Page 1

®

ENGINEERING COMPANY INC.

51 Winthrop Road

Chester, Connecticut 06412-0684

Phone: (860) 526-9504

Fax: (860) 526-2009

Internet: www.whelen.com

Sales/Service e-mail: aviation@whelen.com

Installation Guide:

Model(s) 9045301, 9045302

P/N(s): 01-0790453-01, -02

LED Wingtip Anti-Collision /

Position Light Assembly

TSO-C30c

TYPE I & II;

APPROVED

TSO-C96a

CLASS II;

APPROVED

EQUIPMENT LIMITATIONS:

An approved forward lighting system consists of at least two

lightheads, one mounted on each wingtip. A separate flasher

assembly, such as model 9045600, is required for each light assembly.

The unit must be mounted parallel to the vertical and horizontal

centerlines of the aircraft to project the patterns properly. This light

assembly must be mounted behind a clear lens.

The maximum length of the interface cable between the light assembly

and the flasher/current source is 20 feet using 20 AWG wire.

Certain types of installations may require additional testing.

SHROUD REQUIREMENT:

If justified by the Aircraft installation and additional FAA testing of

compliance to TSO-C30c and TSO-C96a the shroud may not be

required.

Remove and discard the two, #6 screws that are used to secure the

shroud. Carefully remove the shroud. CAUTION: Do not touch the LED

lens.

CONTINUED AIRWORTHINESS:

The anti-collision light is designed with 36 LEDs. The position light is

designed with 12 red or 10 green LEDs.

If any one bank fails, the flasher module should be checked. If the

module checks good, replace the lighthead. If any one LED fails, the

unit must be repaired or replaced.

Note: The system has an internal diagnostic circuit to detect failures.

After 20-25 seconds if a failure is detected the amber fault light will

illuminate.

INSTALLATION PROCEDURE:

The following information is to assist you in installing a Whelen light

system. The installation procedure described in the following text will

be confined to a single light installation, but is identical for multiple light

installations.

1. Choose the appropriate Model 90453( ) light assembly.

2. Connect the inputs according to the chart shown. Connections to

be in accordance with FAA approved methods.

3. Remove and discard the two #6 screws holding the shroud to the

unit. Carefully install the shroud as shown in Figure 1.

4. Using appropriate, approved hardware, install light assembly and

insure that all leads are clear of any obstructions and ty-rap as

required. Secure light assembly, using vibration resistant

threaded fasteners.

5. Check all avionics systems for interference from this installation.

6. A flight check should be performed by a properly certified pilot.

7. Update aircraft records, complete Form 337 and obtain FAA field

Aviation

approval for installation, as necessary.

MADE IN THE U.S.A.

(Shroud not shown)

The conditions and tests required for TSO approval of this

article are minimum performance standards. It is the

responsibility of those installing this article either on or within

a specific type or class of aircraft to determine that the aircraft

installation conditions are within the TSO standards. TSO

articles must have separate approval for installation in aircraft.

The article may be installed only if performed under 14 CFR

part 43 or the applicable airworthiness requirements.

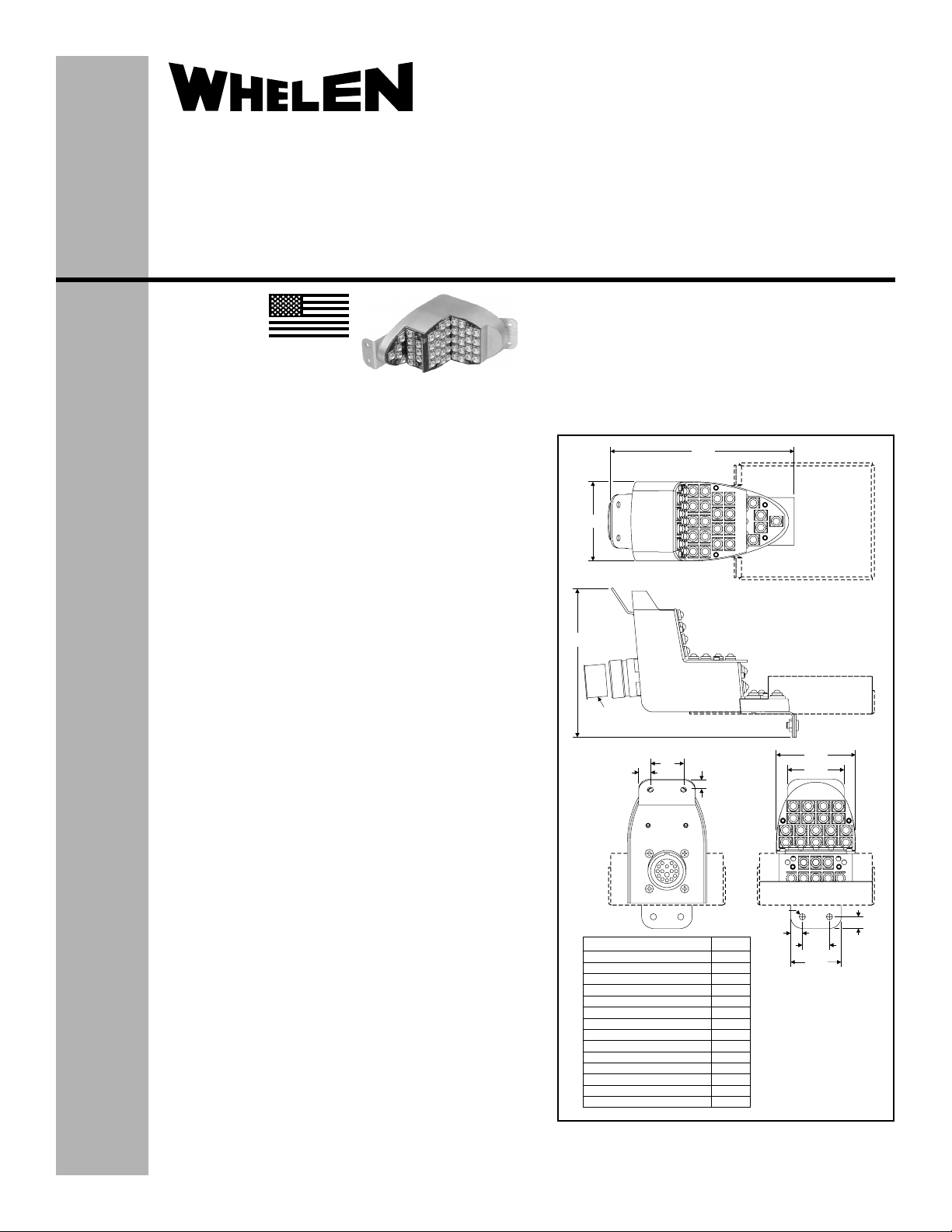

4.86

Shroud shown

.27

for reference

only.

2.10

1.43

.720

1.26

.31

2.10

3.94

Dust

Cap

.88

.27

D38999 / 20FD15PN Contact

Anti-Collision

Anti-Collision

Anti-Collision

Anti-Collision

Anti-Collision

Anti-Collision

Anti-Collision

Anti-Collision

Position

Position

Position

Fault Indicator

Anode A

Cathode A1

Cathode A2

Cathode A3

Anode B

Cathode B1

Cathode B2

Cathode B3

Anode

Cathode 1

Cathode 2

.31

4 X Ø.164

M

K

L

A

R

J

H

G

N

C

D

F

©2009 Whelen Engineering Company Inc.

Form No.14422 (100110)

Page 1

Loading...

Loading...