Page 1

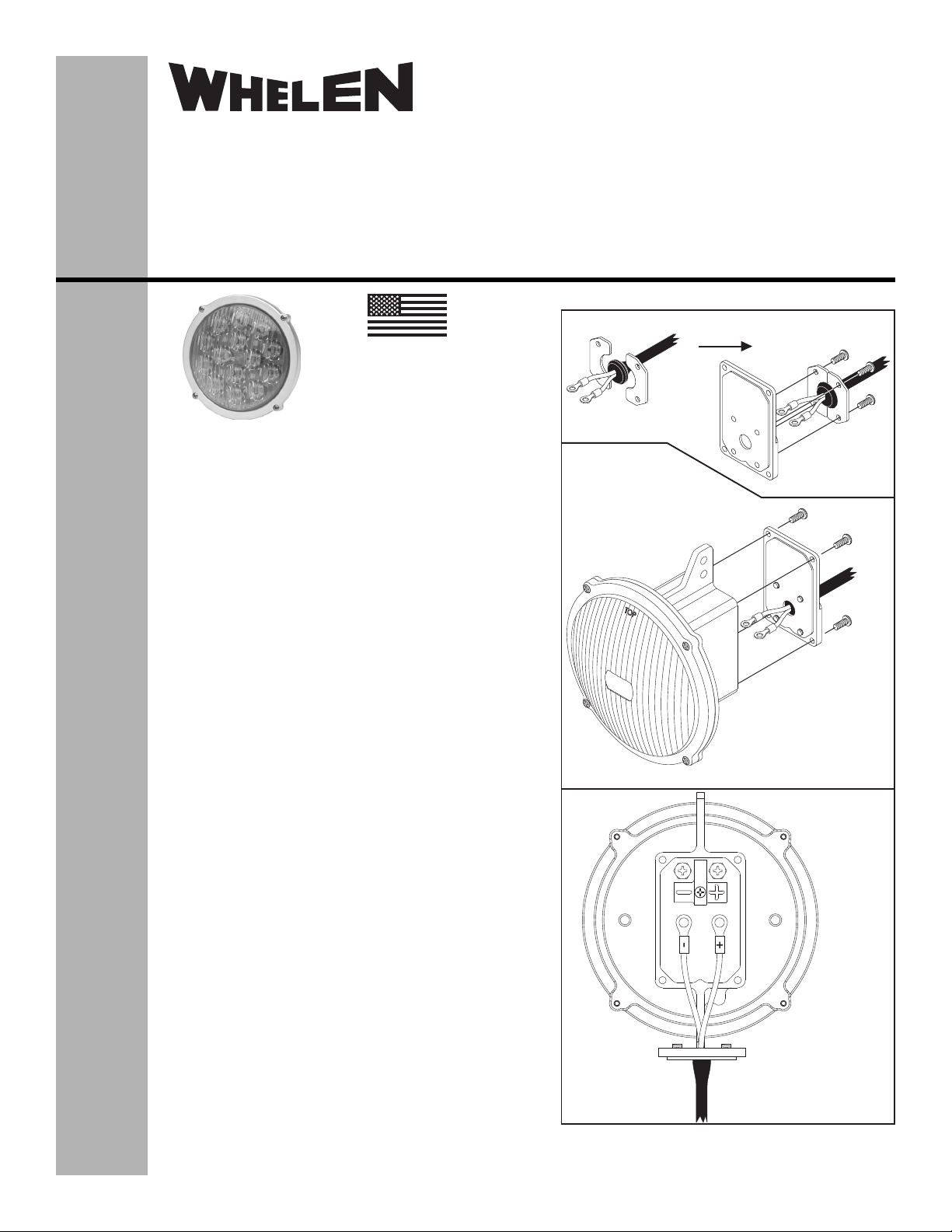

IMPORTANT: Polarity of the

input wires must match the

polarity indicated on the

light assembly!

Fig.1

Fig.2

Fig.3

®

MADE IN THE U.S.A.

ENGINEERING COMPANY INC.

51 Winthrop Road

Chester, Connecticut 06412-0684

Phone: (860) 526-9504

Fax: (860) 526-2009

Internet: www.whelen.com

Sales/Service e-mail: aviation@whelen.com

SPECIFICATIONS:

Nominal Operational Voltage:.................. 28VDC

Input Current (Nominal): .......................... 1.3 Amps

CONTINUED AIRWORTHINESS:

The Taxi Light, Model 9058900, consists of two banks of

seven LEDs, for a total of 14 LEDs. If one LED fails as a

short, the other 13 will continue to operate. If an LED fails

open, all seven LEDs in that bank will be off and the other

bank will operate normally. There is no FAR requirement for

this light. Inspect the lens. Replace if there is excessive

scratching, pitting, discoloration or cracking.

Installation Guide:

Aviation model: 9058900

P/N: 01-0790589-00

4-Inch Taxi Light Assembly

INSTALLATION PROCEDURES:

The following information is to assist in the installation of a

Whelen LED Taxi Light.

1. Remove the rear cover and cable clamps.

2. Engage the existing input cable with the cable clamps

and secure to the rear cover as shown in Fig. 1.

3. Before the rear cover is installed onto the light

assembly (Fig. 2), connect the taxi light inputs to the

assembly according to the polarity indicated. Note:

This unit is polarity sensitive and will not function

if not wired properly (see Fig. 3). Connect the power

lead to an appropriately sized breaker. Connections to

be in accordance with FAA approved methods. Coat

connections so as to prevent corrosion.

4. Using appropriate hardware, install light assembly and

insure that all leads are clear of any obstructions and

secure as required. Secure light assembly, using

vibration resistant threaded fasteners. NOTE: Make

sure the “UP” arrow is properly oriented.

5. Check all avionics systems for interference from this

installation.

6. A flight check should be performed by a properly

certified pilot.

7. Update aircraft records, complete Form 337 and obtain

FAA field approval for installation, as necessary.

Aviation

©2012 Whelen Engineering Company Inc.

Form No.14535 (112712)

Page 1

Page 2

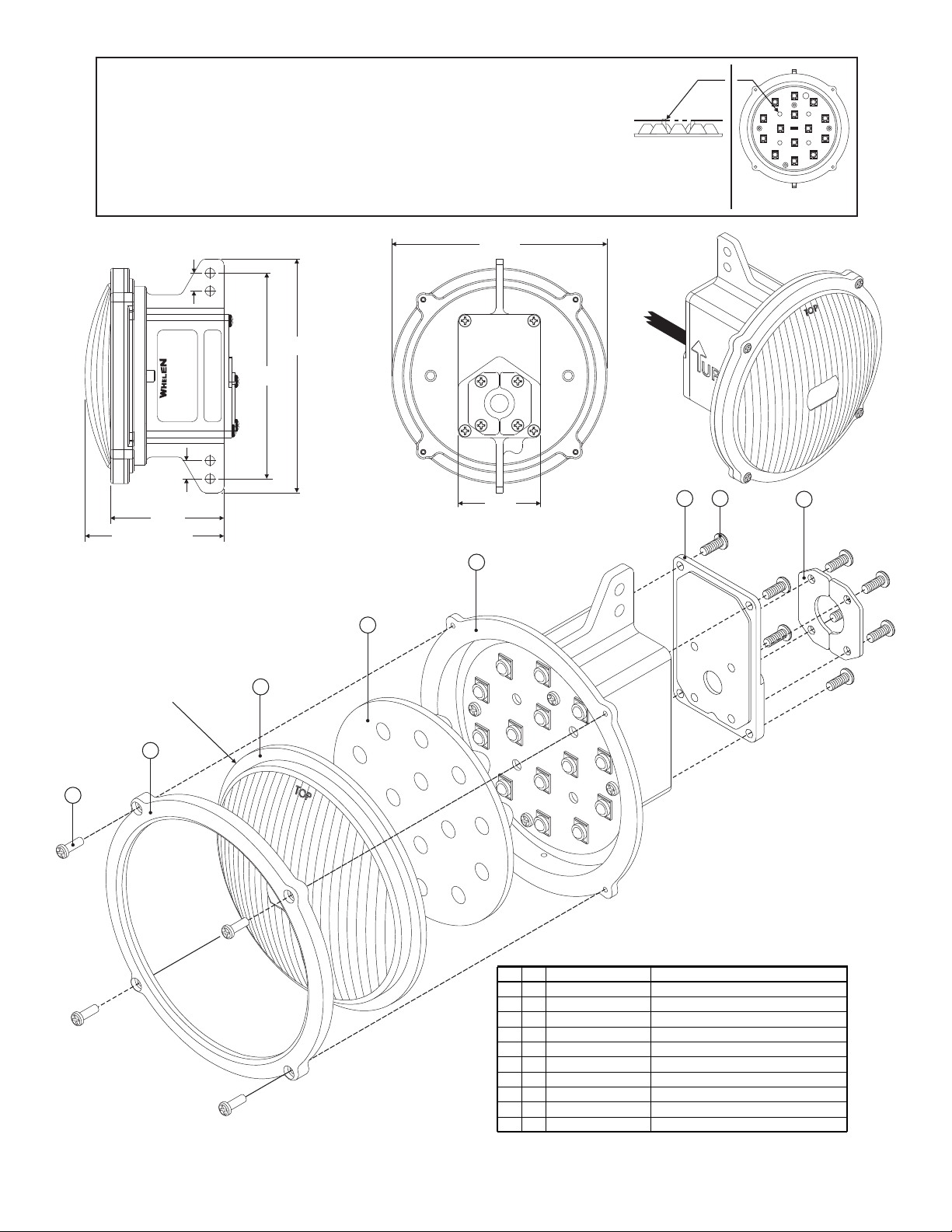

231

1

1

1

1

8

2

ITEM PART NUMBER DESCRIPTION

MODEL 9058900 TAXI LIGHT

4-40 X 7/16" PPHMS MS51957-16

6-32 X 3/8" PPHMS MS51957-28

CLAMP, CABLE

RETAINER, LENS

LENS, SPREADER

REFLECTOR, OPTIC

SUB-ASSEMBLY, 90589

COVER, BACK

01-0790589-00

14-0050505-16

19-171146-300

68-1181212A3S

68-5971090-01

01-0271692-00

11-271688-100

14-0050503-28

07-531313-005

QTY

4

5

6

7

8

14

*

4.488

5.09

.394

.394

2.48

3.03 (REF)

4.70

1.80

5

3

4

6

7

8

ENGINEERING COMPANYINC., CHESTER, CT 06412-0684, (860) 526-9504

MODEL90589

PN: 01-0790589-00

28 VDC 1.3AMPS

MFG DATE: XX/XX

REV. X

SN:XXXXX

WWW.

.COM

®

PROTECTTHE POLYCARBONATE LENS FROM

CLEANING SOLUTIONSAND HYDRAULIC FLUID

DURING MAINTENANCE

1

2

TOP

VIEW

FRONT

VIEW

Lens Replacement:

1. Remove the #4-40 lens retainer screws (Item 1). Remove the retainer and replace the

outer lens.

2. When re-assembling, note the longer post on the backside of the reflector (Item 4)

mates to the deeperholeof the sub-assembly (Item 5) shownatright.

3. To prevent damage to the lens, do not overtightenthe #4-40 screws. Tighten until there

is no gap between the retainer (Item 2) and sub-assembly (Item 5), then torque screws

to 3-5 lb/in.

64971D

J1

CAUTION!

Protect the polycarbonate

lens from cleaning solutions

and hydraulic fluids during

maintenance.

Page 2

Loading...

Loading...