Page 1

®

ENGINEERING COMPANY INC.

51 Winthrop Road

Chester, Connecticut 06412-0684

900 Series LED Lighthead

Installation Manual

Phone: (860) 526-9504

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Canadian Sales e-mail: canadiansales@whelen.com

Customer Service e-mail: custserv@whelen.com

Safety First

This document provides all the necessary information to allow your Whelen product to be properly and safely installed.

Before beginning the installation and/or operation of your new product, the installation technician and operator must

read this manual completely. Important information is contained herein that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of automotive electronics,

systems and procedures.

• If mounting this product requires drilling holes, the installer MUST be sure that no vehicle components or other

vital parts could be damaged by the drilling process. Check both sides of the mounting surface before drilling

begins. Also de-burr any holes and remove any metal shards or remnants. Install grommets into all wire

passage holes.

• If this manual states that this product may be mounted with suction cups, magnets, tape or Velcro®, clean the

mounting surface with a 50/50 mix of isopropyl alcohol and water and dry thoroughly.

• Do not install this product or route any wires in the deployment area of your air bag. Equipment mounted or

located in the air bag deployment area will damage or reduce the effectiveness of the air bag, or become a

projectile that could cause serious personal injury or death. Refer to your vehicle owner’s manual for the air bag

deployment area. The User/Installer assumes full responsibility to determine proper mounting location, based

on providing ultimate safety to all passengers inside the vehicle.

• For this product to operate at optimum efficiency, a good electrical connection to chassis ground must be

made. The recommended procedure requires the product ground wire to be connected directly to the NEGATIVE

(-) battery post.

• If this product uses a remote device to activate or control this product, make sure that this control is located in

an area that allows both the vehicle and the control to be operated safely in any driving condition.

• Do not attempt to activate or control this device in a hazardous driving situation.

• This product contains either strobe light(s), halogen light(s), high-intensity LEDs or a combination of these

lights. Do not stare directly into these lights. Momentary blindness and/or eye damage could result.

• Use only soap and water to clean the outer lens. Use of other chemicals could result in premature lens cracking

(crazing) and discoloration. Lenses in this condition have significantly reduced effectiveness and should be

replaced immediately. Inspect and operate this product regularly to confirm its proper operation and mounting

condition. Do not use a pressure washer to clean this product.

• It is recommended that these instructions be stored in a safe place and referred to when performing

maintenance and/or reinstallation of this product.

• FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND INSTRUCTIONS COULD RESULT IN DAMAGE TO

THE PRODUCT OR VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR PASSENGERS!

Automotive: Lightheads

For warranty information regarding this product, visit www.whelen.com/warranty

©2001 Whelen Engineering Company Inc.

Form No.13629M (120711)

Page 1

Page 2

ARROW / WIDE ANGLE / FLOOD

Colored

This wire color will be whatever the color

of its LED is when light is switched on.

+12 VDC

Black

White/Violet

Ground

Scan-Lock™

Wire Color

Function

BACK-UP

Colored

This wire color will be whatever the color

of its LED is when light is switched on.

+12 VDC

Black

Ground

Wire Color

Function

Yellow

Brown

White

Wht/Vio

Stop Turn/ (+ 12 VDC)

Taillight (+12 VDC)

Ground

Scan-Lock™

Wire Color

Function

BRAKE / TAIL / TURN

Yellow or Red

Black

Yellow or Red

+12 VDC

+12 VDC

, Control Wire 1

, Control Wire 2

Ground

Wire Color

Function

SPLIT / SMT

White

Grey

Black

Positive (+) High Power

Positive (+) Low Power

Ground

Wire Color

Function

COMPARTMENT LIGHT

Wiring:

IMPORTANT NOTICE! This product has been designed for improved

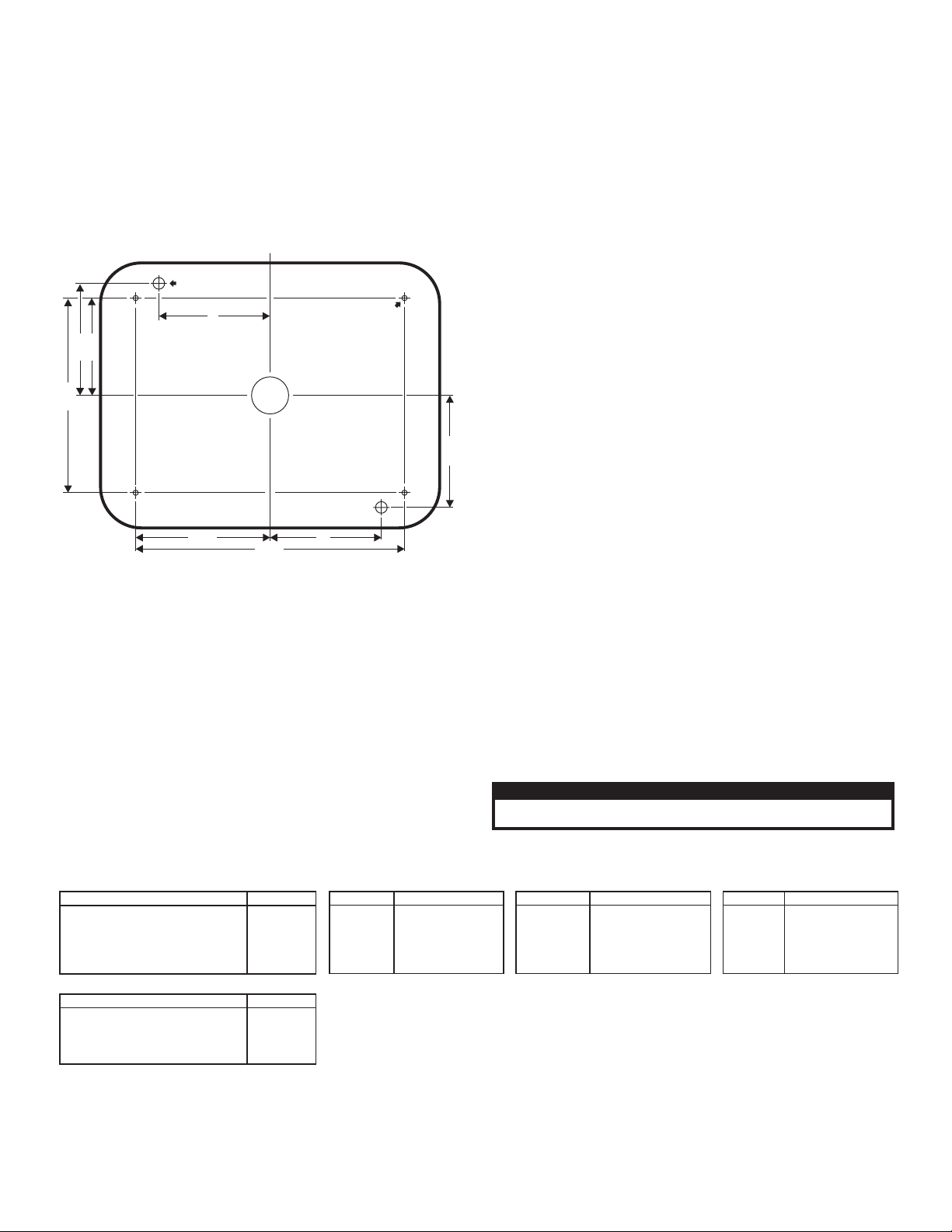

7.250"

3.625"

2.625"

5.250"

3.020"

3.020"

3"

3"

5/16"(.312")Hole

(2 Places)

.250" (1/4")

mounting hole for

grommet (4 places)

1"

WIRE

HOLE

900 Series

Mounting

Dimensions

CAUTION! DO NOT LOOK DIRECTLY AT THESE LED’S WHILE THEY ARE ON.

MOMENTARY BLINDNESS AND/OR EYE DAMAGE COULD RESULT!

IMPORTANT WARNING!

visibility. Prior to installing this product on any vehicle, check your

state motor vehicle codes to confirm that this product complies with

any and all state statutes.

Typical Mounting Style:

1. Using the dimensions from the diagram below, mark off and drill the

two 5/16” diameter vent tube holes and the 1” center wire hole into the

mounting surface. Make sure lighthead will not interfere with existing

equipment and be aware of any items on the opposite side of the

mounting surface.

2. Insert the two vent tubes extending from the rear of the lighthead into

their holes making sure that the lighthead is oriented as shown. Using

a scribe or similar tool, mark off the 4 mounting holes.

3. Using a 1/4” drill bit drill the four mounting holes and install the flange

grommet. Install a rubber grommet (customer supplied) into the 1” wire

hole.

WARNING! All customer supplied wires that connect to the positive

terminal of the battery must be sized to supply at least 125% of the

maximum operating current and FUSED at the battery to carry the

load. DO NOT USE CIRCUIT BREAKERS WITH THIS PRODUCT!

4. Using appropriately sized wires, run the lighthead wires to their

connections (see wiring). Fuse the +12VDC connections at 3 Amps and

test the operation of the lighthead before securing it to the vehicle.

5. Position lighthead components onto mounting surface and secure the

lighthead to the vehicle using four #8 x 1½” sheet metal screws.

This product draws significantly less current than a standard incandescent

automotive bulb. If your flasher does not operate properly, it may be

necessary to replace your existing flasher module with a Whelen 3TERM

flasher module. Contact your sales representative for specific vehicle

application.

Scan-Lock™ (White/Violet)

WARNING: Pattern selection requires the LEDs to be turned on. Do

not look directly at the LEDs while the unit is on.

TO CHANGE PATTERNS: Apply +12 volts to the WHITE/VIOLET wire for

less than 1 second and release to cycle forward to the next available

pattern. Apply +12 volts to the WHITE/VIOLET wire for more than 1

second and release to cycle back to the previous pattern.

TO CHANGE DEFAULT PATTERN: When the desired pattern is

displayed, allow it to run for more than 5 seconds. The lighthead will now

display this pattern when initially activated.

TO RESTORE FACTORY DEFAULT PATTERN: With the power to the

lighthead off, apply +12 volts to the WHITE/VIOLET wire. Now turn power

to the lighthead on. The factory default pattern should now be displayed.

A Normally Open momentary switch can be used to control Scan-Lock™.

Flash Patterns: SignalAlert™ 75 > SignalAlert 150 > SingleFlash 375 >

SingleFlash 150 > SingleFlash 75 > SingleFlash 150 > DoubleFlash 150 >

DoubleFlash 75 > CometFlash® 75 > ActionFlash™ > ModuFlash™ >

ComAlert™ > ActionScan™ > SignalAlert Steady > Steady (Brake) Brake

Patterns: SignalAlert Steady > Steady Brake SYNC Patterns: SignalAlert

75 simultaneous - 75 FPM > SignalAlert 75 alternating - 75 FPM Arrow

Patterns: Sequence to Solid 150 FPM > Sequence to Solid 80 FPM >

Sequence to Solid-Steady On: Fast > Sequence to Solid-Steady On: Slow

> SignalAlert™ To Steady On > Steady On Dual Color Patterns:

SingleFlash 680 alternating > SingleFlash 240 alternating > Singleflash

120 alternating > SingleFlash 150 simultaneous > DoubleFlash 240

alternating > DoubleFlash 120 alternating > DoubleFlash 150

simultaneous > CometFlash 120 alternating

simultaneous > ActionFlash alternating > ActionFlash alternatingsimultaneous > ModuFlash™ alternating > ModuFlash™ simultaneous >

SignalAlert 120 alternating > SignalAlert 100 simultaneous > ActionScan

alternating-simultaneous > Action Single, 4-110 FPM-2-65 FPM > CH1

Steady-CH2 SF120 > CH1 Steady-CH2 Action Single > CH1 Steady-CH2

CometFlash® 120 > Ch1 Steady / CH2 FastAction

IMPORTANT! Before returning this vehicle to active service, visually

confirm the proper operation of this product, as well as all vehicle

components/equipment.

> CometFlash 120

Page 2

Page 3

PART NUMBER KEY:

01-0683738___

TERMINATION

LED/LENS COLOR

STYLE

TERMINATION

0 =

1 =

2 =

3 =

NONE

DEUTSCH

AMP PINS

3 POS. CON.

SHIPPED LOOSE

3 POS. AMP

2 =

2 =

STYLE

2 =

3 =

5 =

6 =

B =

/ MIN

ARROW

WIDE ANGLE

FLOOD

/ MAX

B-T-T

B-T-T

COMPARTMENT LIGHT

B-T-T / CERTIFIED

BTT MAX 24V

BACKUP

9 =

N =

E =

7 =

LED/LENS COLOR

A=

B =

C =

G =

R =

AMBER-AMBER

BLUE-BLUE

WHITE-CLEAR

GREEN-GREEN

RED-RED

1 =

2 =

4 =

5 =

S =

K =

W =

6 =

7 =

8 =

AMBER-CLEAR

BLUE-CLEAR

GREEN-CLEAR

RED-CLEAR

AMB-AMB-AMB

RED-AMB-RED-AMB

RED-RED-RED

AMB-AMB-CLEAR

RED-AMB-CLEAR

RED-RED-CLEAR

OPTIONAL FLANGE KIT / 900 SERIES

PART NUMBER DESCRIPTIONITEMQTY

FLANGE GASKET

38-0481440-00

A1

FLANGE KIT SEALwith

01-0462945-01

*

B1

11-783130-002

FLANGE with SEAL

A

B

234

01-06837382R_

01-06837383A_

01-06837383R_

01-06837385A_

01-06837385B_

01-06837385C_

01-06837385G_

01-06837385R_

01-06837386C_

01-0683738BR_

LIGHTHEAD 900 LED B-T-T (MIN) - RED

LIGHTHEAD 900 LED WIDE ANGLE - AMBER

LIGHTHEAD 900 LED WIDE ANGLE - BLUE

LIGHTHEAD 900 LED WIDE ANGLE - WHITE

LIGHTHEAD 900 LED WIDE ANGLE - GREEN

LIGHTHEAD 900 LED WIDE ANGLE - RED

LIGHTHEAD 900 LED B-T-T (MAX) - RED

LIGHTHEAD 900 LED ARROW - AMBER

LIGHTHEAD 900 LED ARROW - RED

LIGHTHEAD 900 LED FLOOD - WHITE

SCREW, #8 X 1 1/2" PPHSMS

15-081416-240

68-1182268-10

LENS, NON OPTIC - AMBER

68-1182268-30

LENS, NON OPTIC - CLEAR

68-1182268-50

LENS, NON OPTIC - RED

68-1183542-10

LENS, OPTIC - AMBER

68-1183542-20

LENS, OPTIC - BLUE

68-1183542-30

LENS, OPTIC - CLEAR

68-1183542-40

LENS, OPTIC - GREEN

68-1183542-50

LENS, OPTIC - RED

01-0283754-52

01-0283754-13

SUB ASSY. LED ARROW -AMBER

01-0283754-53

SUB ASSY, LED ARROW - RED

01-0283754-15

SUB ASSY, LED WIDE ANGLE -AMBER

01-0283754-25

SUB ASSY, LED WIDE ANGLE - BLUE

01-0283754-35

SUB ASSY, LED WIDE ANGLE - WHITE

01-0283754-45

SUB ASSY, LED WIDE ANGLE - GREEN

01-0283754-55

SUB ASSY, LED WIDE ANGLE - RED

01-0283754-36

SUB ASSY, LED FLOOD - WHITE

01-0283754-5B

10-0522908-**

LABEL, LED LIGHTHEAD

38-0481690-00

GASKET

SUB ASSY, LED B-T-T (MIN) - RED

SUB ASSY, LED BRAKE/TAIL/TURN (MAX) RED

01-06837385S_

LIGHTHEAD 900 LED WIDE ANGLE - AMB/AMB

01-068373857_

LIGHTHEAD 900 LED WIDE ANGLE - RED/AMBER

01-06837385W_

LIGHTHEAD 900 LED WIDE ANGLE - RED/RED

02-0363407-AR

LENS, OPTIC - AMBER/RED

01-0283754-A5

SUB ASSY, LED WIDE ANGLE -AMBER/AMBER

01-0283754-K5

SUB ASSY, LED WIDE ANGLE - RED/AMBER

01-0283754-R5

SUB ASSY, LED WIDE ANGLE - RED/RED

11-786976-000

FLANGE GROMMET, 900 SERIES

SUB ASSY, LED BRAKE/TAIL/TURN (MIN) - RED/DEUTSCH

02-0383754152

02-0383754153

02-0383754113

SUB ASSY, LED ARROW - RED/DEUTSCH

SUB ASSY. LED ARROW -AMBER/DEUTSCH

02-038375415B

02-0383754136

02-0383754155

02-0383754145

02-0383754135

02-0383754125

02-0383754115

SUB ASSY, LED FLOOD - WHITE/DEUTSCH

SUB ASSY, LED WIDE ANGLE - RED/DEUTSCH

SUB ASSY, LED WIDE ANGLE - GREEN/DEUTSCH

SUB ASSY, LED WIDE ANGLE - WHITE/DEUTSCH

SUB ASSY, LED WIDE ANGLE - BLUE/DEUTSCH

SUB ASSY, LED WIDE ANGLE -AMBER/DEUTSCH

SUB ASSY, LED BRAKE/TAIL/TURN (MAX) - RED/DEUTSCH

SUB ASSY, LED WIDE ANGLE -AMB/AMB/DEUTSCH

SUB ASSY, LED WIDE ANGLE - RED/AMB/DEUTSCH

SUB ASSY, LED WIDE ANGLE - RED/RED/DEUTSCH

02-03837541R5

02-03837541K5

02-03837541A5

01-06837389C0

LIGHTHEAD 900 LED COMPARTMENT LIGHT

SUB ASSY, LED COMPARTMENT LIGHT

01-0283754-39

01-0683738NR0

LIGHTHEAD 900 LED B/T/T (CERTIFIED) RED

01-0283754-5N

SUB ASSY, LED B/T/T CERTIFIED - RED

02-0383754252

SUB ASSY, 900 LED BRAKE/TAIL/TURN(MIN)AMP

02-03837542( )3

SUB ASSY, 900 LED ARROW, AMP PINS

02-03837542( )5

SUB ASSY, 900 LED WIDE ANGLE,AMP PINS

02-0383754236

SUB ASSY, 900 LED FLOOD, AMP PINS

02-0383754258

SUB ASSY, 900 LED BRAKE/TAIL/TURN (MAX)AMP

LIGHTHEAD 900 LED B-T-T (MIN) - AMP

LIGHTHEAD 900 LED ARROW - AMP

LIGHTHEAD 900 LED WIDE ANGLE - AMP

LIGHTHEAD 900 LED FLOOD -WHITE, AMP

LIGHTHEAD 900 LED B-T-T (MAX) - AMP

39-0403013-04

HOUSING, 3 POS PIN AMP

01-0683738BR2

01-06837386C2

01-06837385( )2

01-06837383( )2

01-06837382R2

01-0683738ER0

LIGHTHEAD 900 LED B-T-T (MAX) 24V - RED

SUB ASSY, 900 LED BRAKE/TAIL/TURN (MAX) 24V

01-0283754-5E

LENS, OPTIC SCENE - CLEAR

68-1983892-30

01-06837387C0

LIGHTHEAD 900 LED BACK-UP - WHITE

02-038375435B

SUB ASSY, LED BRAKE/TAIL/TURN (MAX) - RED/3PAMP

4

1

1

1

1

1

4

1

1

1

1

1

4

1

1

1

1

1

4

1

1

1

A/R

1

1

4

1

1

1

A/R

1

1

4

1

1

1

A/R

A/R

A/R

A/R

A/R

A/R

1

4

1

1

1

A/R

A/R

A/R

A/R

A/R

A/R

1

-

4

1

1

1

A/R

1

1

4

1

1

1

1

1

4

1

1

1

A/R

1

A/R

4

1

1

1

A/R

A/R

1

A/R

4

1

1

1

A/R

1

A/R

4

1

A/R

1

1

1

A/R

A/R

4

1

A/R

1

1

1

A/R

4

1

A/R

1

1

1

A/R

4

1

A/R

1

1

1

A/R

4

1

A/R

1

1

1

A/R

4

1

A/R

1

1

1

A/R

4

1

A/R

1

1

1

A/R

4

1

A/R

1

1

1

A/R

4

1

A/R

1

1

1

A/R

A/R

SUB ASSY. LED ARROW -AMBER/3P AMP

02-0383754313

4

1

A/R

1

1

1

A/R

2

3

11

12

13

14

15

16

17

18

19

20

4

5

6

7

8

9

10

1

21

22

30

31

32

33

34

35

36

37

38

39

23

24

25

26

27

28

29

40

41

49

50

51

42

43

44

45

46

47

48

ITEM

PART NUMBER

DESCRIPTION

QTY QTY QTY QTYQTYQTYQTYQTYQTYQTYQTYQTYQTYQTYQTYQTYQTYQTYQTY QTY QTY QTY

48

4645

4241

40

50

3635

27

1918

10

47

21

1

22

13

30

16

33

14

31

17

34

15

32

586972349

38 39

44

24 25

26

37

5143

2928

1211

Page 3

Loading...

Loading...