Page 1

®

ENGINEERING COMPANY INC.

51 Winthrop Road,

Chester, Connecticut 06412

Phone: (860) 526-9504

Fax: (860) 526-4078

Internet: www.whelen.com

Sales e-mail: autosale@whelen.com

Vehicle Specific Lighthead Housings

for M4, M7, LINZ6, TIR3,

400, 500 & 700-series Lightheads

Installation Guide:

2005 - present

Canadian Sales e-mail: autocan@whelen.com

Customer Service e-mail: custserv@whelen.com

Safety First

This document provides all the necessary information to allow your Whelen product to be properly and safely installed.

Before beginning the installation and/or operation of your new product, the installation technician and operator must

read this manual completely. Important information is contained herein that could prevent serious injury or damage.

• Proper installation of this product requires the installer to have a good understanding of automotive electronics,

systems and procedures.

• If mounting this product requires drilling holes, the installer MUST be sure that no vehicle components or other

vital parts could be damaged by the drilling process. Check both sides of the mounting surface before drilling

begins. Also de-burr any holes and remove any metal shards or remnants. Install grommets into all wire

passage holes.

• If this manual states that this product may be mounted with suction cups, magnets, tape or Velcro®, clean the

mounting surface with a 50/50 mix of isopropyl alcohol and water and dry thoroughly.

• Do not install this product or route any wires in the deployment area of your air bag. Equipment mounted or

located in the air bag deployment area will damage or reduce the effectiveness of the air bag, or become a

projectile that could cause serious personal injury or death. Refer to your vehicle owner’s manual for the air bag

deployment area. The User/Installer assumes full responsibility to determine proper mounting location, based

on providing ultimate safety to all passengers inside the vehicle.

• For this product to operate at optimum efficiency, a good electrical connection to chassis ground must be

made. The recommended procedure requires the product ground wire to be connected directly to the NEGATIVE

(-) battery post.

• If this product uses a remote device to activate or control this product, make sure that this control is located in

an area that allows both the vehicle and the control to be operated safely in any driving condition.

• Do not attempt to activate or control this device in a hazardous driving situation.

• This product contains either strobe light(s), halogen light(s), high-intensity LEDs or a combination of these

lights. Do not stare directly into these lights. Momentary blindness and/or eye damage could result.

• Use only soap and water to clean the outer lens. Use of other chemicals could result in premature lens cracking

(crazing) and discoloration. Lenses in this condition have significantly reduced effectiveness and should be

replaced immediately. Inspect and operate this product regularly to confirm its proper operation and mounting

condition. Do not use a pressure washer to clean this product.

• It is recommended that these instructions be stored in a safe place and referred to when performing

maintenance and/or reinstallation of this product.

• FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND INSTRUCTIONS COULD RESULT IN DAMAGE TO

THE PRODUCT OR VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR PASSENGERS!

Automotive: Lightheads

For warranty information regarding this product, visit www.whelen.com/warranty

©2005 Whelen Engineering Company Inc.

Form No.13996J (050609)

Page 1

Page 2

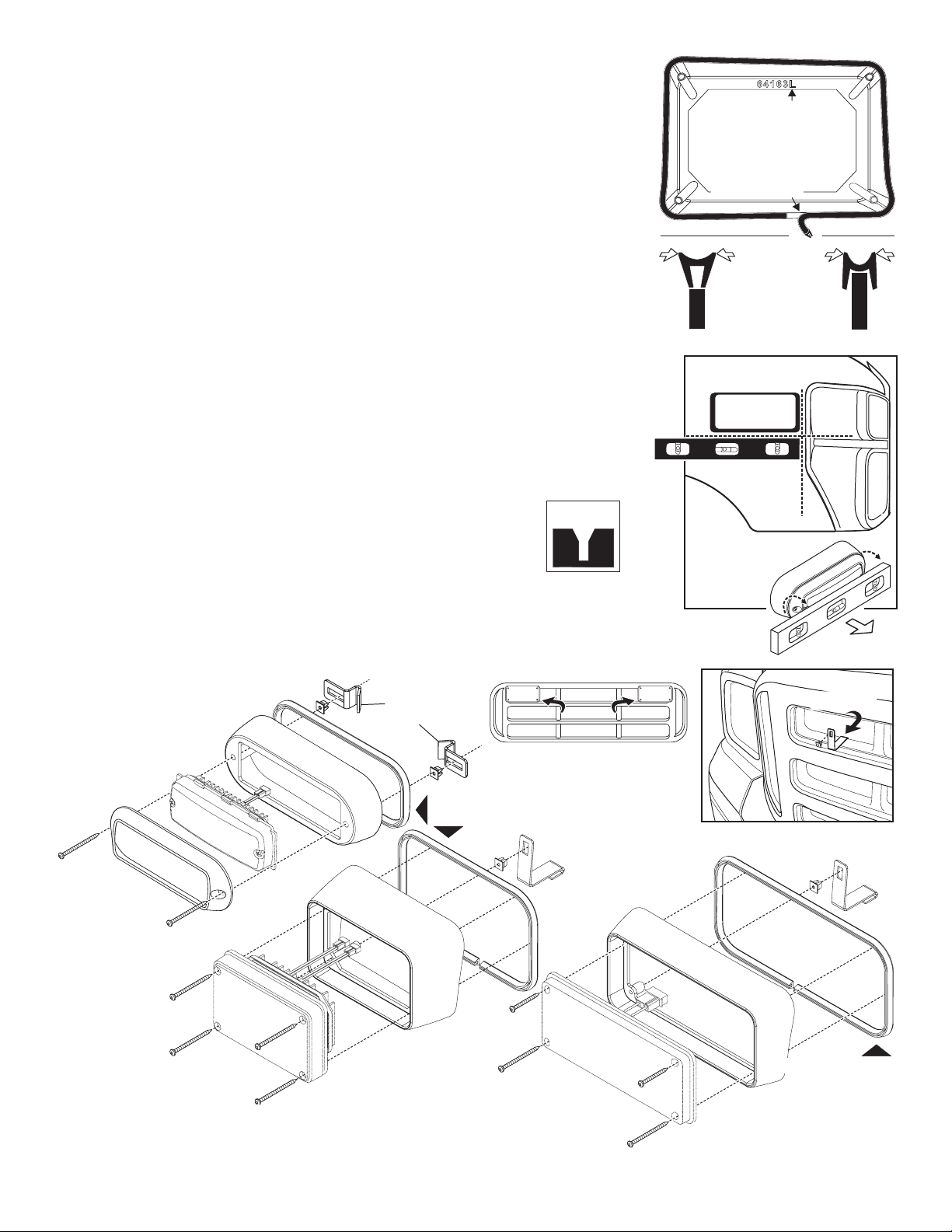

Installation:

WARNING: Lights on the front of the vehicle must be mounted a minimum of 18” apart,

measured from the center of the lighthead. They must also be a minimum of 30” from the road

and be mounted below the windshield.

1. Before mounting, be sure the vehicle is parked on a level surface. First install the supplied rubber

gasket onto the housing. Start the gasket at the bottom of the housing. The gasket is made longer

than needed and you will have to cut off the excess so it will fit. Pinching the back of the gasket

together as you install it, will make the job easier (see illustration). No gasket is needed for most

grille mount flanges.

2. Find the mounting location photo of the vehicle and lighthead you are doing the installation on.

The photo will show the mounting location for your vehicle. Some photos may have specific

mounting instructions for that particular vehicle.

3. Position the housing onto the mounting surface in the area indicated in the photo for your vehicle.

The housing is contoured to the body of each model vehicle and will fit perfectly when in the exact

mounting position it is designed for. In the part number of the housing there will be an “L” or an “R”

to indicate whether it goes onto the left or right of the vehicle.

Front fender of vehicle: Mount housing as far forward as possible for maximum effectiveness.

Front of vehicle: The housing mounts to the front of the hood. No less than 18” apart.

Vehicle grille: The housing will mount approximately to the upper corner of the grille. Each housing is

contoured to fit around the grille of the vehicle it is designed for (see photo for mounting location). No

gasket is used for most. The supplied clamp hooks into the grillee as shown below and on page 4.

4. When the housing is positioned in its exact location (fitting perfectly to the vehicle with no space at

all between vehicle and housing) check it with a level. When you have it level mark the mounting

holes off onto the mounting surface.

CAUTION: When mounting onto fiberglass, after you drill the mounting holes,

chamfer the top of the hole to prevent the fiberglass from cracking with use.

5. Drill the mounting holes with an appropriately sized drill bit. You will also need to

drill a wire hole. Refer to the lighthead manual for size and location.

6. Secure housing (with lighthead) to vehicle using supplied mounting hardware.

IMPORTANT: Certain housings may have up to four different sized mounting screws to match the

vehicle contour. To be sure you use the correct screws, insert them into the housing before

mounting. All four screws should extend out of the housing the same amount.

Chamfered

drill hole

"L" or "R" in part number

indicates left or right side

of vehicle

Start gasket on

bottom of housing

Gasket

Installation

Tip:

When installing the gasket,

pinch the top together to

open the gasket, which will

HOUSING

make installation easier.

Make sure the housing is

level with the road.

Also be sure that the

lighthead projects

straight forward

and not up or

down.

HOUSING

These drawings indicate

Grille clip mounting hardware

the order of mounting

hardware, lenses and

gaskets. Most grille light

housings do not use

gaskets. Certain models

use clamps which hook

Grille

mount

only

Use the lower, inner mounting hole for the grille

mount clip as shown above.

into the grille.

Mounting Gasket

500 Series

400/500 Series 18-1/2"

P/N 38-0542989-04

Grille

mount

only

400 Series

700 Series

IMPORTANT NOTE: This manual covers vehicle specific custom lighthead housings. If you

have a standard flat housing the mounting location will not be as critical as described here.

Housings mounted to the front of the vehicle must still be at least 18” apart.

Clamp will hook

around grille here

Grille

mount

only

Mounting Gasket

700 Series / 23"

P/N 38-0542989-05

Page 2

Page 3

Extended Flange Mounting Gasket

S

A

E

W

-

1

8

0

S

A

E

W

-

1

8

0

M4 Series (16") P/N 380542989-05

Mounting Location Photos

M4 FREIGHTLINER / ESERIES / ® M2 GRILL MOUNT

Mounting for the 400, 700 and M7 Series is the same.

REAR VIEW

of GRILLE

Extended Flange Mounting Gasket

M7 Series (25") P/N 38-0452989-05

The other 2 mounting holes must be drilled

GRILLE

LINZ6 M2 Grille Mount

™ FREIGHTLINER®

Page 3

Mount to thick

part of grille

0

8

1

-

W

E

A

S

S

A

E

W

-

1

8

0

Page 4

700 SERIES

S

S

400 SERIES

INTERNATIONAL®

M2

GRILL MOUNT

2005 INTERNATIONAL®

HOOD MOUNT

700 SERIES / / MOUNT2005 INTERNATIONAL® FENDER

F

F

3-1/4"

L

A

T

A

L

A

FREIGHTLINER® M2 or

INTERNATIONAL®

TIR3™ FENDER MOUNT

The INTERNATIONAL (not shown) uses

the same mounting measurements.

1/2"

R

E

A

T

A

R

E

A

500 SERIES

FREIGHTLINER® M2

GRILLE MOUNT

700 SERIES / ® M2

GRILL MOUNT

400 SERIES

400 SERIES

INTERNATIONAL® M2

FREIGHTLINER

GRILL MOUNT

GRILL MOUNT

E

E

FREIGHTLINER

® M2

See previous page

for rear view of

mounting.

FREIGHTLINER® M2

8-1/2"

F

L

A

T

A

R

E

A

F

L

A

T

A

R

E

A

1/2"

M4 SERIES

FENDER MOUNT

1-1/2"

See previous page

for rear view of

mounting.

5 / 2005 FORD®F-450 / FENDER00SERIE

4 / 2005 FORD®F-450 / FENDER00SERIE

700 SERIES GRILL MOUNT2005 INTERNATIONAL®, E - STATIONARY GRILLE

IMPORTANT NOTE: e

IMPORTANT NOTE:

The grill mount flange for the International is only for

models with the "Stationary Grille".

7 2005 / FORD®F-450 FENDER00SERIES//

Page 4

Page 5

CHEVY EXPRESS / GRILLE MOUNT / for 700, 400, M4 & M7 SERIES

700 or 400 Series Lighthead

(

)

700 shown

12.75" 12.75"

M7 Series Lighthead

12.75" 12.75"

500 SERIES / " " SERIES /2005 FORD® "E" or F GRILLE

500 SERIES / 2005 "E" or "F" SERIES / HOODFORD®

HEADLIGHT

500 SERIES / "E" SERIES / FENDER2005 FORD® or "F"

M4 Series Lighthead

Mounting Location:

Measure 12.75" from the exact center of the hevy logo to the exact center of the

12.75" 12.75"

C

lighthead. This is your mounting location.

1-3/4"

WHEEL WELL

H

E

A

T

H

G

I

L

D

Mounting Location:

1-3/4" from the edge of the

9"

headlight to the front edge

of the bracket. And 9" from

the top of the bumper to

the flat part of the bottom

of the bracket.

M7 SERIES / CHEVY EXPRESS / FENDER MOUNT

BUMPER

HEADLIGHT

4 2005 Ford® or "F"00 SERIES / "E" SERIES / FENDER

HEADLIGHT

700 SERIES "E" SERIES / FENDER/ 2005 FORD® or "F"

M7 / CHEVROLET® / 4500 or 5500SERIES / FENDER

Page 5

1-3/4"

WHEEL WELL

H

E

A

D

Mounting Location:

1-3/4" from the edge of the

9"

headlight to the front edge

of the bracket. And 9" from

the top of the bumper to

the flat part of the bottom

of the bracket.

400 or 700 SERIES / CHEVY EXPRESS / FENDER MOUNT

BUMPER

T

H

G

I

L

Page 6

Bracket bends in

Housing has indentation which

fits

over shape of grill.

through grille here

FRONT VIEW OF GRILLE

400 SERIES / GMC® / CHEVY® 4500/5500

GRILLE MOUNT

NOTE: The 700 series grill

mount will mount the same.

Housing

e

Mounting

Plate

Grille Clamp

REAR VIEW OF GRILLE

Bracket bends in

through grille here

Secure lighthead

housing to grommets.

Mounting Hint:

First secure the housing

to the mounting plate and then

mount the housing (with plate

attached) to the grille.

Grommet

Mounting

plate

5 - CHEVY 4500/5500 -00 SERIES FENDER 400 SERIES FENDER- CHEVY - 4500/5500 - 700 SERIES FENDER- CHEVY - 4500/5500 -

2007-2009 DODGE® or INTERNATIONAL® SPRINTER

Mount in the level area between the

headlight and the wheel well. The

400 and 500 series mount the same

6"

Be sure

sliding

door

doesn't

touch

lighthead.

6"6"

Meeasur from center

point of lighthead

6"6"

Mounting Plate

HEADLIGHT

1-5/8"

2-5/8"

Upper Rear - 600 SERIES

1/2" from door seam

Upper Front - 600 SERIES

3/4"

from

door

seam

5-1/2"

7/8"

1-1/4"

from

door

seam

Upper Rear - M4 SERIES Upper Front - M4 SERIES

SPRINTER / GRILLE MOUNT

Housing has indentation which

Housing has an indentation which

fits over shape of grill.

fits over the shape of the grille.

Freightliner® - M4 SERIES

Dodge - 500 SERIES

R

O

O

5-3/8"

WINDOW

Front Fender - 700 SERIES

Center the flange between the

F

wheel well, headlight trim and bumper.

Front Fender - M4 SERIES

Front Fender - M7 SERIES

HEADLIGHT

Page 6

Loading...

Loading...