion mounting lip.

4. Repeat this procedure for the remaining mounting foot and return the

lightbar to its right side-up position.

5. Position the lightbar onto the vehicle roof in the desired mounting

location. One often selected location is directly above the B-pillars.

This area is the strongest part of the roof. Refer to your lightbar

manual for cable exit location, to be sure that the lightbar is facing the

proper direction.

6. Adjust the two mounting feet outwards so that they are as close to

the edge of the roof as possible. Make s ure that both mounting feet

are in full contact with the roof. Be sure that there is no less than 1/2”

clearance between the roof and the lightbar at their closest point.

When the mounting feet are in their proper position, lightly tighten the

locking plate allen head set screws.

7. Turn the lightbar upside down and firmly tighten all of the set screws

from step 6 (2 or 4 per side).

8. On the adjustable foot, use the hole in the pad as a guide to drill the

two holes into the mounting foot at the locations shown.

Standard

Mounting

Bolt

Bolt

Locking

Plate

Foot

Mounting

Foot

Base

Nut

Washer

Mounting

Pad

9. Place the lightbar in its final mounting position on the vehicle, mark

the mounting hole locations off onto the mounting surface, remove

the lightbar and drill the mounting holes.

10. Place the lightbar back onto the vehicle lined up with the mounting

holes and secure the mounting feet to the vehicle with the supplied

hardware.

Mounting

Pad

Washer

Nut

Adjustable

Mounting

Foot

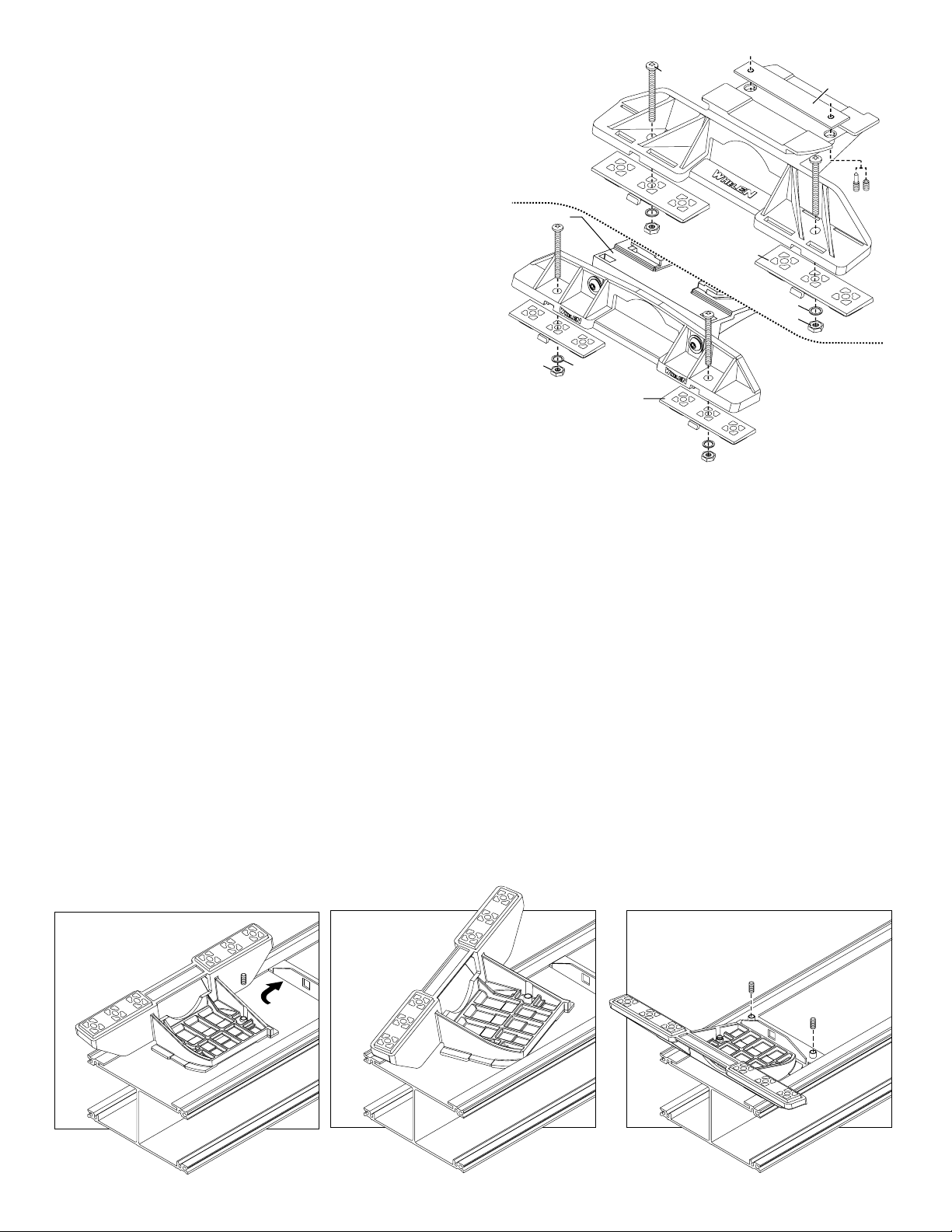

Strap Mounting:

1. Locate the mounting foot, anchor plate and locking plate included with

your lightbar. If not already present, install the locking plate onto the

mounting foot. When properly positioned, this plate is centered from sideto-side on the mounting foot.

2. Flip the lightbar upside-down to expose the bottom of the extrusion and

place the mounting foot onto the extrusion.

3. Rotate the mounting foot 90° in a counter-clockwise direction. Make sure

that the edges of t he mounting f oot s wing int o p ositi on u nde r t he ex tru sion

mounting lip. Install an anchor plate onto the extrusion in the same

manner.

4. Repeat this procedure for the remaining mounting foot and anchor plate

and return the lightbar to its right side-up position.

5. Position the lig htbar ont o the v eh icle ro of in the d esi red mou nt ing locat ion .

One often selected location is directly above the B-pillars. This area is the

strongest part of the roof. Refer to your lightbar manual for cable exit

location, to be sure that the lightbar is facing the proper direction.

6. Adjust the two mounting feet outwards so that they are as close to the

edge of the roof as possible. Both mounting feet must be in full contact

with the roof. Be sure that there is no less than 1/2” clearance between

Insert foot into extrusion with locking plate

attached.

ANCHOR

PLATE

Twist mounting foot into

position

roof and lightbar at their closest poin t. When the mounti ng feet are in the ir

proper position, lightly tighten the locking plate allen head set screws.

7. Return the lightbar to an upside-down position. Slide each anchor plate

outwards until it is fully engaged with its corresponding mounting foot.

With the mounting feet and anchor plates in their proper positions firmly

tighten all of the s et screws (2 or 4 per side). Flip the lightba r right side-up

and return it to its mounting position.

8. Open both drivers side doors. In the area directly below the mounting

foot, pull the weatherstrip away from the vehicle so the area where the

mounting strap will be secured is expos ed. Repeat for the other side.

9. Insert the mounting strap through the mounting foot. Be sure that the

strap fits flush against the area where it will be secured onto the vehicle.

Insert the tension bolt through the mounting strap and anchor plate, into

the tinnerman nut. Tighten slightly with a long-shafted, Phillips

screwdriver. Repeat procedure for pas senger side.

10. If your mounting strap has mounting holes in the end of the strap, use

these holes as a template to drill appropriately sized pilot holes through

the strap and into the vehicle. Repeat for passenger side of the vehicle.

11. Firmly tighten the tension bolt s t o secure the lightbar to the vehicle.

Loosely secure foot and locking plate.

Page 2

Page 3

NOTE: Model MKAJ is an adjustable mounting foot. On this model you

may loosen the screws on the rear of the foot and adjust the angle of the

lightbar. This feature can be used if the angle of the roof is not level with

the road. IMPORTANT: To adjust the leveling screws you must use a

torque wrench set at 35 to 40in./lbs.

Adjustable Foot

Model MKAJ

Tension

Bolt

Mounting

Screw

Adjustment

screws

Lock

Washer

5" Mounting Foot

METAL SCREW

SHEET

METAL

SCREWS

NOTE: The mounting straps are made to fit the contours of individual

NOTE:

NOTE:

NOTE:

NOTE:

NOTE:

NOTE:

Mounting Strap

Locking

BOLT

STRAP

vehicles. The strap

for your vehicle

mounting foot, it will assemble differently than the standard

mounting foot. It also uses an extension to compensate for

the extra height. Follow these illustrations for assembly.

Mounting to the lightbar is the same.

Anchor Plate

Plate

Tinnerman

Nut

Nut

Mounting

Foot

Mounting

Pad

MOUNTING FOOT

EXTENSION

SPLIT LOCK

WASHER

shown here is for example only. The strap

may look different. If your lightbar has a 5"

Allen

screws

Mounting

Foot Base

NUT

Model

MKAJ

Tighten screws

with torque wrench

set at 35 to 40 in/lbs

Mounting

Screw

TINNERMAN

NUT

FOOT

ANCHOR

PLATE

VEHICLE ROOF

Mounting

Strap

Tension

Bolt

Plate slides into

lightbar extrusion

SET

SCREW

Locking

Plate

Standard Foot

Anchor

Plate

Model MKEZ

Tinnerman

Nut

Mounting

Foot

IMPORTANT: For strap mounted bars, be sure you have the right sized

lightbar for your vehicle. The lightbar should be approximately the same

width as the vehicle roof. If too large or small it will not mount properly

1/2" MIN. CLEARANCE

NOTE: Unless otherwise specified, the lightbar mounting feet must be sitting as close to the edge of the roof as possible. They must also be

in full contact with the roof and not be hanging off the edge.

to the vehicle and may come loose during driving.

Page 3

Page 4

Routing your Edge® Lightbar Cable(s)

1. To protect the headliner from damage caused by drilling the cable access

hole through the vehicle roof, allow a 5” to 7” distance between roof and

headliner by lowering the headliner before drilling.

2. Using a 1” hole saw, drill the cable access hole.

NOTE:There may be a roof support member that spans the distance between

the driver’s and passenger’s side. DO NOT DRILL THROUGH THIS MEMBER!

Adjust the location un til the hole can be drilled without contacting this support member.

3. Use a round file to smooth and de-burr the edges of the hole.

4. Insert a 1” grommet (user supplied) into the cable access hole.

5. Insert the cable(s) through the cable access hole into the vehicle. Use RTV

silicone to weatherproof the access hole after the cable(s) are pulled

completely into the vehicle.

6. Route the cable(s) down through the B-pillar. The cable(s) must make a 90°

turn to enter the B-pillar. Although routing the cable in this manner may be

difficult, this has been determined to be the best procedure. It is up to the

installation technicians discretion whether to route the cable(s) as

recommended or use an alternative route. Pull the full length of the cable(s)

out of the hole at the base of the B-pillar (Fig. 1) and route towards your

switch panel. Refer to the instructions included with your switches for switch

wiring information.

NOTE: The outer surfaces of this product may be cleaned with mild

soap and water. Use of any other chemicals may void product warranty. Do not use a pressure washer.

Fig. 1

DRILLING THE CABLE ACCESS HOLE

FRONT OF LIGHTBAR

For

lightbars

cables exiting

with

the Driver-side

of the extrusion

Drill cable access hole in appropriate area

for your lightbar (see note)

CABLE EXIT HOLE

F

R

O

N

T

For

lightbars

cables exiting

with

the Passenger-side

of the extrusion

B-PILLAR

(INSIDE VIEW)

WIRE SHIELD

WIRING DIAGRAM

(8/C 14GA CABLE)

+ POS. DC INPUT

CABLE INPUT LOCATION

FRONT

BROWN - (REAR FLASHER OR OTHER DESIRED OPTION)

RED - (OUTBOARD ROTATOR)

ORANGE - (CENTER ROTATOR )OR OTHER DESIRED OPTION

YELLOW - (DRIVER ALLEY )OR OTHER DESIRED OPTION

GREEN - (PASS. ALLEY )OR OTHER DESIRED OPTION

BLUE - (INBOARD ROTATOR )OR OTHER DESIRED OPTION

VIOLET - (FRONT FLASHER )OR OTHER DESIRED OPTION

GRAY - (TAKEDOWN )OR OTHER DESIRED OPTION

BLACK - TO NEGATIVE TERMINAL OF BATTERY

Page 4

Loading...

Loading...