Page 1

®

ENGINEERING COMPANY INC.

Route 145, Winthrop Road,

Chester, Connecticut 06412

Phone: (860) 526-9504

Fax: (860) 526-2009

Internet: www.whelen.com

Sales/Service e-mail: aviation@whelen.com

Installati on Guide:

Model 90088( )-Series

Models 9008818, 9008819,

P/N:01-0790088-18, 01-0790088-19

LED Anti-Collision Light Assembly

OPERATING INSTRUCTIONS:

Operational Voltage:. . . . . .28 VDC (nominal)

Average Input Current:. . . .0.56 Amps / 3 Amps Peak @ .25 Sec.

The conditio ns and te sts requ ired for TSO app roval of th is articl e

are minimum performance standards. It is the responsibility of

those installing this article either on o r within a specific type or

class of aircraft to determine that the aircraft installation

conditions are within the TSO standards. TSO articles must have

separate approval for installation in aircraft. The article may be

installed only if performed under 14 CFR part 43 or the applicable

airworthiness requirements.

CONTINUED AIRWORTHINESS: The 90088 series led anti-collision

light assembly is designed with 2 banks of 7 leds. Should any one led or

bank fail, the unit must be repaired or replaced. Inspect the lens for

excessive scratches or pitting. Replace if necessary.

EQUIPMENT LIMITATIONS: The ClassiIII anti-collision system must

produce a minimum of 100 effective candelas in aviation red or white,

360° around the vertical axis, 30° above and below the horizontal plane.

A single beacon on the topside of the fus elage and a single bea con on

the underside of the fuselage will meet this requirement.

INSTALLATION PROCEDURES: The following information is t o assist

in the installation of a Whelen LED Anti-Collision Light Assembly.

1. Choose the appropriate 90088( ) replacement light assembly

which is most applicable to your aircr aft. Lower mounts have a

drain hole in the lens.

2. The installation procedure described in the following text will be

confined to a single light installation, but is identical for multiple

light installations.

3. Remove old light, locate and save the existin g +28VDC lead and

(-) ground lead. Clean and prep lead ends as required.

4. Use existing mounting holes and hardware.

5. Connect the +28 VDC and (-) ground leads equipped with an

appropriate sized breaker to the LED Light. Both lead s must be

connected by an approved FAA connection.

6. Install light assembly and ins ure that the wire leads are clear of

any obstructions and ty-wrap a s required. Us e lock washer s and/

or thread lock on all thr eaded fasteners. Seal the base and (8)

mounting screws as required.

7. Check all avionics systems for interference from the installation.

8. A flight check should be performed by a properly certified pilot.

9. Update aircraft records, complete For m 337 and obtain FAA field

approval for installation.

Aviation

MADE IN THE U.S.A.

TSO-C96a

CLASS III

APPROVED

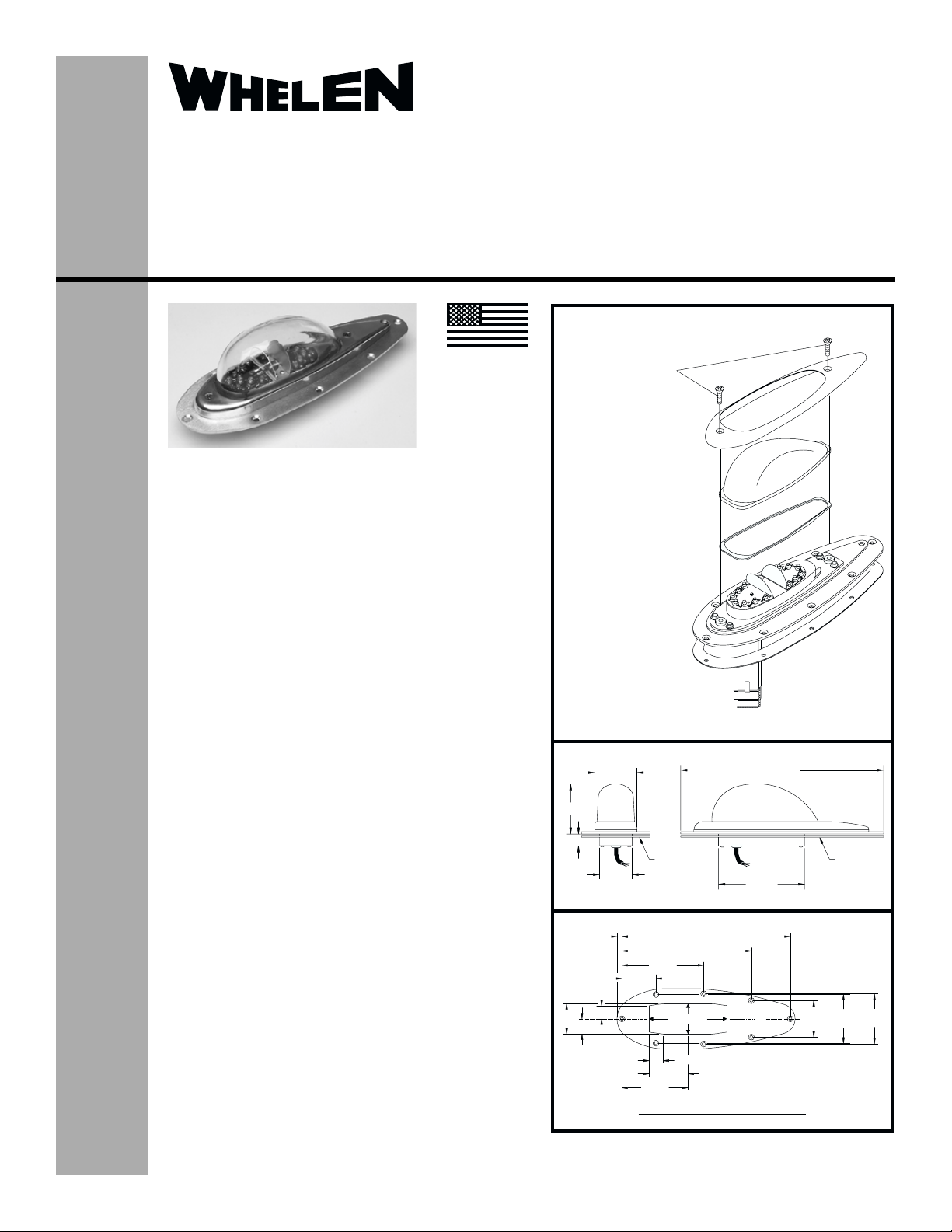

Screw, #10-32 x ½”

Phillips FHMS

Lens Retainer

19-171019-01S

68-4270579-30 ( )

68-4270579-31 ( )

01-0271022-04 9008818 & 19

2.38

2.84

.675

1.84

.30

.84 TYP

1.95

.975

Lens, Clear

9008818/upper

9008819/lower

L

ens Gasket

38-0270584-00

LED

Assembly

()

Baseplate Gasket

38-0270585-00

White/Blue - (28VDC)

Mounting

Gasket

5.250

2.187

CUTOUT

2.50 TYP

4.246

SUGGESTED MOUNTING PATTERN

White - (-)Ground

Shield

10.812

8.312

.90 TYP

4.86

C

L

Input Wires

11.43

2.342

CENT.

Mounting

Gasket

3.124

CENT.

3.218

CENT.

©2006 Whelen Engineering Company Inc.

Form No.14044 (060606)

Page 1

Loading...

Loading...