Page 1

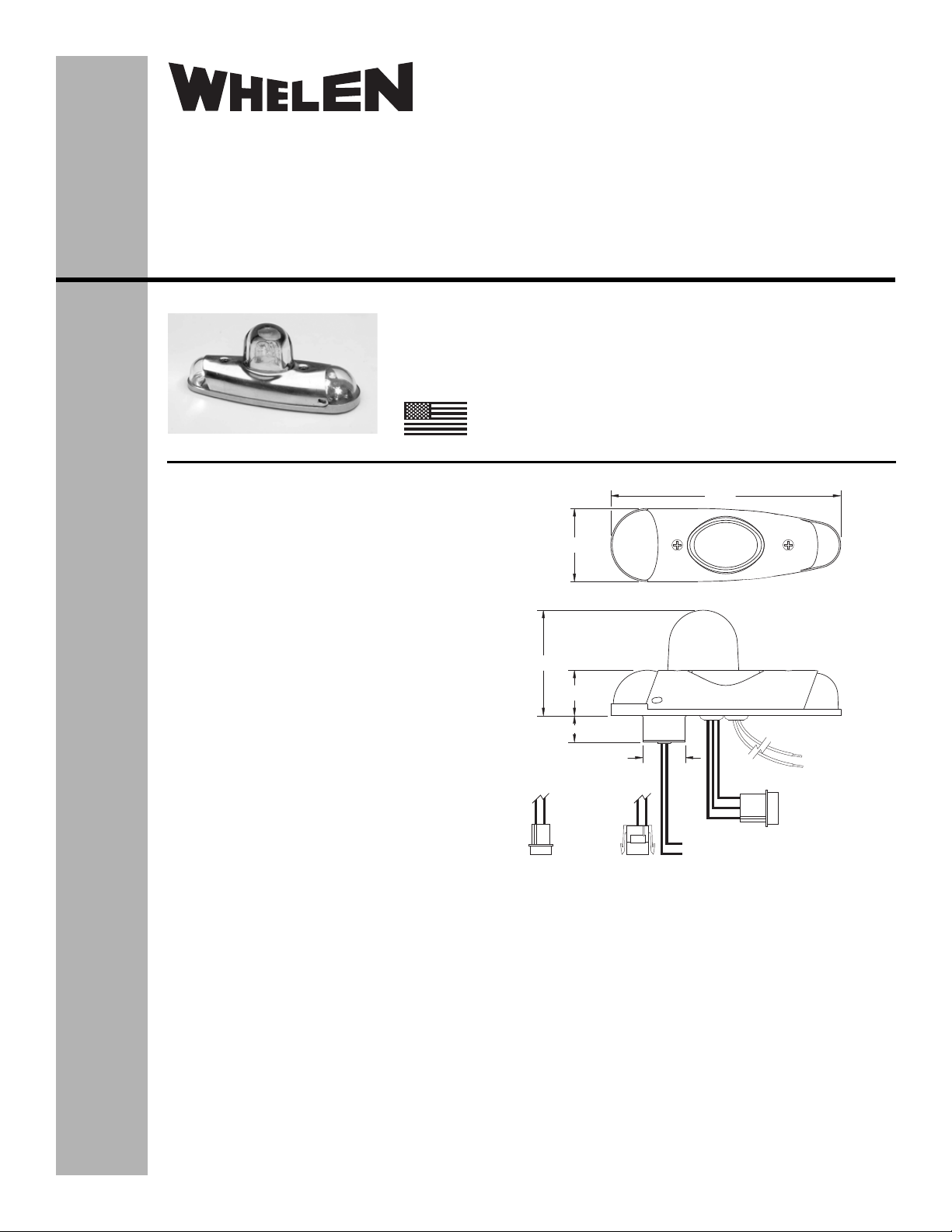

5.69

1.87

2.46

1.08

.618 MIN

RED(+14VDC)

BLACK(-)GROUND

1.25 DIA

POS 3 - WHITE (TRIGGER)

POS 2 - BLACK (CATHODE)

POS 1 - RED (ANODE)

Tail Light Wires

(14V Versions Only)

WHITE (+28VDC) OR RED (+14VDC)

BLACK (-) GROUND

P 1 - WHT (+28VDC)

P2P3-

os

os BLK (-) Ground

os N/C

P 1 - WHT (+28VDC)

P2-

os

os BLK (-) Ground

NOTE Connector for

9034007, 9034008

NOTE Connector for

9034009, 9034010

J2

123

J1

J2

®

ENGINEERING COMPANY INC.

MADE IN THE U.S.A.

Route 145, Winthrop Road,

Chester, Connecticut 06412

Phone: (860) 526-9504

Fax: (860) 526-2009

Internet: www.whelen.com

Sales/Service e-mail: aviation@whelen.com

Installation Guide: 90340( )-series

Models 9034001 - 9034010

P/N: 01-0790340-01 through -10

LED Position Light/Strobe Assembly

POSITION LIGHT:

Operational Voltage: . . . . . . . . . . .14/28 VDC (nominal)

Input Current: . . . . . . . . . . . . . . . .0.5 / 0.25 Amps

EQUIPMENT LIMITATIONS: An approved lighting system

consists of two lights, one located on each wingtip. The

baseplate must be mounted parallel to the vertical and

horizontal centerlines of the aircraft to project the patterns

properly. The strobe tube assembly must be connected to

a strobe power supply, such as Whelen model 70888,

70879 or other approved models.

CONTINUED AIRWORTHINESS: The 90340 series LED

wingtip position light assembly is designed with 3 forward

LED’s and two aft LED’s. If any one LED fails, the unit

must be repaired or replaced.

Note: To reduce eye strain use an optical filter such as

dark glasses or a blue covering dome diring LED

inspection.

Inspect the lens. Replace if there is excessive scratching,

discoloration or cracking.

INSTALLATION PROCEDURES: The following

information is to assist in the installation of a Whelen

90340 Light System.

1. Choose the appropriate 90340( ) series replacement

light assembly.

2. The installation procedure described in the following

text will be confined to a single light installation, but is

identical for multiple light installations.

3. Remove the old light, locate and save the existing

+VDC lead and (-) ground lead. Clean and prep ends

as required.

4. Make sure the existing system is equipped with an

appropriate sized breaker. Connect the existing +14/

28 VDC lead to the POSITIVE wire on the input cable

assembly (supplied with the light assembly). Connect

the existing ground lead to the GROUND wire on the

input cable assembly or use the supplied connector

as shown in the illustrations. Both leads must be

connected by an approved FAA connection. Insure

that the wire leads clear of any obstructions and ty-

Aviation

wrap as required. Connect the strobe, J1, to the

strobe power supply as shown in the figure.

©2007 Whelen Engineering Company Inc.

Form No.14112C (030413)

TSO-C30c

TYPES I, II, III

APPROVED

TSO-C96a

CLASS II

APPROVED

Page 1

The conditions and tests required for TSO approval of this

article are minimum performance standards. It is the

responsibility of those installing this article either on or

within a specific type or class of aircraft to determine that

the aircraft installation conditions are within the TSO

standards. TSO articles must have separate approval for

installation in aircraft. The article may be installed only if

performed under 14 CFR part 43 or the applicable

airworthiness requirements.

5. Remove the shroud from the light assembly.

6. Position the base of the new light assembly onto the mounting

surface. Insert three (3) #6-32 pan head screws into the

mounting hole and tighten firmly. Reinstall the lens so that the

two notches are positioned under the shroud, with each notch

equadistant to the centerline.

7. Check all avionics systems for interference from the installation.

8. A flight check should be performed by a properly certified pilot.

9. Update aircraft records, complete Form 337 and obtain FAA

field approval for installation, as required.

Page 2

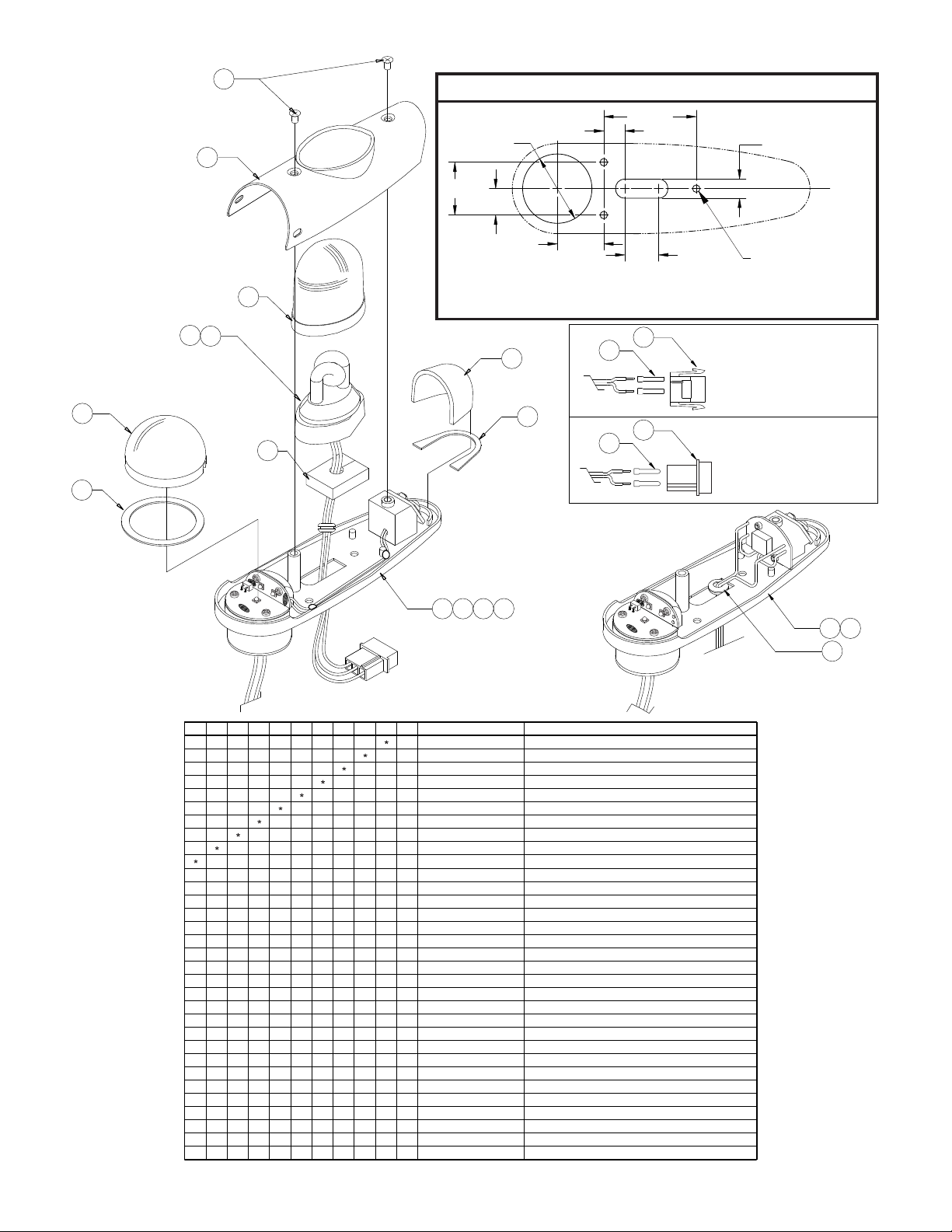

17

16

15

13

14

8

1

2

11

10

9

12

18

20

19

21

3546

7

01-07903 -0840

01-07903 -0740

01-07903 -0640

01-07903 -0540

01-07903 -0440

01-07903 -0340

01-07903 -0240

QTY.QTY.QTY. QTY.QTY. QTY.QTY. QTY.QTY. QTY.

01-0790340-01

PART NUMBER

1

1

1

1

1

1

2

2

1

1

1

1

1

1

2

2

-

1

11

11

11

1

-

MODEL 9034002 FINAL ASSY (14V RED, RFI)

MODEL 9034001 FINAL ASSY (14V GRN, RFI)

DESCRIPTION

MODEL 9034007 FINAL ASSY (28V GRN, RFI)

MODEL 9034008 FINAL ASSY (28V RED, RFI)

MODEL 9034006 FINAL ASSY (28V RED, RFI)

MODEL 9034005 FINAL ASSY (28V GRN, RFI)

MODEL 9034004 FINAL ASSY (28V RED, RFI)

MODEL 9034003 FINAL ASSY (28V GRN, RFI)

LENS, CLEAR/COATED A612

68-2290005-34

36-0050626-02

01-02 -0271789

01-02 -0471789

01-02 -1071789

01-07903 -040 9

01-07903 -40 10

68-3950903A30

68-3950902A30

38-0250901-00

01-02 -0371789

01-02 -0971789

1

1

1

1

1

1

1

1

111

1

1

01-0271789-01

1

1

1

1

1

1

1

111111

1111

1

1

1

1

1

1

1

111

11

1111

111

1

1

1

1

1

1

11

11

1

11

1111

38-0230021-01

21-11061209-00

38-0130878-01

36-0050626-01

MODEL 9034009 FINAL ASSY (28V GRN, RFI)

MODEL 9034010 FINAL ASSY (28V RED, RFI)

ASS'Y, FLASHTUBE 12.50" LEADS W/GROMMET

ASS'Y, FLASHTUBE 6.00" LEADS W/GROMMET

LENS, CLEAR TAIL POSITION LT HARDCOAT

GASKET, TAIL POSITION LIGHT MODEL 90340

ASS'Y, ANTICOL/ POS LT GRN (28V)

ASS'Y, ANTICOL/ POS LT GRN (28V)

ASS'Y, ANTICOL/ POS LT RED (14V)

ASS'Y, ANTICOL/ POS LT GRN (14V)

GROMMET, 3/16" ID

ASS'Y, ANTICOL/ POS LT RED (28V)

ASS'Y, ANTICOL/ POS LT RED (28V)

GASKET, FLASHTUBE,A600 (.375)

GASKET, POSITION LIGHT SPLIT

LENS, CLEAR FWD POSITION LIGHT

39-0501326-04

39-0501316-04

14-0050508-27

1

2

2

1

2

1

2112

1

2

2

1

11

2212

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

---

-

-

-

-

-

-

-

-

----

-

-

-

-

-

-

-

-

-

---

-

-

-

-

-

-

---

-

-

-

---

-

---

-

-

-

-

-

39-0403811-04

39-0402313-04

19-170049-010

3

1

2

8

4

5

7

6

9

10

12

11

13

16

18

14

15

17

19

20

21

SOCKET, 20-14AWG, .084 COMM MATE-N-LOK

PIN, 20-14 AWG

SCREW, 6-32 5/16 PFHMS CSNK MS51959-27

HOUSING, 3 POS SCKT PANEL MT

HOUSING, 2 POS PIN, COMM MATE-N-LOK

RETAINER, A600 LENS COMPLETE

ITEM

14V VIEW

28V VIEW

2

POS 2 - BLACK (-) GROUND)

POS 2 - BLACK (-) GROUND)

POS 3 - N/C

POS 1 - WHITE (+28VDC)

POS 1 - WHITE (+28VDC)

01-0790340-07 & -08

01-0790340-09 & -10

2

1

2

1.31 DIA

.880

1.75

.40

1.00

.50

.64

.36

3 x 0.140 DIA

MOUNTING HOLE

FOR #6-32

SCREWS

MOUNTING DIMENSIONS

J2

Page 2

Loading...

Loading...